Shaft Design

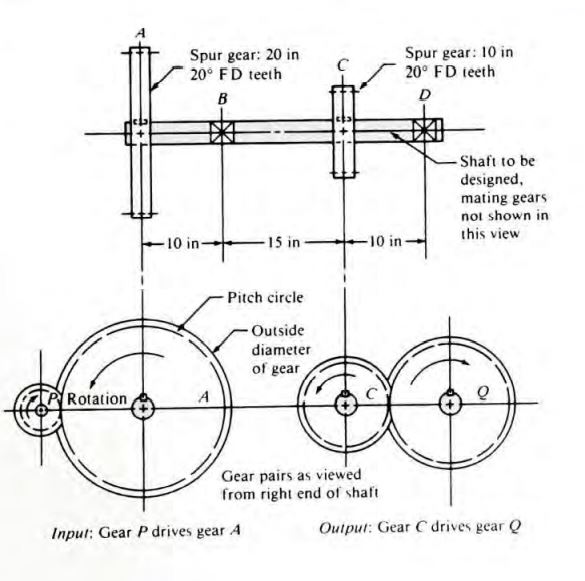

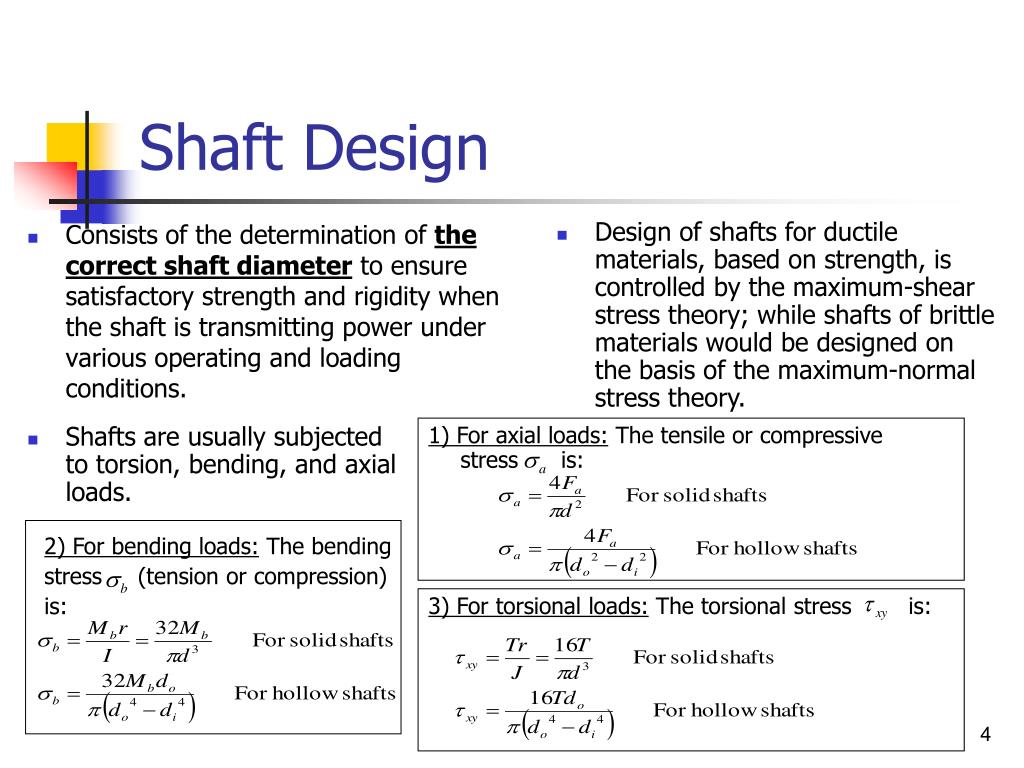

Shaft Design - Web shaft design involves consideration of the layout of features and components to be mounted on the shaft, specific dimensions and allowable tolerances, materials, deflection, frequency response, life, and manufacturing constraints. It is integral to any mechanical system in which power is transmitted from a prime mover, such as an electric motor or. A vehicle crankshaft is a prime example of a mechanical shaft, as shown in the above figure. Web shaft design consists primarily of the determination of the correct shaft diameter to ensure satisfactory strength and rigidity when the shaft is transmitting power under various operating conditions. Shaft failure analysis is critical. • load bearing components should be placed next to the bearings to minimize the bending due to large forces. Most of rotary prime movers either motors or turbines use shaft to transfer the power. • shafts should be kept short to. Shaft are usually circular in cross section, and. • in most cases, only two bearings should be used in most cases. Bearings are required for support. • load bearing components should be placed next to the bearings to minimize the bending due to large forces. A vehicle crankshaft is a prime example of a mechanical shaft, as shown in the above figure. Shaft failure analysis is critical. A shaft is the component of a mechanical device that transmits rotational motion and. It is integral to any mechanical system in which power is transmitted from a prime mover, such as an electric motor or. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Web understanding the design, function, and applications of shafts is essential for anyone working with mechanical systems. A vehicle crankshaft is a prime. Shaft are usually circular in cross section, and. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Shaft failure analysis is critical. A shaft is the component of a mechanical device that transmits rotational motion and power. It is integral to any mechanical system in which power is transmitted from a prime mover, such. Web shaft design consists primarily of the determination of the correct shaft diameter to ensure satisfactory strength and rigidity when the shaft is transmitting power under various operating conditions. • shafts should be kept short to. • load bearing components should be placed next to the bearings to minimize the bending due to large forces. Most of rotary prime movers. • in most cases, only two bearings should be used in most cases. Shaft failure analysis is critical. Web shaft design involves consideration of the layout of features and components to be mounted on the shaft, specific dimensions and allowable tolerances, materials, deflection, frequency response, life, and manufacturing constraints. Shaft are usually circular in cross section, and. This comprehensive guide. • shafts should be kept short to. Bearings are required for support. This comprehensive guide simplifies the complexities of shafts, making them accessible and easy to comprehend, regardless of your experience in the field. A shaft is the component of a mechanical device that transmits rotational motion and power. Web machine elements such as gears, pulleys, flywheels, clutches, and sprockets. Bearings are required for support. Web shaft design consists primarily of the determination of the correct shaft diameter to ensure satisfactory strength and rigidity when the shaft is transmitting power under various operating conditions. Web understanding the design, function, and applications of shafts is essential for anyone working with mechanical systems. It is integral to any mechanical system in which. Web machine elements such as gears, pulleys, flywheels, clutches, and sprockets are mounted on various shaft types and are used to transmit power from the driving device, such as a motor or engine. It is integral to any mechanical system in which power is transmitted from a prime mover, such as an electric motor or. Bearings are required for support.. • shafts should be kept short to. Web machine elements such as gears, pulleys, flywheels, clutches, and sprockets are mounted on various shaft types and are used to transmit power from the driving device, such as a motor or engine. It is integral to any mechanical system in which power is transmitted from a prime mover, such as an electric. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Bearings are required for support. Web machine elements such as gears, pulleys, flywheels, clutches, and sprockets are mounted on various shaft types and are used to transmit power from the driving device, such as a motor or engine. A shaft is the component of a. Web machine elements such as gears, pulleys, flywheels, clutches, and sprockets are mounted on various shaft types and are used to transmit power from the driving device, such as a motor or engine. This comprehensive guide simplifies the complexities of shafts, making them accessible and easy to comprehend, regardless of your experience in the field. • in most cases, only two bearings should be used in most cases. Web understanding the design, function, and applications of shafts is essential for anyone working with mechanical systems. A vehicle crankshaft is a prime example of a mechanical shaft, as shown in the above figure. Most of rotary prime movers either motors or turbines use shaft to transfer the power. Web shaft design involves consideration of the layout of features and components to be mounted on the shaft, specific dimensions and allowable tolerances, materials, deflection, frequency response, life, and manufacturing constraints. A shaft is the component of a mechanical device that transmits rotational motion and power. • shafts should be kept short to. Bearings are required for support. Web shaft design consists primarily of the determination of the correct shaft diameter to ensure satisfactory strength and rigidity when the shaft is transmitting power under various operating conditions. Shaft are usually circular in cross section, and.

SHAFT and Key Ways B02 DESIGN In SolidWorks Tutorials

Design of mechanical shaft procedure Mechanical shaft design

Solidworks simulation shaft design YouTube

Design of mechanical shaft procedure Mechanical shaft design

Shaft with torsional and bending compliance MATLAB

Calculation of shafts according to DIN 743 MDESIGN shaft

Ultimate Guide on What is Shaft Learn Types, Materials & Design

L17 Shafts Shaft Design YouTube

PPT Shaft Design PowerPoint Presentation, free download ID3955524

PPT Shaft Design PowerPoint Presentation, free download ID3955524

It Is Integral To Any Mechanical System In Which Power Is Transmitted From A Prime Mover, Such As An Electric Motor Or.

Shaft Failure Analysis Is Critical.

• Load Bearing Components Should Be Placed Next To The Bearings To Minimize The Bending Due To Large Forces.

Related Post: