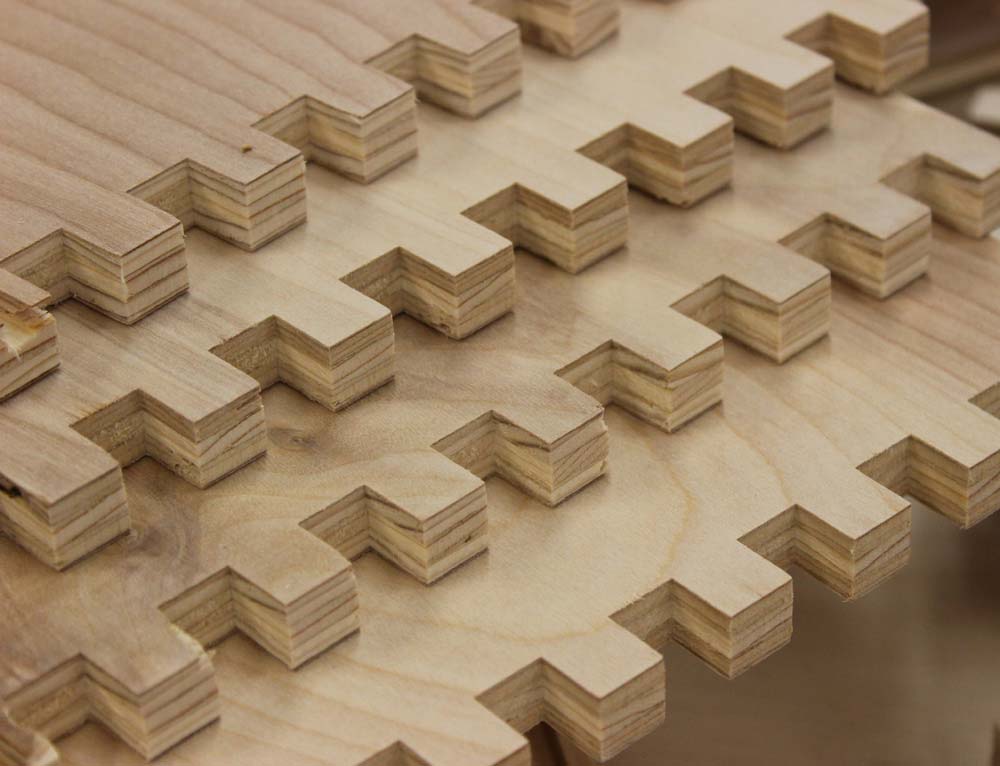

Plywood Drawer Joints

Plywood Drawer Joints - Web assembly of drawer boxes with either dovetail joints or finger joints is essentially the same as for a simple drawer box. These three joinery methods maximize the strength of plywood joints. Web there are lots of different ways to make drawers, but in this instructables article i will be showing you how i made drawers using box joints. Measure and cut the side pieces. Web some are stronger, some are more aesthetically pleasing, some are complex, and some are simply basic but all that's needed to get the job done. But those plies also weaken butt joints in project construction. I used a router table in the past but find the table saw to be much faster. Learn to create box joints ,. The drawers are made from 18mm baltic birch assembled with box. If you are using 1⁄2 plywood for drawer sides instead of solid wood, use only high. The plywood will be edged with real wood to hide the fact that it's ply. Measure and cut the side pieces. Learn to create box joints ,. This method makes a really nice. Simply provide the details of which type of. One of the reasons i like box joints is. Web if you’re ready to order plywood drawer for your bathroom or kitchen cabinetry project it is simple and fast to order with dc drawers. Web i'm using 3/4 plywood for drawers in a project and 1/2 plywood for some smaller drawers. Since showing endgrain is generally avoided whenever. Simply provide. These three joinery methods maximize the strength of plywood joints. Measure and cut the side pieces. Mock assemble the box and drill at least three pilot holes at each joint. But those plies also weaken butt joints in project construction. Simply provide the details of which type of. Web assembly of drawer boxes with either dovetail joints or finger joints is essentially the same as for a simple drawer box. One of the reasons i like box joints is. Wide variety of supplies1 year labor warrantyhuge selectionlowest price guarantee Web there are lots of different ways to make drawers, but in this instructables article i will be showing. I used a router table in the past but find the table saw to be much faster. Web i've used a dado/rabbit type joint on numerous plywood drawer boxes with good results. The drawers are made from 18mm baltic birch assembled with box. Use a square to align the pieces at a 90 degree angle, then screw the sides to. Web if you’re ready to order plywood drawer for your bathroom or kitchen cabinetry project it is simple and fast to order with dc drawers. Mock assemble the box and drill at least three pilot holes at each joint. Since showing endgrain is generally avoided whenever. Learn to create box joints ,. The plywood will be edged with real wood. Mock assemble the box and drill at least three pilot holes at each joint. The strongest way to attach drawer sides to the front and back to the sides relies on dovetail joints. Web apply wood glue where the boards will be joined together. Simply provide the details of which type of. Web some are stronger, some are more aesthetically. Web some are stronger, some are more aesthetically pleasing, some are complex, and some are simply basic but all that's needed to get the job done. I used a router table in the past but find the table saw to be much faster. Web i'm using 3/4 plywood for drawers in a project and 1/2 plywood for some smaller drawers.. Plywood's multiple layers (or plies) make it more economical and resistant to seasonal movement than solid wood, especially for large panels. I used a router table in the past but find the table saw to be much faster. Web if you’re ready to order plywood drawer for your bathroom or kitchen cabinetry project it is simple and fast to order. The plywood will be edged with real wood to hide the fact that it's ply. Wide variety of supplies1 year labor warrantyhuge selectionlowest price guarantee Plywood's multiple layers (or plies) make it more economical and resistant to seasonal movement than solid wood, especially for large panels. Mock assemble the box and drill at least three pilot holes at each joint.. Read ahead to learn the many. Web some are stronger, some are more aesthetically pleasing, some are complex, and some are simply basic but all that's needed to get the job done. Web there are lots of different ways to make drawers, but in this instructables article i will be showing you how i made drawers using box joints. Web i've used a dado/rabbit type joint on numerous plywood drawer boxes with good results. One of the reasons i like box joints is. Since showing endgrain is generally avoided whenever. If you are using 1⁄2 plywood for drawer sides instead of solid wood, use only high. I used a router table in the past but find the table saw to be much faster. Web assembly of drawer boxes with either dovetail joints or finger joints is essentially the same as for a simple drawer box. Measure and cut the side pieces. But those plies also weaken butt joints in project construction. The drawers are made from 18mm baltic birch assembled with box. Web make sure your drawer sides and fronts are milled to uniform thicknesses before you begin. Learn to create box joints ,. Wide variety of supplies1 year labor warrantyhuge selectionlowest price guarantee Plywood's multiple layers (or plies) make it more economical and resistant to seasonal movement than solid wood, especially for large panels.

Box Joint Drawers Made Out of Plywood The Down To Earth Woodworker

Locking Rabbet Joints Woodworking Project Woodsmith Plans

Box Joint Drawers Made Out of Plywood The Down To Earth Woodworker

Making Drawers Using Plywood ⋆ 🌲

Plywood Drawer Joint General Woodworking The Patriot Woodworker

joinery Easy drawer joints for plywood Woodworking Stack Exchange

Plywood Drawer Joint Page 2 General Woodworking The Patriot

Plywood Drawer Joint General Woodworking The Patriot Woodworker

Plywood Drawer Joint General Woodworking The Patriot Woodworker

Plywood Drawer Joint General Woodworking The Patriot Woodworker

The Strongest Way To Attach Drawer Sides To The Front And Back To The Sides Relies On Dovetail Joints.

Use A Square To Align The Pieces At A 90 Degree Angle, Then Screw The Sides To The Front And Back With 1 ¼ Wood.

The One Difference You’ll Find Is That It Takes Longer To Apply.

This Method Makes A Really Nice.

Related Post: