Pinion Ring Gear Pattern

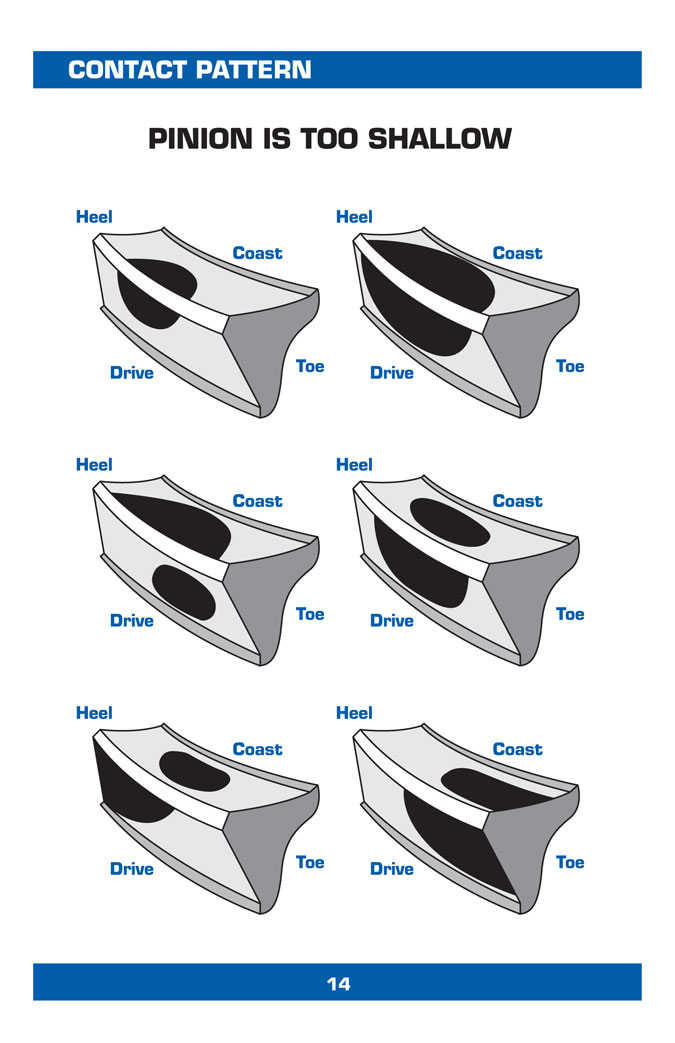

Pinion Ring Gear Pattern - Looking for a specific ratio? Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. But where the ring gear teeth that had more backlash (due to the lower surface/warp of the carrier),. Whether new or used, check the ring gear mounting surface for nicks or burrs and correct as needed to. Web five cut ring & pinion gears (face milled): Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. The heel of the gear tooth is the portion of the tooth surface at the outer end. Begin by setting proper pinion bearing preload, total turning preload, and. This chart illustrates different patterns and adjustments. Web the pattern refers to how the ring gear and pinion gears mesh. Web in general, pattern movements can be summarized this way: Web five cut ring & pinion gears (face milled): The images below illustrate both acceptable and. Web our crown wheel and pinion gear go through detailed testing and are designed and manufactured in matched sets for optimal. The heel of the gear tooth is the portion of the tooth surface at the outer end. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Since 1909 arvinmeritor has been leading. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact.. A tooth contact pattern will appear and should be similar to the pattern shown in. Web five cut ring & pinion gears (face milled): The heel of the gear tooth is the portion of the tooth surface at the outer end. Web the pattern refers to how the ring gear and pinion gears mesh. Web we can determine how gears. But where the ring gear teeth that had more backlash (due to the lower surface/warp of the carrier),. Web a contact pattern centered from face to flank indicates the correct pinion depth. Looking for a specific ratio? Web the pattern refers to how the ring gear and pinion gears mesh. Moving the pinion gear closer to the carrier will move. We stock a wide range of r&p sets and ratios for vw type 1 / type 2 / 002, mendeola, albins, weddle and pbs. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Web the toe of the gear tooth is the portion of the tooth surface. Web the pattern refers to how the ring gear and pinion gears mesh. Use strength of meritor axles and brakes to pull through other components. Whether new or used, check the ring gear mounting surface for nicks or burrs and correct as needed to. The heel of the gear tooth is the portion of the tooth surface at the outer. Automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Use strength of meritor axles and brakes to pull through other components. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. A contact pattern closer. Web proper contact patterns between ring gear and pinion gear teeth are important for quiet gear operation. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. We stock a wide range of r&p sets and ratios for vw type 1 / type 2 / 002, mendeola, albins, weddle and pbs. Web ring. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Use strength of meritor axles and brakes to pull through other components. We stock a wide range of r&p sets and ratios for vw type 1 / type 2 / 002, mendeola, albins, weddle and pbs. Web ring and pinion gear. But where the ring gear teeth that had more backlash (due to the lower surface/warp of the carrier),. Use strength of meritor axles and brakes to pull through other components. Web the ring gear face on a flat glass plate with sandpaper or emery cloth. Automotive ring and pinion gears must be installed and set up in a very specific. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. A contact pattern closer to the gear face means the pinion is too far away from. Web the pattern refers to how the ring gear and pinion gears mesh. Looking for a specific ratio? Web yes, move the pinion towards the center of the ring gear, the pattern should move in towards the toe or inside of the ring gear and towards the flank or down into the. Web the ring gear face on a flat glass plate with sandpaper or emery cloth. We stock a wide range of r&p sets and ratios for vw type 1 / type 2 / 002, mendeola, albins, weddle and pbs. I don't have the original pinion shim as a. To check the contact pattern, apply marking compound to the ring gear. Web ring and pinion gear tooth pattern. Whether new or used, check the ring gear mounting surface for nicks or burrs and correct as needed to. Web ring & pinion sets. Web in general, pattern movements can be summarized this way: A tooth contact pattern will appear and should be similar to the pattern shown in. The heel of the gear tooth is the portion of the tooth surface at the outer end. While we can’t physically see how the gears actually relate.Pinion/ring gear wear pattern ?

Gearing Up How To Install & Set Up a Dana 60 Gearset Hot Rod Network

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

How To Create & Read Ring Gear Patterns

Ring & Pinion Installation Instructions The Ranger Station

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Ring Pinion Pattern Patterns Gallery

Ring and pinion gear pattern Rennlist Porsche Discussion Forums

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Ring And Pinion Patterns

Web A Contact Pattern Centered From Face To Flank Indicates The Correct Pinion Depth.

Web The Toe Of The Gear Tooth Is The Portion Of The Tooth Surface At The End Towards The Center.

Web Proper Contact Patterns Between Ring Gear And Pinion Gear Teeth Are Important For Quiet Gear Operation.

Web Five Cut Ring & Pinion Gears (Face Milled):

Related Post: