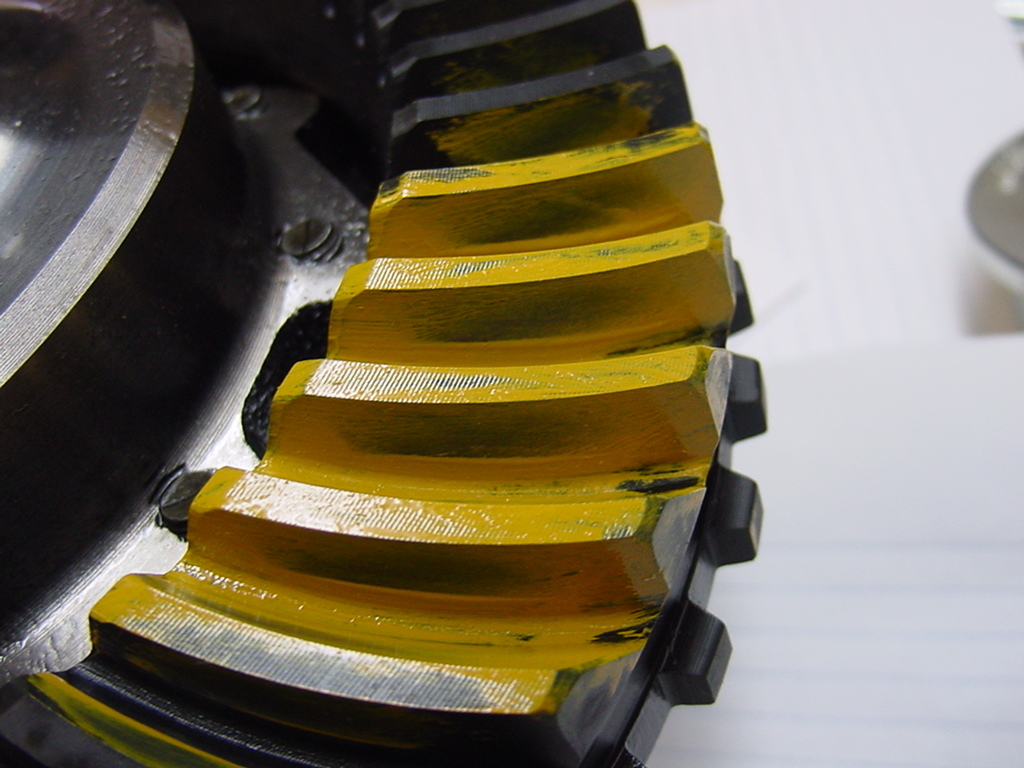

Ring Pinion Pattern

Ring Pinion Pattern - To correct the pattern the pinion needs to be moved away from the ring gear so that it is positioned farther. Web pinion resistance against the rotating ring gear helps establish a good pattern. Web at.039 pinion shim, the contact pattern on the ring gear was favoring the root of the ring gear on the drive side. Web five cut ring & pinion gears (face milled): Web in general, pattern movements can be summarized this way: When setting the pinion position, many of the service manuals required a final pinion position check by using guages that verified the dimension from the center line of the different carrier (center line of ring gear) to the face of the pinion (button). Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Web ring gear and pinion tooth contact pattern the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Begin by setting proper pinion bearing preload, total turning preload, and ring gear backlash. This chart illustrates different patterns and adjustments. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. I can see the the.014 lash, that the pattern is more crisp and i am getting more tooth contact on the ring, but the pattern on both are still on the very edge of the toe. Web after the gears are. The coast pattern will move deeper toward the tooth flank and slightly toward the heel. I can see the the.014 lash, that the pattern is more crisp and i am getting more tooth contact on the ring, but the pattern on both are still on the very edge of the toe. This is done using gear marking compound and checking. To check the contact pattern, apply marking compound to the ring gear teeth and run the gears under load. Web sackman, here are the results from the.024 pinion shim at the bottom of the lash spectrum to the top of the lash spectrum. Web ring gear and pinion tooth contact pattern the toe of the gear tooth is the portion. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. Pinion bearing preload usually provides enough resistance for a good pattern, but additional resistance can be added by wrapping a shop towel around the yoke and pulling the two ends tight. Web shows how varying pinion depth and back lash a. Web sackman, here are the results from the.024 pinion shim at the bottom of the lash spectrum to the top of the lash spectrum. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web ring & pinion tooth pattern interpretation. Ring gears use a pilot bearing that The coast pattern. Automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. To check the contact pattern, apply marking compound to the ring gear teeth and run the gears under load. The heel of the gear tooth is the portion of the tooth surface at the outer. Web when setting up a ring & pinion, there are four critical settings that need to be correct in order to get proper setup and good gear life. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. To correct the pattern, move the pinion toward the ring gear centerline. At.028 pinion shim, the contact. Ring gears use a pilot bearing that The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web five cut ring & pinion gears (face milled): Web a contact pattern centered from face to flank indicates the correct pinion depth. Pinion bearing preload usually provides enough resistance for a good pattern, but additional resistance can be added. Pinion depth (how close the pinion is to the ring gear), backlash (how close the ring gear is to the pinion), pinion bearing preload (how much bearing drag is on the pinion bearings), and carrier. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. Moving the pinion gear closer to. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Web ring & pinion tooth pattern interpretation. Web ring gear and pinion tooth contact pattern the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Web when setting up a ring. Web pattern the pinion needs to be moved towards the ring gear so that it is positioned closer to the ring gear centerline. Sequential graphic detail from too deep to to shallow, and from too little backlash. The coast pattern will move deeper toward the tooth flank and slightly toward the heel. A contact pattern closer to the gear face means the pinion is too far away from the ring gear. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. At.028 pinion shim, the contact pattern on the ring gear moved and was favoring the crown/top of the ring gear on the drive side. This is done using gear marking compound and checking the gear tooth pattern. Web at.039 pinion shim, the contact pattern on the ring gear was favoring the root of the ring gear on the drive side. Ring gears use a pilot bearing that Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. If the contact pattern is towards the flank of the ring gear teeth then the pinion is too close to the ring gear. Web ring gear and pinion tooth contact pattern the toe of the gear tooth is the portion of the tooth surface at the end towards the center. This video was created to give people a basic understanding of. Web proper contact patterns between ring gear and pinion gear teeth are important for quiet gear operation. You should see the wear pattern closer to the toe of the tooth with most gear sets. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns.

Any differential experts care to comment on my ring and pinion pattern

Ring paint/ pinion IH8MUD Forum

Ring and pinion gear pattern Rennlist Porsche Discussion Forums

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

How To Create & Read Ring Gear Patterns

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring And Pinion Patterns

Ring and pinion pattern garu's please help CorvetteForum Chevrolet

Ring Pinion Pattern Patterns Gallery

RING AND PINION TOOTH CONTACT PATTERN...mine with pic MGB & GT Forum

To Correct The Pattern The Pinion Needs To Be Moved Away From The Ring Gear So That It Is Positioned Farther.

Pinion Bearing Preload Usually Provides Enough Resistance For A Good Pattern, But Additional Resistance Can Be Added By Wrapping A Shop Towel Around The Yoke And Pulling The Two Ends Tight.

To Check The Contact Pattern, Apply Marking Compound To The Ring Gear Teeth And Run The Gears Under Load.

How Did The Pinion Move.

Related Post: