Sbc Ring Gap Chart

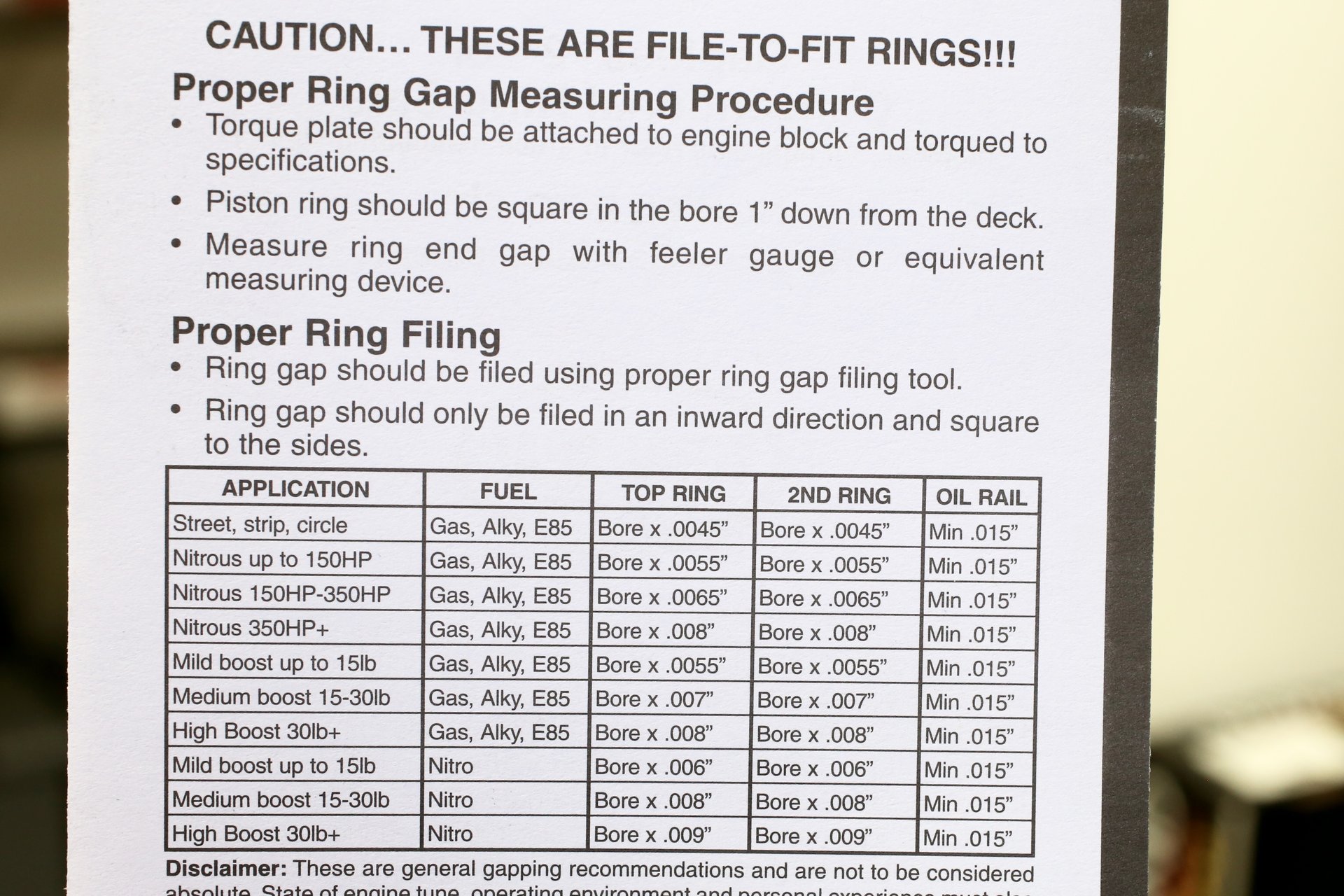

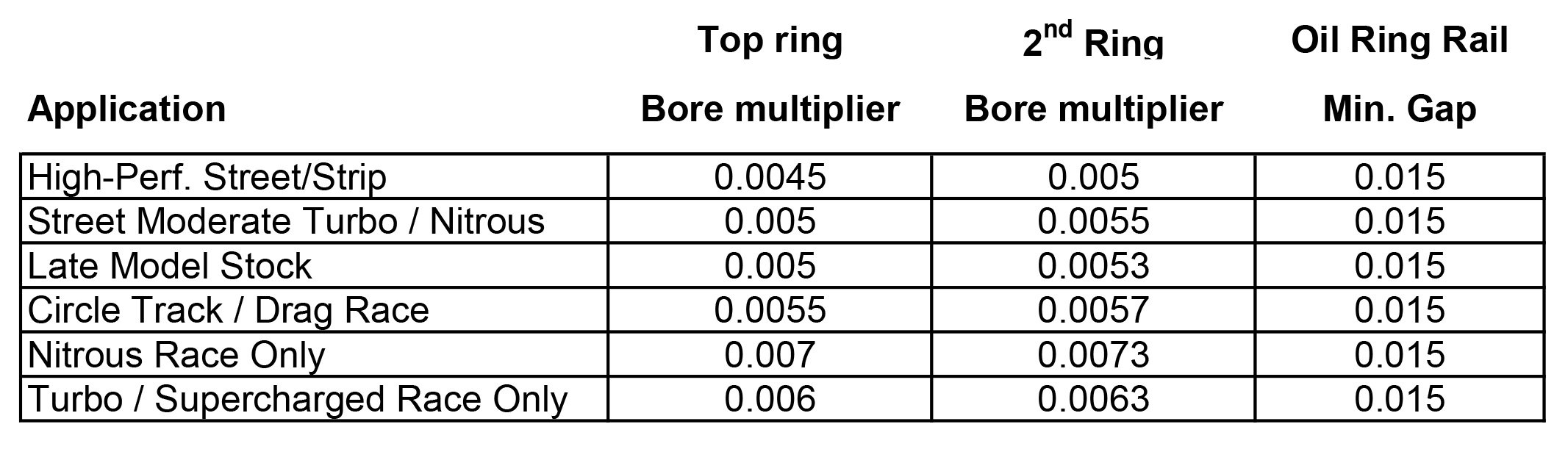

Sbc Ring Gap Chart - Web learn how to measure and adjust ring gaps for optimal performance and oil control. Are sold without any express warranty or any implied warranty of. Oh, and the '67 in your garage looks really nice! Multiply bore size x ring end gap factor. Due to the nature of performance applications, the parts sold by united engine & machine co. Web modern piston design locates the top ring higher for improved requires a larger top ring end gap. Web the gaps listed in jeff's mahle chart should work for your federal mogul/speed pro pistons, daron. Web ring end gap should be measured with the ring square in the bore on a fresh hone. Web basic rule of thumb for n/a engines without nitrous is.0045 to.0050 inch of gap, per inch of bore diameter for the top ring and.0055 to.0060 per inch of bore. Does this apply to a 350? Looking at the chart, je recommends a minimum end. Web the following chart indicates the specifications for compression ring gap as outlined by the sae (society of automotive engineers) as standards for the automotive. Use this chart to determine the proper end gap for. Web modern piston design locates the top ring higher for improved requires a larger top ring. In this article, we’re going to explore how to select, measure, and adjust. Multiply bore size x ring end gap factor. Web always follow the manufacturers instructions for best results. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. Web ring end. See the sae standards and charts for compression ring gap clearances and the effect of. Web ring end gap should be measured with the ring square in the bore on a fresh hone. To find the proper ring end gap, multiply your bore size by the ring end gap factor. Web safe top ring end gaps can be found by. Check with your piston manufacturer for recommended clearances. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment. Web ring end gap should be measured with the ring square in the bore on a fresh hone. Web always follow the manufacturers instructions for best results. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. Web modern piston design locates the. Are sold without any express warranty or any implied warranty of. Web the recommended measuring procedure is as follows: Web always follow the manufacturers instructions for best results. Here, we explain why rings need a gap, how to do it,. Some second ring sets can be set slightly looser,. Below is a chart which contains the recommended end gap. Use this chart to determine the proper end gap for. Multiply bore size x ring end gap factor. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. Web use the chart below to. Web learn how to measure and adjust ring gaps for optimal performance and oil control. Web the following chart indicates the specifications for compression ring gap as outlined by the sae (society of automotive engineers) as standards for the automotive. Web use the chart below to determine the minimum ring end gap. Cylinder should be free of any taper. Does. For a naturally aspirated street engine using a cast piston with. Here, we explain why rings need a gap, how to do it,. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. Check with your piston manufacturer for recommended clearances. Oh, and the. Web ring end gap should be measured with the ring square in the bore on a fresh hone. Web use the chart below to determine the minimum ring end gap. Here are a few scans of instructions from edelbrock that seems to be very usefull. Web the recommended measuring procedure is as follows: Web learn how to measure and adjust. See the sae standards and charts for compression ring gap clearances and the effect of. Here are a few scans of instructions from edelbrock that seems to be very usefull. Due to the nature of performance applications, the parts sold by united engine & machine co. Web the gaps listed in jeff's mahle chart should work for your federal mogul/speed pro pistons, daron. Web safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart below. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. Are sold without any express warranty or any implied warranty of. Web modern piston design locates the top ring higher for improved requires a larger top ring end gap. Below is a chart which contains the recommended end gap. In this article, we’re going to explore how to select, measure, and adjust. Cylinder should be free of any taper. Looking at the chart, je recommends a minimum end. A torque plate should be installed on the engine (if applicable) and torqued to the same specification as the cylinder head. Check with your piston manufacturer for recommended clearances. Web the recommended end gap is determined by the bore size and the application which the ring set will be utilized. Web #1 · mar 18, 2002.

SBC Piston Ring and Rod Orientation (For the First time Builders) YouTube

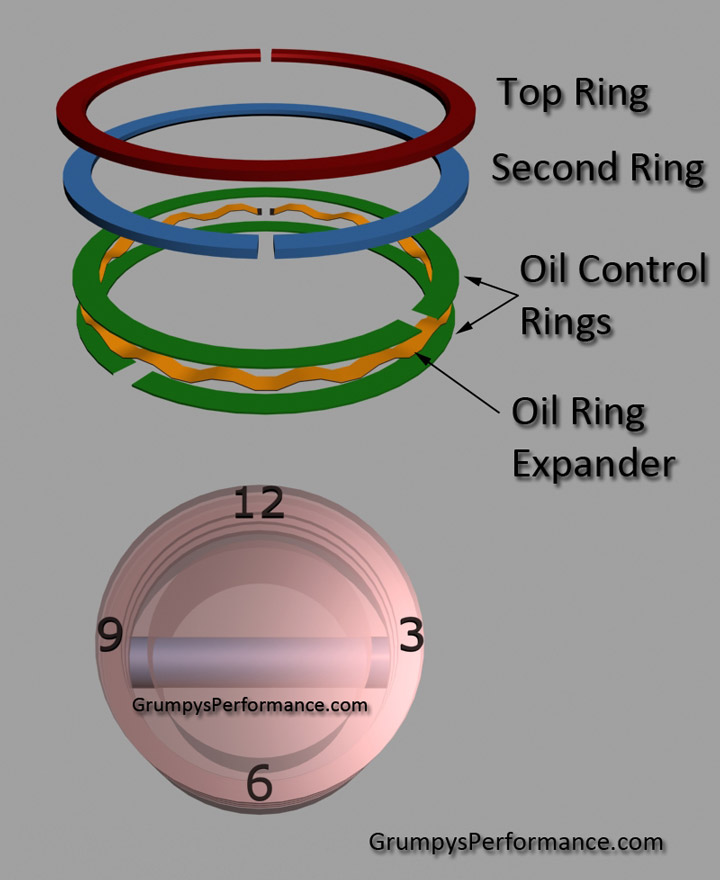

ring gapping and basic piston ring info YOULL NEED Grumpys

383 SBC Ring Gap and Cam Bearing setup! YouTube

Piston Ring Gap Placement GM Square Body 1973 1987 GM Truck Forum

How to FileFit and Install Piston Rings

Piston Ring Gaps Critical But Simple Skills High Performance Academy

Setting Timing on the SBC 350 and the Ford 302

How to gap piston rings. I show you how I file fit my rings for my

Blueprint Series The How And Why Of Setting Piston Ring End Gap

Piston Ring End Gap Chart

Web Basic Rule Of Thumb For N/A Engines Without Nitrous Is.0045 To.0050 Inch Of Gap, Per Inch Of Bore Diameter For The Top Ring And.0055 To.0060 Per Inch Of Bore.

Web Always Follow The Manufacturers Instructions For Best Results.

Web Ring End Gap Should Be Measured With The Ring Square In The Bore On A Fresh Hone.

Some Second Ring Sets Can Be Set Slightly Looser,.

Related Post: