Polyester Resin Mix Ratio Chart

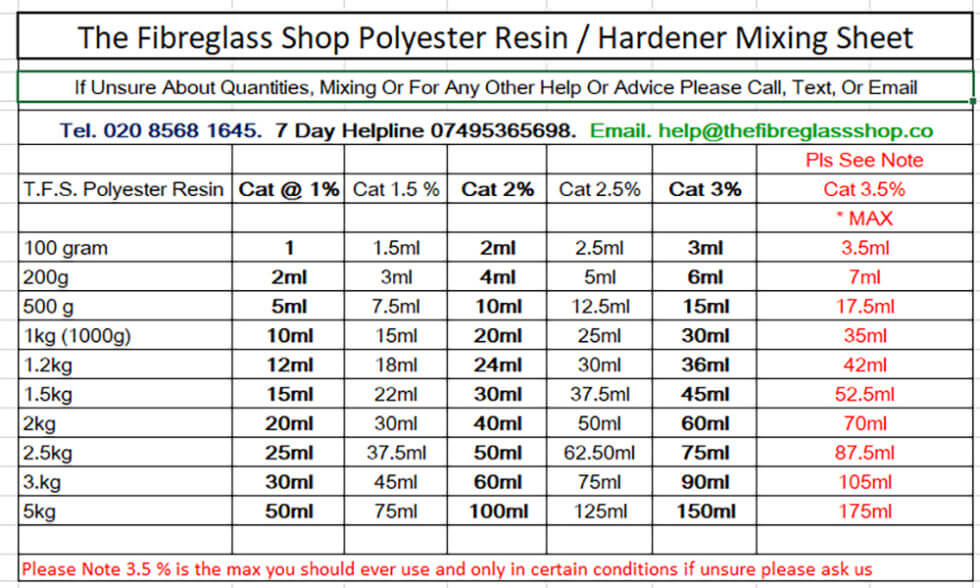

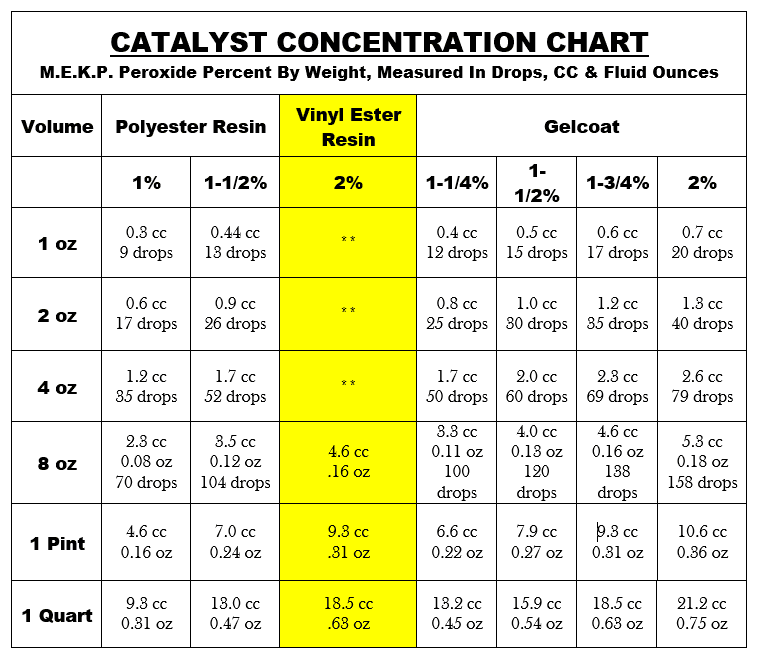

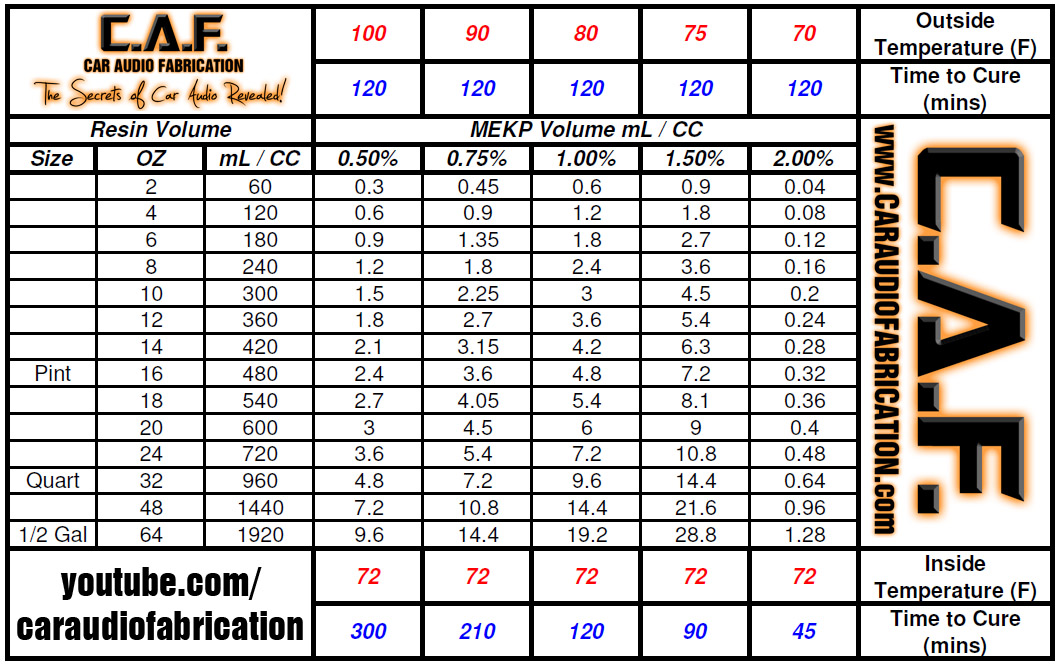

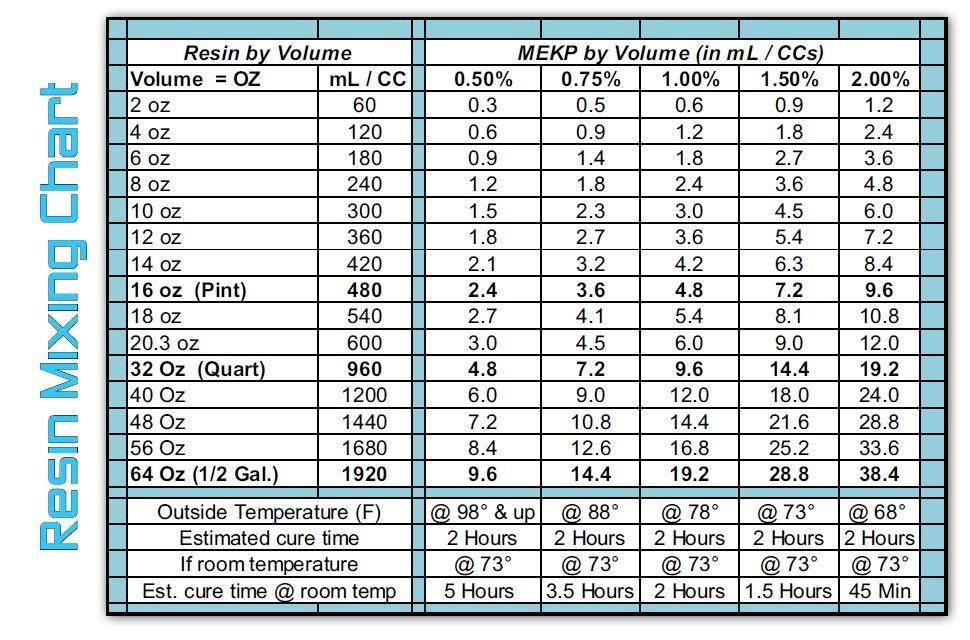

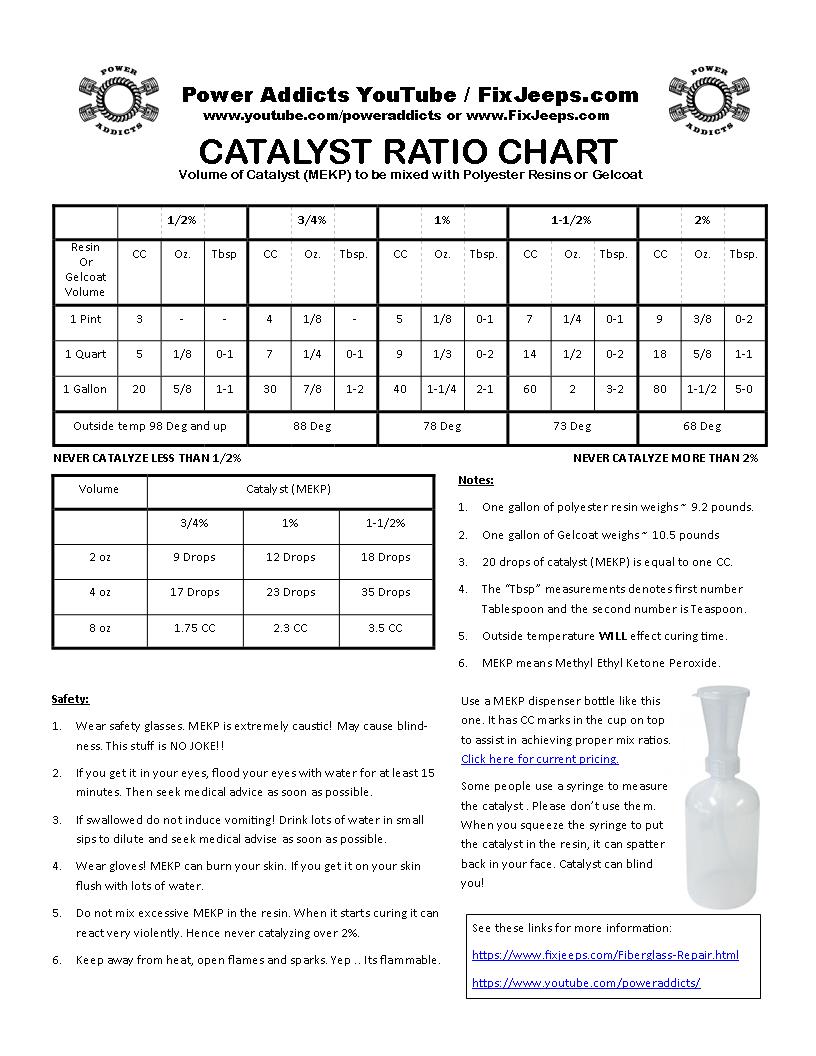

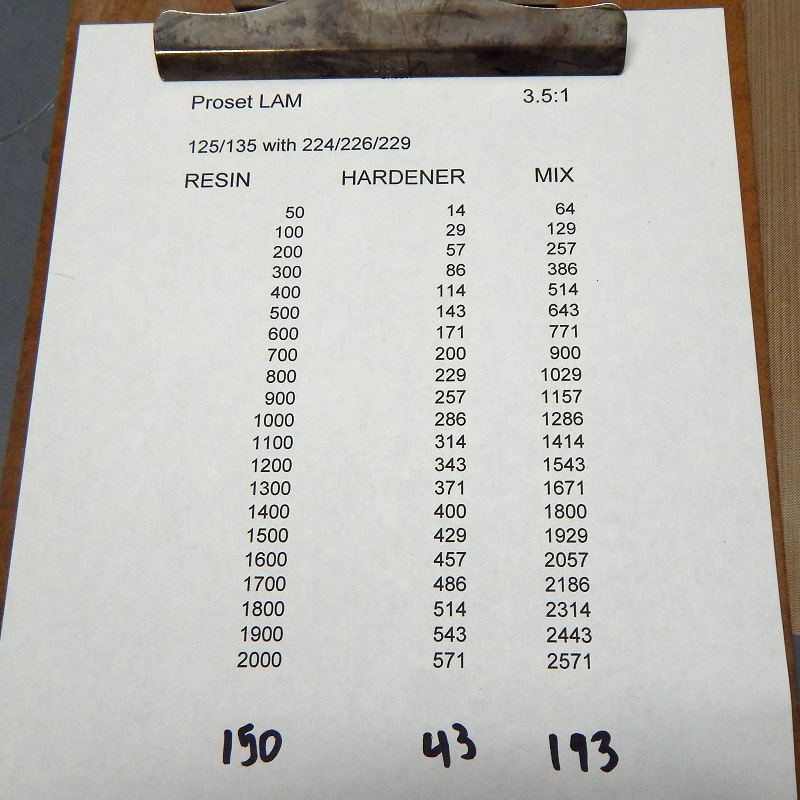

Polyester Resin Mix Ratio Chart - Once mixed, these two parts make a chemical reaction so. So, you have 10.8 kg of fibreglass matting, 10.8 x 2 = 21.6 kg of resin minimum, say 25kg of resin to be safe. Web the best way to catalyze is to measure and use from 1 to 2%. Methyl ethyl ketone peroxide (mekp) is an organic peroxide used in the marine. The ratio range for catalyst to resin is 1 to 2 percent hardener to the total volume of resin to be used. Web generally speaking, for polyester resins, the mixing ratio is 2% i.e. Get some small calibrated containers for resin and then even smaller ones, or a marked eye dropper for catalyst. Web in this video we explain how to add catalyst to polyester resin for fiberglass repair or building new parts. Web mek, short for mekp, is the “hardener” or catalyst for polyester resin and vinylester resin systems including isothalic and gelcoat. Below are two free mekp calculators and a mekp chart to simplify the process of determining the proper ratio of resin to. Web polyester resin is an excellent matrix material in the creation of fibreglass (grp) in the presence of a catalyst and combined with glass fibre chopped strand matting (csm). Add wax solution to make hotcoat resin. Methyl ethyl ketone peroxide (mekp) is an organic peroxide used in the marine. For the water clear casting polyester. Once mixed, these two parts. Web polyester resin is an excellent matrix material in the creation of fibreglass (grp) in the presence of a catalyst and combined with glass fibre chopped strand matting (csm). For the water clear casting polyester. The ratio range for catalyst to resin is 1 to 2 percent hardener to the total volume of resin to be used. Web mek, short. The ratio range for catalyst to resin is 1 to 2 percent hardener to the total volume of resin to be used. Web the resin to hardener mixing ratio will be so much of part a, (the resin) mixed with so much of part b (the hardener). Web totalboat resin mix ratios, application temperatures, pot life, working times and cure. Depending on the amount of resin needed, pour the appropriate ratios of. The ratio is approximately one ounce of hardener per. Methyl ethyl ketone peroxide (mekp) is an organic peroxide used in the marine. Add this amount of catalyst to cure resin. Our ratio calculator will determine the. For the water clear casting polyester. One gallon of gelcoat weighs approximately 10.5 lbs. Web polyester resin/gelcoat is catalyzed with mekp (methyl ethyl ketone peroxide). Catalyst chart for polyester resin, gel coat and vinyl ester marine resins. Below are two free mekp calculators and a. Once mixed, these two parts make a chemical reaction so. Depending on the amount of resin needed, pour the appropriate ratios of. For example, four drops of hardener will be 1 percent of 1 ounce of. One gallon of gelcoat weighs approximately 10.5 lbs. The tables below display data for totalboat epoxy products and other resins. Depending on the amount of resin needed, pour the appropriate ratios of. Web the resin to hardener mixing ratio will be so much of part a, (the resin) mixed with so much of part b (the hardener). Web one gallon of polyester resin weighs approximately 9.2 lbs. Web mek, short for mekp, is the “hardener” or catalyst for polyester resin. Our ratio calculator will determine the. One gallon of gelcoat weighs approximately 10.5 lbs. Web totalboat resin mix ratios, application temperatures, pot life, working times and cure times. Web in this video we explain how to add catalyst to polyester resin for fiberglass repair or building new parts. The ratio range for catalyst to resin is 1 to 2 percent. Add this amount of catalyst to cure resin. 20ml for every 1kg of resin in working conditions at room temperature. The weight of mekp 925 is 1.125 grams per cc. Web trojan fibreglass uses two methods for mixing ratios, all polyester and vinylester resins are measured by weight. Web our mix chart for polyester and vinylester resins. One gallon of gelcoat weighs approximately 10.5 lbs. Web in this video we explain how to add catalyst to polyester resin for fiberglass repair or building new parts. Our ratio calculator will determine the. Web polyester resin is an excellent matrix material in the creation of fibreglass (grp) in the presence of a catalyst and combined with glass fibre chopped. Web polyester resin is an excellent matrix material in the creation of fibreglass (grp) in the presence of a catalyst and combined with glass fibre chopped strand matting (csm). The ratio is approximately one ounce of hardener per. And epoxy resins are measured by volume. Web mek, short for mekp, is the “hardener” or catalyst for polyester resin and vinylester resin systems including isothalic and gelcoat. Web totalboat resin mix ratios, application temperatures, pot life, working times and cure times. One gallon of gelcoat weighs approximately 10.5 lbs. It should be added before the catalyst and is recommended to add at. Polyester resins are commonly used with fiberglass and. Add this amount of catalyst to cure resin. Below are two free mekp calculators and a mekp chart to simplify the process of determining the proper ratio of resin to. Web catalyst large quantity chart catalyst concentration resin quantity quart gallon 5 gallon 1/2% 1/16 oz 2/3 oz 3 1/3 oz 3/4% 1/4 oz 1 oz 5 oz 1% 1/3 oz 1 1/3 oz 6. 20ml for every 1kg of resin in working conditions at room temperature. Web generally speaking, for polyester resins, the mixing ratio is 2% i.e. Methyl ethyl ketone peroxide (mekp) is an organic peroxide used in the marine. Below are two free mekp calculators and a. Web mix the polyester resin with a catalyst named methyl ethyl ketone peroxide (mekp) to begin curing.

Polyester Resin Mixing Ratio Chart

How to Apply Gelcoat by Brush and Roller How to Articles Bottom

Polyester Resin Mixing Ratio Chart

Polyester Resin Mixing Ratio Chart

How To Mix Polyester Resin

Polyester Resin Mix Ratio Chart

Polyester Resin Mix Ratio Chart

Polyester Resin Mixing Ratio Chart

Polyester Resin Mix Ratio Chart

General Purpose Polyester Fiberglass Resin Kit FGCI

Web Mek, Short For Mekp, Is The “Hardener” Or Catalyst For Polyester Resin And Vinylester Resin Systems Including Isothalic And Gelcoat.

Depending On The Amount Of Resin Needed, Pour The Appropriate Ratios Of.

The Weight Of Mekp 925 Is 1.125 Grams Per Cc.

Web Catalyst & Wax Solution.

Related Post: