Ratchet And Pawl Design

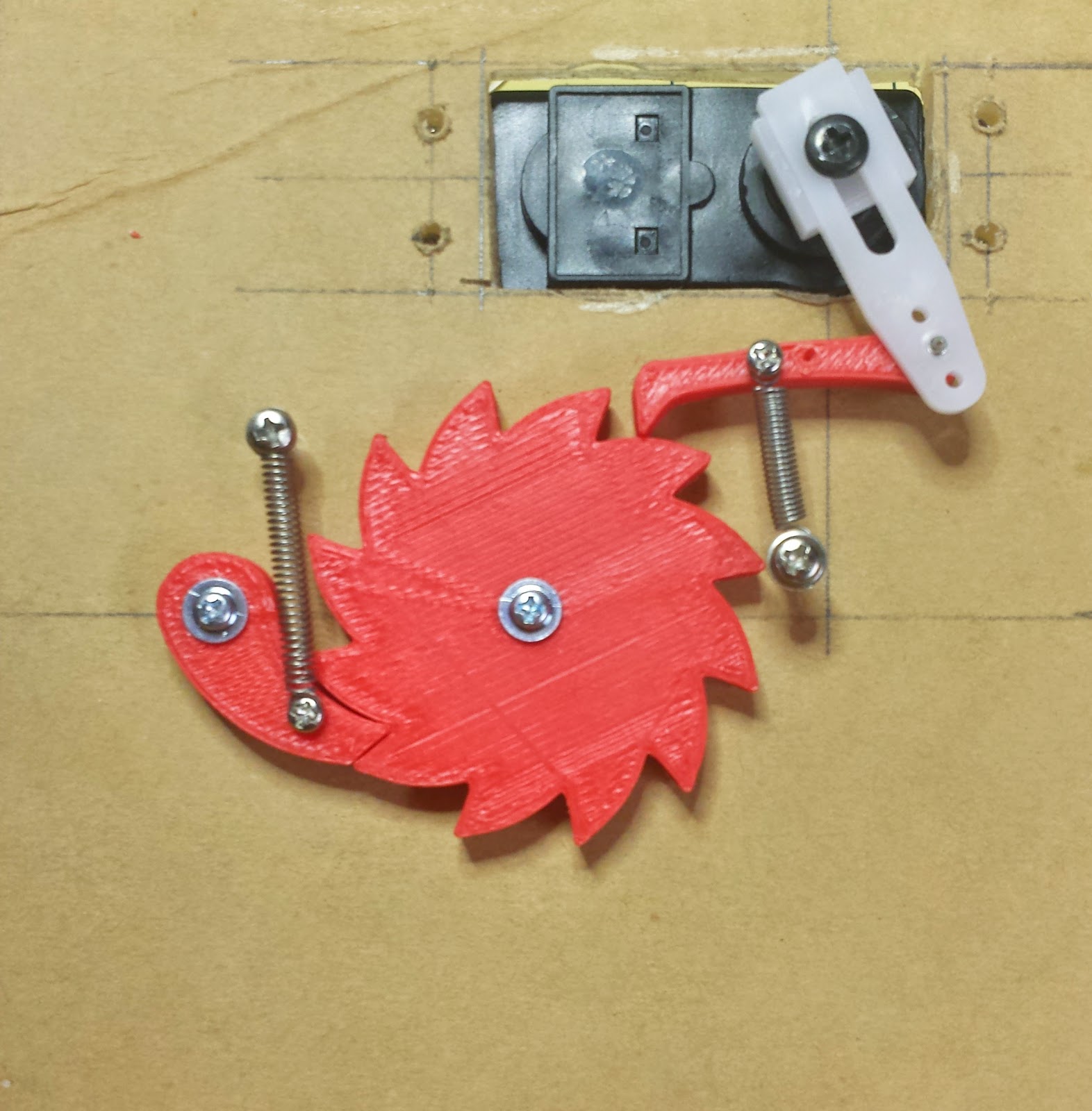

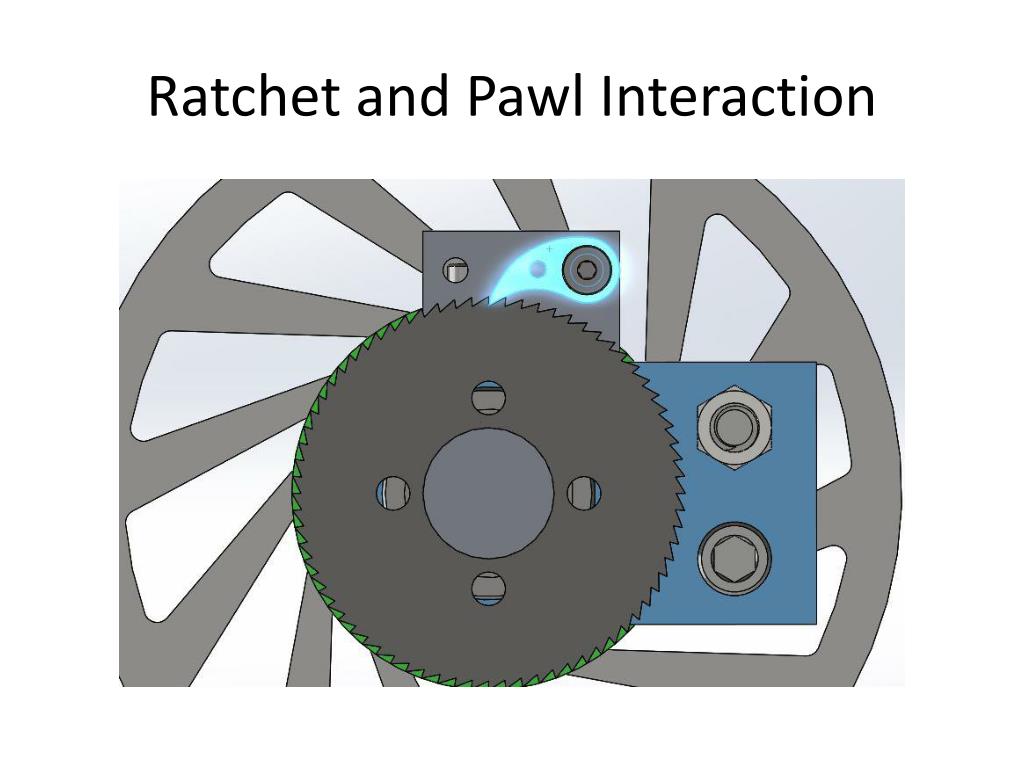

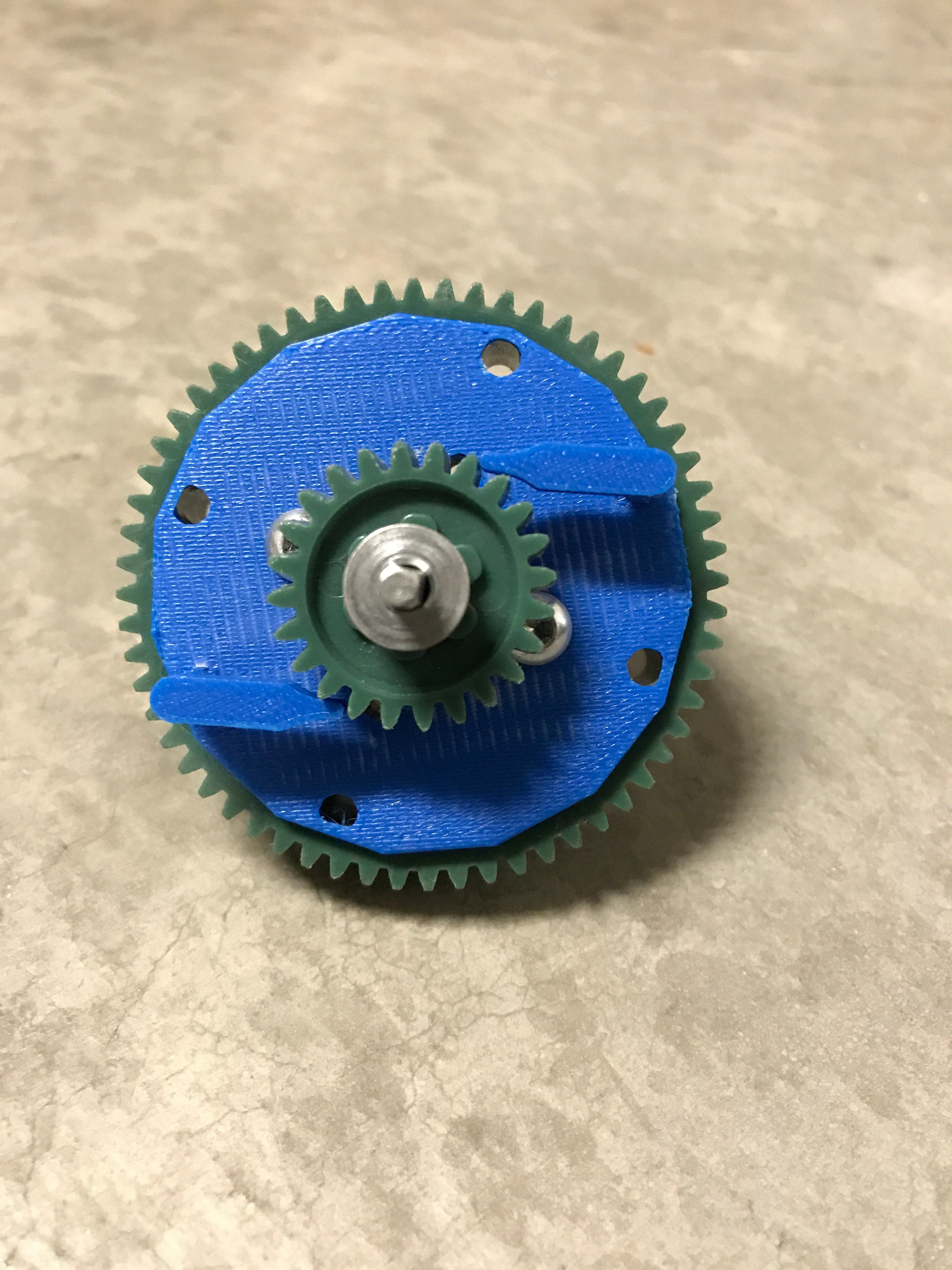

Ratchet And Pawl Design - Web ratchet and pawl mechanism design calculations. A ratchet fits onto a shaft and is locked onto the shaft by a key . A) effect of friction between pawl and eccentric shaft on driving torque, b) effect of friction between pawl tip. Web standard pawl and ratchet design. A is the ratchet wheel, and b is an oscillating lever carrying the driving pawl, c. In it's simplest form, this design consists of a surface that is toothed and a pawl (which is a lever that engages the toothed surface and only allows movement in one direction). Web in this chapter we discuss the ratchet and pawl, a very simple device which allows a shaft to turn only one way. Web in this video tutorial we will learn how to model & simulation of pawl & ratchet in solidworks. The following formula has been used in the calculation of ratchet gears for crane design. Web preview ratchet type gear design calculator. This design is by far the most common on bicycle freehubs, and as such the least expensive to employ. Their thinking is that the weight weenies. Web ratchet and pawl is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Web the ratchet pawl mechanism is designed for. Web in this video tutorial we will learn how to model & simulation of pawl & ratchet in solidworks. This is part 10 of mechanism video tutorial series in solidwo. Web join 13,850,000 engineers with over 6,180,000 free cad files. The ratchet and pawl mechanism is commonly used in mechanical power transmission systems as a means of allowing motion in. If the vehicle approaches a positive gradient, the gyro sensor send signal to the relay to energize the solenoid which engages the ratchet and pawl mechanism. M = ( p 2 l s n ) / f. Ratchets and pawls are usually made of: This paper focuses on three aspects: Web in this video tutorial we will learn how to. Studying the diagram you will see that as the ratchet wheel turns and the pawl falls into the 'dip' between the teeth. Web autodesk fusion 360 tutorial showing how to design a rachet & pawl mechanism in simple steps.tools used in this video are1. Web the animation below shows the realistic size of a ratchet and pawl mechanism, in place.. Web the ratchet pawl mechanism is designed for four important conditions: You are to design a ratchet mechanism to fit in the back of a delivery van. The ratchet and pawl mechanism is commonly used in mechanical power transmission systems as a means of allowing motion in one direction only. The following formula has been used in the calculation of. Web in this video tutorial we will learn how to model & simulation of pawl & ratchet in solidworks. P = circular pitch, in inches (mm), measured at. This system will be used to lift heavy packages from the van to ground level. Web the ratchet pawl mechanism is designed for four important conditions: 155k views 6 years ago. A supplementary pawl at d prevents backward motion of the wheel. Studying the diagram you will see that as the ratchet wheel turns and the pawl falls into the 'dip' between the teeth. Web in this video tutorial we will learn how to model & simulation of pawl & ratchet in solidworks. The following formula has been used in the. Web ratchet and pawl mechanism design calculations. Web a ratchet mechanism is based on a wheel that has teeth cut out of it and a pawl that follows as the wheel turns. P = [ ( f m ) / ( l s n ) ] 1/2. Web preview ratchet type gear design calculator. Their thinking is that the weight. Their thinking is that the weight weenies. The ratchet and pawl mechanism is commonly used in mechanical power transmission systems as a means of allowing motion in one direction only. A ratchet fits onto a shaft and is locked onto the shaft by a key . The following formula has been used in the calculation of ratchet gears for crane. A is the ratchet wheel, and b is an oscillating lever carrying the driving pawl, c. If the vehicle approaches a positive gradient, the gyro sensor send signal to the relay to energize the solenoid which engages the ratchet and pawl mechanism. The following formula has been used in the calculation of ratchet gears for crane design. Studying the diagram. Web ratchet and pawl calculation. Web standard pawl and ratchet design. A ratchet is a wheel with a shape similar to a circular saw blade or horizontal milling cutter. This paper focuses on three aspects: Web a ratchet mechanism is based on a wheel that has teeth cut out of it and a pawl that follows as the wheel turns. Their thinking is that the weight weenies. 155k views 6 years ago. Studying the diagram you will see that as the ratchet wheel turns and the pawl falls into the 'dip' between the teeth. Web the ratchet pawl mechanism is designed for four important conditions: In it's simplest form, this design consists of a surface that is toothed and a pawl (which is a lever that engages the toothed surface and only allows movement in one direction). The following formula has been used in the calculation of ratchet gears for crane design. A supplementary pawl at d prevents backward motion of the wheel. Web ratchet and pawl is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. A ratchet fits onto a shaft and is locked onto the shaft by a key . Web join 13,850,000 engineers with over 6,180,000 free cad files. This calculator provides the linear distance moved by a pawl in one complete turn of a ratchet wheel.

How to design a Rachet & Pawl Mechanism in Autodesk Fusion 360

Figure 3 from A Study on Design and Fabrication of Screw Jack Lifter

Ultimaker 2 Prints Ratchet and Pawl Mechanism

Ratchet and Pawl YouTube

TienI Ratchet Handle design structure

PPT P14007 Wheelchair Assist Subsystem Design Review PowerPoint

Single Gear Ratchet and Pawl Online Challenges

Design ConceptRatchet and Pawl MechanismInventor Studio YouTube

how to design a ratchet and pawl Google Search Cad Software, Software

![Working of Ratchet and pawl mechanism [Animation] YouTube](https://i.ytimg.com/vi/e2ohnmPZ3W0/maxresdefault.jpg?sqp=-oaymwEmCIAKENAF8quKqQMa8AEB-AH-CYAC0AWKAgwIABABGBMgRCh_MA8=&rs=AOn4CLBoxAjGXf50WvAN1B-UaFLISkrpow)

Working of Ratchet and pawl mechanism [Animation] YouTube

The Teeth Are Uniform But Are Usually Asymmetrical, With Each Tooth Having A Moderate Slope On One Edge And A Much Steeper Slope On The Other Edge.

This Design Is By Far The Most Common On Bicycle Freehubs, And As Such The Least Expensive To Employ.

Web Ratchet And Pawl Mechanism.

Web In This Video Tutorial We Will Learn How To Model & Simulation Of Pawl & Ratchet In Solidworks.

Related Post: