Ring Gear Pattern Chart

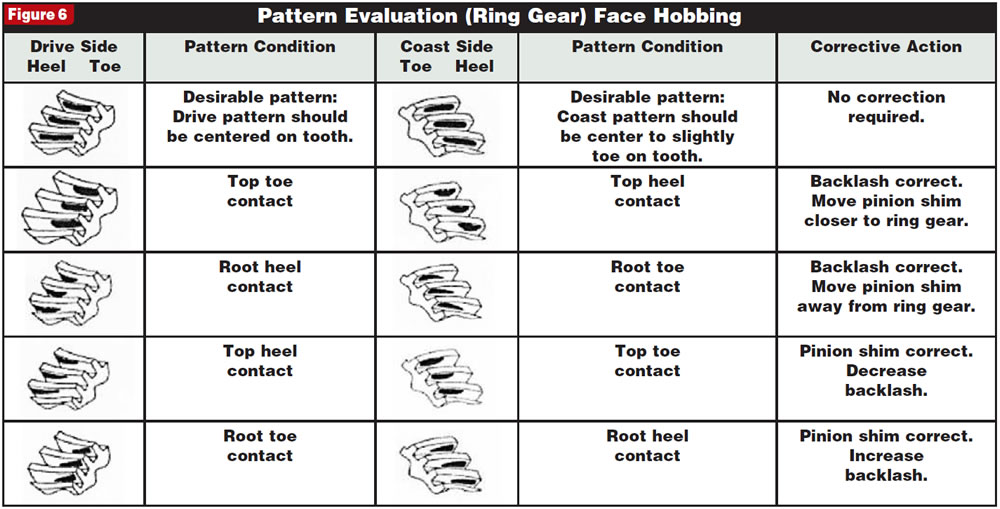

Ring Gear Pattern Chart - Web you must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. 7.20 / 181mm ring gear diameter: Bearing preload, total turning preload, and ring gear backlash. Web ring gear contact pattern interpretation of face hobbed (uniform tooth depth) gear teeth. Become an 1871 club member today to get the f&s journal, a $15 merch store reward + exclusive benefits. Turn left from flame brazier #1 and run past the hostile crab. Every gear has a characteristic pattern. Web when setting up the positioning of a ring and pinion in any rear end, there are only two settings that need to be done/measured correctly to ensure proper gear setup and long gear life. Or an ominous clunking sound? 1.625 / 24 ring gear bolts: Web ring gear and pinion tooth pattern interpretation. The top land of a gear tooth is the surface of the top of the tooth. The procedure involves changing the pinion position via. There's also upgradable crafted gear in season of discovery, which we cover further down. Become an 1871 club member today to get the f&s journal, a $15 merch. 1.625 / 24 ring gear bolts: Web how to create & read ring gear patterns. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web last updated on 02/28/2022. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Every gear has a characteristic pattern. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. 7.33 / 186mm pinion diameter / spline: Web directly between the site. One is manufactured by face hobbing, while the other one is manufactured by face milling. Web the pattern refers to how the ring gear and pinion gears mesh. Web when setting up the positioning of a ring and pinion in any rear end, there are only two settings that need to be done/measured correctly to ensure proper gear setup and. Web proper contact patterns between ring gear and pinion gear teeth are important for quiet gear operation. Web automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web how to create. One is manufactured by face hobbing, while the other one is manufactured by face milling. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. There's also upgradable crafted gear in season of discovery, which we cover further down. The toe of the gear tooth is the portion. The order in which adjustments are made during differential assembly and setup are: 7.20 / 181mm ring gear diameter: Web automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Web five cut ring & pinion gears (face milled): * pinion depth (how close the. 7.20 / 181mm ring gear diameter: Turn left from flame brazier #1 and run past the hostile crab. Web how to create & read ring gear patterns. Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure.. Ideally, the contact pattern should be seen in the. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Web directly between the site of grace at the siofra river bank and the place with all the flame pillars, under an obelisk closest to the staircase. To check the contact. The heel of the gear tooth is the portion of the tooth surface at the outer end. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. The order in which adjustments are made. The coast pattern will move deeper toward the tooth flank and slightly toward the heel. Turn left from flame brazier #1 and run past the hostile crab. Web five cut ring & pinion gears (face milled): Web automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. First, we list the gear that is simply crafted and done, and in the next. The toe of the gear tooth is the portion of the tooth surface at the end towards the center. Pulling off a proper differential setup comes down to precise adjustments. Web when setting up the positioning of a ring and pinion in any rear end, there are only two settings that need to be done/measured correctly to ensure proper gear setup and long gear life. Web last updated on 02/28/2022. Web ring gear contact pattern interpretation of face hobbed (uniform tooth depth) gear teeth. * pinion depth (how close the pinion is to the ring gear) * backlash (how close the ring gear is to the pinion). Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. 7.20 / 181mm ring gear diameter: Proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Every gear has a characteristic pattern. Web in general, pattern movements can be summarized this way:

Ring And Pinion Gear Pattern Chart

How To Create Read Ring Gear Patterns

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

How To Create & Read Ring Gear Patterns

Ring paint/ pinion IH8MUD Forum

Gear pattern advice The H.A.M.B.

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring Gear Pattern Chart

Once backlash is within spec you can set the pinion depth by reading

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

Ideally, The Contact Pattern Should Be Seen In The.

Web Here's How To Achieve The Best Ring & Pinion Contact Pattern , Every Time, In Just 3 Simple Steps!Reading Contact Patterns Can Be Daunting When Looking At Th.

See Manufacturer Or The Gearset For Exact Specifications And Special Instructions Before Attempting To Adjust The Ring And Pinion.

The Top Land Of A Gear Tooth Is The Surface Of The Top Of The Tooth.

Related Post: