Nailing Pattern For Wall Sheathing

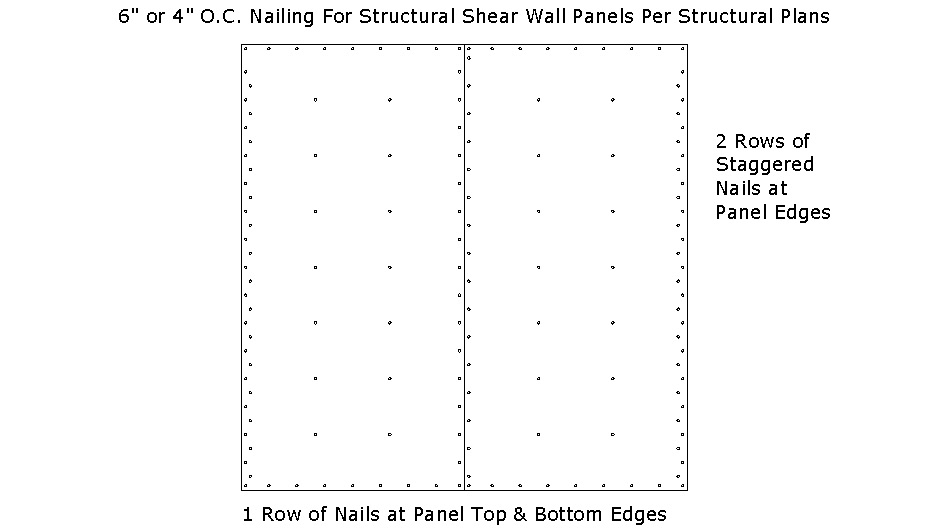

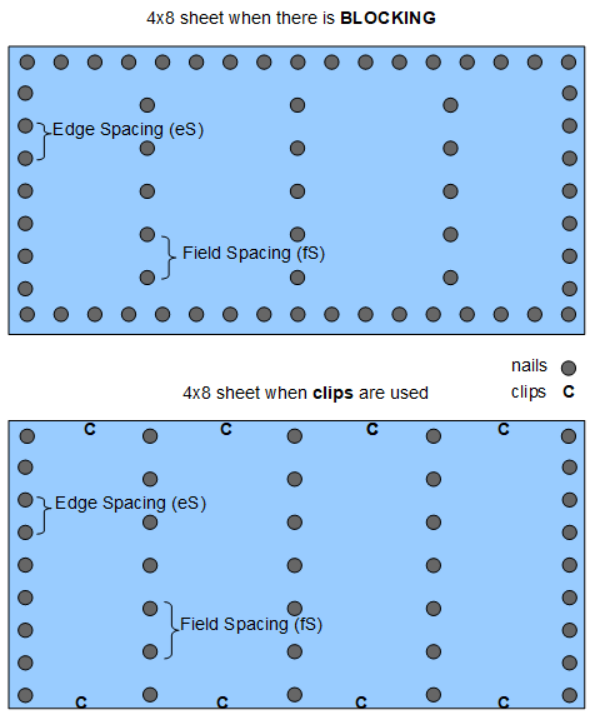

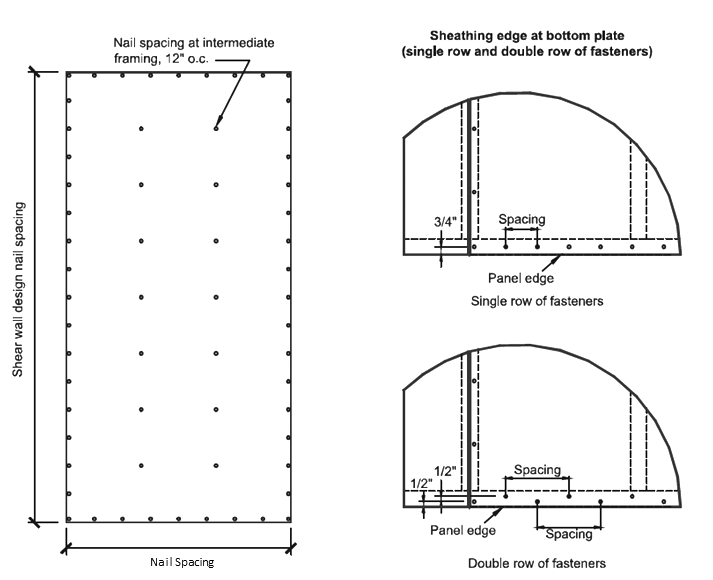

Nailing Pattern For Wall Sheathing - The universal building code specifies nailing patterns for structural wall sheathing of 12 inches on center in the field and 6 inches on center along the edges. Web this installation manual covers basic installation recommendations for zip system sheathing when used in both roof and wall applications. Ventilate the roof according to current building codes. Web straighten the wall. There are hundreds of different nailing patterns for tons of building materials ranging from drywall to trusses and everything in between. Cover roof sheathing with shingle underlayment felt. Web some building codes do provide prescriptive methods and nailing patterns but the shear and uplift values must be calculated to determine the schedule. Web wood structural panel sheathing shall be attached with 8d (2.5 x 0.131) nails not greater than 6 inches on center along panel edges and 12 inches on center at intermediate supports, and all panel joints shall occur over studs or blocking. Web the most critical nails are at the corners and along edges in contact with the framing. Properly fasten panels (including fastening and spacing hints) step 4: Web proper installation of apa rated sheathing for roof applications. Web for years, many of us simply installed sheathing horizontally & used a 16 penny nail slid between the sheets to help ensure there was room for expansion & to help reduce the swelling caused by an moisture that got between the two sheets. Properly fasten panels (including fastening and. The universal building code specifies nailing patterns for structural wall sheathing of 12 inches on center in the field and 6 inches on center along the edges. Refer to lateral force resisting systems section for screw requirements for shear wall applications. Install shingles according to manufacturer recommendations. Web a correct nailing pattern helps create a tight seal between sheathing panels,. Web nail the panels 3/8 of an inch from the edge when nailing near the outer dotted lines. Web take a deeper look into the proper quantity, placement, and techniques for nailing wall assemblies together with different types of nails. They hold the corner down and keep it from lifting. Not 2” or 3” or 4” but 3/8” from the. It’s the right size wall sheathing for raised heel truss system. Following these simple construction steps for roof sheathing will provide best performance and minimize complaint callbacks. Not 2” or 3” or 4” but 3/8” from the corner. Web for those who are uninitiated in the world of fasteners, a nailing pattern or fastener schedule is the national, state or. Web proper installation of apa rated sheathing for roof applications. Ventilate the roof according to current building codes. The nails should be about 3/8 in. Check the nailing surface is level. Doing so inside the stud bays allows you to easily remove. Web nail the panels 3/8 of an inch from the edge when nailing near the outer dotted lines. Web in this episode of shop class, builder ben bogie shares tips for laying out and securely nailing wall sheathing. When framing is done and you’re ready to install zip system sheathing on a house, you should first snap a level line. Place the nails 12 inches apart, using the circles and the squares as a reference marker. This is crucial for maintaining the building envelope’s integrity and protecting against water damage, mold, and rot. The universal building code specifies nailing patterns for structural wall sheathing of 12 inches on center in the field and 6 inches on center along the edges.. Install shingles according to manufacturer recommendations. Always check for a level. In the center of the sheet and 6 in. Always check for level nailing surface. Place the nails 12 inches apart, using the circles and the squares as a reference marker. In this article, i will look at each of these in detail. Doing so inside the stud bays allows you to easily remove. Cover roof sheathing with shingle underlayment felt. They hold the corner down and keep it from lifting. Web the most critical nails are at the corners and along edges in contact with the framing. Web for those who are uninitiated in the world of fasteners, a nailing pattern or fastener schedule is the national, state or regional building code allowances for fastening specific materials. In this article, i will look at each of these in detail. Place the nails 12 inches apart, using the circles and the squares as a reference marker. When framing. When framing is done and you’re ready to install zip system sheathing on a house, you should first snap a level line on each wall to ensure your first course of panels is straight. Properly fasten panels (including fastening and spacing hints) step 4: Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. Web in this episode of shop class, builder ben bogie shares tips for laying out and securely nailing wall sheathing. Check the nailing surface is level. In the center of the sheet and 6 in. Install shingles according to manufacturer recommendations. For nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Web wood structural panel sheathing shall be attached with 8d (2.5 x 0.131) nails not greater than 6 inches on center along panel edges and 12 inches on center at intermediate supports, and all panel joints shall occur over studs or blocking. Use 8d or similar nails and, from the inside of the stud bays*, tack the bottom plate to the deck at intervals adequate to straighten and retain the plate position. Not 2” or 3” or 4” but 3/8” from the corner. It’s the right size wall sheathing for raised heel truss system. The nails should be about 3/8 in. Web a correct nailing pattern helps create a tight seal between sheathing panels, minimizing gaps where moisture can penetrate. Can windstorm be used with raised heel (energy) truss systems? Refer to lateral force resisting systems section for screw requirements for shear wall applications.Roof Framing Geometry Shear Wall Plywood Nailing & Structural Issues

Shear Walls, The Basics JLC Online

Plywood Sheathing Nails Nail Ftempo

Plywood Sheathing Nailing Pattern Nail Ftempo

Wall Sheathing Nailing Pattern Timber Structures / Estruturas de Ma…

Plywood Sheathing Nailing Pattern Nail Ftempo

Structural Shear Wall Nailing in Commercial and Residential Framing

Plywood Sheathing Nailing Pattern Nail Ftempo

Nails for Wall Sheathing

Plywood Sheathing Nailing Pattern Nail Ftempo

Web Some Building Codes Do Provide Prescriptive Methods And Nailing Patterns But The Shear And Uplift Values Must Be Calculated To Determine The Schedule.

Web Take A Deeper Look Into The Proper Quantity, Placement, And Techniques For Nailing Wall Assemblies Together With Different Types Of Nails.

Web Straighten The Wall.

Always Check For A Level.

Related Post: