Push Stick Pattern

Push Stick Pattern - Keep your hands away from blades and cutters, and hold work securely with this vital shopmade accessory. Web push stick is a safety device that helps you to control movement of working piece when operate on some of the machines, especially when working on tablesaw, jointer, router table or a bandsaw. Web the following push sticks can be built in your workshop, mostly from scrap, and will keep you safe every time you use them. This is an easy one. I’ve been using this kind of push stick for a long time time, and i go into a few of the benefits of this type in the video at the bottom of the page. 175k views 10 years ago. Web making a plywood push stick. Web push sticks can come in different shapes and sizes, they can be made out of wood or plastic, and they can be made at home or purchased from a store too. A quick and easy to build push stick. Diy do it yourself free woodworking plans push sticks tablesaw jigs workshop projects. Web make a push stick for your saw table: I’ve been using this kind of push stick for a long time time, and i go into a few of the benefits of this type in the video at the bottom of the page. Keep your hands away from blades and cutters, and hold work securely with this vital shopmade accessory.. This free template allows you to easily create your own push stick exactly like the one i use every day in my shop—a push stick is essential for guiding stock safely through table saws, routers, and other power tools. Use good quality straight scrap wood. Push sticks are used to push stock through your table saw without getting your fingers. A quick and easy to build push stick. This free template allows you to easily create your own push stick exactly like the one i use every day in my shop—a push stick is essential for guiding stock safely through table saws, routers, and other power tools. You can easily make push sticks out of scrap plywood that you have. >> 8 classic push stick plans. Web a push stick keeps your hands away from sawblades and cutterheads and allows you to hold workpieces securely. 175k views 10 years ago. Web today i'll show you how to make a push stick, push blocks, and sanding blocks for your woodshop. Web the style push stick i’m showing you here is an. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. A quick and easy to build push stick. 2) plywood push block (see pic/popup) 3) how to make a push block. Web a push stick keeps your hands away from sawblades and cutterheads and allows you to hold workpieces. I start by printing the template and pasting it onto a piece of plywood: A quick and easy to build push stick. And why these are the best push sticks and sanding blocks. 1) push block w/2 alt handles + push sticks. Web using a plywood push stick can help keep your fingers out of the way and give you. Keep your hands away from blades and cutters, and hold work securely with this vital shopmade accessory. Web push stick templates, can be made using scrap wood. Push stick keeps your hands away from machine cutting zone, it also helps to produce a smoother cuts. Web the style push stick i’m showing you here is an easy design that you. Web making a plywood push stick. The point of a push stick is to allow you to push wood that is very short or narrow through something like a table saw without getting your fingers close to that dangerous blade. I traced one of my push sticks and made a pattern for you, it can be downloaded here: Push stick. Web push stick templates, can be made using scrap wood. Web using a plywood push stick can help keep your fingers out of the way and give you more confidence. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. Web making a plywood push stick. 1) push block. Check out the video on how to make it and here are some images and the stencil that you can print out, trace and replicate. Web this is a very simple template for push sticks. Learn how to build a diy push stick, here. I start by printing the template and pasting it onto a piece of plywood: Web push. Web this is a very simple template for push sticks. As such, don't take the lowly push… Use good quality straight scrap wood. Web the following push sticks can be built in your workshop, mostly from scrap, and will keep you safe every time you use them. Learn how to build a diy push stick, here. Once you’ve printed out your pattern you can either use a jig saw, or band saw to cut these out of scrap plywood or 1x boards. Push stick keeps your hands away from machine cutting zone, it also helps to produce a smoother cuts. Web make a push stick for your saw table: Check out this diy push stick that i made for my woodshop! I start by printing the template and pasting it onto a piece of plywood: Diy do it yourself free woodworking plans push sticks tablesaw jigs workshop projects. This simple, but useful plan comes from “fine woodworking” and the design of the simple push stick comes from ellen kaspen. Web the mighty diy push stick. And why these are the best push sticks and sanding blocks. 2) plywood push block (see pic/popup) 3) how to make a push block. Push sticks, like the light saber, are often the jedi woodworker’s first project.

Woodworking Plans Table Saw Push Stick Pattern PDF Plans

Woodworking Template Table Saw Push Sticks Kurt's Blog

How To Make THE BEST Push Stick YouTube

Saw Handle Push Stick Design Files for CNC fusion 360 Etsy Table

Push Stick / The Wood Whisperer Store Easy woodworking ideas, Plywood

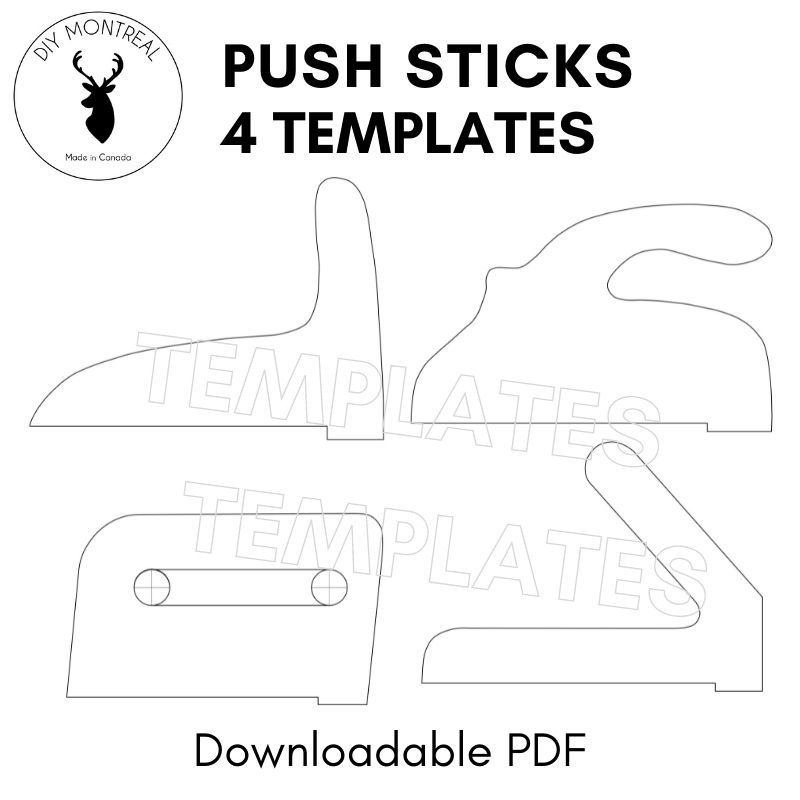

Push Sticks Printable Templates 4 Designs DIY Montreal

Printable Push Stick Template Printable Word Searches

Push Stick Gabarits pour travail du bois, Atelier de menuiserie

Woodworking Template Table Saw Push Sticks Kurt's Blog

Unique Push stick Woodworking essentials, Diy projects engineering

Web The Style Push Stick I’m Showing You Here Is An Easy Design That You Can Make Without A Bandsaw.

>> 8 Classic Push Stick Plans.

Making My Favourite Push Stick.

You Can Easily Make Push Sticks Out Of Scrap Plywood That You Have Laying Around The Shop.

Related Post: