Mould Design

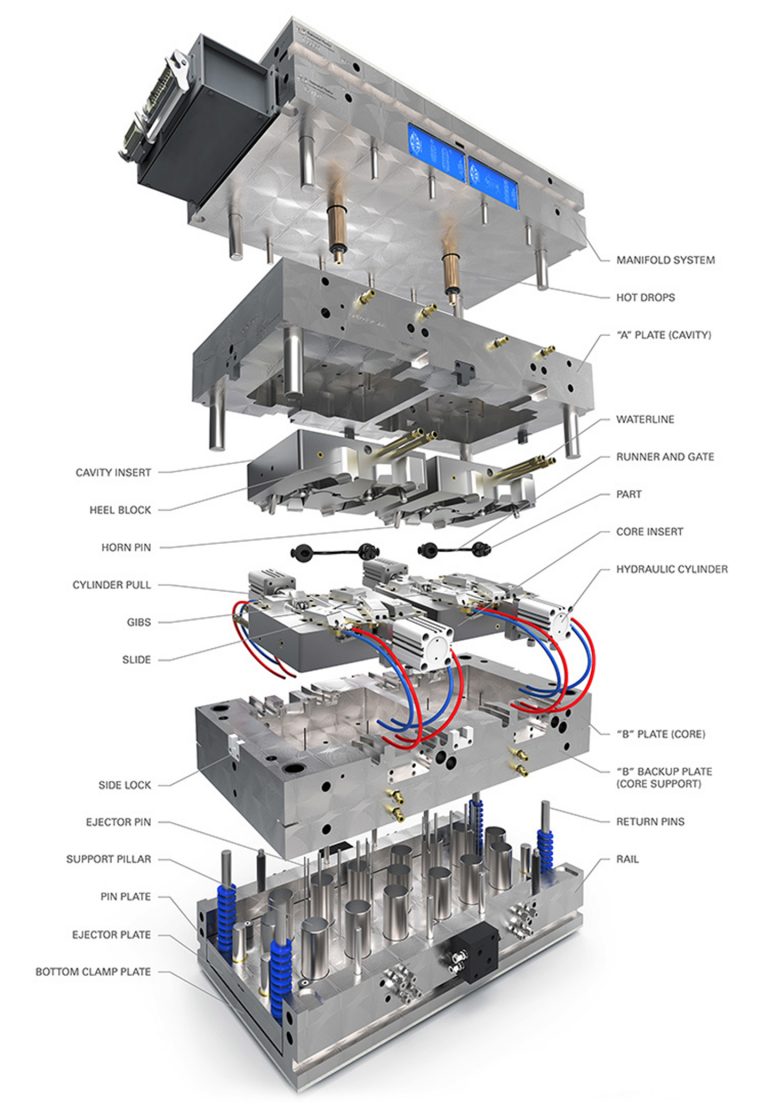

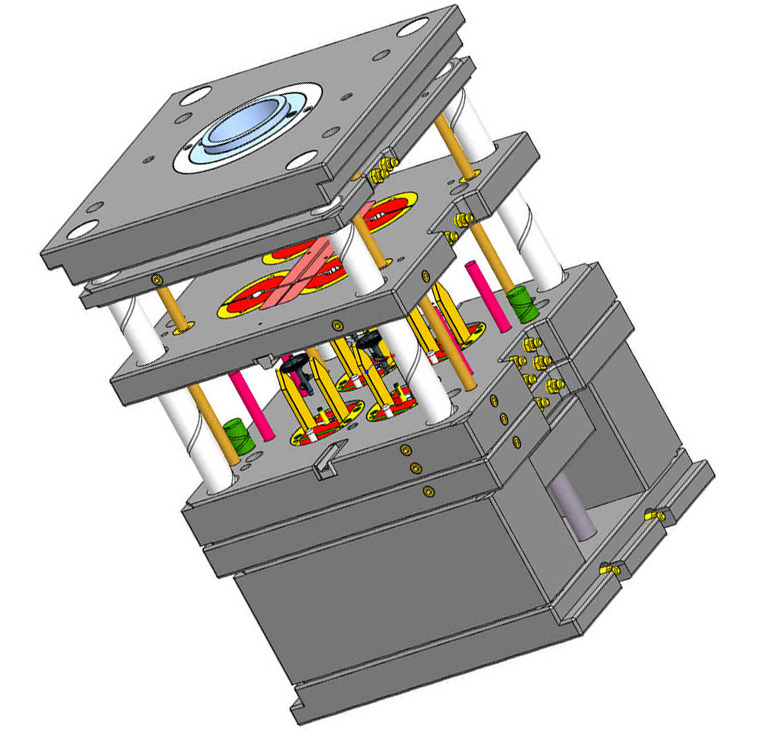

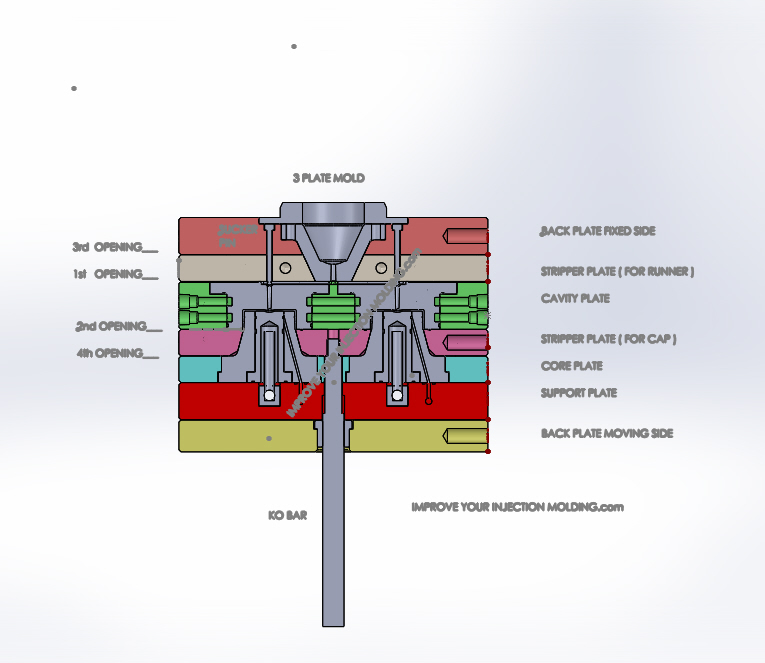

Mould Design - Here are some reasons why design is important for injection molding. Ccm quality management system certified to iso 13485:2016. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. Mold design has great impact on productivity and part quality, directly affecting the profitability of the molding operation. Web injection mold standard, mold series, common mold steels and applications, drawing format and standards, geometry format, construction, and standards. Fcm quality management system certified to iso 9001:2015. Web the process taken when designing a mold depends on the plastic part to be molded. Web designing and developing custom molds as well as plastic injection molding of parts, setting us apart from other companies in this market. Web fundamentals of injection mold design. Discussions follow featuring the foundations of each system and how they all affect the formation of the plastic part and the final part quality. Request a quote today to get started. Web your top core design company. Web using the authentic mold wizard library, besides adding standard mold components, students will be able to customize them to meet the dimensional requirements. Web designing and developing custom molds as well as plastic injection molding of parts, setting us apart from other companies in this market.. The course begins by identifying the five key systems of a mold: The design of the mold, as well as the part being molded, has a significant impact on the success of the process. Request a quote today to get started. The success of a mold manufacturer boils down to its ability to deliver high quality products at the. Web. Web reduce tool development time by reusing your company's standards, including: How it works, design principles, materials, and quality systems. Here are some reasons why design is important for injection molding. Accelerate the mold design process by standardizing components. The course begins by identifying the five key systems of a mold: Web a few key mold design strategies can go a long way in improving your mold building operations and customer support. Web plastic injection molding company with 22+ years of experience. Web injection mold standard, mold series, common mold steels and applications, drawing format and standards, geometry format, construction, and standards. For the full guide, check out the links below.. • from cad drawings to prototyping, to production: Zillow has 25 photos of this $509,990 3 beds, 2 baths, 1,805 square feet condo home located at 7557 laureate blvd unit 6307, orlando, fl 32827 built in 2024. Mold design has great impact on productivity and part quality, directly affecting the profitability of the molding operation. • do you have a. Web the following information is an overview of the most important elements for injection molded parts and represents both general injection mold design best practices and decades of personal experience. Web using the authentic mold wizard library, besides adding standard mold components, students will be able to customize them to meet the dimensional requirements. Web reduce tool development time by. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. 7557 laureate blvd unit 6307. Web your top core design company. • from cad drawings to prototyping, to production: The design of the mold, as well as the part being molded, has a significant impact on the success of the. We offer custom product design, plastic injection mold design, metal stamping die design with tooling, production and engineering support. Web the following information is an overview of the most important elements for injection molded parts and represents both general injection mold design best practices and decades of personal experience. Web a few key mold design strategies can go a long. Web injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a specific shape or design. The success of a mold manufacturer boils down to its ability to deliver high quality products at the. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold. Web the process taken when designing a mold depends on the plastic part to be molded. The remainder of this article will discuss the interrelationships between injection molding tool design and part design. Request a quote today to get started. Let basilius assist with your injection molding project. The process begins with analyzing the plastic part, designing for manufacturing, cad,. They include channels for fill, cooling, vents for air, linear bearings, ejector pins and other features. The course begins by identifying the five key systems of a mold: The design of the mold, as well as the part being molded, has a significant impact on the success of the process. Ccm quality management system certified to iso 13485:2016. How it works, design principles, materials, and quality systems. Web the process taken when designing a mold depends on the plastic part to be molded. For the full guide, check out the links below. Here are some reasons why design is important for injection molding. Plastic manufacturers in florida offering. Repurpose project templates and adapt proven designs to new molds. Web the most fundamental knowledge needed for any designer faced with designing an injection molded part is understanding the basics of mold (also referred to as tool) design. Request a quote today to get started. Making the students capable of performing mold flow analysis using the dedicated easy fill advanced plugin is the highlight of the course. Web fundamentals of injection mold design. Web reduce tool development time by reusing your company's standards, including: Download for free the pdf version of the injection molding manufacturing and design guide.

Lifter mold design in 2021 Mould design, Plastic injection molding

Anatomy of a Mold PTI Plastic Injection Molding

Injection Molding Mold Design Tutorial Mold design Guidance Upmold

Fifteen steps of molding design and design focus Gud Mould

Inhouse mold making design for precision plastics

Mold Design & Product development Supporting Company Upmold

What is mould design and manufacturing

Mold Design Tutorial Moldmaking Resource

3 Plate Mold Design For Plastic Injection Molding Leafly Mould Blog

Tutorials on Mould Designing An Introduction to Split Cavity Mould

Accelerate The Mold Design Process By Standardizing Components.

• Do You Have A Mold?

Web Plastic Injection Molding Company With 22+ Years Of Experience.

Seamless Transition By Providing Us With An Existing Mold For Production Of Your Parts.

Related Post: