Sigma Chart

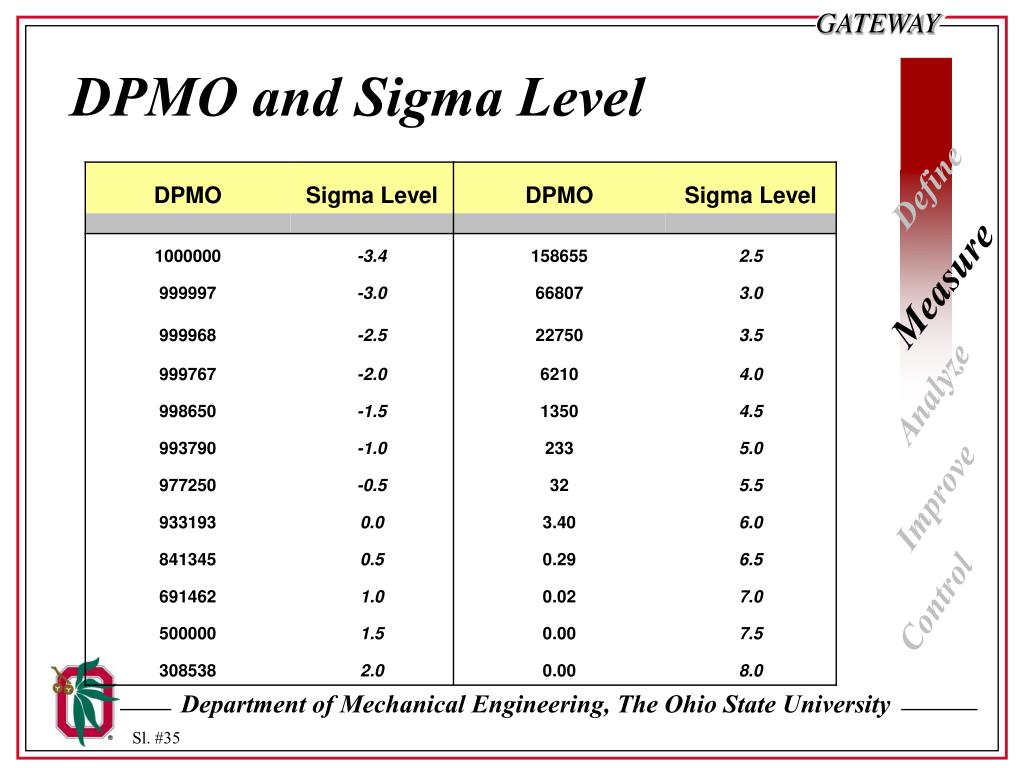

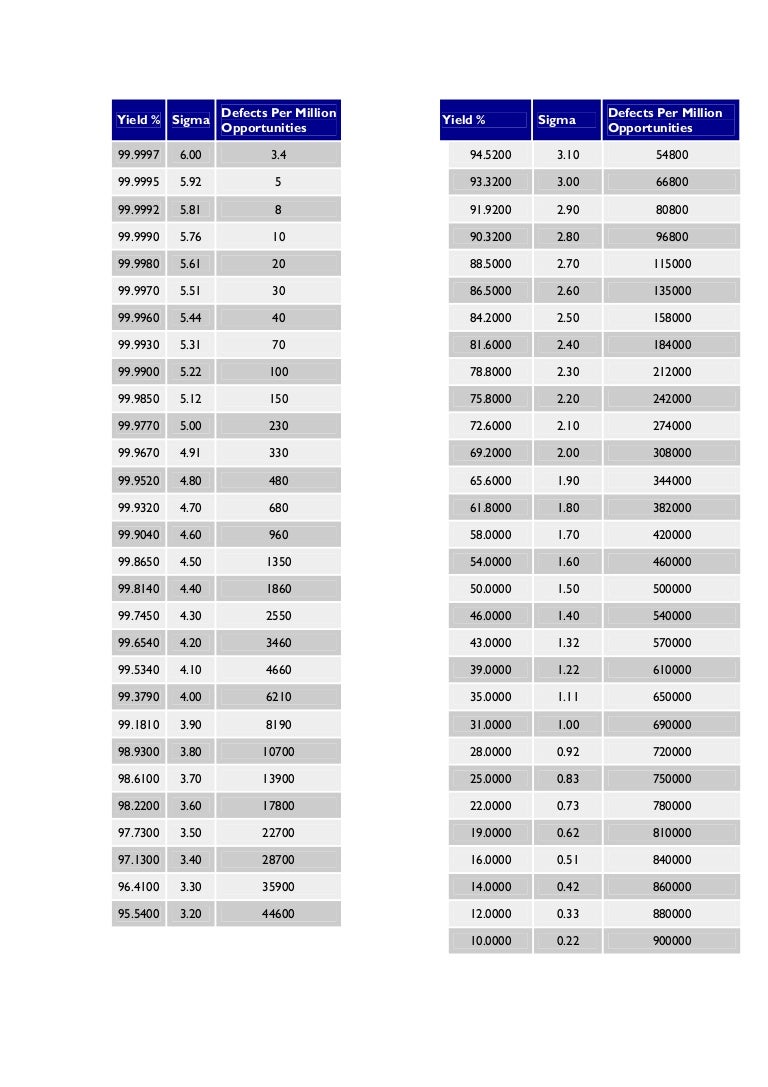

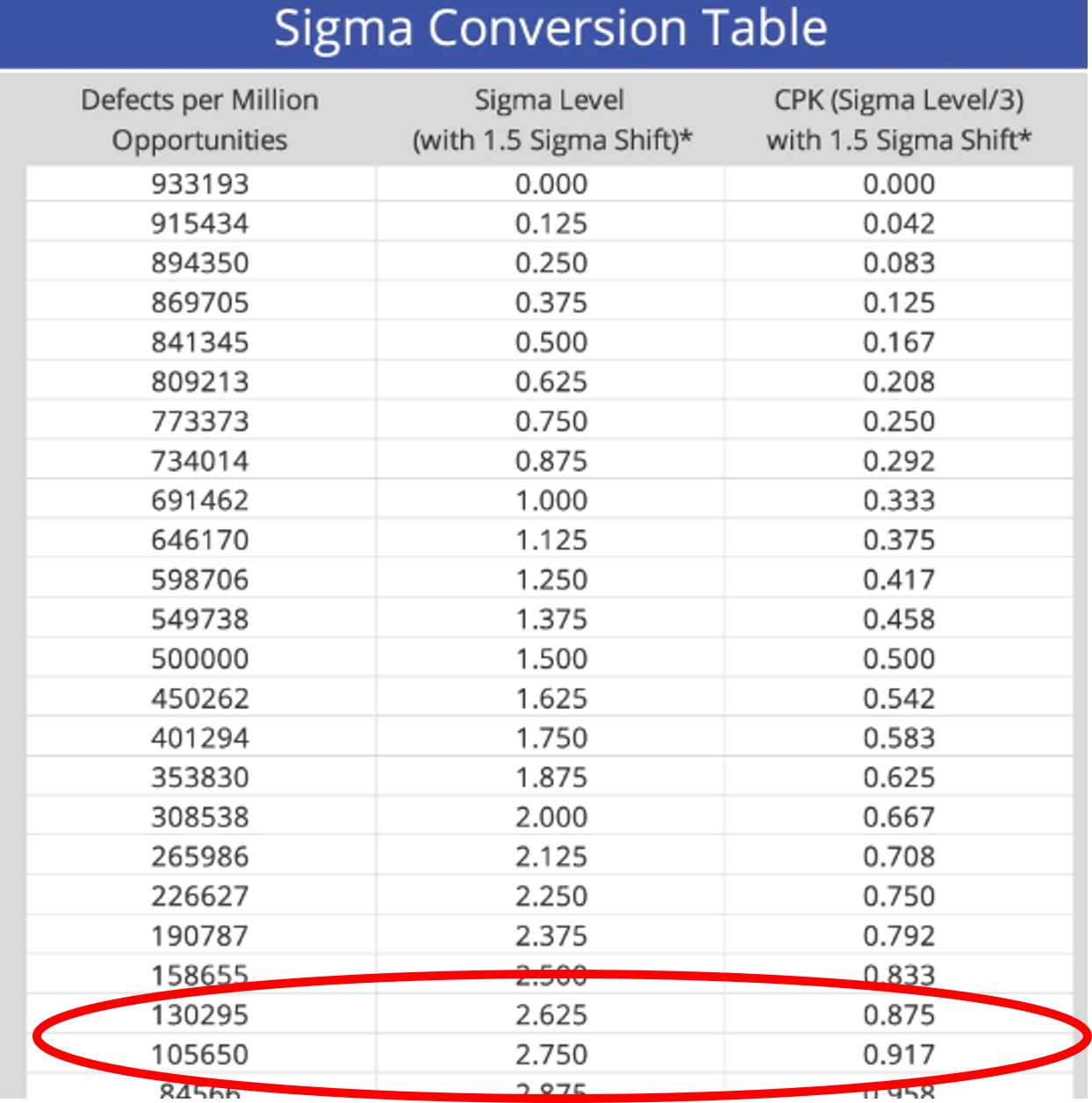

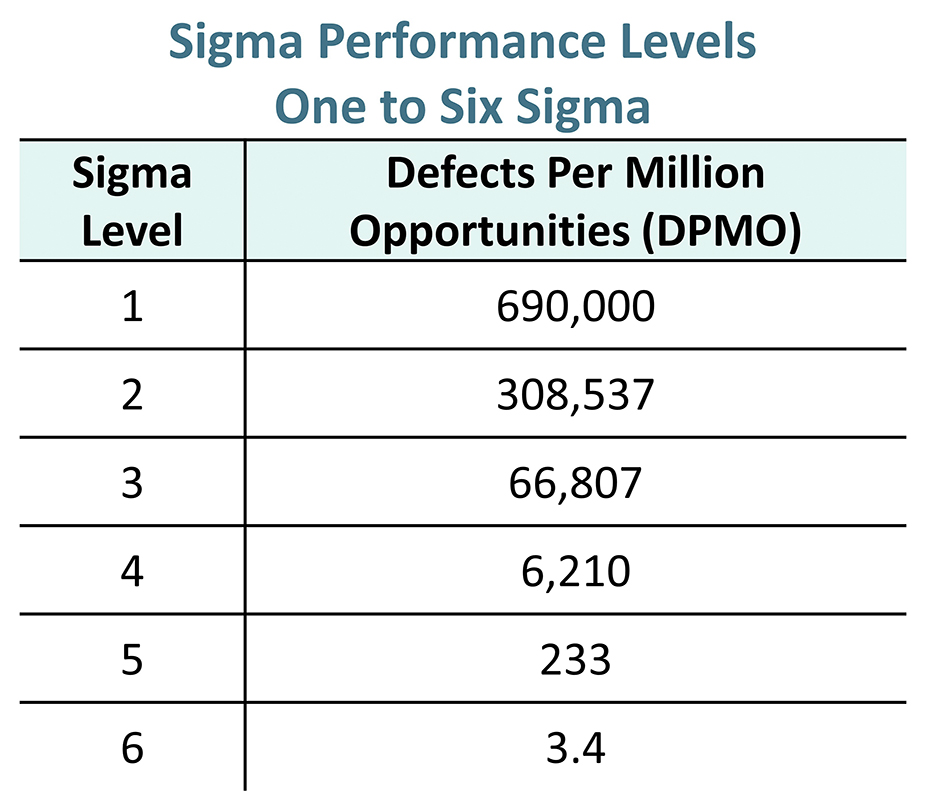

Sigma Chart - It is actually two plots to. Web x bar r chart is used to monitor the process performance of continuous data. D 2 for a subgroup. Secure & reliableextensive shape librariescollaborativeintuitive The mean or average change in the process over time from subgroup values. Web learn about sigma chart calculations in our spc statistical process control knowledge center, written by author spc demystified. Web control charts are used as a way to display the performance of a process over time. Web understanding the fundamentals of spc charts, including common cause vs. The control chart is a graphical display of quality characteristics that are. Web we will explain the use and benefits of a control chart, plus provide a few best practices for using them to monitor the variation in your processes. Web we will explain the use and benefits of a control chart, plus provide a few best practices for using them to monitor the variation in your processes. This is done by plotting the measured output data points on a chart, allowing those viewing. The mean or average change in the process over time from subgroup values. Web x bar. The mean or average change in the process over time from subgroup values. The charts help us track process statistics over time and. Explore different types of control charts, their. D 2 for a subgroup. Web learn about sigma chart calculations in our spc statistical process control knowledge center, written by author spc demystified. Reduce the need for inspection. Web x bar s control chart definitions. Web for a range control chart, sigma is estimated using the following formula: Web control the performance of a process by knowing when and when not to take action. Web x bar r chart is used to monitor the process performance of continuous data. Web control the performance of a process by knowing when and when not to take action. D 2 for a subgroup. Web use this acids and bases chart to find the relative strength of the most common acids and bases. Web control charts are used as a way to display the performance of a process over time. Web x bar. Web learn about sigma chart calculations in our spc statistical process control knowledge center, written by author spc demystified. The mean or average change in the process over time from subgroup values. Web control charts are used as a way to display the performance of a process over time. Web learn how to choose the right six sigma chart based. D 2 for a subgroup. Explore different types of control charts, their. Web x bar s control chart definitions. When learning about six sigma, it may help to consider these charts, which detail how sigma level relates to defects per. Web learn how to choose the right six sigma chart based on the type of data you have. Web x bar s control chart definitions. When learning about six sigma, it may help to consider these charts, which detail how sigma level relates to defects per. Web donald trump introduced the woman who operates his new favorite immigration chart, which he claims has “saved his life”. It is actually two plots to. Web use this acids and bases. The mean or average change in the process over time from subgroup values. Web learn what control charts are, how they work, and why they are important for process improvement and quality management. Web control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. This is done by plotting the measured output. Web control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. You can also use them to collect data from subgroups at set time periods. The mean or average change in the process over time from subgroup values. Understand and predict process capability based on. Web control the performance of a process. You can also use them to collect data from subgroups at set time periods. Web control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Web use this acids and bases chart to find the relative strength of the most common acids and bases. Web control the performance of a process by. Explore different types of control charts, their. The mean or average change in the process over time from subgroup values. Web control the performance of a process by knowing when and when not to take action. Web x bar r chart is used to monitor the process performance of continuous data. Web for a range control chart, sigma is estimated using the following formula: D 2 for a subgroup. Where d 2 is a control chart constant that depends on the subgroup size. Web learn what control charts are, how they work, and why they are important for process improvement and quality management. Secure & reliableextensive shape librariescollaborativeintuitive The control chart is a graphical display of quality characteristics that are. Web understanding the fundamentals of spc charts, including common cause vs. Web donald trump introduced the woman who operates his new favorite immigration chart, which he claims has “saved his life”. Reduce the need for inspection. Web x bar s control chart definitions. Web use this acids and bases chart to find the relative strength of the most common acids and bases. The charts help us track process statistics over time and.

PPT Six Sigma PowerPoint Presentation, free download ID591997

6 Sigma Control Chart Introduction Toolkit from Leanscape

6SigmaConversionTable.pdf Six Sigma Quality

Example of a Sigma Method Decision Chart. Inaccuracy (bias, trueness

Sigma Table

sigma conversion chart

Converting DPMO to Sigma Level and Cpk A StepbyStep Guide

Six Sigma Kaufman Global Reduce process variation and improve quality

Solved Refer to Table 6.1 Factors for Comauting Control

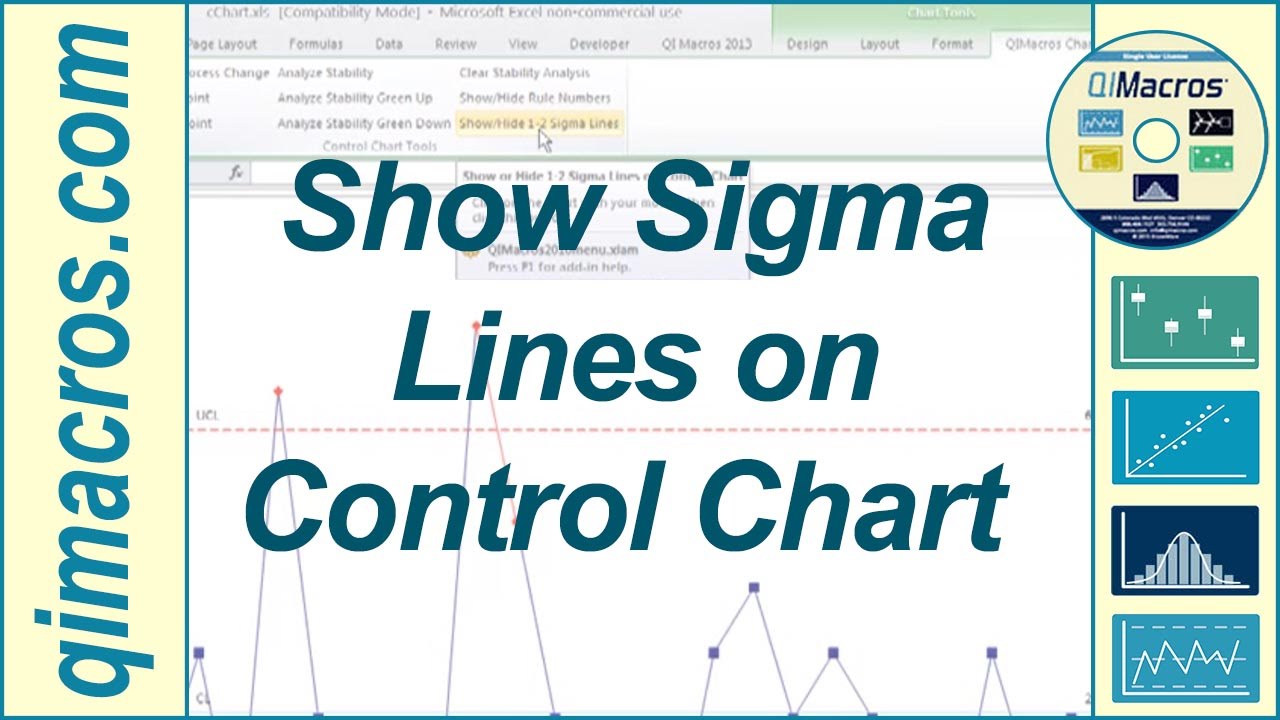

Show 12 Sigma Lines on Control Chart YouTube

Special Cause Variation, Chart Components (Centerline, Control Limits), And Different Chart Types For.

Web Control Charts Are Used As A Way To Display The Performance Of A Process Over Time.

S = R /D 2.

Web We Will Explain The Use And Benefits Of A Control Chart, Plus Provide A Few Best Practices For Using Them To Monitor The Variation In Your Processes.

Related Post: