Oxy Acetylene Cutting Tip Chart

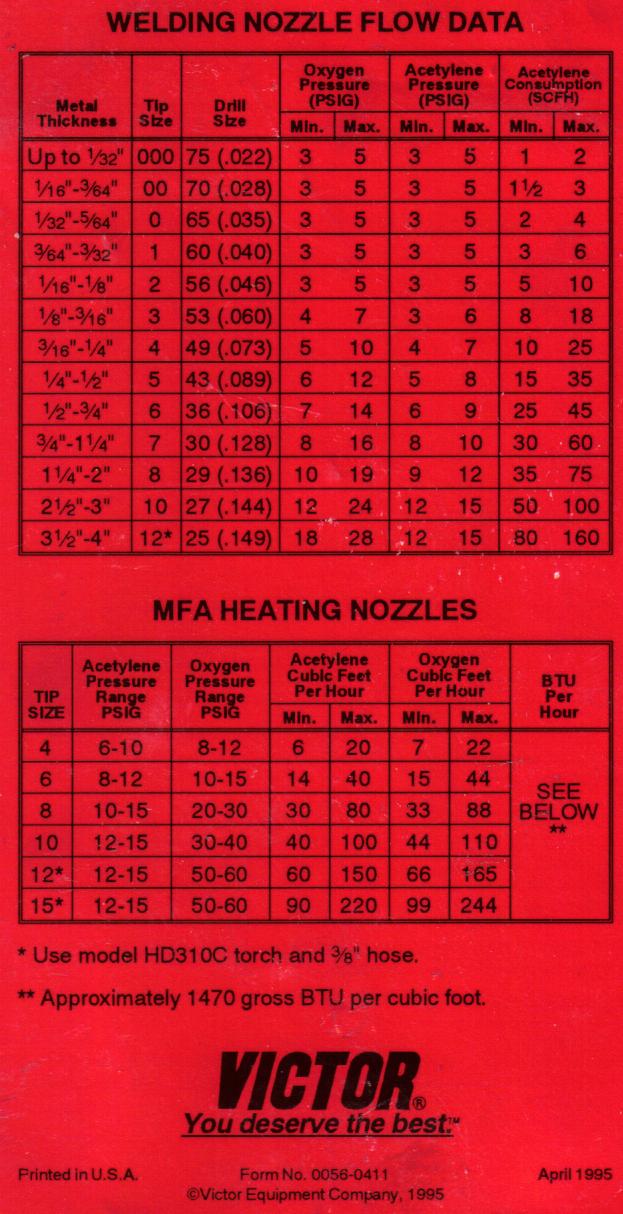

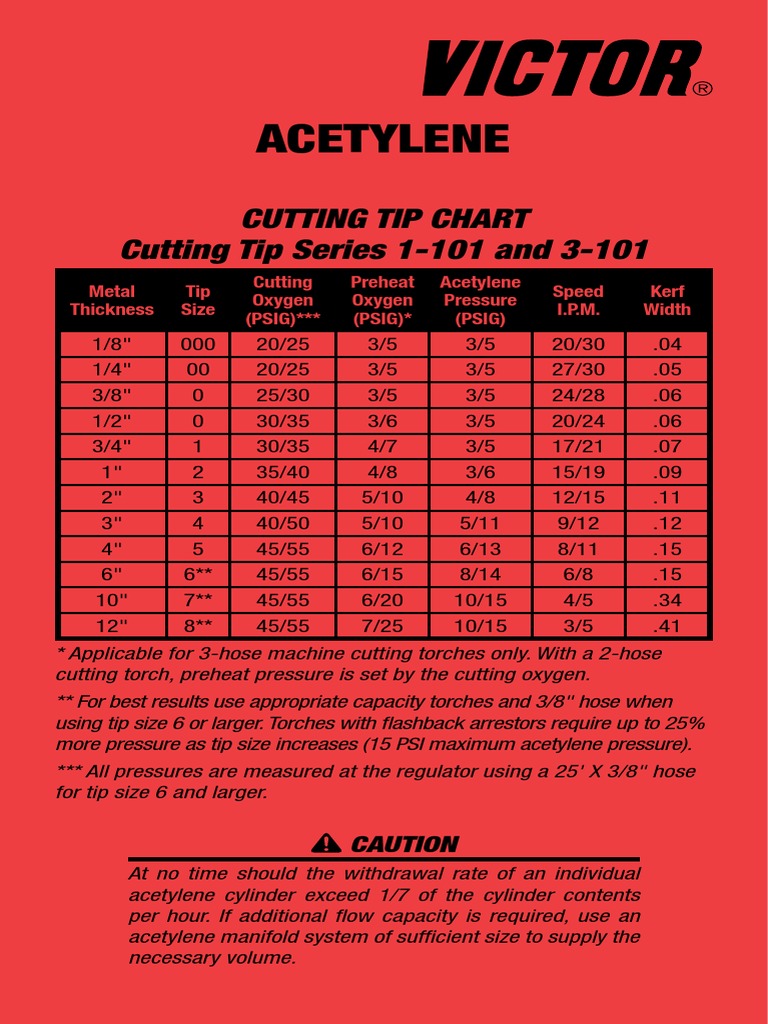

Oxy Acetylene Cutting Tip Chart - Each gas fuel needs the proper torch tip in order to be used properly and efficiently. Web step #3 cutting oxygen adjustment procedure. In order to comfortably and safely see the flame when welding or cutting, welding goggles must be worn. Metal thickness pressure (psig) consumption (scfh) drill size cutting oxygen preheat oxygen mm inch tip size reg. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. Web either oxyacetylene or oxypropane works well for torch cutting. Acetylene tips are manufactured with four or six preheat holes and are produced to allow light, medium, and heavy preheats for. Web longest lasting cutting tip for dependable performance. The tip is angled at 20º. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. Tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch. Hose for size 4 and larger. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. Each gas fuel needs the proper torch tip in order to be used properly and efficiently. * applicable for three. One being the tip you choose. If additional flow capacity is required, use an acetylene manifold system of suficient size to supply the nec. Web medium preheat tip with two milled flat sides. Cuts up to 3/16 in. Web step #3 cutting oxygen adjustment procedure. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. Acetylene tips are manufactured with four or six preheat holes and are produced to allow light, medium, and heavy preheats for. Web here we will discuss the various types of cutting torch tips and the. We have what you need. Selecting welding gases for spring projects. Small task or big project? In stock and ready to ship. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Set supply pressure for cutting oxygen pressure at supply regulator to approximately 90 psi adjust cutting oxygen pressure on hi/low preheat manifold regulator to the value shown in the chart above. Arguably one of the most important components that will affect both of these is your cutting tip choice. Web longest lasting cutting tip for dependable performance. Web here we. Cuts up to 3/16 in. Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. If additional flow capacity is required, use an acetylene manifold system of suficient size to supply the nec. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig.. Web how to select the correct cutting tips for your oxygen acetylene torch. Retro systems 430 clay valley center, ks 67147. Tables show approximate gas pressures for welding or cutting. ** to provide required flow, use 3/8 i.d. Web longest lasting cutting tip for dependable performance. Each gas fuel needs the proper torch tip in order to be used properly and efficiently. *minimum of one 350 cu. Web step #3 cutting oxygen adjustment procedure. Small task or big project? * applicable for three hose machine torch only. Retro systems 430 clay valley center, ks 67147. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. Whether you are buying your first cutting torch or replacing your current one, there are a few things you need to consider in order to get the. For additonal information refer to www.harrisproductsgroup.com. With a two hose cutting torch, preheat pressure is set by the cutting oxygen. In stock and ready to ship. Tables show approximate gas pressures for welding or cutting. Set supply pressure for cutting oxygen pressure at supply regulator to approximately 90 psi adjust cutting oxygen pressure on hi/low preheat manifold regulator to the value shown in the chart above. Tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. This chemical reaction is called oxidation and rust is the result of the process of oxidation. One being the tip you choose. We have what you need. Whether you are buying your first cutting torch or replacing your current one, there are a few things you need to consider in order to get the best one for your project. *minimum of one 350 cu. A chemical reaction occurs when oxygen contacts metal. Acetylene tips are manufactured with four or six preheat holes and are produced to allow light, medium, and heavy preheats for. In order to comfortably and safely see the flame when welding or cutting, welding goggles must be worn. Web medium preheat tip with two milled flat sides.Oxy Acetylene Tip Chart

Oxyacetylene Torch Settings Chart

Oxy Acetylene Victor Welding Tip Chart

Oxy Acetylene Cutting Torch Settings Chart A Visual Reference of

SÜA Oxy/Acetylene Cutting Tips Replacement for 6290 Select Qtty and

Oxy Acetylene Welding Rod Chart

How Does The Oxy Acetylene Cutting Torch Work? Tools Focus

Oxyacetylene Cutting Pressure Chart

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

Oxyacetylene Cutting Pressure Chart

Web Either Oxyacetylene Or Oxypropane Works Well For Torch Cutting.

The Recommended Setting Is For The Fuel Gas Regulator To Be Set At 10 Psig And The Oxygen Regulator At 45 Psig.

Retro Systems 430 Clay Valley Center, Ks 67147.

Arguably One Of The Most Important Components That Will Affect Both Of These Is Your Cutting Tip Choice.

Related Post: