Piping Design Layout

Piping Design Layout - Web equipment layout is one of the most important deliverable of a piping department. Web piping and instrumentation diagrams are the piping designer’s roadmap for laying out piping systems. Web this short guide will walk you through the key factors to consider when designing your process piping system as well as the critical steps you will need to follow to complete the process with ease. Your suggestions and comments are highly welcomed. Learners can perform the flexibility analysis and recommend the optimum pipe routing with proper pipe supports and hangers. Deals with specific pieces of equipment and their most efficient layout in the overall plant design configuration; Web all piping shall be routed so as to provide a simple, neat and economical layout, allowing for easy support and adequate flexibility. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Web piping layout must be carried out with process requirements, economy, orderliness, stress and supporting requirements in mind. An overview of the procedures and workflow methods used in plant layout and piping design is also provided and the physical quantities and units commonly used are presented. Web the design of industrial piping systems course offers a comprehensive understanding of the principles and practices essential for designing effective piping systems in industrial environments. In other words, p&ids are schematics or diagrams that lay out the basics of a piping design for what will. Your suggestions and comments are highly welcomed. Web piping engineering is a specialized discipline. Crude oil & gas gathering central facilities. Web equipment layout is one of the most important deliverable of a piping department. Web piping layout & design considerations for installation plan a degree of freedom. Piping should be arranged on horizontal racks at specific elevations. Learners can perform the flexibility analysis and recommend the optimum pipe routing with proper pipe supports. Web this project standard and specification covers minimum requirement(s) for general aspects to be considered in design of piping for petroleum and petrochemical plants to be designed in accordance with ansi b31.3 which includes but not limited to the following: The content is organized into several categories which can be accessed from the menu on the right side. Following points. Web equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity requirements, structure philosophy. This course covers critical topics such as material selection, system layout, stress analysis, and safety standards, providing participants. All piping systems are engineered to transport a fluid or gas safely and reliably from one piece. Web the design of industrial piping systems course offers a comprehensive understanding of the principles and practices essential for designing effective piping systems in industrial environments. Web piping and instrumentation diagrams are the piping designer’s roadmap for laying out piping systems. Check out following articles targeting various aspects of equipment and piping layout. Piping system is an assembly of pipe,. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Web piping and instrumentation diagrams are the piping designer’s roadmap for laying out piping systems. This course covers critical topics such as material selection, system layout, stress analysis, and safety standards, providing participants. Web the design. Web this section covers plot plans, equipment layout, piping layouts and safety in piping design. Web piping engineering is a specialized discipline of mechanical engineering that deals with the design of piping and layout of equipment and process units in chemical, petrochemical or hydrocarbon facilities. This course covers critical topics such as material selection, system layout, stress analysis, and safety. Web equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity requirements, structure philosophy. The content is organized into several categories which can be accessed from the menu on the right side. Web it involves planning the layout, selecting materials, and determining the connections between pipes, valves, and other. Addresses the plant layout requirements for the most common process unit equipment; Web this project standard and specification covers minimum requirement(s) for general aspects to be considered in design of piping for petroleum and petrochemical plants to be designed in accordance with ansi b31.3 which includes but not limited to the following: Piping is divided into two main categories: Piping. Web in order to execute the piping designs of a project efficiently, it is essential that you initially identify and address all of the prerequisites that must be in place for the piping designers to start work. The list of articles under each category can be accessed by clicking on the relevant category. Web piping engineering is a specialized discipline. All piping systems are engineered to transport a fluid or gas safely and reliably from one piece of equipment to another. Deals with specific pieces of equipment and their most efficient layout in the overall plant design configuration; Web this chapter covers the fundamentals of piping and instrumentation diagrams (p&ids) and their significance in process plant layout and piping design. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Web all piping shall be routed so as to provide a simple, neat and economical layout, allowing for easy support and adequate flexibility. Web the fundamental aspects of process plant layout and piping design are discussed. The content is organized into several categories which can be accessed from the menu on the right side. Web it involves planning the layout, selecting materials, and determining the connections between pipes, valves, and other components. The basics of piping system. This course covers critical topics such as material selection, system layout, stress analysis, and safety standards, providing participants. Web this short guide will walk you through the key factors to consider when designing your process piping system as well as the critical steps you will need to follow to complete the process with ease. Web learn about piping design and layout rules from piping engineering professionals. Web equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity requirements, structure philosophy. Web piping design general consideration involves determining the most efficient and effective layout of pipes, selecting appropriate materials and fittings, calculating pressure drops and flow rates, and ensuring the system meets safety and regulatory requirements. Piping system is an assembly of pipe, fittings, valves, and specialty components. Web piping and instrumentation diagrams (p&ids) are articulate drawings of a processing plan with various symbols and abbreviations that entail the piping and process equipment with its instrumentation and control machinery.

Need Facility Layout and Piping Design? Highlander Engineering

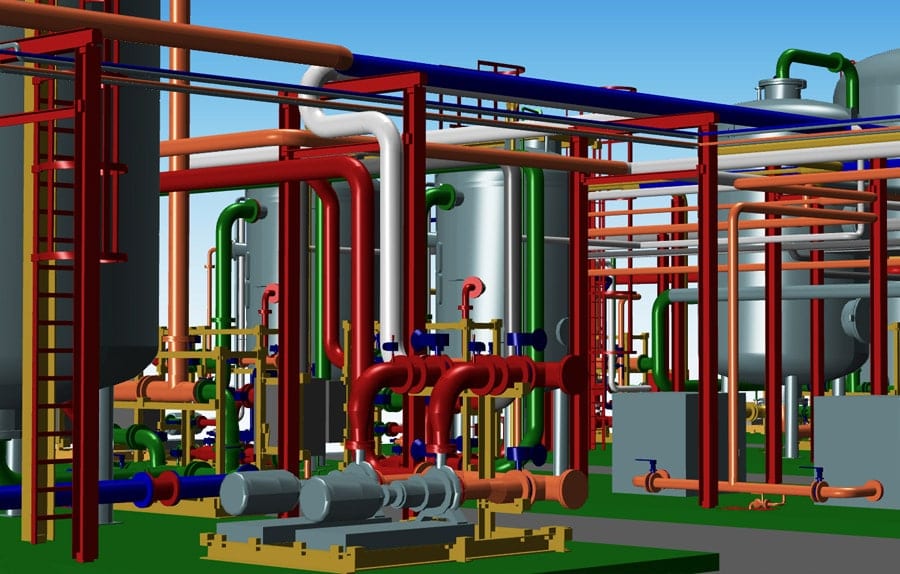

Application of ComputerAided Design to Piping Layout

Piping Design & Piping Layout at Rs 500/meter in Thane

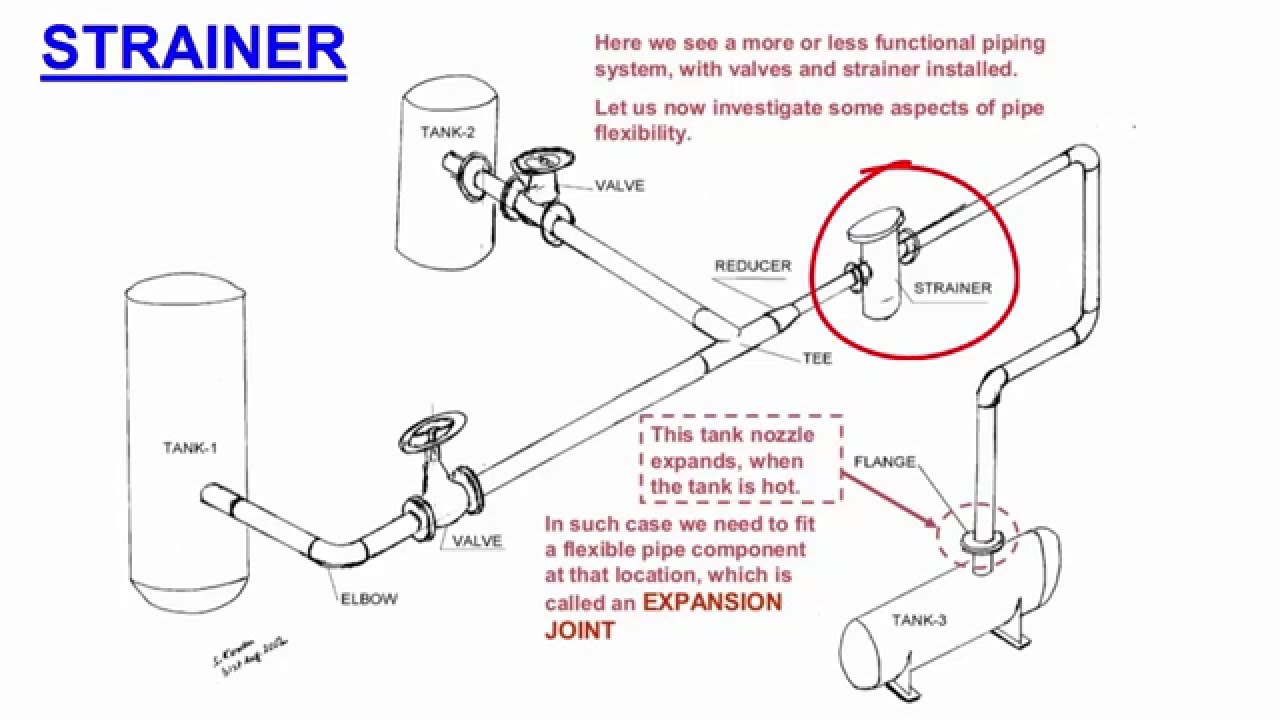

Piping basics_ Piping design factors/Simple piping layout YouTube

Piping LayoutPurpose and General Rules

Piping Layout Considerations Calgary, AB

Pump Piping Design Considerations Make Piping Easy

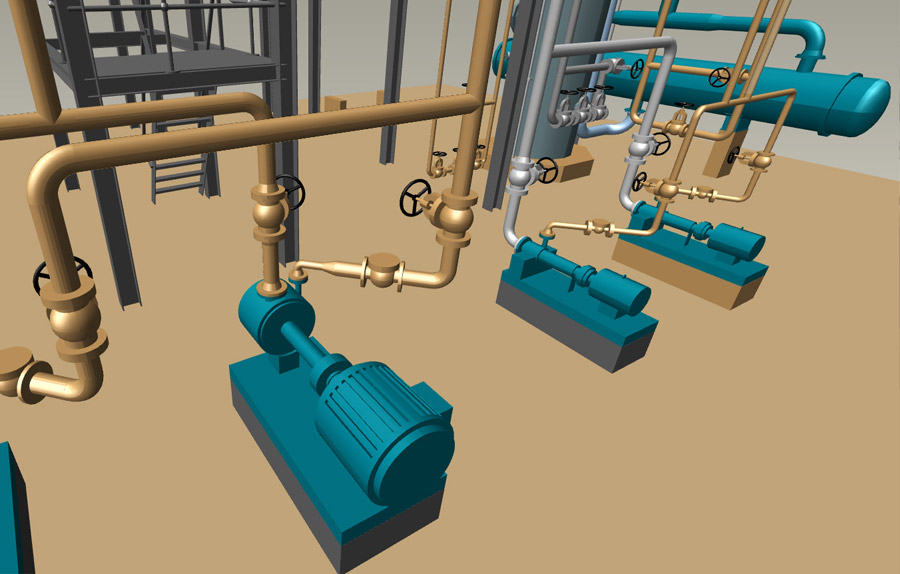

3D Piping Design Software MPDS4

Fundamentals of Process Plant Layout and Piping Design Engineering

Piping Design and Drafting Services 2D and 3D Piping Layouts

Crude Oil & Gas Gathering Central Facilities.

The List Of Articles Under Each Category Can Be Accessed By Clicking On The Relevant Category.

Your Suggestions And Comments Are Highly Welcomed.

Web Equipment Layout Is One Of The Most Important Deliverable Of A Piping Department.

Related Post: