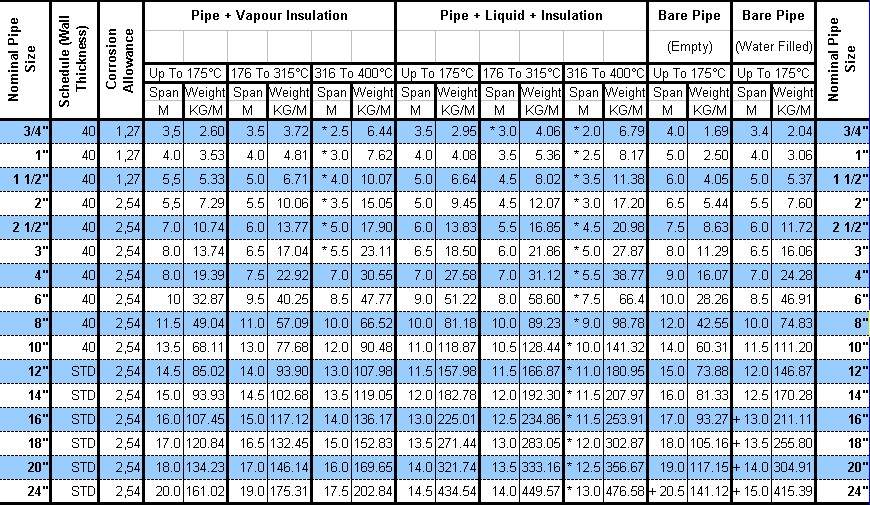

Pipe Support Spacing Chart

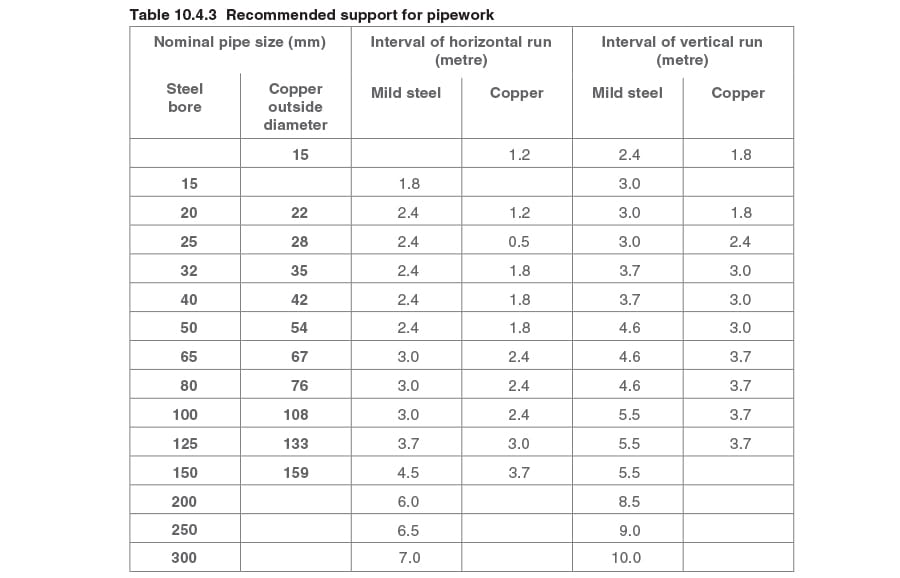

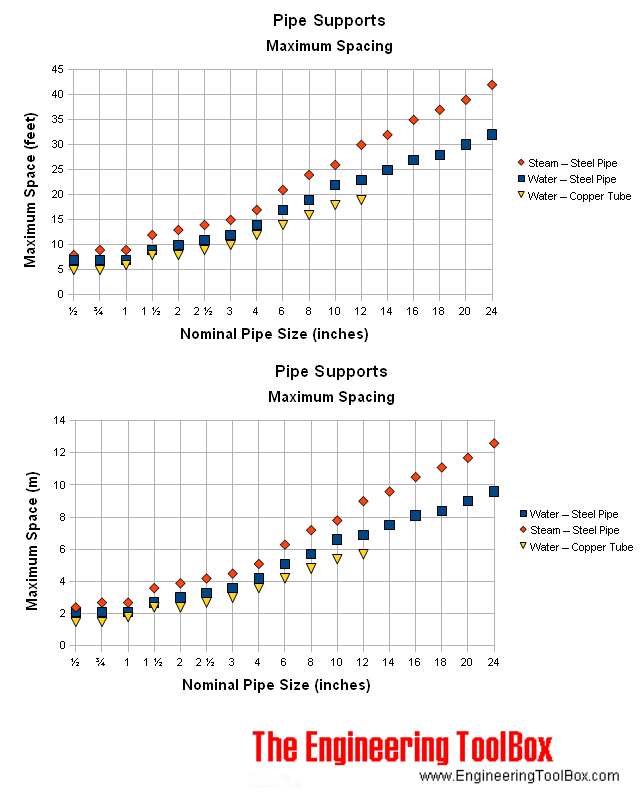

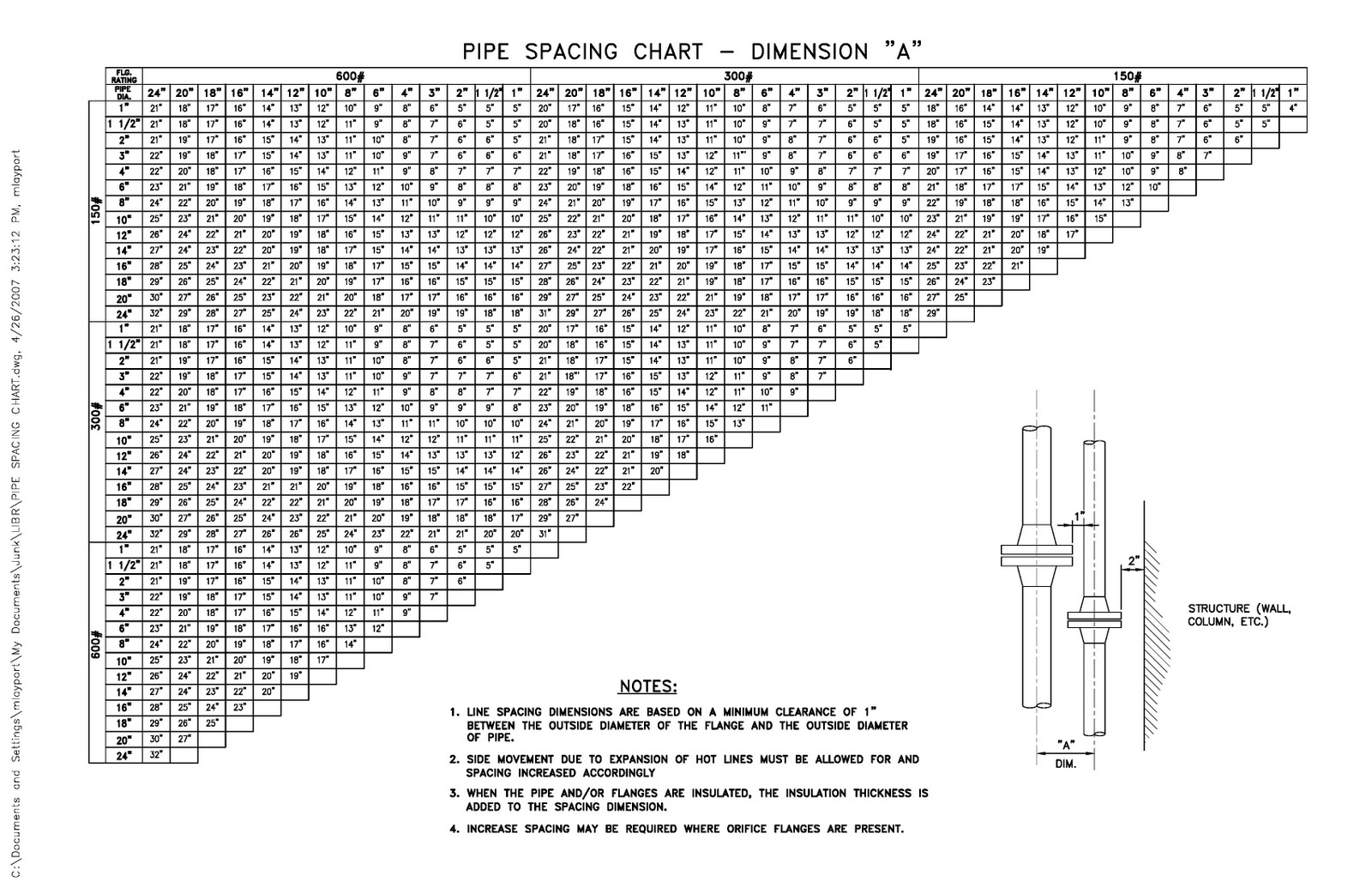

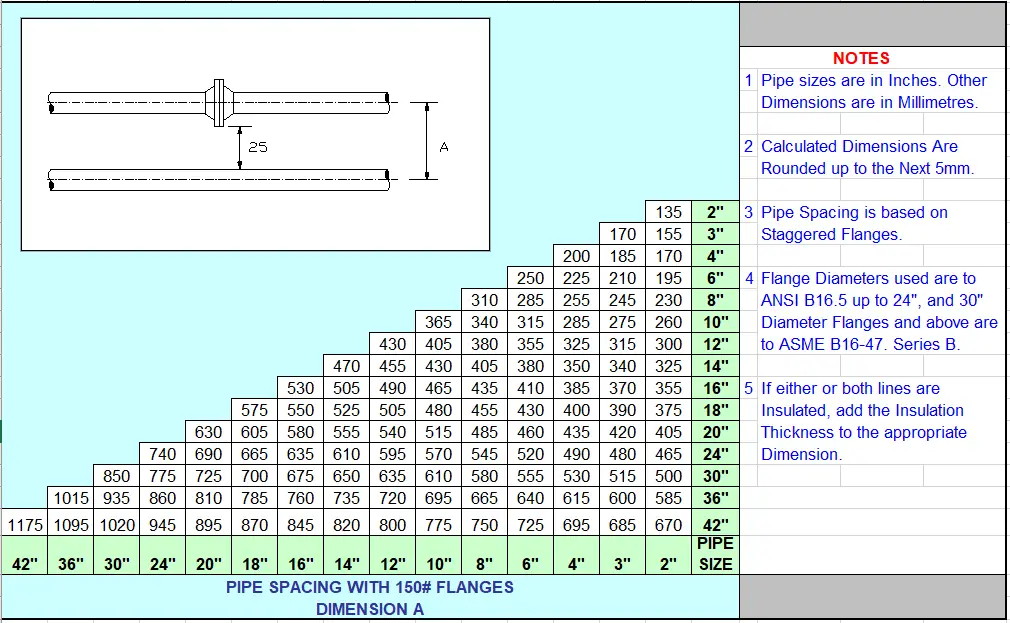

Pipe Support Spacing Chart - Pipe outside diameters as per ansi asme b36.10. Web this calculator provides the calculation of pipe support spacing for a given set of input parameters. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such as. Web minimize stresses in the piping. Web the best rule of thumb for hanger spacing for pipe is the pipe diameter in feet plus 10. If you are working on an inspected job, you will also need to be aware of any specific code requirements for pipe support in your area. The calculation is applicable only for uniform pipe without any attached concentrated weight, such as a valve. Maintain the intended layout and slope. Web pipe support spacing for deflection control design calculator. Web in this comprehensive guide, we will discuss the intricacies of pipe support spans, covering design considerations, factors on which it depends, best practices, and pipe support spacing charts based on different codes and standards. Maintain the intended layout and slope. Optimize the type, size and location of pipe supports. Web pipe support spacing for deflection control design calculator. Flange od from 26″ as per asme b16.47 type a. Minimize reaction loads on equipment nozzles. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such as. Flange od from 26″ as per asme b16.47 type a. The primary factors determining pipe wall thickness are hoop stress caused. Minimize reaction loads on equipment nozzles. Web individual piping materials have independent considerations for span and placement of supports. Pipe outside diameters as per ansi asme b36.10. The primary factors determining pipe wall thickness are hoop stress caused by internal pressure, and longitudinal stresses caused by pressure, weight. Web minimize stresses in the piping. Web this pipe support spacing calculation was developed based upon equations contained in section 6.2 of pipe stress engineering published by peng engineering. Pipe spacing charts are very useful while routing pipes over a pipe rack or sleepers where lines of various sizes run parallel to. Web this spacing chart is a kind of general guideline that gives an idea. 300# pn40 150# pn10 pn25 for traced piped add the od of tracer to insulation. Clear gap can be changed as per your company standard by going to settings menu. Web pipe support hanger spacing and pipe wall thickness. Web the best rule of thumb for hanger spacing for pipe is the pipe diameter in feet plus 10. Pipe spacing. Web minimize stresses in the piping. Maintain the intended layout and slope. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such as. The spacing between supports for a pipe is determined. If you are working on an inspected job, you will also need to be aware of any specific code requirements for pipe support in your area. Clear gap can be changed as per your company standard by going to settings menu. Pipe size relates to the maximum allowable span between pipe supports. Table 1.0 suggests minimum pipe hanger spacing for. Pipe outside diameters as per ansi asme b36.10. Clear gap can be changed as per your company standard by going to settings menu. As pipe size increases, the weight of the pipe also increases. Web calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and b16.47. Web pipe supports offered in this section are designed. Web this pipe support spacing calculation was developed based upon equations contained in section 6.2 of pipe stress engineering published by peng engineering. Pipe guides and slides are designed to allow longitudinal movement due to thermal expansion and contraction of pipe. Pipe spacing charts are very useful while routing pipes over a pipe rack or sleepers where lines of various. Web this pipe support spacing calculation was developed based upon equations contained in section 6.2 of pipe stress engineering published by peng engineering. Web in this comprehensive guide, we will discuss the intricacies of pipe support spans, covering design considerations, factors on which it depends, best practices, and pipe support spacing charts based on different codes and standards. Optimize the. As pipe size increases, the weight of the pipe also increases. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such as. The calculation is applicable only for uniform pipe without any attached concentrated weight, such as a valve. Flange od upto 24 inch as per ansi asme b16.5. Pipe guides and slides are designed to allow longitudinal movement due to thermal expansion and contraction of pipe. Web this calculator provides the calculation of pipe support spacing for a given set of input parameters. Web this pipe support spacing calculation was developed based upon equations contained in section 6.2 of pipe stress engineering published by peng engineering. The spacing between supports for a pipe is determined by the pipe’s diameter, wall thickness, unsupported length, modulus of elasticity, allowable stress, and the desired spacing between supports. Span is a function of the weight that the supports must carry. Maintain the intended layout and slope. Optimize the type, size and location of pipe supports. The purpose of pipe supports is to control the weight effects of the piping system, as well as loads caused by pressure thrust, vibration, wind, earthquake, shock, and thermal displacement. Recommended support spacing may be determined from equation 1. Web the tables below recommends horizontal spacing based on pipe size, schedule, material (pvc or industrial grade cpvc), and operating temperature. Pipe size relates to the maximum allowable span between pipe supports. Web individual piping materials have independent considerations for span and placement of supports.

Hangers Support Spacing and Rod Size for Horizontal Pipes

Steel Pipe Support Spacing Chart

Piping Support Spacing Chart

Pipe Support Spacing Chart Pdf

Pipe Spacing Chart PDF Matériaux de construction Génie du bâtiment

Steel Pipe Support Spacing Chart

PVC Pipe Support Spacing in Feet PDF

Pipe Spacing Chart Pipeline Spacing Chart What Is Piping

Pipe Support Spacing Chart

Piping Support Spacing Chart

Web The Best Rule Of Thumb For Hanger Spacing For Pipe Is The Pipe Diameter In Feet Plus 10.

If You Are Working On An Inspected Job, You Will Also Need To Be Aware Of Any Specific Code Requirements For Pipe Support In Your Area.

Web In This Comprehensive Guide, We Will Discuss The Intricacies Of Pipe Support Spans, Covering Design Considerations, Factors On Which It Depends, Best Practices, And Pipe Support Spacing Charts Based On Different Codes And Standards.

My Lowe's Rewardsbuying Guidescurbside Pickup Availablelowest Price Guarantee

Related Post: