Robot Claw Design

Robot Claw Design - Then you've come to the right place! Test your new device around the house to see what objects you can grip and grab. Web this instructable will show you how to 3d print and build a simple robot claw that you can then attach to any of your arduino projects. It is meant to show a basic geometry and to give people a head start on building a claw to meet their project's needs. Known sometimes as robot claw grabbers, robot claws consist of two claws, or jaws, that grasp an object by coming together from opposite sides of an object. This project is a simple robot claw that could be added to many robotics projects. N more advanced robot designs. The gripper arm works just like the arms of an octopus. This robot claw is actuated with a single 9g servo motor, whose movement is controlled by a push button switch. Plot of the claw's principal axis angle ß change from its original position (see inset) under. It is meant to show a basic geometry and to give people a head start on building a claw to meet their project's needs. Plot of the claw's principal axis angle ß change from its original position (see inset) under. Pull the trigger and discover the mechanisms that make the claw work. The new design replaces the current pneumatic actuators. Web axiomatic design principles were employed to design a claw to be much lighter, more compact and with more precise grip. Web the design of robotic soft matter capable of emulating the complex movements of living organisms such as mechanical actuation, shape transformation, and autonomous translation remains a grand challenge in soft materials science. Here is a video of it:. This project is a simple robot claw that could be added to many robotics projects. Pull the trigger and discover the mechanisms that make the claw work. This design focuses on gripping power and the finished claw is capable of picking up most anything that can fit into its jaws, including cell phones and a large roll of duct tape!. This project is a simple robot claw that could be added to many robotics projects. Web design and plan: I used two claws to do this. It is designed as a quick and easy projects for aspiring makers and diyers. Web you’ve mastered the clawbot,we challenge you to move onto ev. Web did you ever think about designing a manipulator claw using servos? I analyzed the steps, actions and worst case scenarios and i decided to stay in the classic design for the robot claw. Web a little while ago, i made a post about using inverse kinematics to make a claw. Is it mostly smooth or is it rough? Web. Web with the addition of a simple servo motor and a little bit of code, the robotic claw can bring life to any project. You could put it on a rc car, make a full robot arm or put it on a stick and use it to grab things. Pull the trigger and discover the mechanisms that make the claw. Web design and plan: Web i need a robot claw to carefully handle a plastic juice cup without breaking the plastic cup or losing it on the way. Sometimes a simple claw design can be the most competitive. Web this is a simple actuated robot claw made out of household materials such as popsicle sticks and cardboard. This robot claw. It is designed as a quick and easy projects for aspiring makers and diyers. (in the real game, the robot will not be controlled by a moving attachment, but rather it will be tweened between positions, looking much. Web axiomatic design principles were employed to design a claw to be much lighter, more compact and with more precise grip. Web. The new design replaces the current pneumatic actuators with a servomotor. They are complex pieces of machinery, from the precise motion to how force will be applied to objects. Sometimes a simple claw design can be the most competitive. Wanna build it as quickly as possible? Is it mostly smooth or is it rough? Test your new device around the house to see what objects you can grip and grab. Web the design of robotic soft matter capable of emulating the complex movements of living organisms such as mechanical actuation, shape transformation, and autonomous translation remains a grand challenge in soft materials science. Web this most simple ev3 robot claw by william is useful. Determine the specifications and size of your robotic claw, including the dimensions of the claw and the range of motion you want it to have. I used two claws to do this. Web this is a novel design for a simple robot claw that can be used for electronics workshops! N more advanced robot designs. Today, i’m going to show you how to control a servo robotic claw using an arduino uno. Web axiomatic design principles were employed to design a claw to be much lighter, more compact and with more precise grip. Here is a video of it: Web this is a simple actuated robot claw made out of household materials such as popsicle sticks and cardboard. This design focuses on gripping power and the finished claw is capable of picking up most anything that can fit into its jaws, including cell phones and a large roll of duct tape! Web if time is available, several prototypes of claws should be developed during the design stage to assess which will be most effective for manipulating game pieces. Plot of the claw's principal axis angle ß change from its original position (see inset) under. Sometimes a simple claw design can be the most competitive. Engineers typically use a few key steps to design robotic grippers, from concept to final production. The gripper arm works just like the arms of an octopus. They are complex pieces of machinery, from the precise motion to how force will be applied to objects. Then you've come to the right place!

Most Simple EV3 Robot Claw YouTube

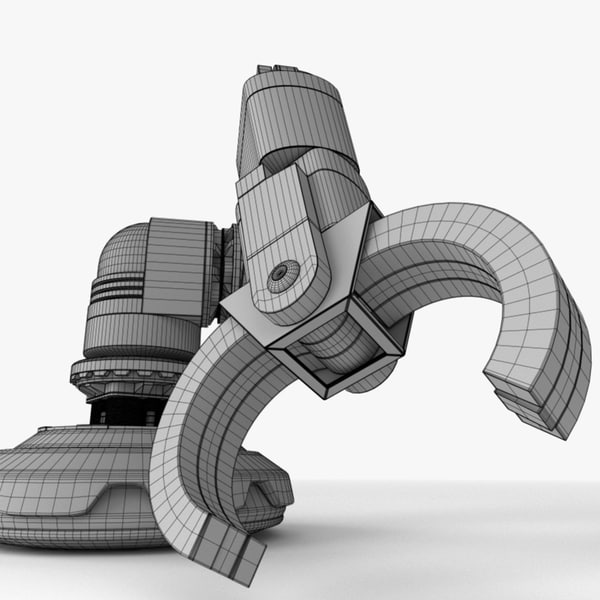

Vector Concept Robot ARM CLAW standard servo 3D CAD Model Library

Robotic claw Vex IQ Robotics / Garra Robótica Autodesk Online Gallery

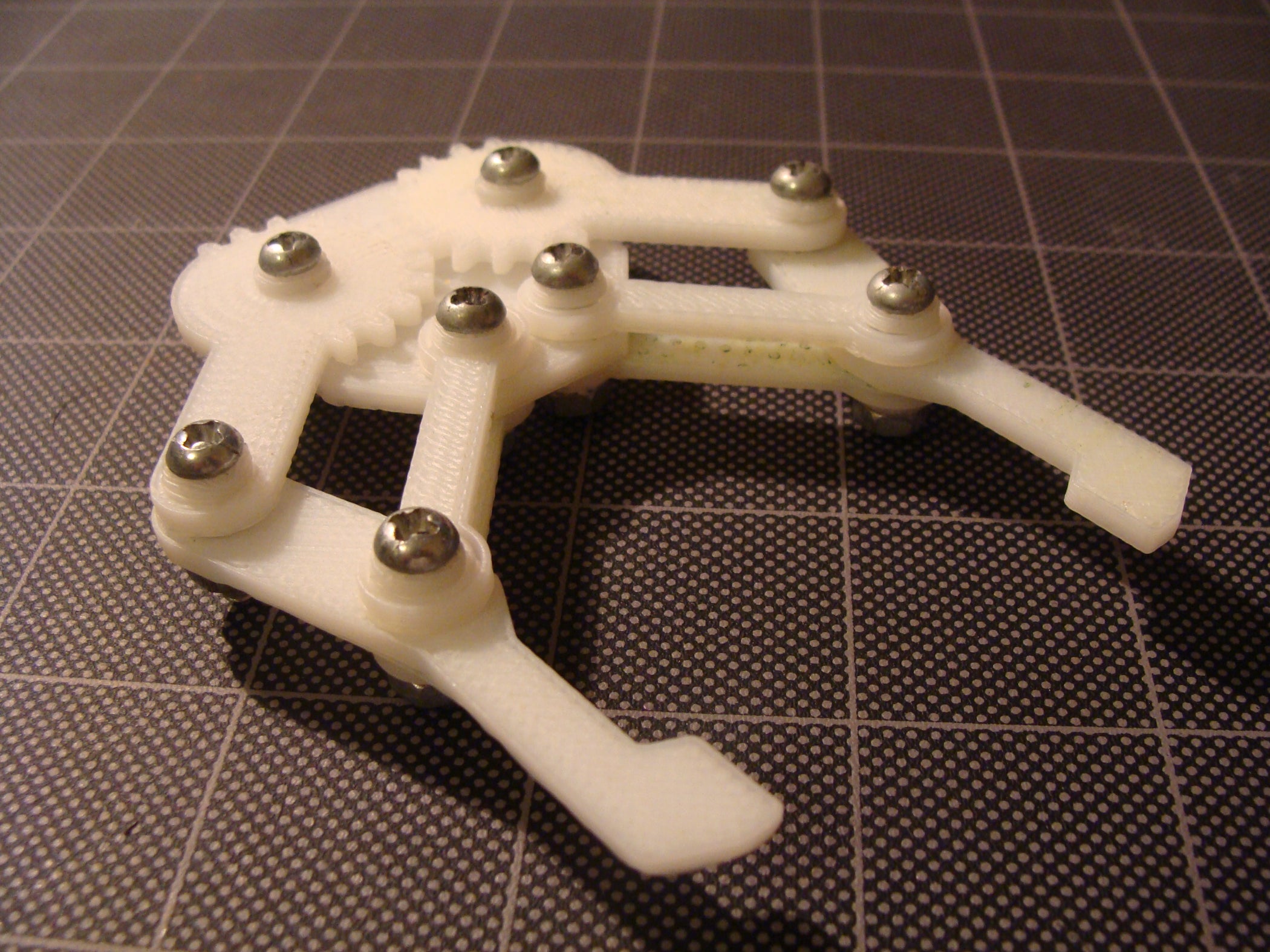

Simple Robot Claw Instructables

V5 CLAW DESIGN VEX ROBOTICS YouTube

Robot claw from manufacturing to marine research

Brown Metal Mechanical Robotic Packing Claw Set Stock Illustration

Robotic Claw Assembly SolidWorks Tutorials YouTube

3d max robotic claw

Simple Robot Claw Instructables

Web Design And Plan:

Web A Little While Ago, I Made A Post About Using Inverse Kinematics To Make A Claw.

The New Design Replaces The Current Pneumatic Actuators With A Servomotor.

This Tutorial Instructs Users To Create A 3D Assembly With Moving Gears, Components, And Restrictions To Create An Articulated Mechanical Claw.

Related Post: