Pump Design

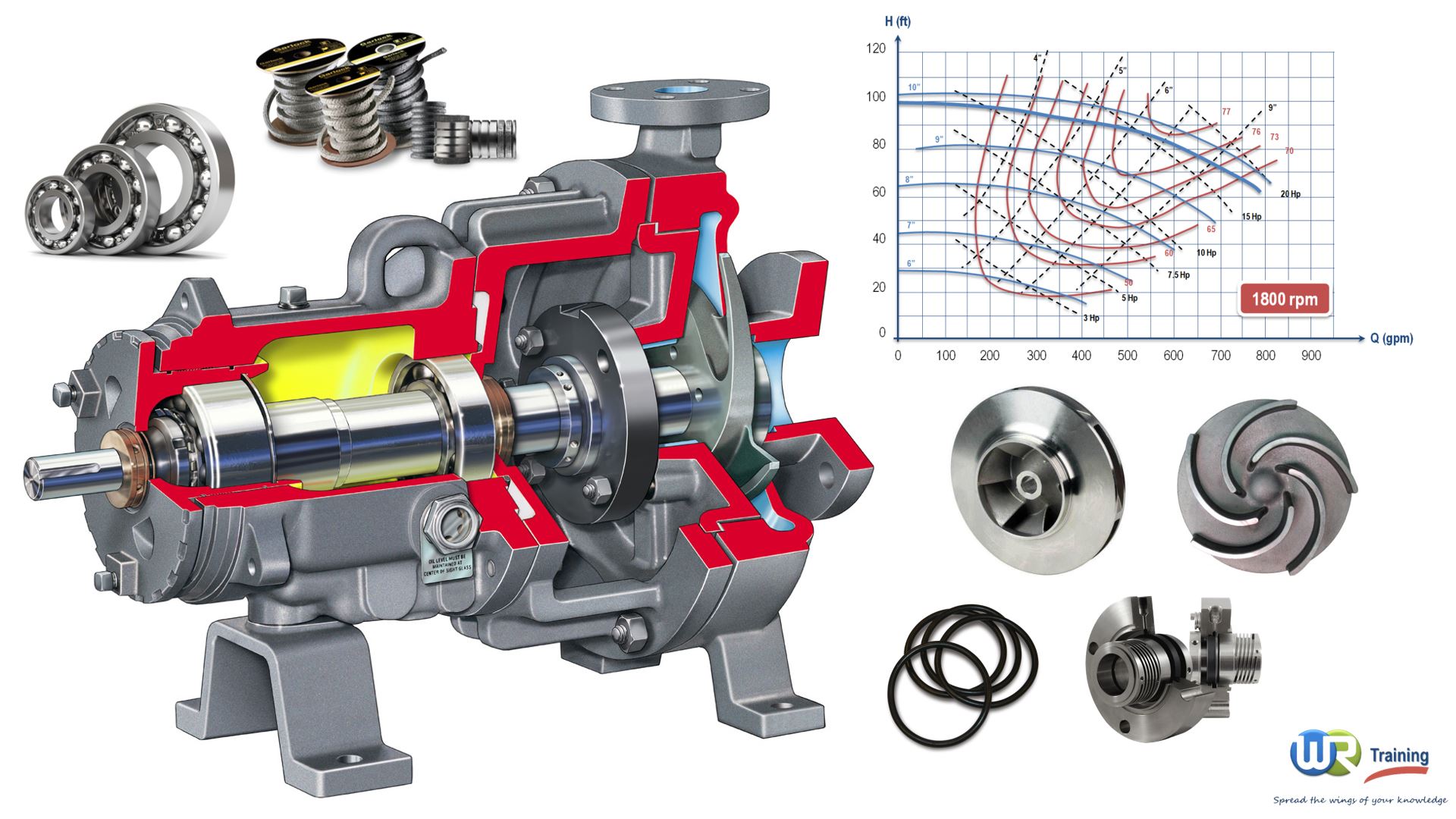

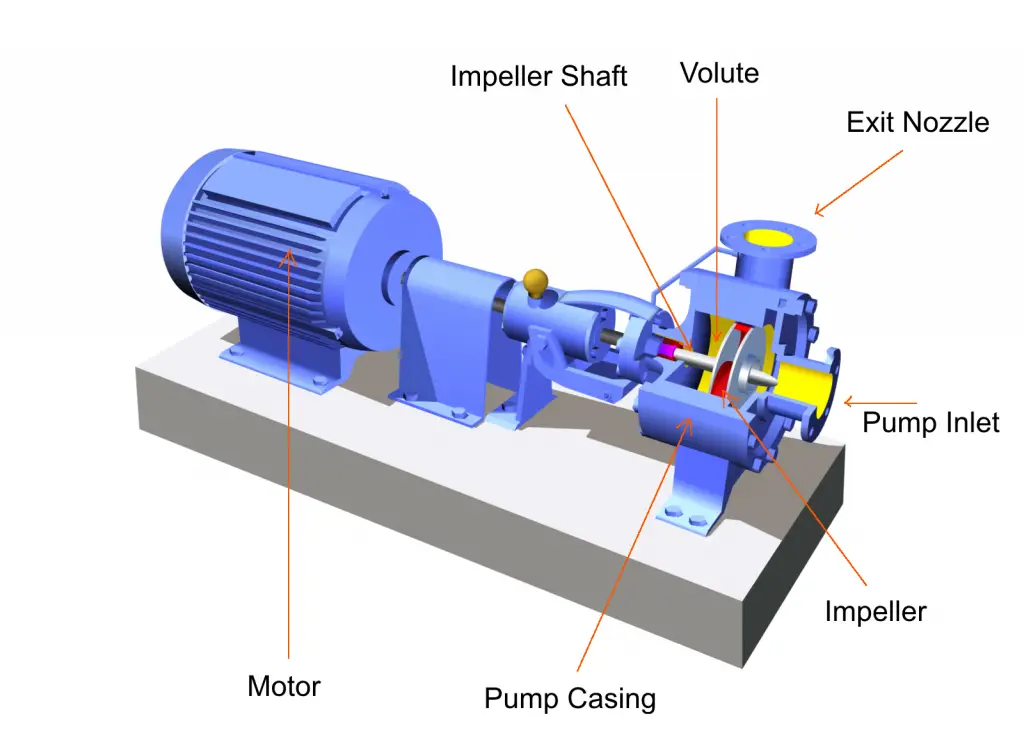

Pump Design - Web simulate your centrifugal pump design in simscale. Why can't we just use discharge pressure? Web but by following these six simple rules, users can avoid premature pump failure and related pump piping pitfalls. Small changes from existing designs to give a slight change in head or flow range; Web pump sizing involves matching the flow and pressure rating of a pump with the flowrate and pressure required for the process. Design using empirical information, tabular and graphical; Before we get to the actual liquid being pumped, let’s discuss why most pumps are rated in units of head (feet or meters) instead of pressure (pounds per square inch [psi], kilopascal [kpa] or barg—a unit of gauge pressure). Learn about the most common centrifugal pump designs. Web this series of articles explains what a pump is, what the main parts of a pump are, how to pick the right pump design for an application, and much more. And computer based approaches which are in some instances based on empirical data and more recently use finite element or finite. Web there are a number of approaches to design, chief among which are: Web this series of articles explains what a pump is, what the main parts of a pump are, how to pick the right pump design for an application, and much more. Design using empirical information, tabular and graphical; Web how to design a pump system. Centrifugal pumps. The mass flowrate of the system is established on the process flow diagram by the mass balance. Total head is related to the discharge pressure of the pump. Total head and flow are the main criteria that are used to compare one pump with another or to select a centrifugal pump for an application. Design using empirical information, tabular and. This type of pump combines a volute casing with a variety of impeller designs. Web how to design a pump system. Learn about the most common centrifugal pump designs. Web gain an understanding of the fundamental principles informing centrifugal pump design, application, and selection. Web this series of articles explains what a pump is, what the main parts of a. The mass flowrate of the system is established on the process flow diagram by the mass balance. Web there are a number of approaches to design, chief among which are: Before we get to the actual liquid being pumped, let’s discuss why most pumps are rated in units of head (feet or meters) instead of pressure (pounds per square inch. Web first things first. Web but by following these six simple rules, users can avoid premature pump failure and related pump piping pitfalls. Total head is related to the discharge pressure of the pump. Total head and flow are the main criteria that are used to compare one pump with another or to select a centrifugal pump for an application.. Web pumps may be classified in two general types, dynamic and positive displacement. Total head and flow are the main criteria that are used to compare one pump with another or to select a centrifugal pump for an application. Positive displacement pumps are those in which energy is imparted to the liquid in a fixed displacement volume, such as a. Decipher the meaning of pump industry vocabulary. The mass flowrate of the system is established on the process flow diagram by the mass balance. Web first things first. Web but by following these six simple rules, users can avoid premature pump failure and related pump piping pitfalls. Learn about the most common centrifugal pump designs. Web simulate your centrifugal pump design in simscale. Design using empirical information, tabular and graphical; Web how to design a pump system. Web first things first. Web but by following these six simple rules, users can avoid premature pump failure and related pump piping pitfalls. Small changes from existing designs to give a slight change in head or flow range; The mass flowrate of the system is established on the process flow diagram by the mass balance. Centrifugal pumps have revolutionized industries with their efficiency, compact design, and ability to move fluids at varying rates and pressures. Web first things first. Why can't we just. Web gain an understanding of the fundamental principles informing centrifugal pump design, application, and selection. Web how to design a pump system. Total head and flow are the main criteria that are used to compare one pump with another or to select a centrifugal pump for an application. The mass flowrate of the system is established on the process flow. Web pumps may be classified in two general types, dynamic and positive displacement. Web simulate your centrifugal pump design in simscale. The mass flowrate of the system is established on the process flow diagram by the mass balance. This type of pump combines a volute casing with a variety of impeller designs. Design using empirical information, tabular and graphical; Web but by following these six simple rules, users can avoid premature pump failure and related pump piping pitfalls. And computer based approaches which are in some instances based on empirical data and more recently use finite element or finite. Positive displacement pumps are those in which energy is imparted to the liquid in a fixed displacement volume, such as a casing or a cylinder, by the rotary motion of gears, screws, or vanes, or by reciprocating pistons or plungers. Total head and flow are the main criteria that are used to compare one pump with another or to select a centrifugal pump for an application. Learn about the most common centrifugal pump designs. Keep suction piping as short as possible. Why can't we just use discharge pressure? Web pump sizing involves matching the flow and pressure rating of a pump with the flowrate and pressure required for the process. Web how to design a pump system. Web gain an understanding of the fundamental principles informing centrifugal pump design, application, and selection. Total head is related to the discharge pressure of the pump.

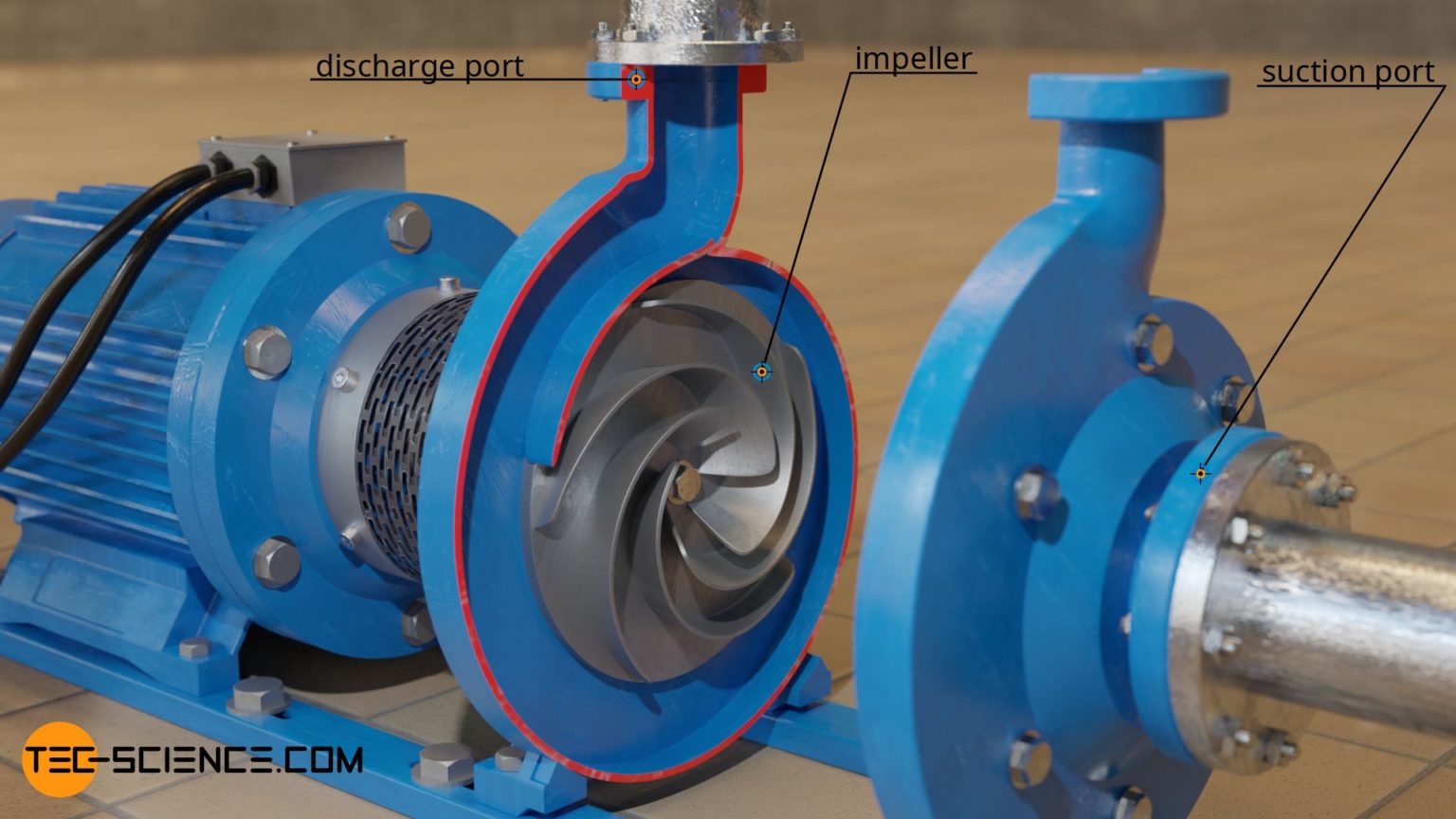

How does a centrifugal pump work? tecscience

How to design a Treated Water Transfer Pump

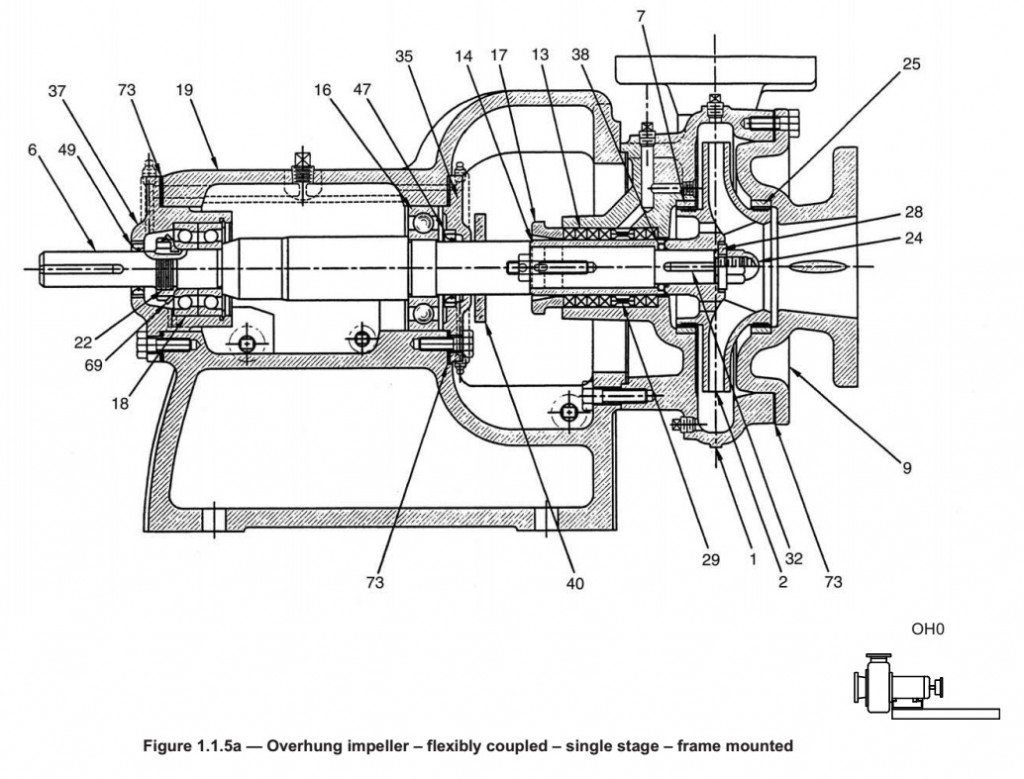

Centrifugal Pump Diagram With Parts

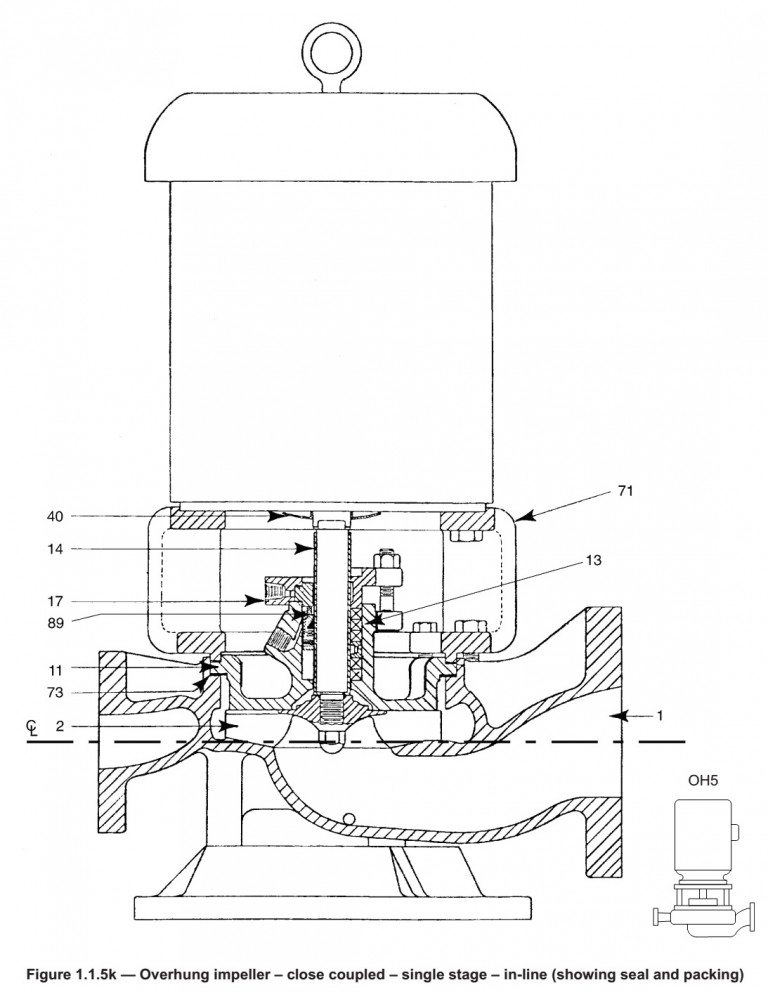

Common Centrifugal Pump Designs Intro to Pumps

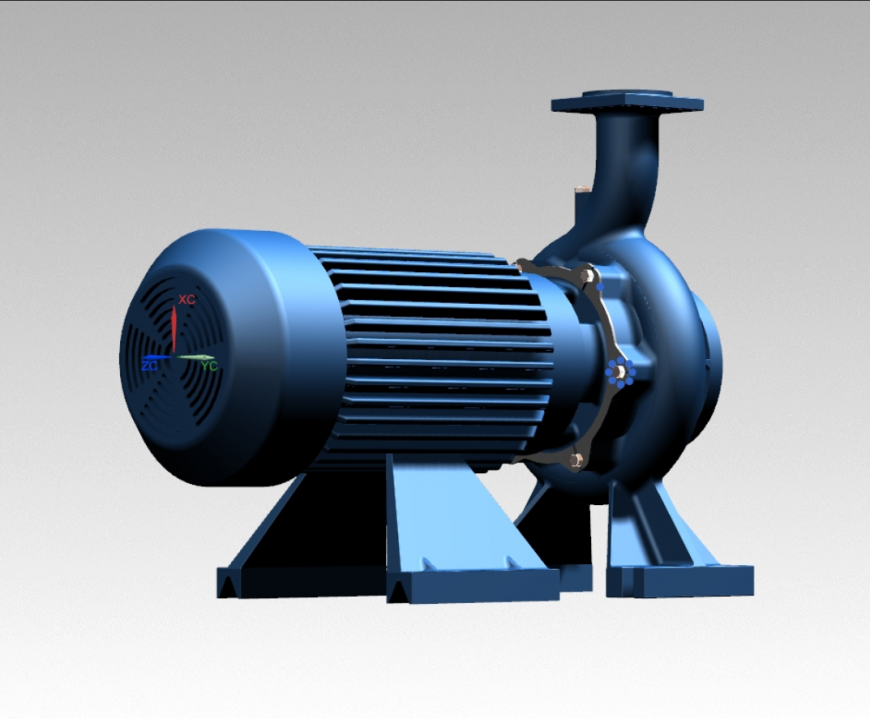

3d close coupled centrifugal water pumps design cad block details dwg

Pump Design Understanding its different part and design

Common Centrifugal Pump Designs Intro to Pumps

Centrifugal pumps Principles, Operation and Design WR Training

What Is A Centrifugal Pump? The Engineer's Perspective

Centrifugal pump design (a) geometry; (b) impeller blade profile

Before We Get To The Actual Liquid Being Pumped, Let’s Discuss Why Most Pumps Are Rated In Units Of Head (Feet Or Meters) Instead Of Pressure (Pounds Per Square Inch [Psi], Kilopascal [Kpa] Or Barg—A Unit Of Gauge Pressure).

Web This Series Of Articles Explains What A Pump Is, What The Main Parts Of A Pump Are, How To Pick The Right Pump Design For An Application, And Much More.

Small Changes From Existing Designs To Give A Slight Change In Head Or Flow Range;

Decipher The Meaning Of Pump Industry Vocabulary.

Related Post: