Pattern Welded

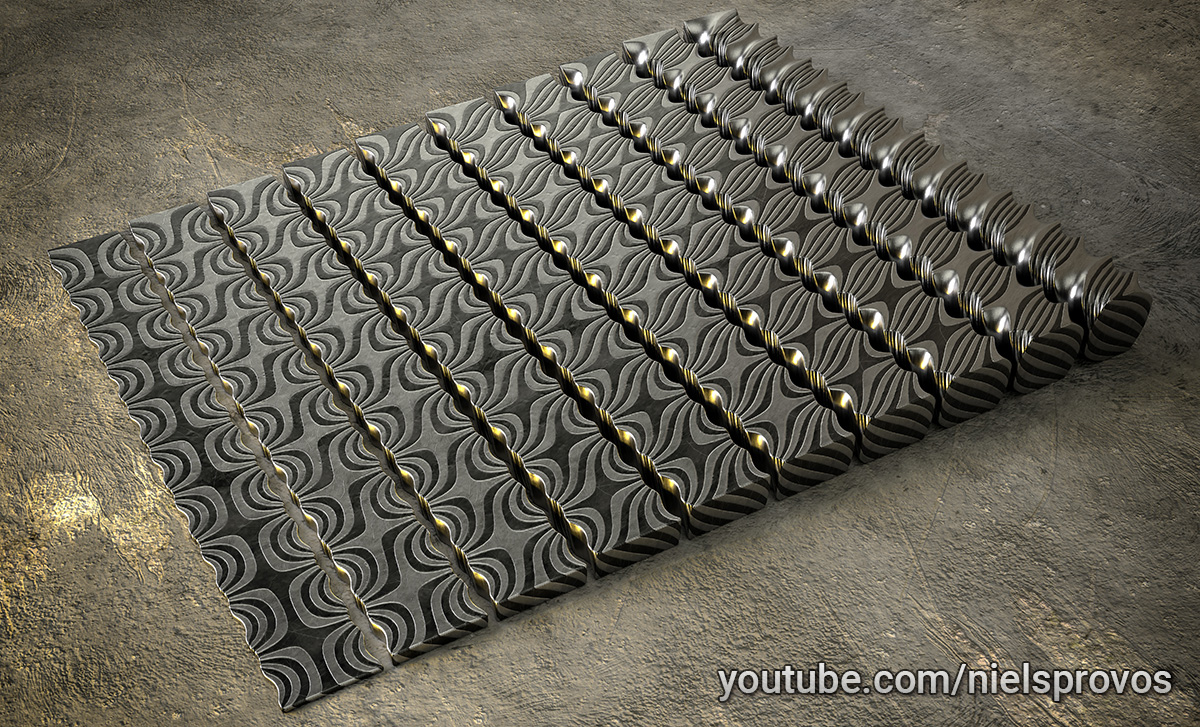

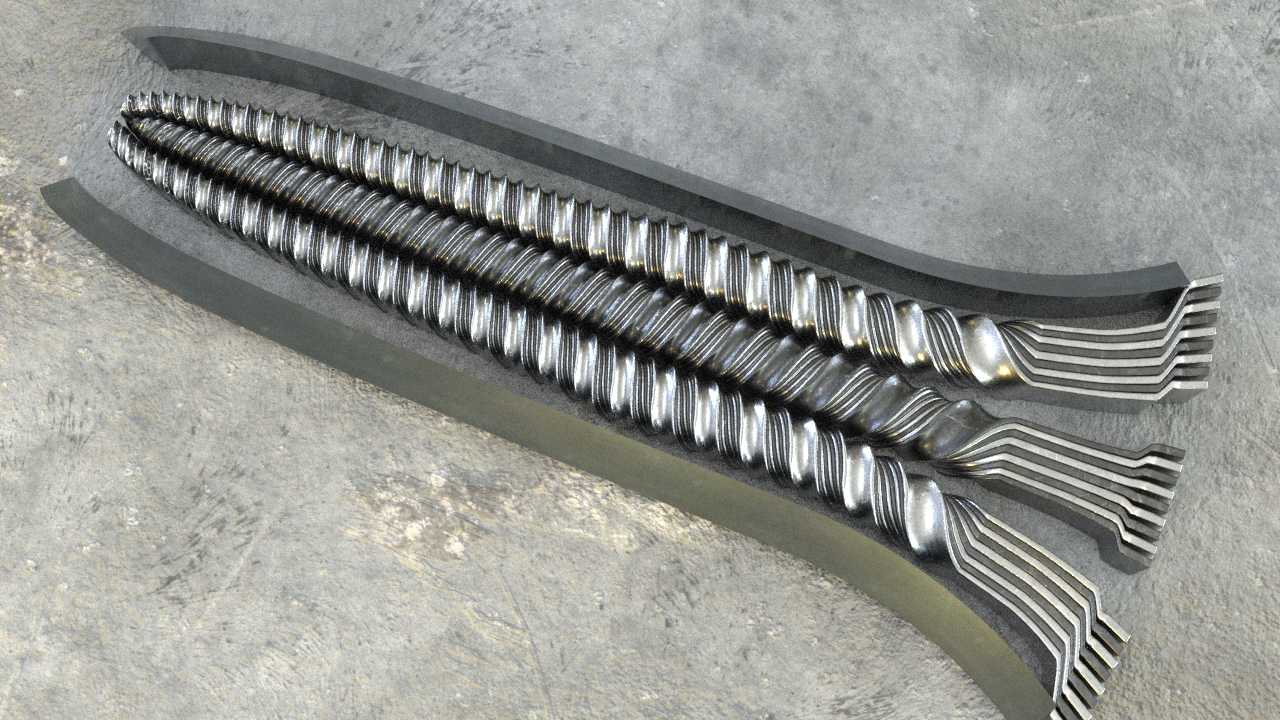

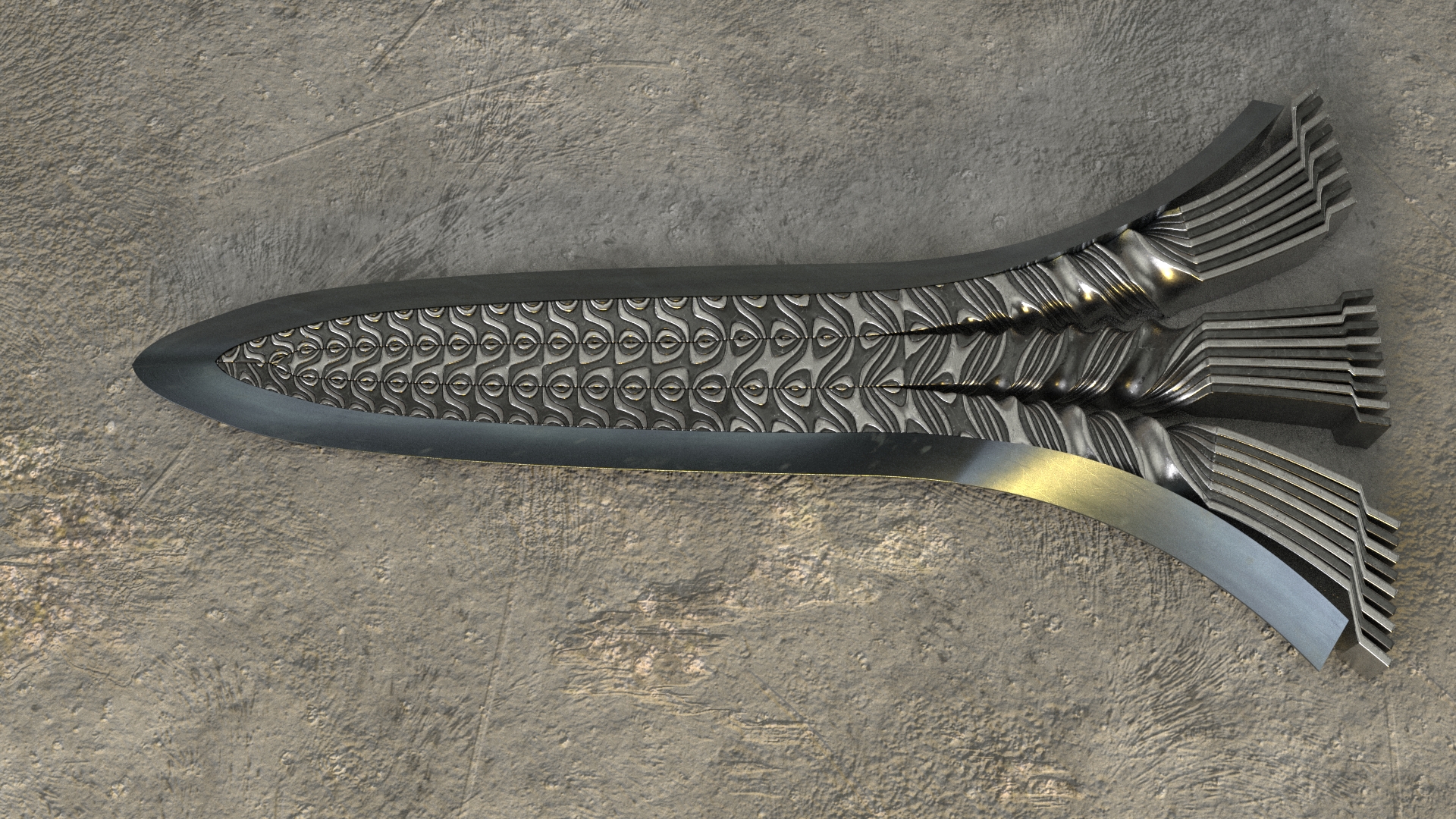

Pattern Welded - It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. Find out how and compare it with the original damascus steel in this article. But pattern welding wasn't the secret to damascus steel. Forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. Web pattern welding steel is a practice in knifemaking that develops striking patterns. The process was required so that strips of steel could for formed into a round barrel. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. Web the term pattern welding refers to the process of forging a sword or blade using multiple pieces of metal with differing composition, twisting them together to create a pattern. Pattern welding is a special way of constructing a sword blade from a lot of iron / steel parts. These patterns form partly because sufficiently differing metals that intersect the surface reflect lights differently. Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated to make simple and bold or. Once the blade is forged, it is then ground and polished the same as any other. With almost all of the patterns twisting is used to develop the pattern.. Forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. The eye catching designs unique to every knife achieved by pattern welding steel is an ancient forging method. This is a recyclable instructible as well as a knife making tutorial. Many different kinds of iron / steel parts are fire welded in. Web have you cried blood when attempting your first pattern welded blade? Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated to make simple and bold or. Many different kinds of iron / steel parts are fire welded in such a way that a. The process was required so that strips of steel could for formed into a round barrel. These metals are then forge welded and twisted to form a pattern that is visible on the blade. Web pattern welding is a technique that is commonly used in the creation of swords and knives from many pieces of metal that have varying compositions.. Damascus steel is beautiful, very sharp, and very tough. 4 x black square section spring washers. Web pattern welding was also commonly used for the production of gun barrels prior to the 20th century; It is not however, any form of magic. These patterns form partly because sufficiently differing metals that intersect the surface reflect lights differently. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. Patterning of the flat laminated billet can be accomplished in many ways. Once the blade is forged, it is then ground and polished the same as any other. It is not however, any form of magic. The iron or. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. The steel bears a wavy pattern, so it is also called persian watered steel. Forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. Web in this video we're talking about. This is a recyclable instructible as well as a knife making tutorial. Web in this video we're talking about the process of making pattern welded steel (damascus), including the final etch to reveal the beautiful visual effect of the contrasting steels. This process of joining many layers of metal is also known as damascus steel. Many different kinds of iron. This instructible assumes a working knowledge of pattern welding. Find out how and compare it with the original damascus steel in this article. With almost all of the patterns twisting is used to develop the pattern. Once the blade is forged, it is then ground and polished the same as any other. These patterns form partly because sufficiently differing metals. Flux between the layers keeps out oxygen and aids seal formation. Many different kinds of iron / steel parts are fire welded in such a way that a pleasing pattern can be observed on one or both sides of a blade. Pattern welding is a special way of constructing a sword blade from a lot of iron / steel parts.. Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated to make simple and bold or. Flux between the layers keeps out oxygen and aids seal formation. Here is something easy that will get you started and boost your confidence. The eye catching designs unique to every knife achieved by pattern welding steel is an ancient forging method. It is not however, any form of magic. These patterns form partly because sufficiently differing metals that intersect the surface reflect lights differently. Web there are two types of damascus steel: Web pattern welding is the process of welding together plates of high, low and sometimes intermediate carbon content steels, drawing them out, cutting and rewelding repeatedly until the desired fineness of material distribution is achieved. These steels also rely on. Patterning of the flat laminated billet can be accomplished in many ways. Web in this video we're talking about the process of making pattern welded steel (damascus), including the final etch to reveal the beautiful visual effect of the contrasting steels. The iron or steel used must be contrasting so that they are optically different and. Web the term pattern welding refers to the process of forging a sword or blade using multiple pieces of metal with differing composition, twisting them together to create a pattern. Web in pattern welding, a pattern is created through manipulating different types of steel by twisting or controlled removal of material. Web pattern welding was also commonly used for the production of gun barrels prior to the 20th century; Web pattern welded steel, also known as damascus steel, is a type of metal with a distinctive, swirling pattern that has been used for centuries to create everything from swords and knives to decorative objects.

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

Pattern Welding Explained

Help me understand pattern welding. Beginners Place Bladesmith's

Pattern Welding Master the Art of Creating Stunning Metal Designs

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

Pattern Welding Explained

Pattern Welding Explained

Pattern Welding Explained

Pattern Welding Explained

How Pattern Welded Steel is Made Explained by Blacksmiths (Part 2 of

Damascus Steel Is Beautiful, Very Sharp, And Very Tough.

Web Pattern Welding, Also Known As Damascus Steel Or Damascene Technique, Is A Traditional Method Of Forging Metals To Create Intricate Patterns And Designs.

Pattern Welding Is A Special Way Of Constructing A Sword Blade From A Lot Of Iron / Steel Parts.

This Process Of Joining Many Layers Of Metal Is Also Known As Damascus Steel.

Related Post: