Shear Wall Nailing Pattern

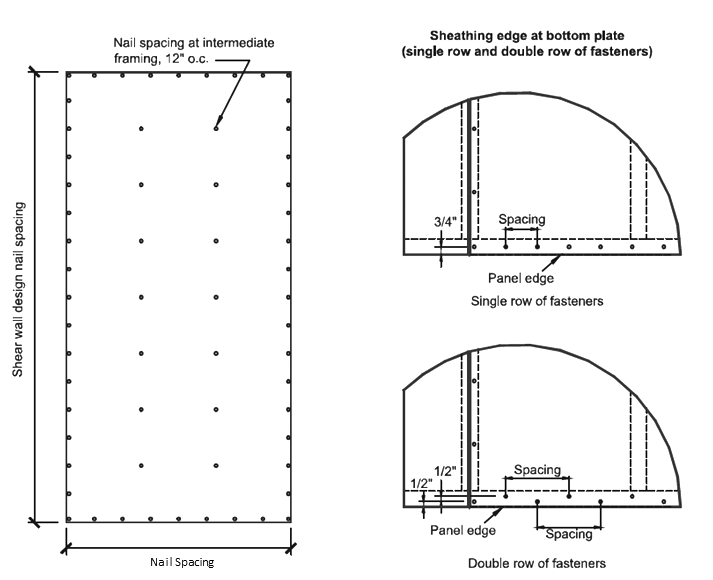

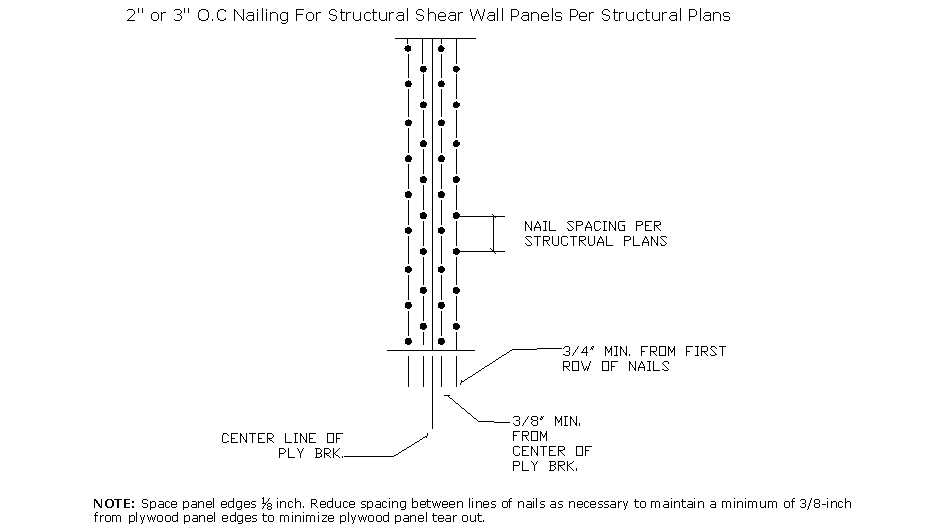

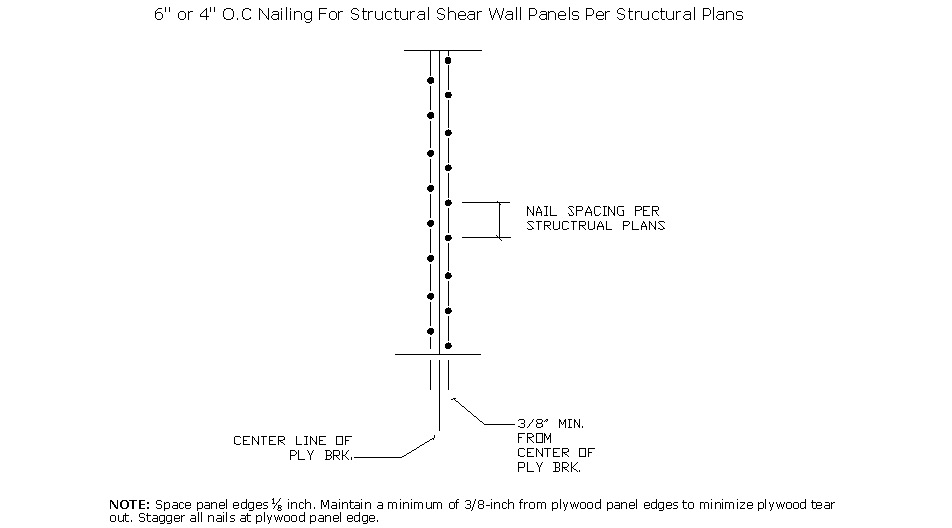

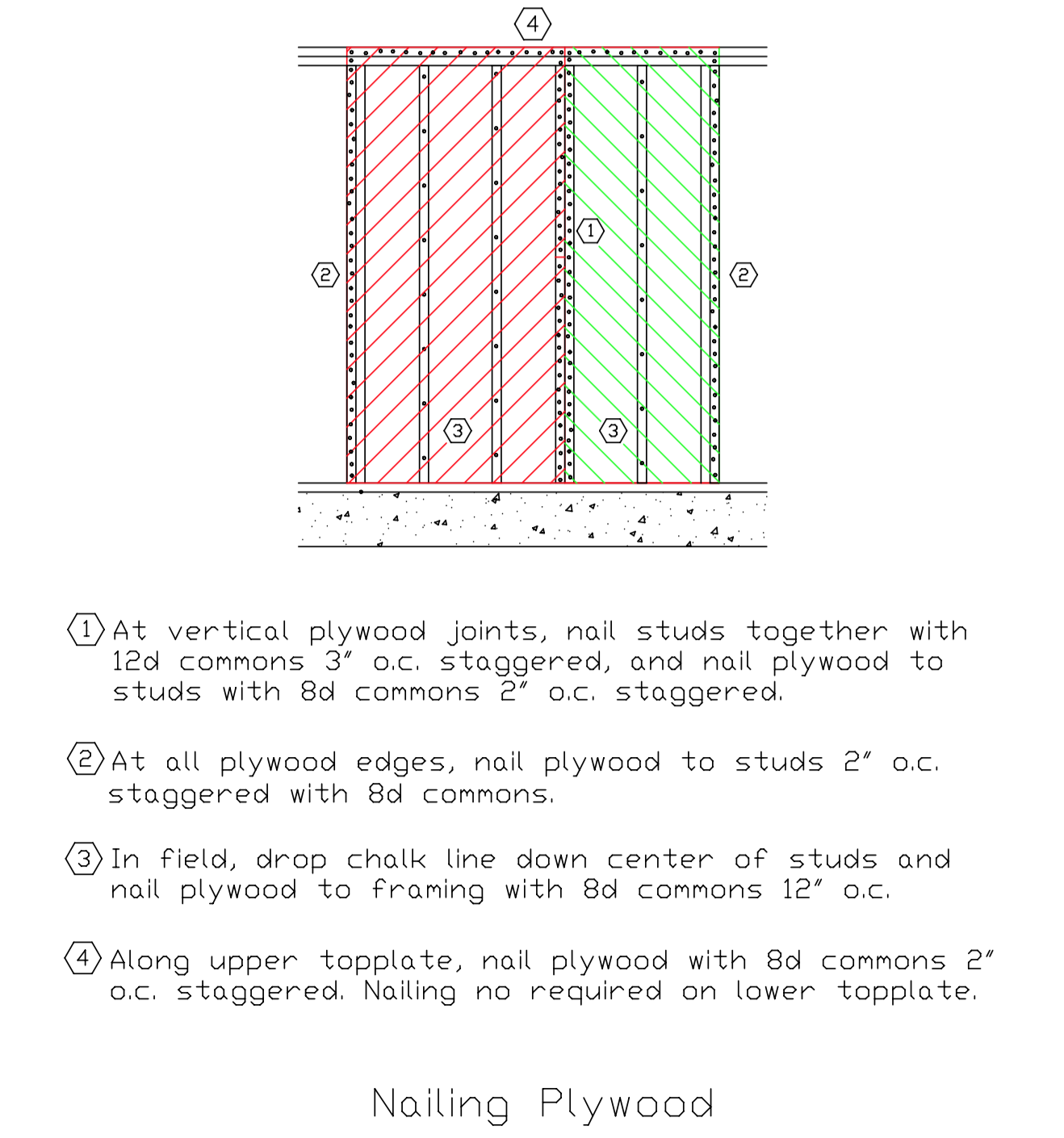

Shear Wall Nailing Pattern - Web shear walls are designed to resist racking. Web an engineer will optimize a shear wall’s design to meet the specific demands of a house, which will dictate details like nail size and nailing schedule, hardware placement, and blocking size and orientation. Web an understanding of how fastener size and installation method can affect the strength of shear walls (a.k.a., braced wall panels) is critical to providing proper wall bracing. Apa rated sheathing meets building code requirements for wall bracing (figures 8 and 9). This list comprises some of the common code violations when installing wood framed shear wall. Examine solutions for splitting issues that can be caused by high nail density in. Web the tables below show the shear wall specification for the walls in the example in a typical format. For nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. 2 rows of staggered nails at panel edges 1 row of nails at panel top & bottom edges Web here's a picture of erik nailing off the 2 o.c. City of rancho palos verdes community development department. This can be accomplished by driving (or shooting) the nail in at a slight angle to the face of plywood. What effects can installation methods and fastener sizes have on the strength of wood structural panel (wsp) wall bracing? Web looking for consensus or opinions on common ways to frame exterior corners. Note that they do not include some detailing that is required for items such as the uniform uplift force on the bottom plate of all perforated shear walls, or the perforated shear walls with osb sheathing on both sides. For nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Nailing for structural shear wall. Continuous wood structural panel wall bracing provides the greatest flexibility when bracing walls with window and door openings. What effects can installation methods and fastener sizes have on the strength of wood structural panel (wsp) wall bracing? Web typical wood structural panel nailing. 3) determine hold down forces and unit shear in each wall. In clearcalcs, you can select your. Apart on panel edges ( below ). 4) select a hold down and sheathing/nailing pattern for. Web here's a picture of erik nailing off the 2 o.c. Web typical wood structural panel nailing. This can be accomplished by driving (or shooting) the nail in at a slight angle to the face of plywood. What effects can installation methods and fastener sizes have on the strength of wood structural panel (wsp) wall bracing? Web a shear wall is simply a cantilevered diaphragm to which load is applied at the top of the wall, and is transmitted out along the bottom of the wall. Web an understanding of how fastener size and installation method can. Nails must be held back 3/8 in. What effects can installation methods and fastener sizes have on the strength of wood structural panel (wsp) wall bracing? Continuous wood structural panel wall bracing provides the greatest flexibility when bracing walls with window and door openings. Web here's a picture of erik nailing off the 2 o.c. Apa rated sheathing meets building. From the edges of sheathing panels and 3/8 in. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. Web typical wood structural panel nailing. The only way to properly install a shear wall is to snap a chalk. I'm looking for some help interpreting the special design provisions for wind and seismic code section 4.3.7 for wood structural panel shear walls. Nailing for structural shear wall panels per structural plans. Web develop a shear wall schedule using shear wall capacities defined in the american wood council’s 2021 special design provisions for wind and seismic (sdpws). Web 2) determine. Web apa panel wall sheathing. This can be accomplished by driving (or shooting) the nail in at a slight angle to the face of plywood. Web nails spaced at 6 inches (152 mm) on center at edges, 12 inches (305 mm) at intermediate supports except 6 inches (152 mm) at all supports where spans are 48 inches (1219 mm) or. Web wood framed shear wall inspection checklist. Nails must be held back 3/8 in. Web an engineer will optimize a shear wall’s design to meet the specific demands of a house, which will dictate details like nail size and nailing schedule, hardware placement, and blocking size and orientation. Web if our design did not have enough capacity to support the. It says nails along intermediate framing members shall be the same size as nails specified for panel edge nailing. Nails must be held back 3/8 in. Web 4 or 6 o.c. It does not address every possible violation, nor is it intended as an instruction manual. Web nails spaced at 6 inches (152 mm) on center at edges, 12 inches (305 mm) at intermediate supports except 6 inches (152 mm) at all supports where spans are 48 inches (1219 mm) or more. The only way to properly install a shear wall is to snap a chalk line down the center of each stud and place a nail 1/4 inch from each side of chalk line. Web if our design did not have enough capacity to support the shear wall force, we could modify the sheathing and nailing to increase that strength. In this article, i will look at each of these in detail. City of rancho palos verdes community development department. Web typical wood structural panel nailing. Apart on panel edges ( below ). In from the edges of framing members. Web an understanding of how fastener size and installation method can affect the strength of shear walls (a.k.a., braced wall panels) is critical to providing proper wall bracing. 2 rows of staggered nails at panel edges 1 row of nails at panel top & bottom edges Web wood framed shear wall inspection checklist. What is the best way to orient the plywood for the best shear strength and nail retention?

8 Tips and Tricks on Effective Shear Wall Construction

Plywood Sheathing Nailing Pattern Nail Ftempo

Shear Walls, The Basics JLC Online

Plywood Sheathing Nailing Pattern Nail Ftempo

Wall Sheathing Nailing Pattern Timber Structures / Estruturas de Ma…

Shear Walls, The Basics JLC Online

Plywood Sheathing Nailing Pattern Nail Ftempo

Structural Shear Wall Nailing in Commercial and Residential Framing

Structural Shear Wall Nailing in Commercial and Residential Framing

8 Tips and Tricks on Effective Shear Wall Construction

What Effects Can Installation Methods And Fastener Sizes Have On The Strength Of Wood Structural Panel (Wsp) Wall Bracing?

Web Apa Panel Wall Sheathing.

Web 2) Determine Usable Walls In Each Line And Distribute Shear Load To Them Proportionally Based On Length.

Examine Solutions For Splitting Issues That Can Be Caused By High Nail Density In.

Related Post: