Pre Engineered Metal Building Foundation Design Example

Pre Engineered Metal Building Foundation Design Example - Web foundations for preengineered buildings typically consist of footings, piers, and grade beams along with a slab on grade. Therefore, you must engage the services of a licensed structural / foundation engineer who is experienced in their design. Foundation design in accordance with 2006 international building code using the reactions provided by the metal building manufacturer for the following design criteria. Among them are tie rods, which can extinguish the opposing lateral reactions, hairpins, which try to incorporate the slab on grade into the lateral force transfer, and many other systems, such as slabs with edge haunches. For nearly 120 years, the name butler manufacturing ™ has been synonymous with innovation. Whether your florida steel building project involves a hipped roof, parapet, leanto or inset bay, there is no challenge our estimators can not tackle. Basically read it cover to cover. So, we’re going over what you need to know and how to get started. Each and every part of your pemb is designed, fabricated, and engineered with precision. In designing hairpins, he takes the approach of hairpin length based on how many bars or wwf bars to lap. Web design information and loads a. Web foundations for preengineered buildings typically consist of footings, piers, and grade beams along with a slab on grade. A concrete slab foundation is the most popular choice for metal buildings. Web pemb hairpin design approach. Quality framing translates to quality foundations. I’ve gone thru and read “foundation and anchor design guide for metal building systems” by alexander newman. Learn about building size & height, site planning & selection, orientation, and more. Things like installing hairpins and ties but these only help with the lateral forces at the base of the column and do nothing to reduce uplift. The footings and wall. The footings and wall piers are cenetered under the columns, and the grade beam is set up to carry the bottom of the metal stud wall. A concrete slab foundation is the most popular choice for metal buildings. Whether your florida steel building project involves a hipped roof, parapet, leanto or inset bay, there is no challenge our estimators can. Each and every part of your pemb is designed, fabricated, and engineered with precision. Learn about building size & height, site planning & selection, orientation, and more. In designing hairpins, he takes the approach of hairpin length based on how many bars or wwf bars to lap. Among them are tie rods, which can extinguish the opposing lateral reactions, hairpins,. Web foundations for preengineered buildings typically consist of footings, piers, and grade beams along with a slab on grade. Learn everything you need to know before the construction project today. Let’s dive in and take a closer look. Web pemb hairpin design approach. The footings and wall piers are cenetered under the columns, and the grade beam is set up. Among them are tie rods, which can extinguish the opposing lateral reactions, hairpins, which try to incorporate the slab on grade into the lateral force transfer, and many other systems, such as slabs with edge haunches. Things like installing hairpins and ties but these only help with the lateral forces at the base of the column and do nothing to. For nearly 120 years, the name butler manufacturing ™ has been synonymous with innovation. Web explore foundation design challenges and solutions for metal buildings, including types, issues, and expert advice for stability and strength Quality framing translates to quality foundations. Web foundations for preengineered buildings typically consist of footings, piers, and grade beams along with a slab on grade. Basically. For nearly 120 years, the name butler manufacturing ™ has been synonymous with innovation. I’ve gone thru and read “foundation and anchor design guide for metal building systems” by alexander newman. Quality framing translates to quality foundations. Web if you want your pemb to last and give you the best return on your investment, here are seven quality tips for. Basically read it cover to cover. Web if you want your pemb to last and give you the best return on your investment, here are seven quality tips for metal building foundations that you can use: Each and every part of your pemb is designed, fabricated, and engineered with precision. Things like installing hairpins and ties but these only help. Foundation design in accordance with 2006 international building code using the reactions provided by the metal building manufacturer for the following design criteria. So, we’re going over what you need to know and how to get started. I’ve gone thru and read “foundation and anchor design guide for metal building systems” by alexander newman. Among them are tie rods, which. Learn about building size & height, site planning & selection, orientation, and more. I’ve gone thru and read “foundation and anchor design guide for metal building systems” by alexander newman. Please reference any useful resources or design examples. Therefore, you must engage the services of a licensed structural / foundation engineer who is experienced in their design. Web explore foundation design challenges and solutions for metal buildings, including types, issues, and expert advice for stability and strength In designing hairpins, he takes the approach of hairpin length based on how many bars or wwf bars to lap. Foundation design in accordance with 2006 international building code using the reactions provided by the metal building manufacturer for the following design criteria. Basically, a concrete slab for metal buildings creates a floor for the structure while supporting the steel framing. Things like installing hairpins and ties but these only help with the lateral forces at the base of the column and do nothing to reduce uplift. Web has anyone done foundation design for pre engineering metal buildings? Web pemb hairpin design approach. Web there are some things you can do to reduce the size of your metal building foundations. Let’s dive in and take a closer look. A concrete slab foundation is the most popular choice for metal buildings. Web foundations for preengineered buildings typically consist of footings, piers, and grade beams along with a slab on grade. So, we’re going over what you need to know and how to get started.

to Providing metal building foundation

Steel Building Foundation Systems Metal Pro Buildings

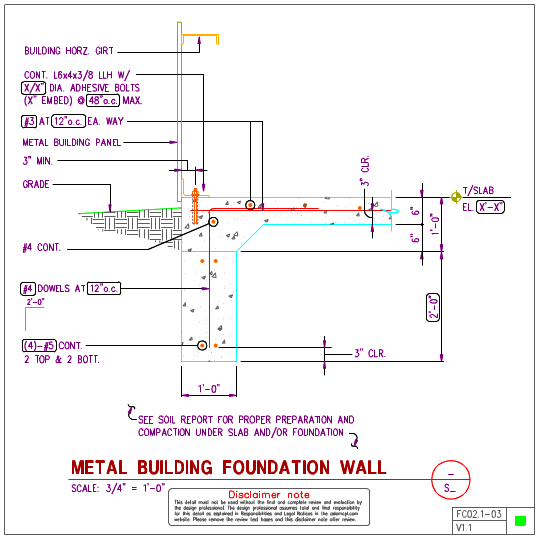

FC02.1 Metal Building Foundation Details AxiomCpl Central

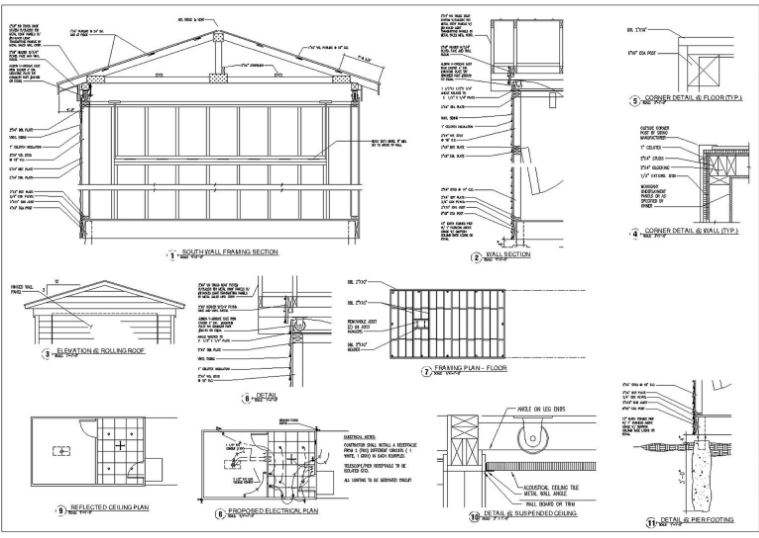

Detailed civil preengineered steel building drawings

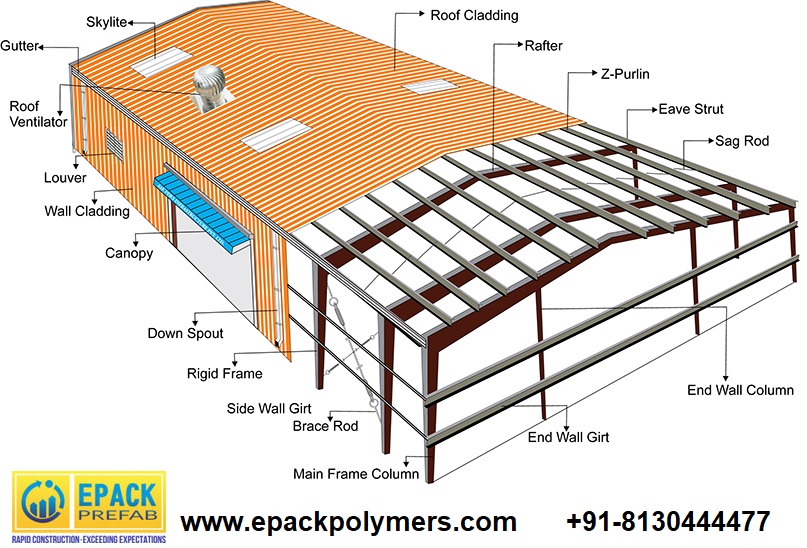

PreEngineered Steel Building Components and Advantages

Using PreEngineered Metal Buildings in Commercial Construction

R & M Steel Metal Building Foundation Design Example

Steel Building Foundation Systems Metal Pro Buildings

The Basics of Foundation Design in Preengineered Buildings EPACK

PreEngineered Metal Building with baseplates below finished floor

Web If You Want Your Pemb To Last And Give You The Best Return On Your Investment, Here Are Seven Quality Tips For Metal Building Foundations That You Can Use:

For Nearly 120 Years, The Name Butler Manufacturing ™ Has Been Synonymous With Innovation.

Among Them Are Tie Rods, Which Can Extinguish The Opposing Lateral Reactions, Hairpins, Which Try To Incorporate The Slab On Grade Into The Lateral Force Transfer, And Many Other Systems, Such As Slabs With Edge Haunches.

The Footings And Wall Piers Are Cenetered Under The Columns, And The Grade Beam Is Set Up To Carry The Bottom Of The Metal Stud Wall.

Related Post: