Nonvalueadded Activities In A Process Design Can Be Eliminated By

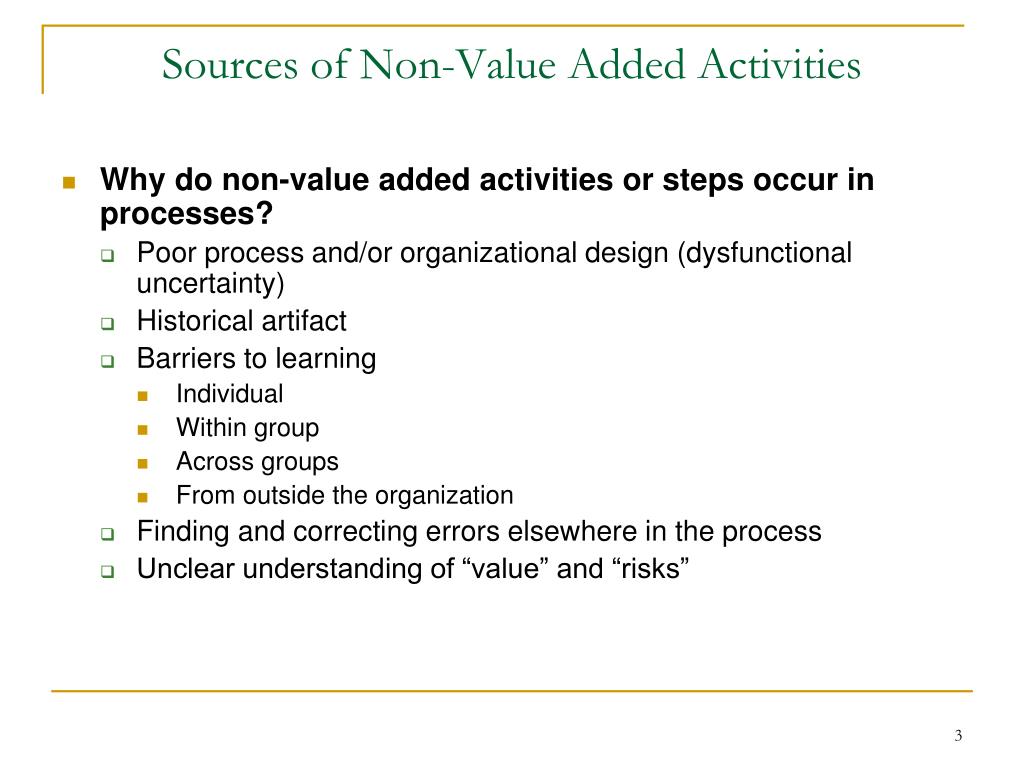

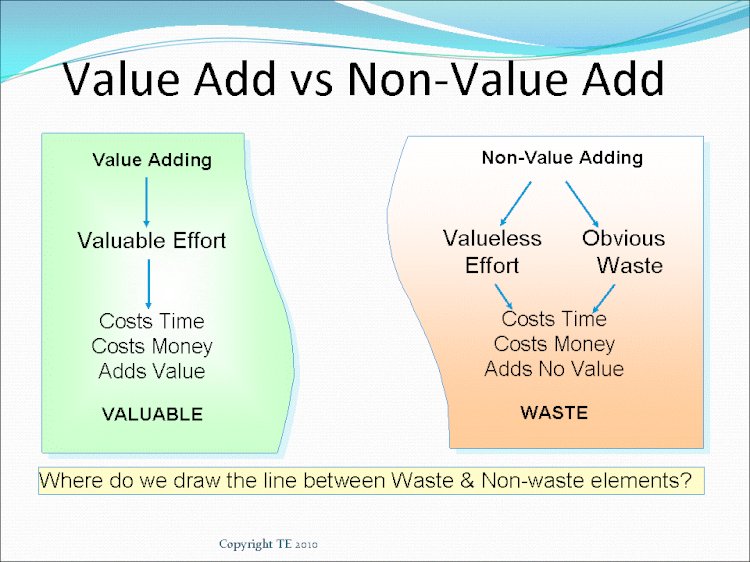

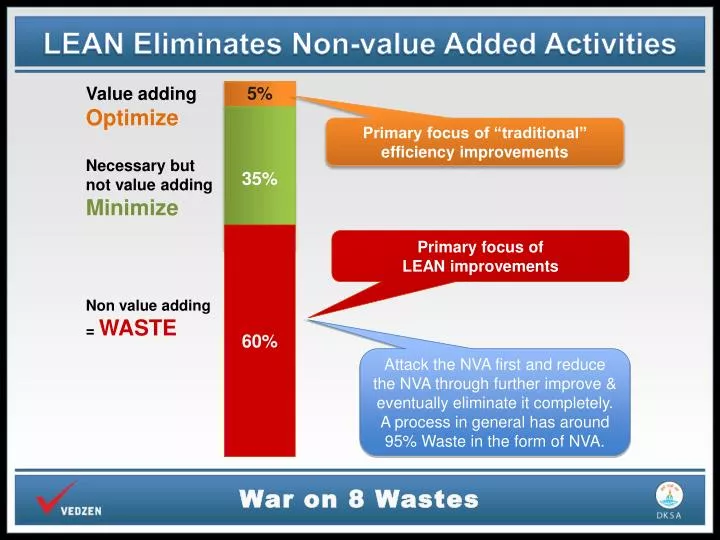

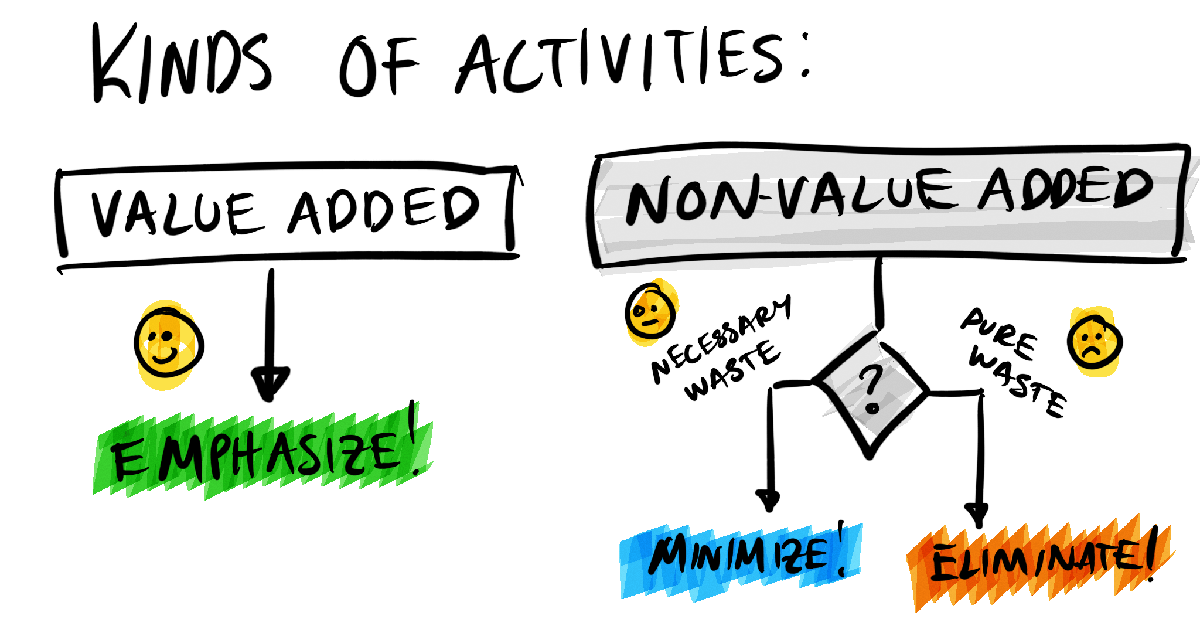

Nonvalueadded Activities In A Process Design Can Be Eliminated By - How much value adding activity is in your process? C) limiting the throughput of all. Web to minimize inputs, all waste must be eliminated. The elimination of nva activities is. It’s important to enhance value for every step of a process. Enhanced with ai, our expert help has broken down your problem into an. To improve any process, focus on eliminating those activities that don’t. B) limiting the throughput of all processes. limiting the throughput of all processes. A) increasing process boundaries b) using value stream mapping c) limiting the throughput. A) increasing process boundaries b) using value stream mapping c) limiting the throughput. Limiting the throughput of all processes. How much value adding activity is in your process? Limiting the throughput of all processes. B) using value stream mapping. Web waste is any activity that does not add value and can be eliminated without affecting the process. Your solution’s ready to go! The elimination of nva activities is. A) increasing process boundaries b) using value stream mapping c) limiting the throughput. Limiting the throughput of all processes. Web by reducing nva activities, organizations can reduce costs, increase customer satisfaction, and improve their bottom line. Enhanced with ai, our expert help has broken down your problem into an. They can be eliminated through. A) using value stream mapping. B) using value stream mapping. Enhanced with ai, our expert help has broken down your problem into an. One example of an nnva could be equipment that is outdated or a work method that is. Limiting the throughput of all processes. Your solution’s ready to go! Web in his blog, stop doing that: Waste in lean falls under 8 defined categories. C) limiting the throughput of all. One example of an nnva could be equipment that is outdated or a work method that is. A) increasing process boundaries b) using value stream mapping c) limiting the throughput. Web waste is any activity that does not add value and can be eliminated without affecting. They can be eliminated through. One example of an nnva could be equipment that is outdated or a work method that is. Enhanced with ai, our expert help has broken down your problem into an. Web to minimize inputs, all waste must be eliminated. To improve any process, focus on eliminating those activities that don’t. Web waste is any activity that does not add value and can be eliminated without affecting the process. It’s important to enhance value for every step of a process. Enhanced with ai, our expert help has broken down your problem into an. Limiting the throughput of all processes. Waste in lean falls under 8 defined categories. B) using value stream mapping. Limiting the throughput of all processes. B) limiting the throughput of all processes. Limiting the throughput of all processes. One example of an nnva could be equipment that is outdated or a work method that is. Limiting the throughput of all processes. It’s important to enhance value for every step of a process. To improve any process, focus on eliminating those activities that don’t. Web waste is any activity that does not add value and can be eliminated without affecting the process. They can be eliminated through. A) using value stream mapping. Limiting the throughput of all processes. It’s important to enhance value for every step of a process. Web by reducing nva activities, organizations can reduce costs, increase customer satisfaction, and improve their bottom line. Waste in lean falls under 8 defined categories. Limiting the throughput of all processes. It’s important to enhance value for every step of a process. Limiting the throughput of all processes. Web by reducing nva activities, organizations can reduce costs, increase customer satisfaction, and improve their bottom line. limiting the throughput of all processes. A) increasing process boundaries b) using value stream mapping c) limiting the throughput. To improve any process, focus on eliminating those activities that don’t. Limiting the throughput of all processes. B) limiting the throughput of all processes. How much value adding activity is in your process? A) using value stream mapping. Enhanced with ai, our expert help has broken down your problem into an. They can be eliminated through. The elimination of nva activities is. Waste in lean falls under 8 defined categories. Web to minimize inputs, all waste must be eliminated.

Which of the Following Is a Non Value Added Activity

PPT Process Improvement and Quality Management PowerPoint

7. Eliminating nonvalueadding activities using flow chart and

examples of value added and nonvalue added activities Презентация на

Non Value Adding, Value Adding Activity, 7 Wastes Work Area for

PPT LEAN Eliminates Nonvalue Added Activities PowerPoint

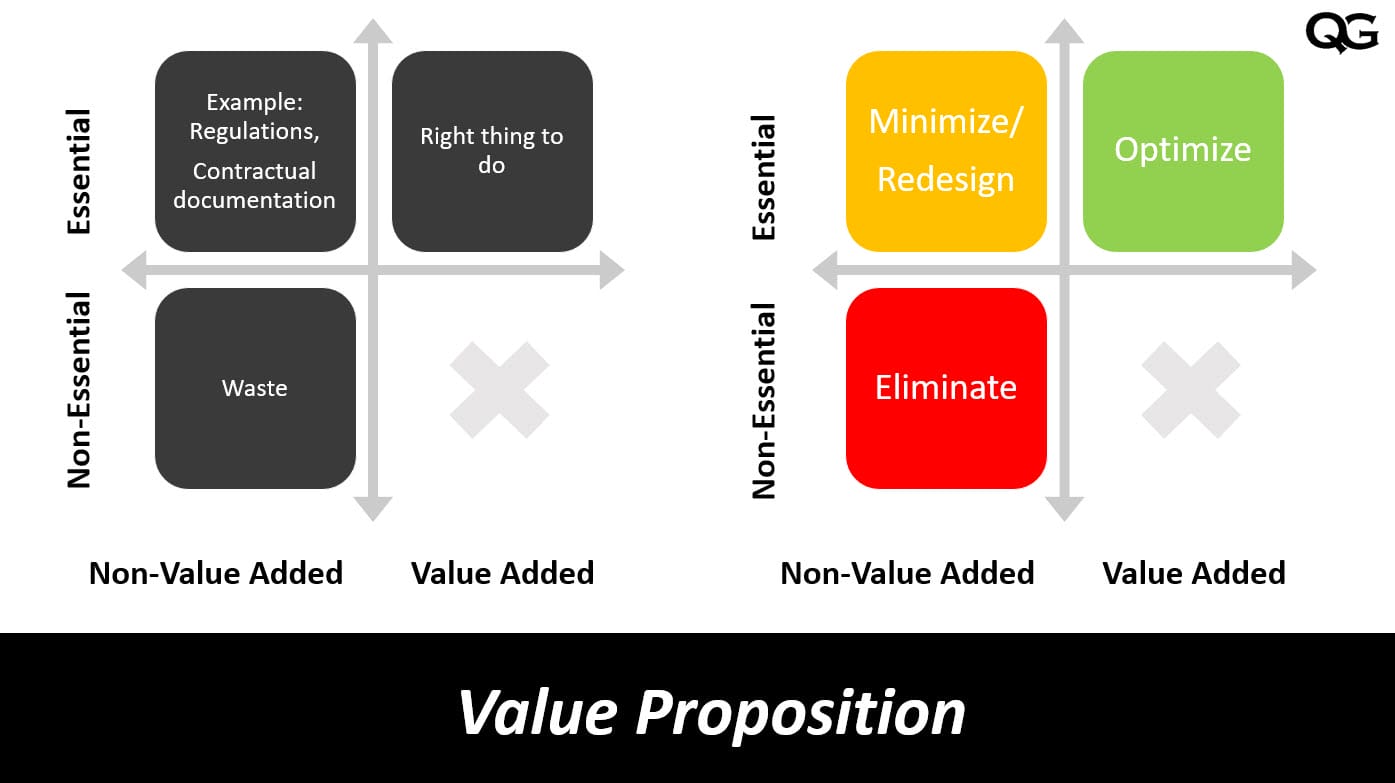

Value Added vs Nonvalue Added Activities Quality Gurus

Nonvalue Added (NVA) Lean Six Sigma Glossary Term

Fishbone diagram of causes of nonvalue add in the process. Download

Solved Nonvalueadded activities in a process design can be

In Terms Of Production Efficiency, There Are Seven Types Of Waste:

B) Using Value Stream Mapping.

Web In His Blog, Stop Doing That:

Web Waste Is Any Activity That Does Not Add Value And Can Be Eliminated Without Affecting The Process.

Related Post: