Oxy Acetylene Cutting Pressure Chart

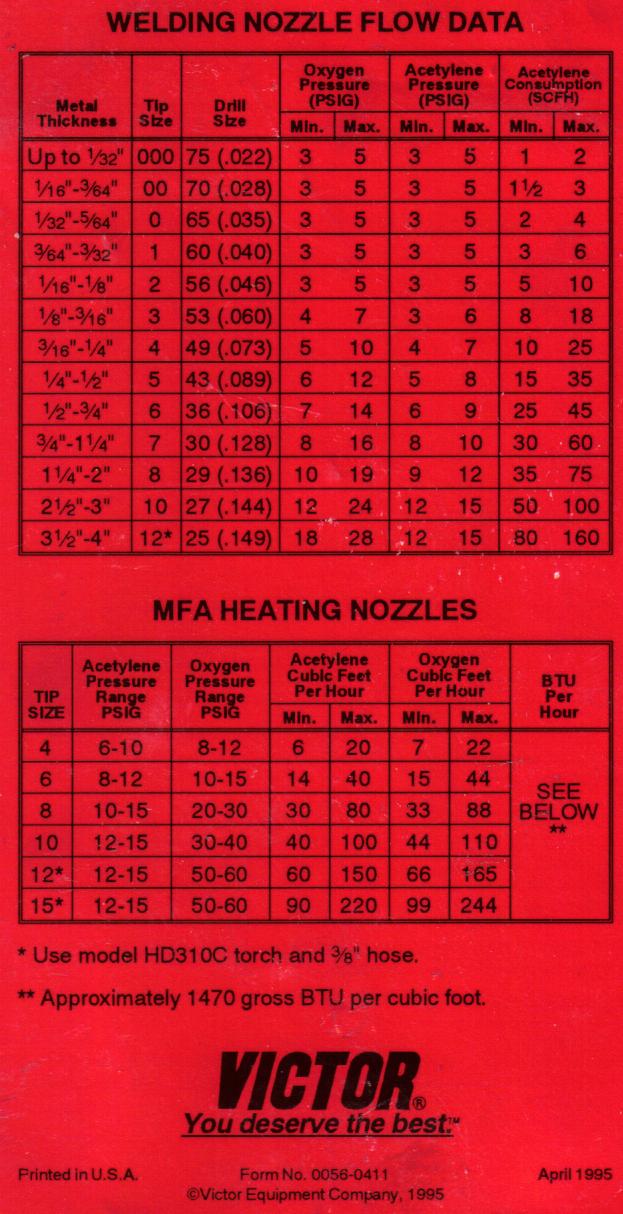

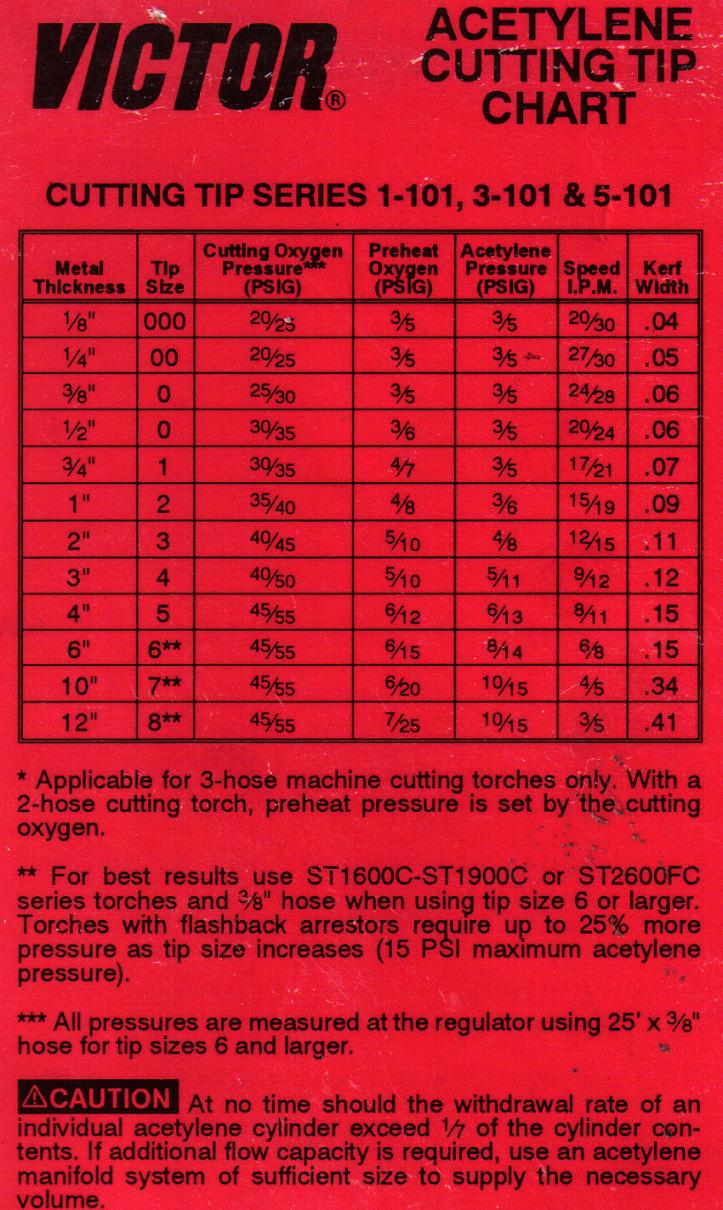

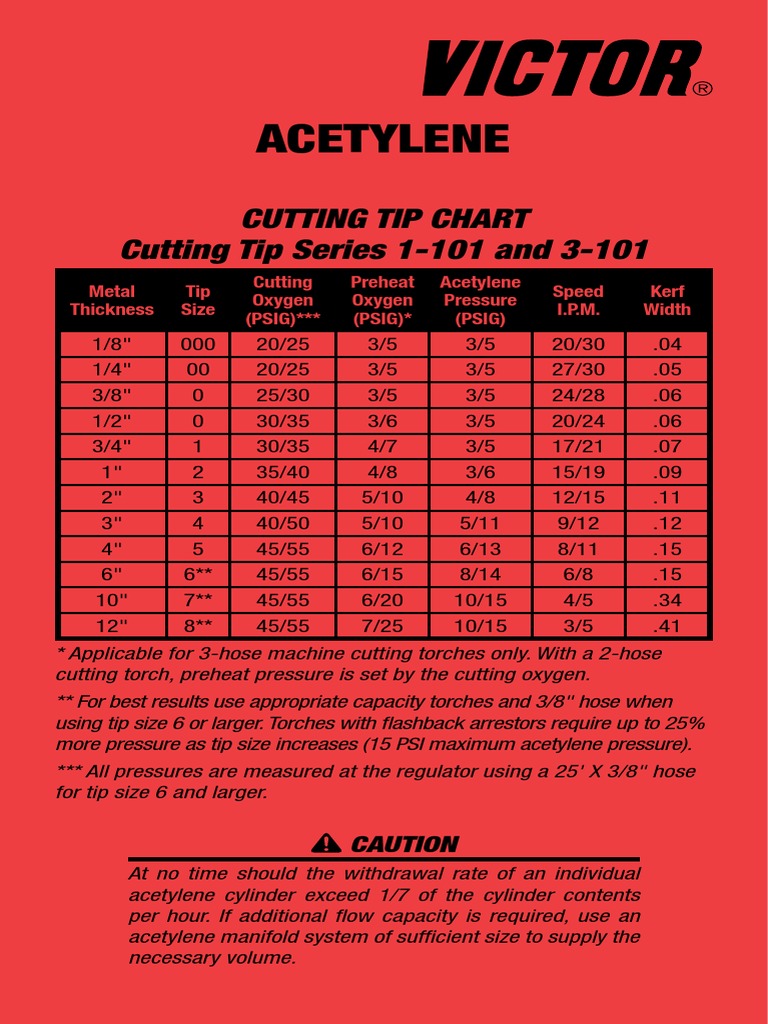

Oxy Acetylene Cutting Pressure Chart - Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Low priceunbelievable pricebest sellersget a gift on temu · adjust regulator p/a screws to tip pressure settings. Web cutting heating brazing correct pressure setting charts. Here is a chart for material thickness, tip size, and. Web acetylene pressure temperature oxygen pressure 355. For cutting 1/4 the recommended tip size is a 00. Generally, the oxygen pressure should be set. Shop our huge selectionread ratings & reviewsshop best sellersfast shipping Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Incorrect pressure can increase the risk of flashback and make flame adjustment difficult. Web setting the correct working pressures. Low priceunbelievable pricebest sellersget a gift on temu Hose for size 4 and larger. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. · separately and slowly open the oxygen and acetylene cylinder valves. Web regulator pressures are for 50 ft (13 m) or less of 3/8 in. If more than 100 ft (31 m). Web to set up an oxy acetylene torch,. Web an oxy acetylene mixture burns the hottest, somewhere around 5800 degrees, and that's what this article will be about: Adjust to the correct flame setting. If more than 100 ft (31 m). Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Web oxy acetylene welding set up and pressure settings chart : Web setting the correct working pressures. Web cutting heating brazing correct pressure setting charts. Shop our huge selectionread ratings & reviewsshop best sellersfast shipping Web friday, 11th december 2020. Web regulator pressures are for 50 ft (13 m) or less of 3/8 in. Web · stand away from front of regulator. Increase regulator pressures if longer hose or smaller i.d. The low fuel gas pressure is applicable when using harris universal pressure mixing systems. Shop our huge selectionread ratings & reviewsshop best sellersfast shipping · adjust regulator p/a screws to tip pressure settings. Web cutting heating brazing correct pressure setting charts. Web · stand away from front of regulator. Web acetylene pressure temperature oxygen pressure 355. Hose for size 4 and larger. If more than 100 ft (31 m). Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Web setting the correct working pressures. Generally, the oxygen pressure should be set. Hose for size 4 and larger. Here is a chart for material thickness, tip size, and. Web the oxygen pressure typically ranges from 30 to 40 psi (pounds per square inch), while the acetylene pressure should be set between 5 and 15 psi. Adjust to the correct flame setting. The low fuel gas pressure is applicable when using harris universal pressure mixing systems. · separately and. It’s important to note that these. Web cutting heating brazing correct pressure setting charts. Web acetylene pressure temperature oxygen pressure 355. For cutting 1/4 the recommended tip size is a 00. · separately and slowly open the oxygen and acetylene cylinder valves. Hose for size 4 and larger. Web the oxygen pressure typically ranges from 30 to 40 psi (pounds per square inch), while the acetylene pressure should be set between 5 and 15 psi. Make use of correct welding & cutting technique. · adjust regulator p/a screws to tip pressure settings. Web friday, 11th december 2020. Web an oxy acetylene mixture burns the hottest, somewhere around 5800 degrees, and that's what this article will be about: Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. · separately and slowly open the oxygen and acetylene cylinder valves. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and. Web oxy acetylene welding set up and pressure settings chart : Web cutting heating brazing correct pressure setting charts. The correct gas pressures are important. In order to comfortably and safely see the flame when. Hose for size 4 and larger. If more than 100 ft (31 m). First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Here is a chart for material thickness, tip size, and. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Generally, the oxygen pressure should be set. Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. The low fuel gas pressure is applicable when using harris universal pressure mixing systems.

Oxyacetylene Cutting Pressure Chart

Oxyacetylene Cutting Pressure Chart

Oxy Acetylene Cutting Pressure Chart vrogue.co

Oxy Acetylene Cutting Torch Settings Chart A Visual Reference of

Oxy Acetylene Cutting Pressure Chart

oxyacetylene regulator pressures?

Oxyacetylene Cutting Pressure Chart

Oxyacetylene Torch Settings Chart

Oxy Acetylene Victor Welding Tip Chart

Oxy Acetylene Cutting Pressure Chart Printable Templates Free

Web Setting The Correct Working Pressures.

Web Regulator Pressures Are For 50 Ft (13 M) Or Less Of 3/8 In.

Propane Is Not As Expensive.

Web The Oxygen Pressure Typically Ranges From 30 To 40 Psi (Pounds Per Square Inch), While The Acetylene Pressure Should Be Set Between 5 And 15 Psi.

Related Post: