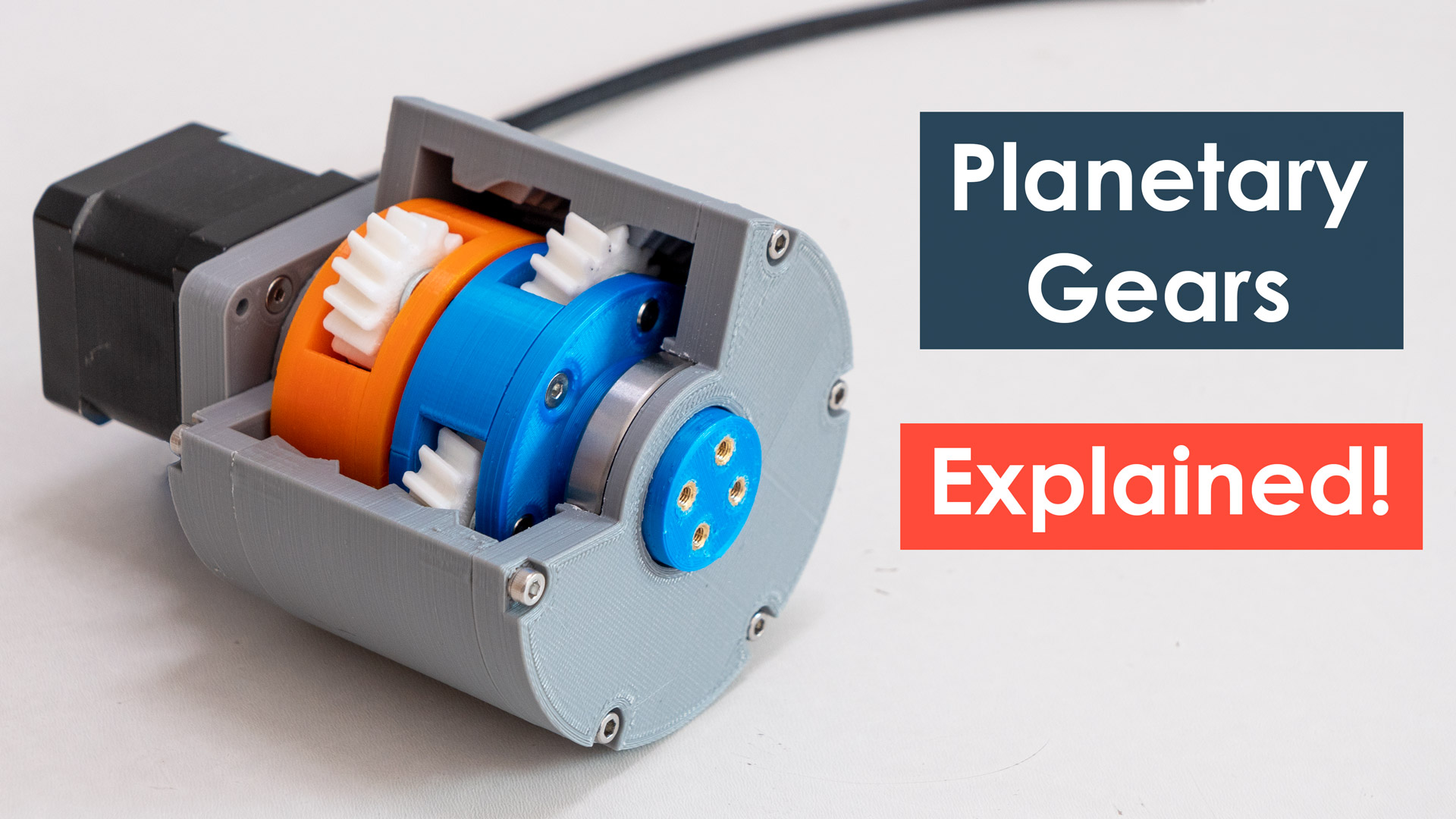

Planetary Gearbox Design

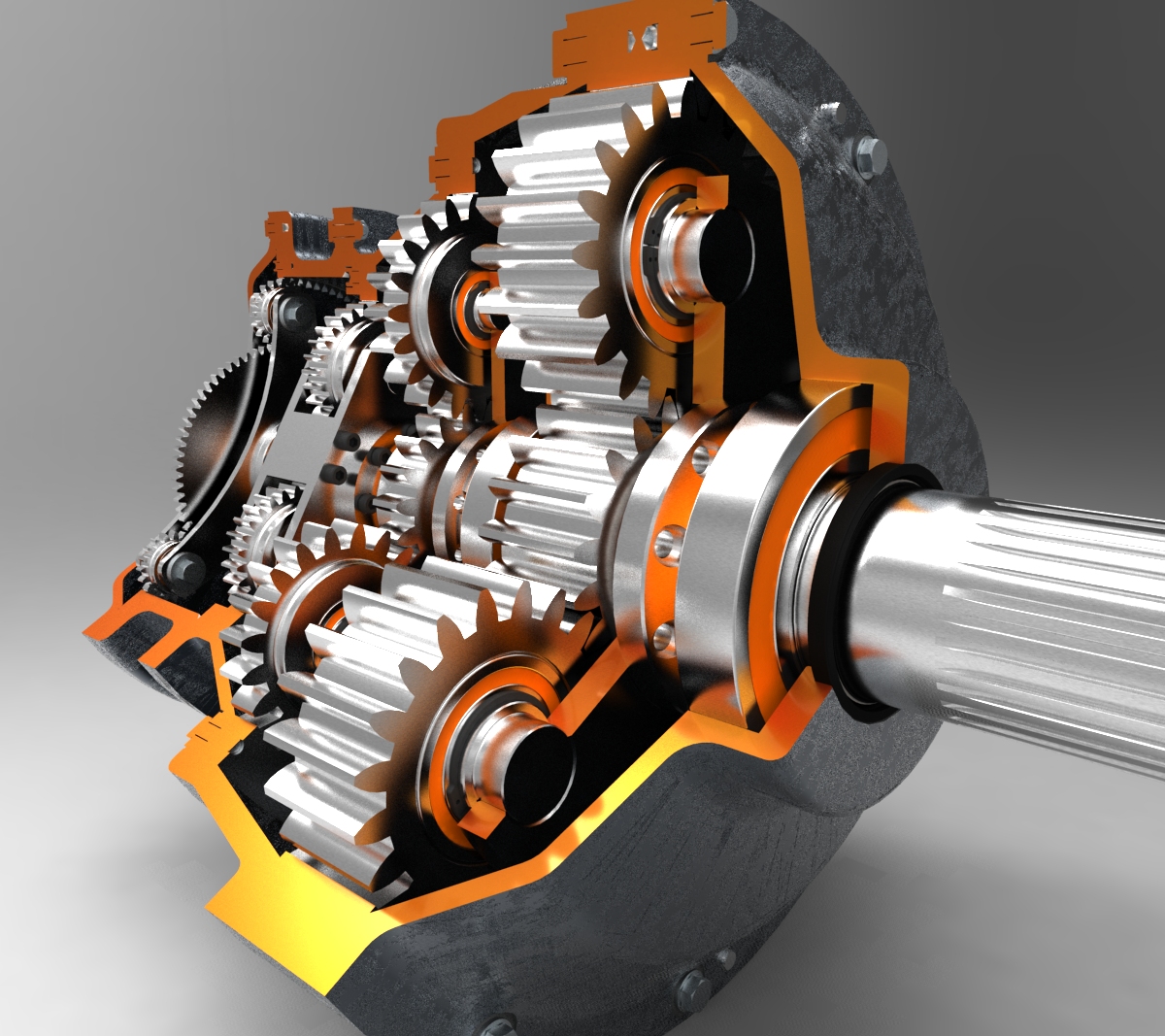

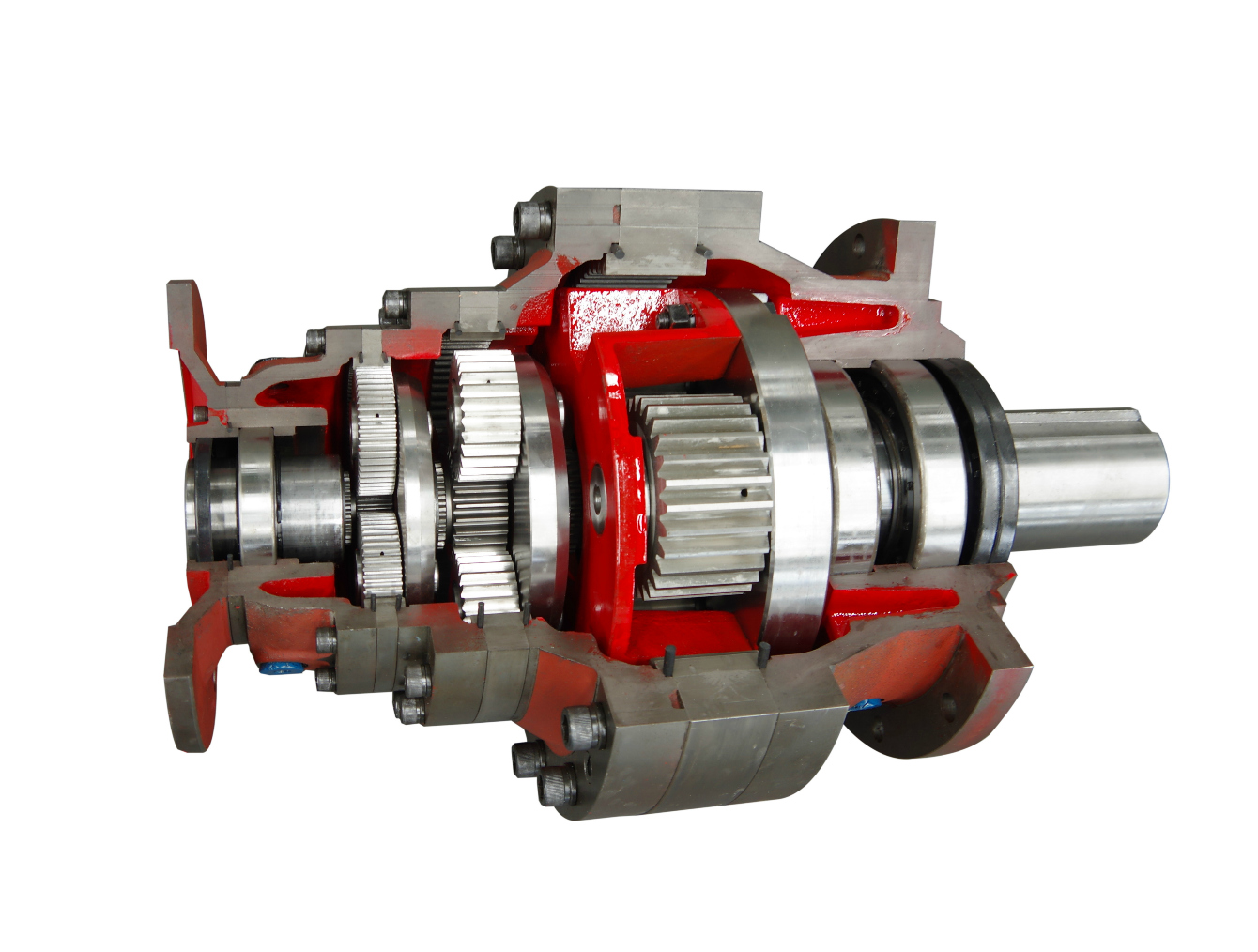

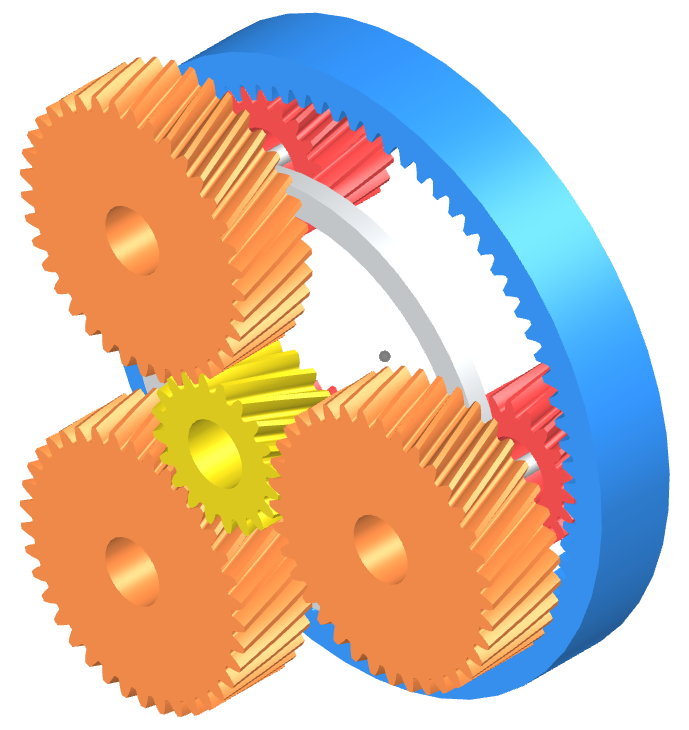

Planetary Gearbox Design - In this setup, a central gear, known as the sun gear, acts as the input and drives the system. A carrier connects the centers of the two gears and rotates, to carry the planet gear(s) around the sun gear. Web basic planetary gearing consists of three sets of gears, each with different degrees of freedom. Web we also specialize in repairing crane wheels, pumps, rolls, screws and barrels, cutting equipments, gearboxes and gears. The design process starts with understanding the basic components of a planetary gearbox: The basics of planetary gearbox design. It consists of spur gears arranged in an epicyclic configuration. In this instructable, i'm going to show you how to design your first planetary gearbox in fusion 360, and at the end, i'm going to 3d print it to see how it works. As the sun gear is driven, the planetary gears rotate the ring gear (also known as outer gear). Web this guide will take you through the steps of designing a planetary gearbox and highlight the benefits of using one. Planetaries with a single sun, ring, and set of planets like shown in the image below. A carrier connects the centers of the two gears and rotates, to carry the planet gear(s) around the sun gear. Web in a planetary gearbox, the sun gear drives the surrounding planetary gears which are fixed to a carrier in order to avoid slipping. It consists of spur gears arranged in an epicyclic configuration. Planetary gear system is use in varies applications such as, clocks, lunar calendar, car mirror, toys,. Some clearance is needed for a planetary gearhead to work effectively. Web this paper presents planetary gear transmissions, designed according to iso 6336 (ref. There are several different methods that can be used to. They come in an array of varieties: Working examples are provided for spur and helical planetary geartrains. Web we also specialize in repairing crane wheels, pumps, rolls, screws and barrels, cutting equipments, gearboxes and gears. The design process starts with understanding the basic components of a planetary gearbox: At the same time, expectations for gear reliability are high. In this setup, a central gear, known as the sun gear, acts as the input and drives the system. In this video, corey explains what planetary gear systems are, how to calculate speeds and their widespread use in transmissions. Web how to design planetary gear systems for beginners. Web basic planetary gearing consists of three sets of gears, each with. Suitable for ball screw, cnc spindles, rack, pinion, rollers, belts, laser equipment, printing machines, working tables, robots, conveyors and indexing systems. A carrier connects the centers of the two gears and rotates, to carry the planet gear(s) around the sun gear. Web this guide will take you through the steps of designing a planetary gearbox and highlight the benefits of. They come in an array of varieties: We are homebodies with a passion for reviving historic spaces. The sun gear is located at the center, and transmits torque to the planet gears that. Ring gear, planet gear, and sun gear. Working examples are provided for spur and helical planetary geartrains. Web planetary gearboxes utilize planetary gears to transfer force and speed from a motor to a desired output. Planet gears rotate around axes that revolve around a sun gear which spins in place. They come in an array of varieties: In this video, corey explains what planetary gear systems are, how to calculate speeds and their widespread use in transmissions.. There are several different methods that can be used to perform planetary gear calculations, including analytical methods, graphical methods, and computer simulations. Web in this tutorial we will learn what is a planetary gear set and how it works, as well as explain how to design our own planetary gearbox and 3d print it so we can see it in. Features include low weight, high speed, compact size and increased torque transmission. The basics of planetary gearbox design. Web basic planetary gearing consists of three sets of gears, each with different degrees of freedom. Web this paper presents planetary gear transmissions, designed according to iso 6336 (ref. Ring gear, planet gear, and sun gear. At the same time, expectations for gear reliability are high. Suitable for ball screw, cnc spindles, rack, pinion, rollers, belts, laser equipment, printing machines, working tables, robots, conveyors and indexing systems. The basics of planetary gearbox design. Web keep reading to understand the calculations necessary for designing planetary gear systems. We are homebodies with a passion for reviving historic spaces. The sun gear, the planet gears, and the ring gear. Web a planetary gear system also known as an epicyclic gearing or planetary gearing. With reverence for the past, we create beautiful, functional homes that make old feel new again. Working examples are provided for spur and helical planetary geartrains. Web in this article we’re going to look at the particulars of planetary gears with an eye towards investigating a particular family of planetary gear setups sometimes known as a ‘differential planetary’ set. Web we also specialize in repairing crane wheels, pumps, rolls, screws and barrels, cutting equipments, gearboxes and gears. Web how to design planetary gear systems for beginners. Web planetary gearboxes utilize planetary gears to transfer force and speed from a motor to a desired output. The planet gear (also known as planetary gear) meshes with the sun gear in such a way that their pitch circles can roll without slippage. In this video, corey explains what planetary gear systems are, how to calculate speeds and their widespread use in transmissions. Features include low weight, high speed, compact size and increased torque transmission. Web an epicyclic gear train (also known as a planetary gearset) is a gear reduction assembly consisting of two gears mounted so that the center of one gear (the planet) revolves around the center of the other (the sun). Ring gear, planet gear, and sun gear. The design process starts with understanding the basic components of a planetary gearbox: They come in an array of varieties: Some clearance is needed for a planetary gearhead to work effectively.

How to design gearbox in solidworks YouTube

![Gear Design, Parts, Function, Ratio & Uses [PDF]](https://www.theengineerspost.com/wp-content/uploads/2022/03/Planetary-Gear-2.jpg)

Gear Design, Parts, Function, Ratio & Uses [PDF]

Gearbox Trapezium Engineering

How to animate gearbox in keyshot? GrabCAD Questions

How Gears Work 3D Printed Gearbox Design and Test

gearbox free 3D Model IAM

How to Design a Single Stage Gearbox 342 DesignWithAjay

Australia Connected Gearbox Efficiency Explained

3 Stage Gear Manufacturers

Gears Design of geartrains for spur and helical

We Are Homebodies With A Passion For Reviving Historic Spaces.

4) As Well As The Maximum Feasible Number Of Planets.

The Basics Of Planetary Gearbox Design.

Web In A Planetary Gearbox, The Sun Gear Drives The Surrounding Planetary Gears Which Are Fixed To A Carrier In Order To Avoid Slipping During Operation.

Related Post: