Pipe Rack Design

Pipe Rack Design - Many factors influenced the design of pipe racks in the oil and gas process facility. You can see some of them below; It connects all equipment with lines that cannot run through adjacent areas. Web a pipe rack is the main artery of a processing unit. In this article, i am going to talk about pipe rack design. Because it is located in the middle of most plants, the pipe rack must be erected first, before it becomes obstructed by rows of equipment. Modern trends focus on incorporating digital tools and automation into pipe rack management, streamlining operations, and optimizing resource utilization. Web discover expert tips for efficient pipe rack design. Number of pipelines and sizes (loads) Optimize your layout with best practices for safety and productivity in industrial settings. Web the field of pipe rack design and technology is continuously evolving, driven by innovations that enhance efficiency, sustainability, and safety. Web pipe rack design guidelines. Number of pipelines and sizes (loads) Modern trends focus on incorporating digital tools and automation into pipe rack management, streamlining operations, and optimizing resource utilization. Optimize your layout with best practices for safety and. Optimize your layout with best practices for safety and productivity in industrial settings. Many factors influenced the design of pipe racks in the oil and gas process facility. Pipe racks are necessary for arranging the process and utility pipelines throughout the plant. Web pipe rack design guidelines. Web the field of pipe rack design and technology is continuously evolving, driven. Many factors influenced the design of pipe racks in the oil and gas process facility. Web a pipe rack is the main artery of a processing unit. Web pipe rack design guidelines. Modern trends focus on incorporating digital tools and automation into pipe rack management, streamlining operations, and optimizing resource utilization. Web the field of pipe rack design and technology. Optimize your layout with best practices for safety and productivity in industrial settings. Number of pipelines and sizes (loads) Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. Web pipe rack design. In this article, i am going to talk about pipe rack design. Number of pipelines and sizes (loads) Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. Many factors influenced the design. Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. Modern trends focus on incorporating digital tools and automation into pipe rack management, streamlining operations, and optimizing resource utilization. Because it is located. Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. Pipe racks are necessary for arranging the process and utility pipelines throughout the plant. Web a pipe rack is the main artery of. It connects all equipment with lines that cannot run through adjacent areas. Web a pipe rack is a structure designed and installed specifically to support multiple pipes, where an adequate building or structure is not available (mainly outside the building). Web discover expert tips for efficient pipe rack design. Because it is located in the middle of most plants, the. Web the field of pipe rack design and technology is continuously evolving, driven by innovations that enhance efficiency, sustainability, and safety. Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. Web a. Optimize your layout with best practices for safety and productivity in industrial settings. Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. Many factors influenced the design of pipe racks in the. Web pipe rack design guidelines. Pipe racks are necessary for arranging the process and utility pipelines throughout the plant. Optimize your layout with best practices for safety and productivity in industrial settings. Web a pipe rack is the main artery of a processing unit. Number of pipelines and sizes (loads) Modern trends focus on incorporating digital tools and automation into pipe rack management, streamlining operations, and optimizing resource utilization. Web the field of pipe rack design and technology is continuously evolving, driven by innovations that enhance efficiency, sustainability, and safety. Web discover expert tips for efficient pipe rack design. It connects all equipment with lines that cannot run through adjacent areas. Web design loads pipe racks should be designed for all gravity and natural hazards such as wind and seismic loads, internal forces induced by restraint of free thermal expansion, and the pipe anchor and guide support loads. You can see some of them below; In this article, i am going to talk about pipe rack design.![]()

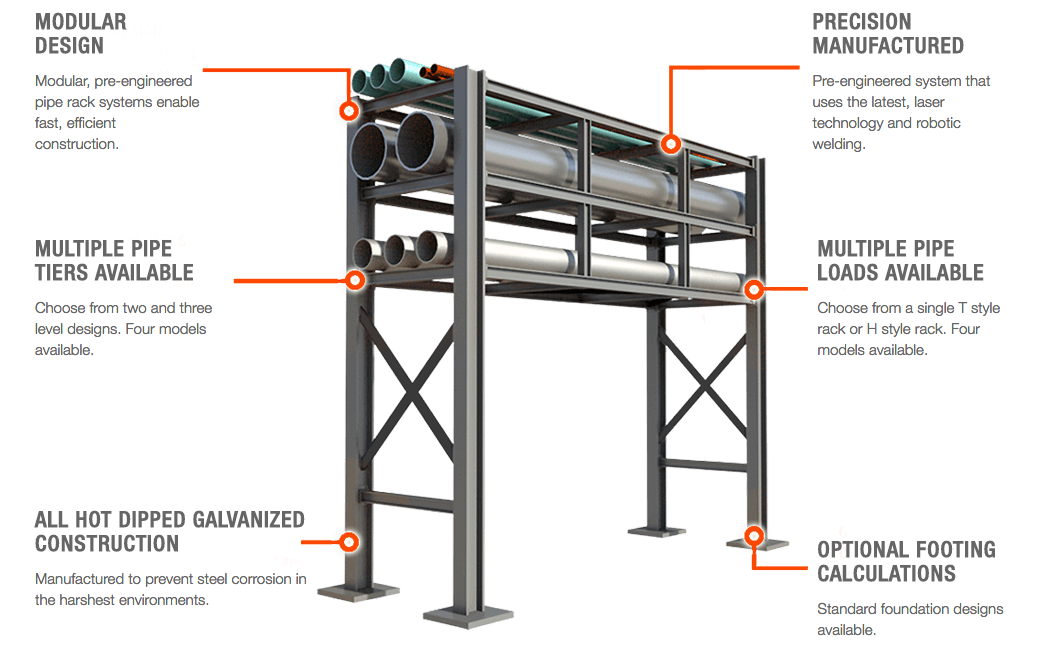

Pipe Racks ErectaRack PreEngineered Modular Pipe Rack Systems

Pipe Rack Design and Calculations Make Piping Easy

Craftsman Cottage Tobacco Pipe Rack Plans

PIPE RACK PIPING PIPINGKNOWLEDGE

![]()

Pipe Racks ErectaRack PreEngineered Modular Pipe Rack Systems

![]()

Pipe Racks ErectaRack PreEngineered Modular Pipe Rack Systems

Pipe Racks ErectaRack PreEngineered Modular Pipe Rack Systems

Pipe Racks ErectaRack PreEngineered Modular Pipe Rack Systems

Pipe Racks Carbis Solutions Fall Protection

Pipe Racks Carbis Solutions Fall Protection

Web A Pipe Rack Is A Structure Designed And Installed Specifically To Support Multiple Pipes, Where An Adequate Building Or Structure Is Not Available (Mainly Outside The Building).

Because It Is Located In The Middle Of Most Plants, The Pipe Rack Must Be Erected First, Before It Becomes Obstructed By Rows Of Equipment.

Many Factors Influenced The Design Of Pipe Racks In The Oil And Gas Process Facility.

Related Post: