P Chart Formula

P Chart Formula - Use p charts when counting. Find out the formulas for plotted points, ratio of observed variation to expected variation, 95%. Web 0.67 (to 2.d.p) 67% n = sample size per sub group (per row) np/n) σ = sum of sample size. [1] center line, [2] upper control limit, & [3] lower control limit. Web the laney p' chart (p prime or modified p chart) works much like an xmr chart. P is the fraction defective in a lot or population. * since the sample size (n) changes at each subgroup (per row), you will have to calculate. The p chart is used when the sample size varies. Web hi @ malvikabhasin, you can add a calculated column =orders [sales]*1.5. Convert the p values to z values. Convert the p values to z values. Calculate the moving range of the z values. Web visit the spc statistical process control knowledge center to learn about p chart calculations. Web the p chart formula. This chart is used to track. Select the method or formula of your choice. Examples include the number of defective products, meals in a restaurant, incorrect prescriptions, bills, invoices,. Control charts dealing with the proportion or fraction of defective product are called p charts (for. Web the laney p' chart (p prime or modified p chart) works much like an xmr chart. Click on qi macros. Web hi @ malvikabhasin, you can add a calculated column =orders [sales]*1.5. Quality american can help you understand the p chart formula! Convert the p values to z values. Web 0.67 (to 2.d.p) 67% n = sample size per sub group (per row) np/n) σ = sum of sample size. Organizations bank on reliable quality and minimal defects fuelling success. Web a p chart is a control chart designed to monitor the proportion of defective items in a process where each item is categorized as either pass or fail. P is the fraction defective in a lot or population. The p chart is used when the sample size varies. Web hi @ malvikabhasin, you can add a calculated column =orders. P is the fraction defective in a lot or population. Web visit the spc statistical process control knowledge center to learn about p chart calculations. Calculate the moving range of the z values. Web the p chart formula. Web learn how to use minitab to create and interpret p charts for process monitoring. Web a p control chart is used to look at variation in yes/no type attributes data. Find out the formulas for plotted points, ratio of observed variation to expected variation, 95%. Web p chart formula: There are only two possible outcomes: Then use the calculated column to create a measure, and use the measure to create the. Find out the formulas for plotted points, ratio of observed variation to expected variation, 95%. Either the item is defective or it is not defective. * since the sample size (n) changes at each subgroup (per row), you will have to calculate. Web the p chart formula. For plotting the p chart in excel we have to calculate the three. Next, you need to calculate the moving ranges (mr) of the z values. Control charts dealing with the proportion or fraction of defective product are called p charts (for. This is done by taking the difference between consecutive values. Click on qi macros menu > control charts (spc) > attribute > p. Calculate the moving range of the z values. Web 0.67 (to 2.d.p) 67% n = sample size per sub group (per row) np/n) σ = sum of sample size. Organizations bank on reliable quality and minimal defects fuelling success. Calculate the moving range of the z values. Then use the calculated column to create a measure, and use the measure to create the. Next, you need to calculate. Web a p control chart is used to look at variation in yes/no type attributes data. Web the p chart is used when the sample size varies. Calculate the moving range of the z values. Convert the p values to z values. What is it and how it works. The proportion or fraction nonconforming (defective) in a population is defined as the ratio of the. For plotting the p chart in excel we have to calculate the three important things i.e. P is the fraction defective in a lot or population. Calculate the moving range of the z values. [1] center line, [2] upper control limit, & [3] lower control limit. The chart is based on the binomial distribution; Web the p chart formula. Organizations bank on reliable quality and minimal defects fuelling success. Examples include the number of defective products, meals in a restaurant, incorrect prescriptions, bills, invoices,. Convert the p values to z values. Use p charts when counting. Click on qi macros menu > control charts (spc) > attribute > p. What is it and how it works. Control charts dealing with the proportion or fraction of defective product are called p charts (for. Web the p chart is used when the sample size varies. Web visit the spc statistical process control knowledge center to learn about p chart calculations.

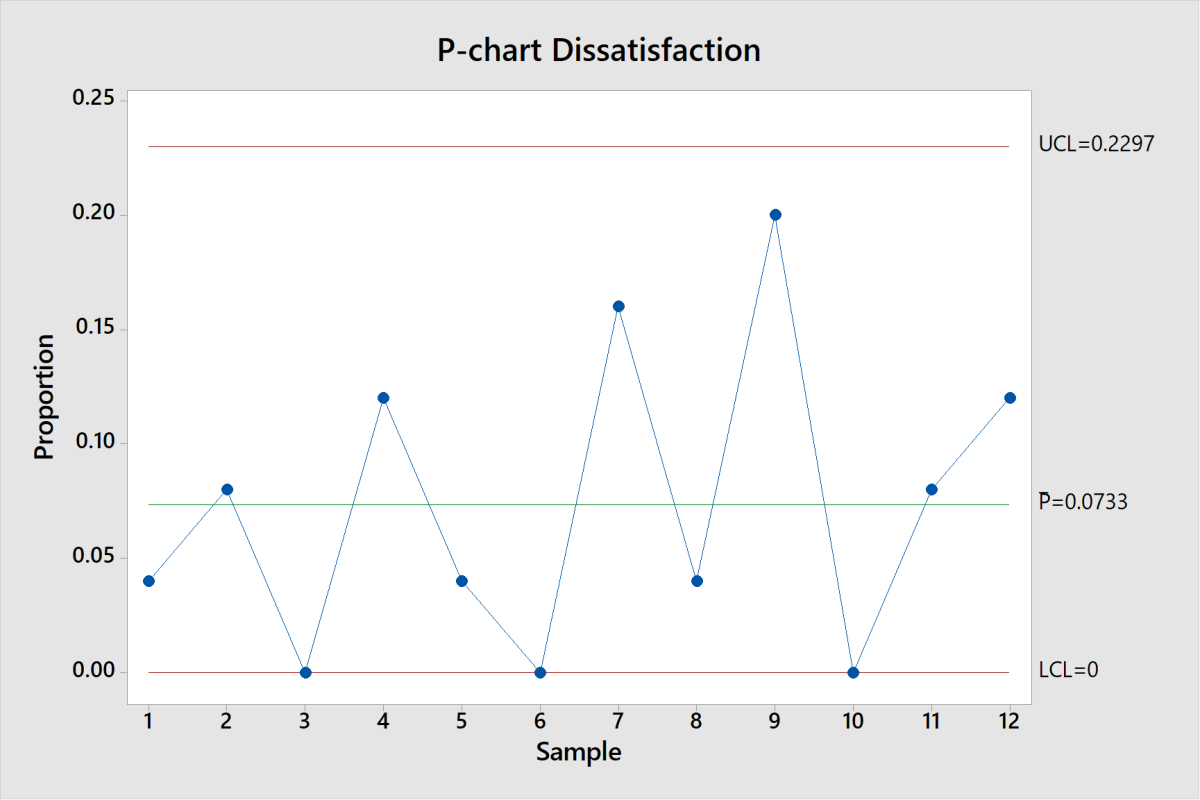

pCharts Attribute Based Control Charts ppt download

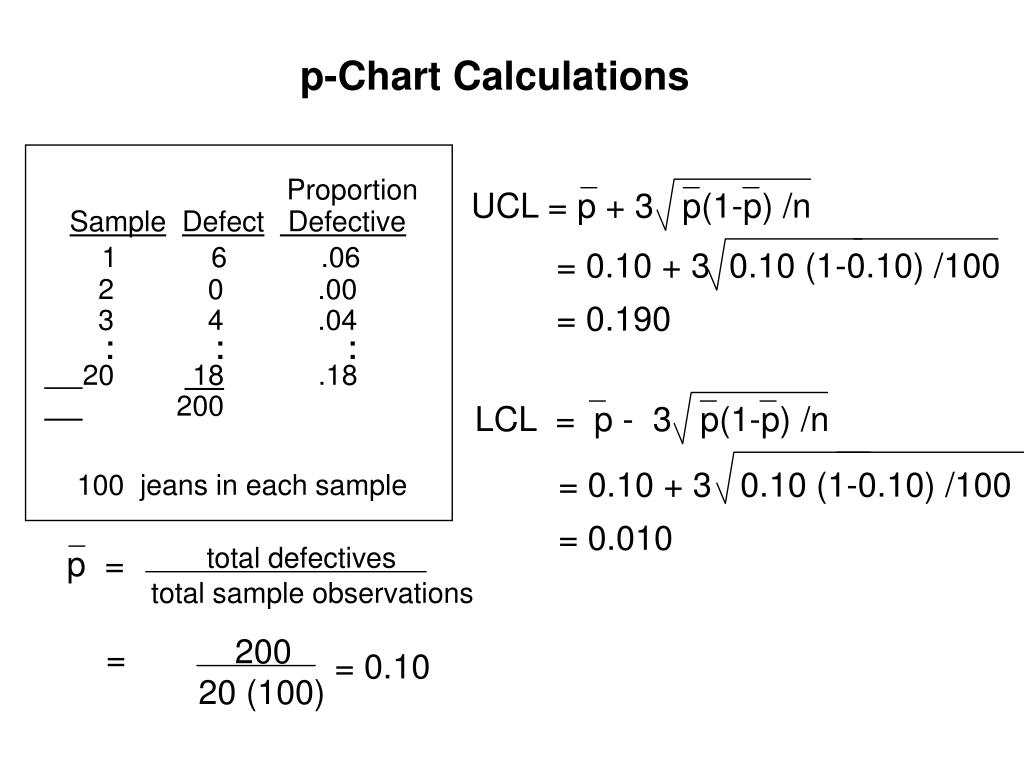

P Chart Calculations P Chart Formula Quality America

P Chart Calculations P Chart Formula Quality America

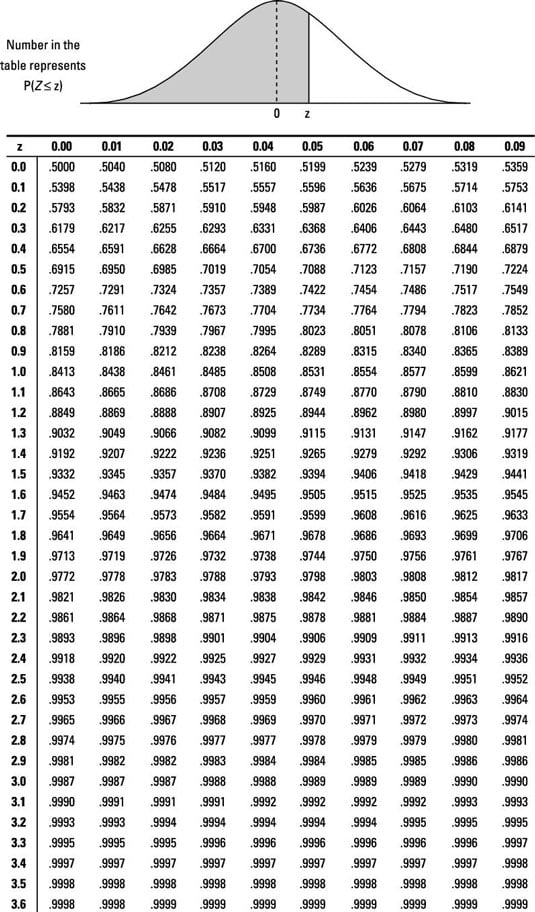

Practice Calculating pValues dummies

How to Create a PChart in Minitab 18 ToughNickel

PPT Statistical Process Control PowerPoint Presentation, free

P' Chart Formula Quality Improvement East London NHS Foundation

P Chart Calculations P Chart Formula Quality America

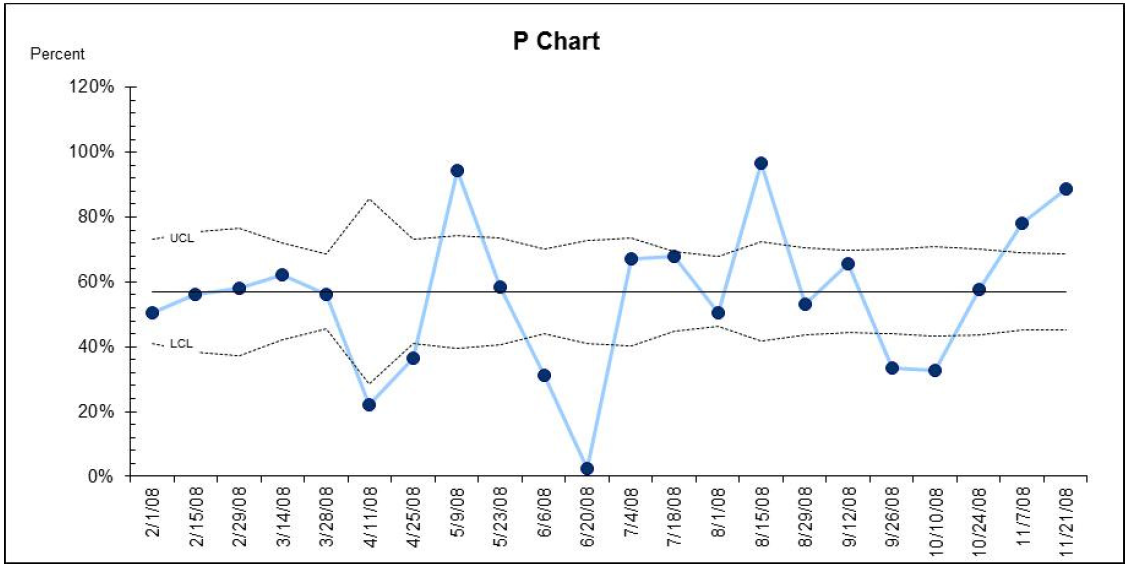

Example P chart Quality Improvement East London NHS Foundation Trust

Example Of P Chart Calculation chartcentral

Web 0.67 (To 2.D.p) 67% N = Sample Size Per Sub Group (Per Row) Np/N) Σ = Sum Of Sample Size.

Select The Method Or Formula Of Your Choice.

Web A P Control Chart Is Used To Look At Variation In Yes/No Type Attributes Data.

The P Chart Is Used When The Sample Size Varies.

Related Post: