Pulley Size Chart

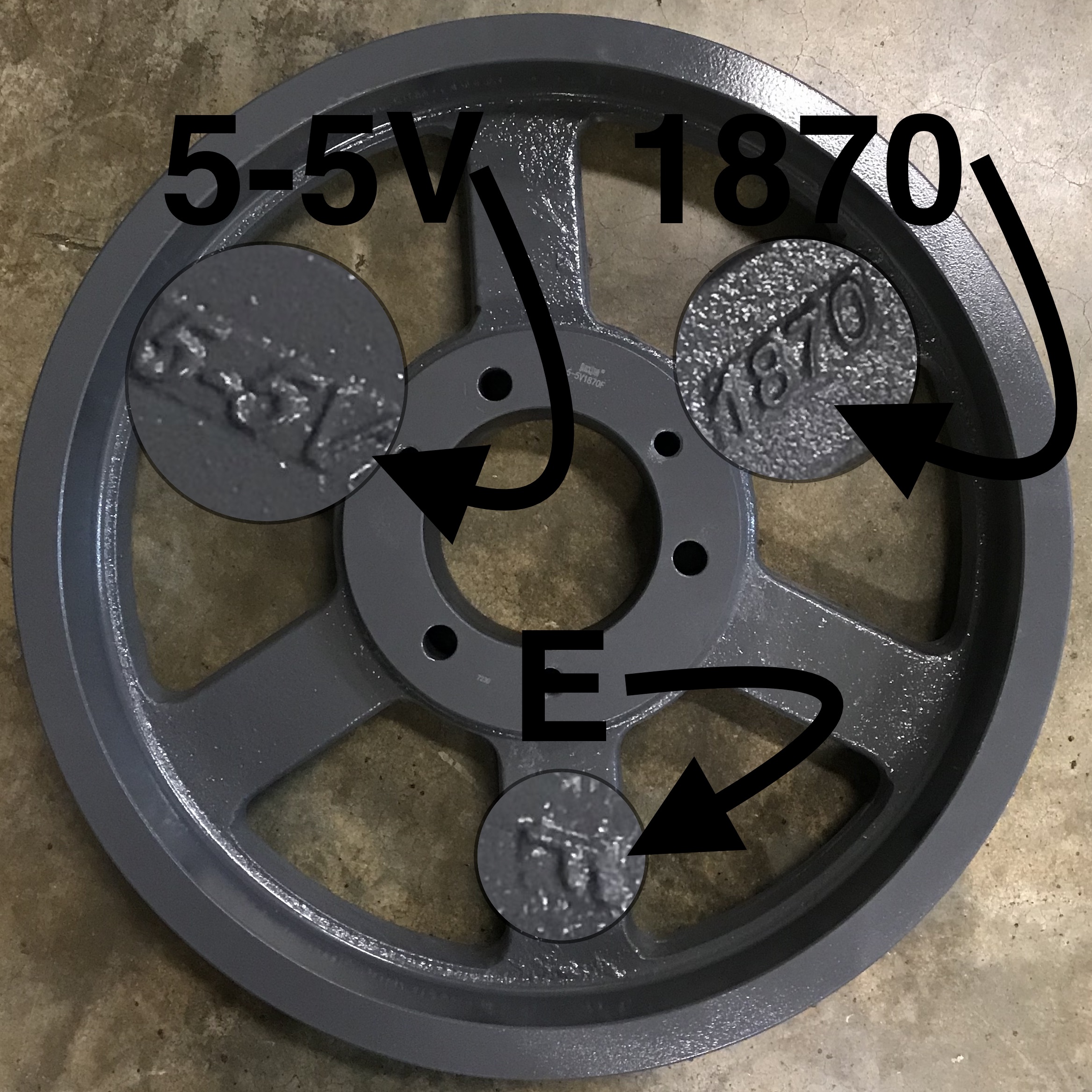

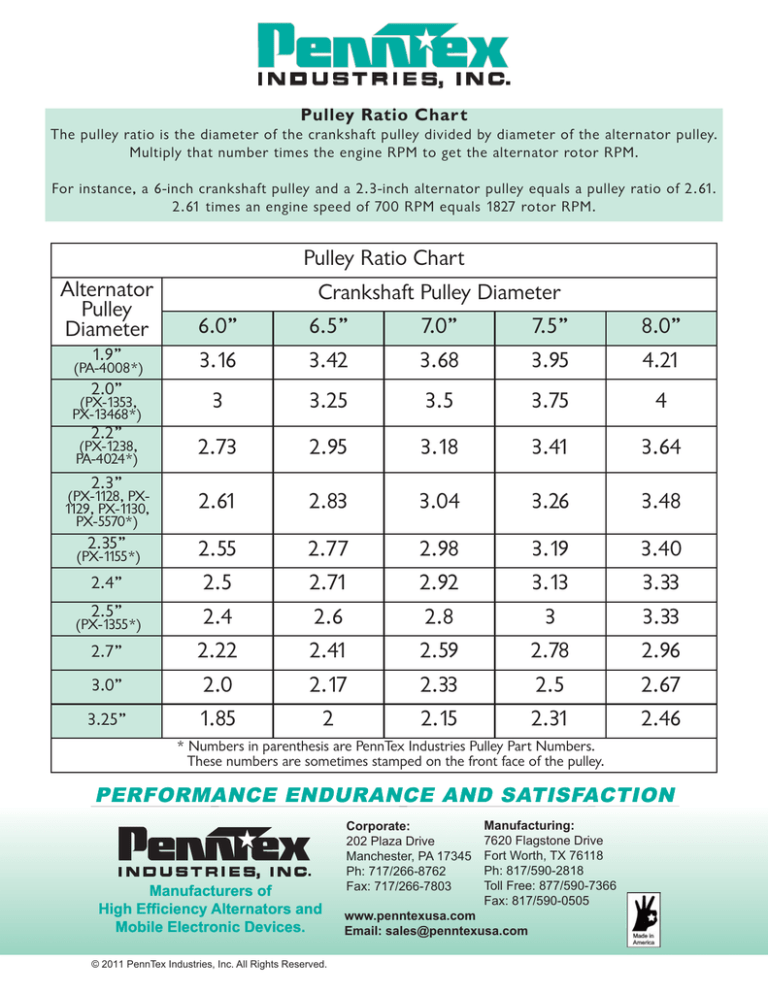

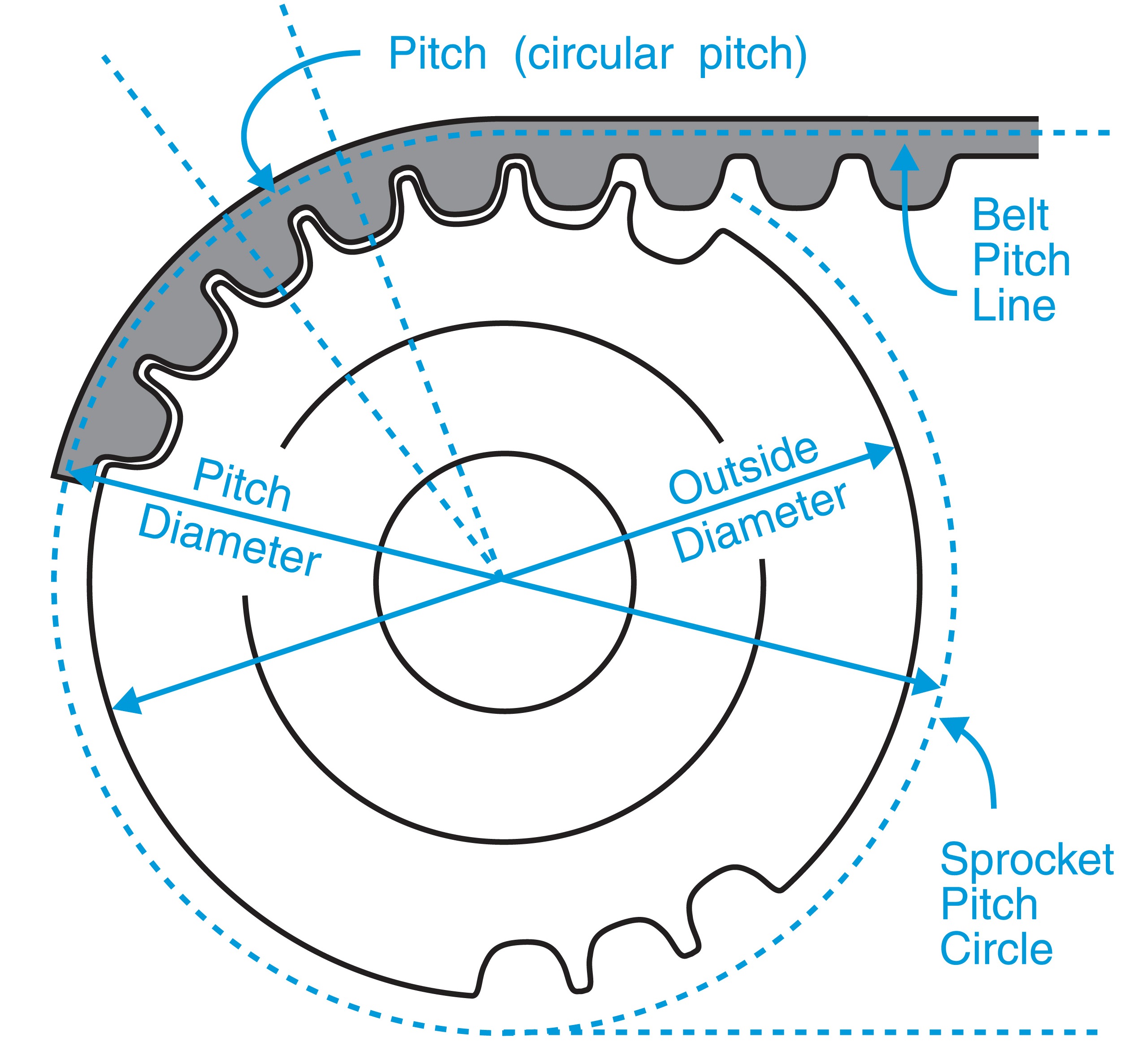

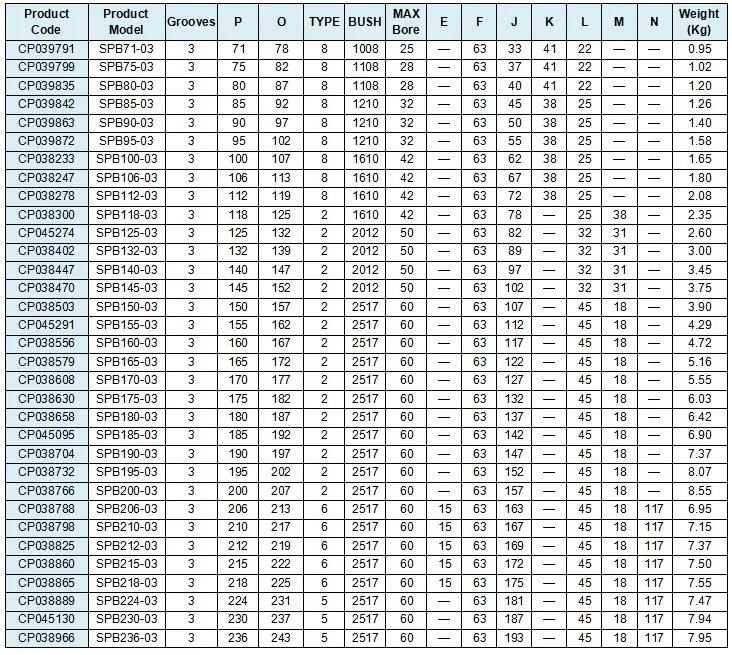

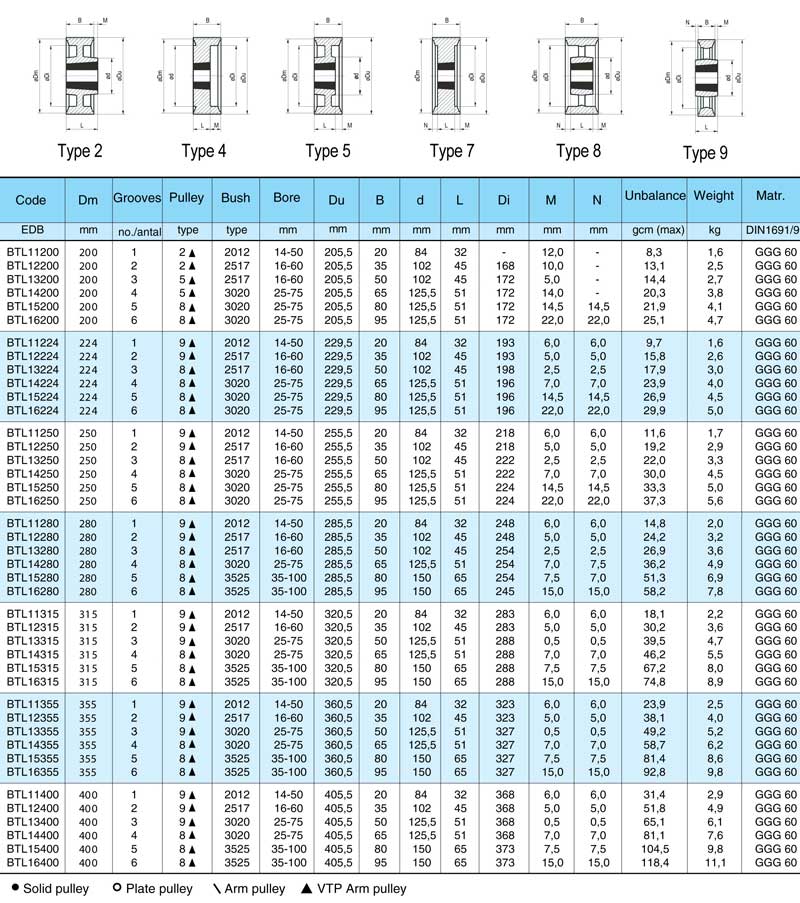

Pulley Size Chart - Designers need high quality components in order to maintain performance and contain operating costs. These pulleys are cast iron. Obtain the motor’s rpm specification to understand the input speed. For shafts of different sizes, it is used with different bores. Web calculation and selection process. Match your pulleys to your belts for extended service life. Heavier loads or materials with sharp edges may require larger pulley diameters. It is only a shaft of one particular size that is fitted. The weight and characteristics of the material being conveyed can affect the mpd. Web shiftbulk is a collaborative platform that simplifies the design and purchasing process for belt conveyor systems. For shafts of different sizes, it is used with different bores. Pulley diameter chart simplifies the process of selecting the appropriate pulley size. Click on the images below to enlarge. To find the rpm (n₂) of the driven pulley, measure its diameter (d₂) and apply the values alongside the driving pulley’s rpm (n₁) in the formula. Heavier loads or materials. Heavier loads or materials with sharp edges may require larger pulley diameters. With a comprehensive database of conveyor components, users can create custom systems and optimize costs and suppliers. Choose from nylon, uhmw, and zinc. Obtain the motor’s rpm specification to understand the input speed. It is slotted from one side which is tightened with a nut and bolt after. Heavier loads or materials with sharp edges may require larger pulley diameters. Measuring a v belt or flat pulley is easy. It is slotted from one side which is tightened with a nut and bolt after fitting the shaft. V and flat belt design and engineering data. Measure the diameter (d₁) of the driving pulley. To calculate the rpm, enter the motor rpm, pulley 1 diameter, and pulley 2 diameter, and click calculate. Outside diameter, or the distance across the pulley when measured between groove edges. Web shiftbulk is a collaborative platform that simplifies the design and purchasing process for belt conveyor systems. Click on the images below to enlarge. Web this is a list. To calculate the rpm, enter the motor rpm, pulley 1 diameter, and pulley 2 diameter, and click calculate. Terre products measuring guide explains pulley specs and dimensions. Outside diameter, or the distance across the pulley when measured between groove edges. Motor and equipment speed for pulleys with different diameters are indicated in the charts below: It is slotted from one. To find the rpm (n₂) of the driven pulley, measure its diameter (d₂) and apply the values alongside the driving pulley’s rpm (n₁) in the formula. Terre products measuring guide explains pulley specs and dimensions. Using the minimum pulley diameter chart: 8c 8 9 1 % 0 % % b 4 & belt series pitch diameter range groove angle dimensions. Heavier loads or materials with sharp edges may require larger pulley diameters. D1 n1= d2n2 (1) where. Web shiftbulk is a collaborative platform that simplifies the design and purchasing process for belt conveyor systems. To calculate the rpm of the machine, provide the dimensions in millimeters. Pulley diameter chart simplifies the process of selecting the appropriate pulley size. D1 n1= d2n2 (1) where. Web calculation and selection process. Using the minimum pulley diameter chart: Web this is a list of useful definitions for use with drives pulleys, idler pulleys, and other mechanical motion parts. Outside diameter, or the distance across the pulley when measured between groove edges. Designers need high quality components in order to maintain performance and contain operating costs. With a comprehensive database of conveyor components, users can create custom systems and optimize costs and suppliers. To calculate the rpm, enter the motor rpm, pulley 1 diameter, and pulley 2 diameter, and click calculate. 8c 8 9 1 % 0 % % b 4 &. To calculate the rpm, enter the motor rpm, pulley 1 diameter, and pulley 2 diameter, and click calculate. Web shiftbulk is a collaborative platform that simplifies the design and purchasing process for belt conveyor systems. 8c 8 9 1 % 0 % % b 4 & belt series pitch diameter range groove angle dimensions a w wb d x s. Pulley diameter chart simplifies the process of selecting the appropriate pulley size. Calculate the required speed ratio between the motor and driven equipment based on the application’s needs. Consider belt type and width: With a comprehensive database of conveyor components, users can create custom systems and optimize costs and suppliers. Measuring a v belt or flat pulley is easy. Outside diameter, or the distance across the pulley when measured between groove edges. Web the following timing belt pulley pitch diameter (p.d.) and timing belt pulley outside diameter (o.d.) charts allow the end user to quickly determine the dimensional requirements for a timing belt drive system. These pulleys are cast iron. Measure the diameter (d₁) of the driving pulley. Web this is a list of useful definitions for use with drives pulleys, idler pulleys, and other mechanical motion parts. To calculate the rpm of the machine, provide the dimensions in millimeters. Cost efficiency is critical in engineering, including power transmission projects. Terre products measuring guide explains pulley specs and dimensions. Web determine which pulley acts as the driver (higher rpm) and which is driven (lower rpm). Belt profile, or the style and sizes of the belt being integrated. Web shiftbulk is a collaborative platform that simplifies the design and purchasing process for belt conveyor systems.

How To Measure a VBelt Pulley & Identify Its Size & Part Number

Pulley Ratio Chart PennTex Industries, Inc.

Timing Belt Pulley Diameter Charts Pfeifer Industries

V Belt Pulley Size Chart

LSA Supercharger Pulley Chart

V Belt Pulley Size Chart

V Belt Pulley Sheave Sizes Table Chart, 58 OFF

Vbelt Pulley Size Chart

Metal Fabrication, Bearings, V Belt, Pulley and Ventilated Turbo Pulley

Gates Idler Pulley Size Chart

To Calculate The Rpm, Enter The Motor Rpm, Pulley 1 Diameter, And Pulley 2 Diameter, And Click Calculate.

It Is Only A Shaft Of One Particular Size That Is Fitted.

The Hub Is A Central Part Of A Pulley, Which Has A Bore For The Shaft.

V And Flat Belt Design And Engineering Data.

Related Post: