Most Efficient Hho Generator Design

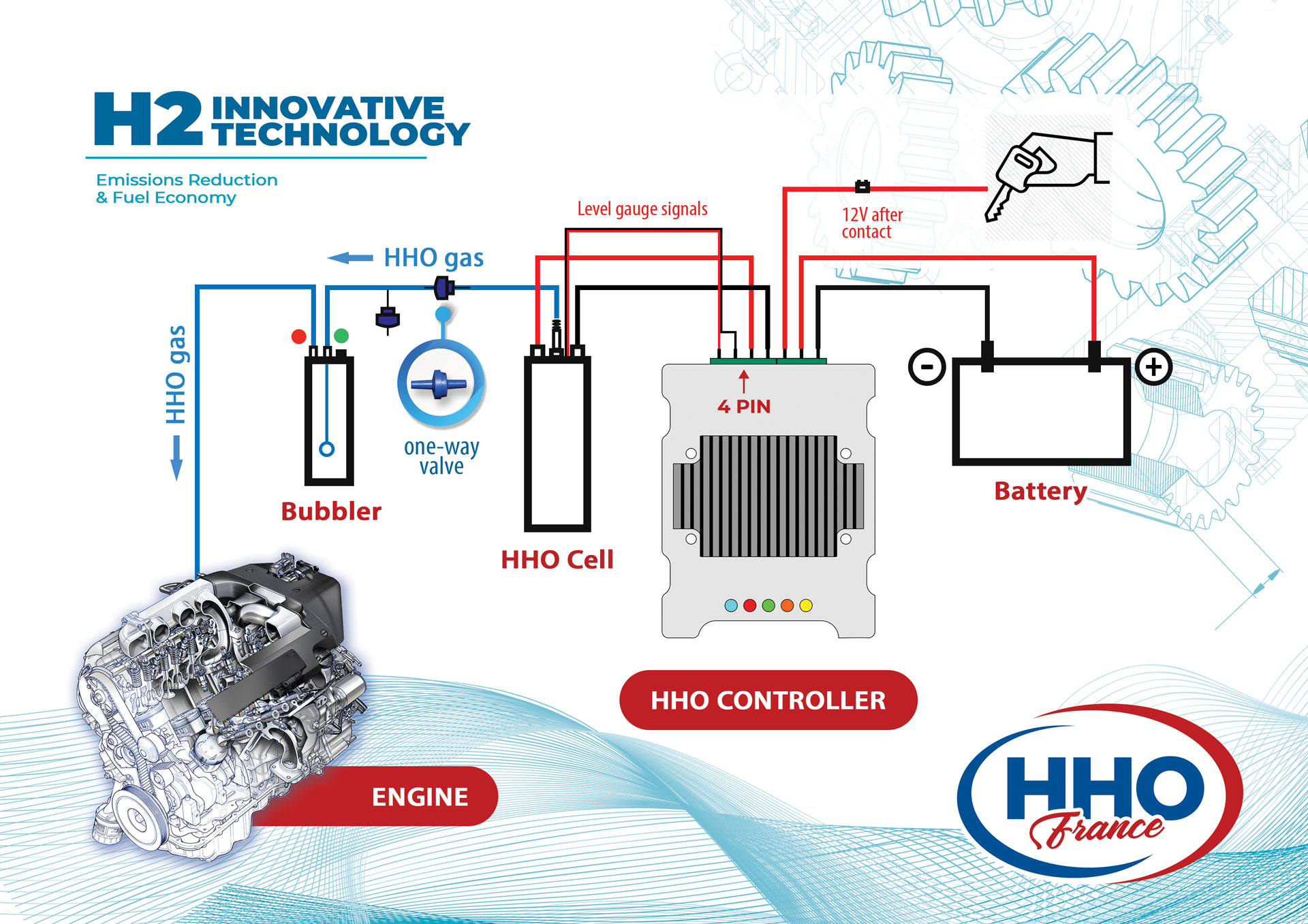

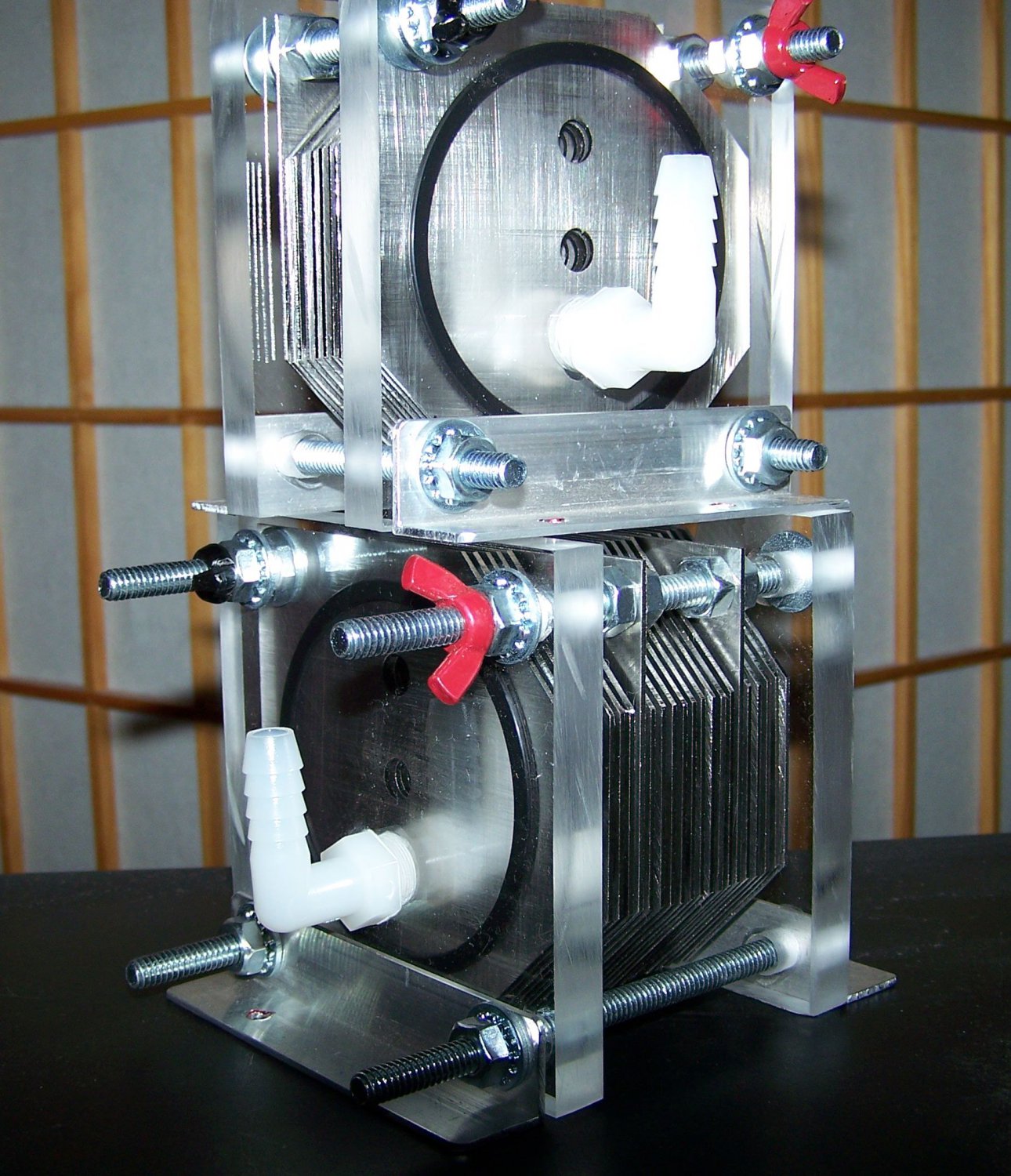

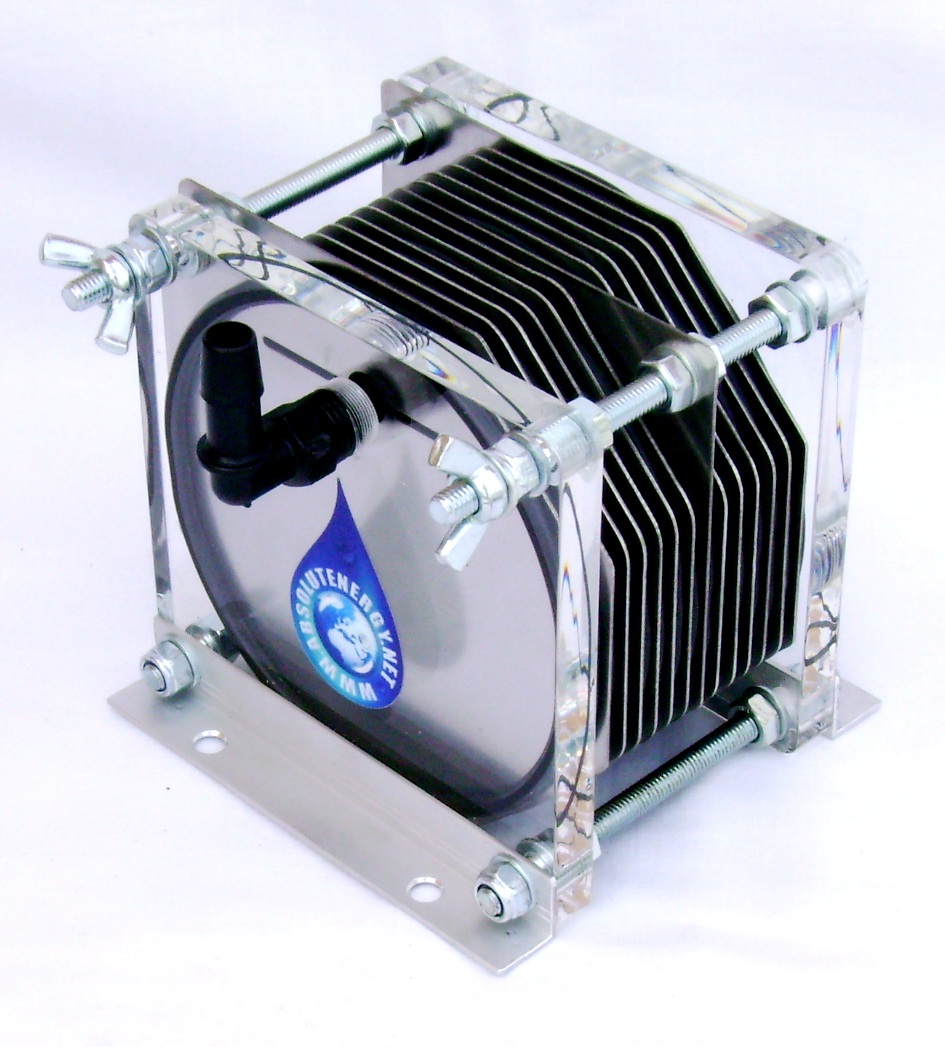

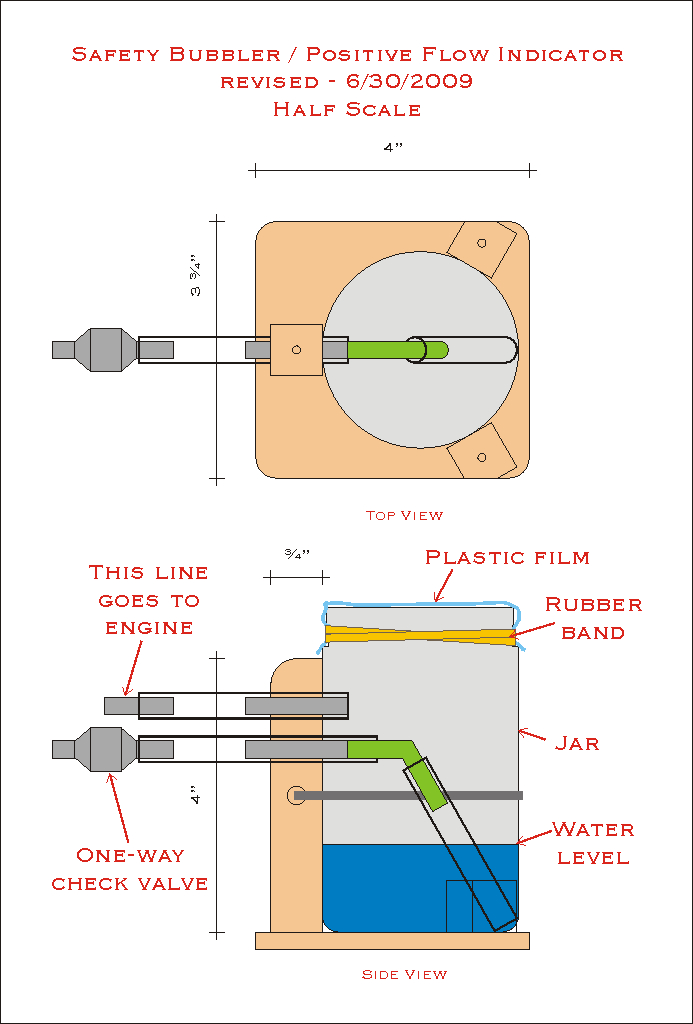

Most Efficient Hho Generator Design - Web the advantages of dry cell hho generators include i) waterless electrolysis, where only water is trapped between the cell plates; Web based on the results of the study, the best variation of hho generators is found in the hole plate electrode 2 with the required power of 180.78 watts and an efficiency of 63.8%. Web the correct combination of a hydrogen generator and an electronic controller is required to achieve maximum fuel saving results. Web in this paper we present a detailed design study of a novel apparatus for safely generating hydrogen (h 2) on demand according to a novel method, using a controlled chemical reaction between water (h 2 o) and sodium (na) metal that yields hydrogen gas of sufficient purity for direct use in fuel cells without risk of contaminating. Web the purpose of this study was to determine the effect of electrodes, current strength, and concentration of nahco3 on the hho gas generator output. This research work seeks to design and develop an oxyhydrogen generator for hho gas production. Select generator from the chart below. In this study, magnetic field lines were defined effectively by field simulation. Their results showed that nitrogen oxides (nox), carbon monoxide (co), and fuel consumption were reduced by 50%, 20%, and 30%, respectively, with an addition of hho gas [14,15]. The yacht has a 62'.4 (19 meter) beam and a 17'3 (5.25 meter) draft. Web to achieve more efficiency for hydrogen production, the magnetic field is applied to the electrolysis cells. Web the advantages of dry cell hho generators include i) waterless electrolysis, where only water is trapped between the cell plates; The lowest co emission levels were in the 2 holes variation, namely 4.01%, and the lowest hc emission levels were in the. 1 outdoor unit and 2 indoor units The generated hydrogen is then injected into the air stream of the vehicle to improve combustion efficiency and fuel economy. Web this research aimed at selecting the most appropriate geometrical design of a hydroxyl booster dry cell, a device which operates on the principles of electrolysis to produce hydroxyl gas commonly referred to. Web we designed an hho generator using different electrode materials and investigated the impact of electrolyte molarity, and plate counts, which determine the efficiency and gas generation capacity of the device. Hydrogen generator consists of feed chamber functioning as the reservoir for electrolyte feed water that can hold water up to 5 liters. Web a predictive approach to optimize a. 1 outdoor unit and 2 indoor units Web use an at pc power supply, a constant current source, and an electrolysis setup to make your own hho generator. In this study, magnetic field lines were defined effectively by field simulation. Hho electrode generator material made of aluminum and brass. The generated hydrogen is then injected into the air stream of. The generated hydrogen is then injected into the air stream of the vehicle to improve combustion efficiency and fuel economy. 1 unit commercial air conditioner (assisted by chilled water) (6 hp): Web based on the results of the study, the best variation of hho generators is found in the hole plate electrode 2 with the required power of 180.78 watts. Web in this paper we present a detailed design study of a novel apparatus for safely generating hydrogen (h 2) on demand according to a novel method, using a controlled chemical reaction between water (h 2 o) and sodium (na) metal that yields hydrogen gas of sufficient purity for direct use in fuel cells without risk of contaminating. Web the. Hho electrode generator material made of aluminum and brass. Web the correct combination of a hydrogen generator and an electronic controller is required to achieve maximum fuel saving results. In a combustion engine, high pressure products of combustion expand through a turbine or a piston in order to generate power. Web the importance of mechanical design is focused on achieving. The lowest co emission levels were in the 2 holes variation, namely 4.01%, and the lowest hc emission levels were in the 4 holes variation, namely 892 ppm. Select generator from the chart below. Web in this paper we present a detailed design study of a novel apparatus for safely generating hydrogen (h 2) on demand according to a novel. Web hysata’s overall electrolyzer system has been designed for ease of manufacturing, scaling and installation, delivering 95 percent overall system efficiency, equivalent to 41.5 kwh/kg, compared to. This research work seeks to design and develop an oxyhydrogen generator for hho gas production. Web use an at pc power supply, a constant current source, and an electrolysis setup to make your. Their results showed that nitrogen oxides (nox), carbon monoxide (co), and fuel consumption were reduced by 50%, 20%, and 30%, respectively, with an addition of hho gas [14,15]. The generated hydrogen is then injected into the air stream of the vehicle to improve combustion efficiency and fuel economy. Web in this paper we present a detailed design study of a. Web hysata’s overall electrolyzer system has been designed for ease of manufacturing, scaling and installation, delivering 95 percent overall system efficiency, equivalent to 41.5 kwh/kg, compared to. Web based on the results of the study, the best variation of hho generators is found in the hole plate electrode 2 with the required power of 180.78 watts and an efficiency of 63.8%. Web the purpose of this study was to determine the effect of electrodes, current strength, and concentration of nahco3 on the hho gas generator output. In this study, magnetic field lines were defined effectively by field simulation. Web the importance of mechanical design is focused on achieving efficient use of the energy provided to the cell that allows the h 2 and o 2 molecules to be separated without overheating the cell, evaporating the water, loss of current due to the geometry of the electrodes (foucault current). The lowest co emission levels were in the 2 holes variation, namely 4.01%, and the lowest hc emission levels were in the 4 holes variation, namely 892 ppm. The generated hydrogen is then injected into the air stream of the vehicle to improve combustion efficiency and fuel economy. Web based on the results of the study, the best variation of hho generators is found in the hole plate electrode 2 with the required power of 180.78 watts and an efficiency of 63.8%. Hho electrode generator material made. Web the advantages of dry cell hho generators include i) waterless electrolysis, where only water is trapped between the cell plates; Web in this paper we present a detailed design study of a novel apparatus for safely generating hydrogen (h 2) on demand according to a novel method, using a controlled chemical reaction between water (h 2 o) and sodium (na) metal that yields hydrogen gas of sufficient purity for direct use in fuel cells without risk of contaminating. 1 unit commercial air conditioner (assisted by chilled water) (6 hp): Web pure hydrogen fuel cell generator (5 kw type, hot water output temperature at 70°c): Web use an at pc power supply, a constant current source, and an electrolysis setup to make your own hho generator. 1 outdoor unit and 2 indoor units The lowest co emission levels were in the 2 holes variation, namely 4.01%, and the lowest hc emission levels were in the 4 holes variation, namely 892 ppm.

Schematic of the dry cell HHO generator. Download Scientific Diagram

Efficient hydrogen generators for affordable hydrogen production

Schematic of the dry cell HHO generator. Download Scientific Diagram

HHO Generator B1 » HHO France

One 21 Plate HHO DRY CELL Best HHO Generator

Hho Dry Cell Circuit Diagram

Hho The Most Efficient Hho Generator

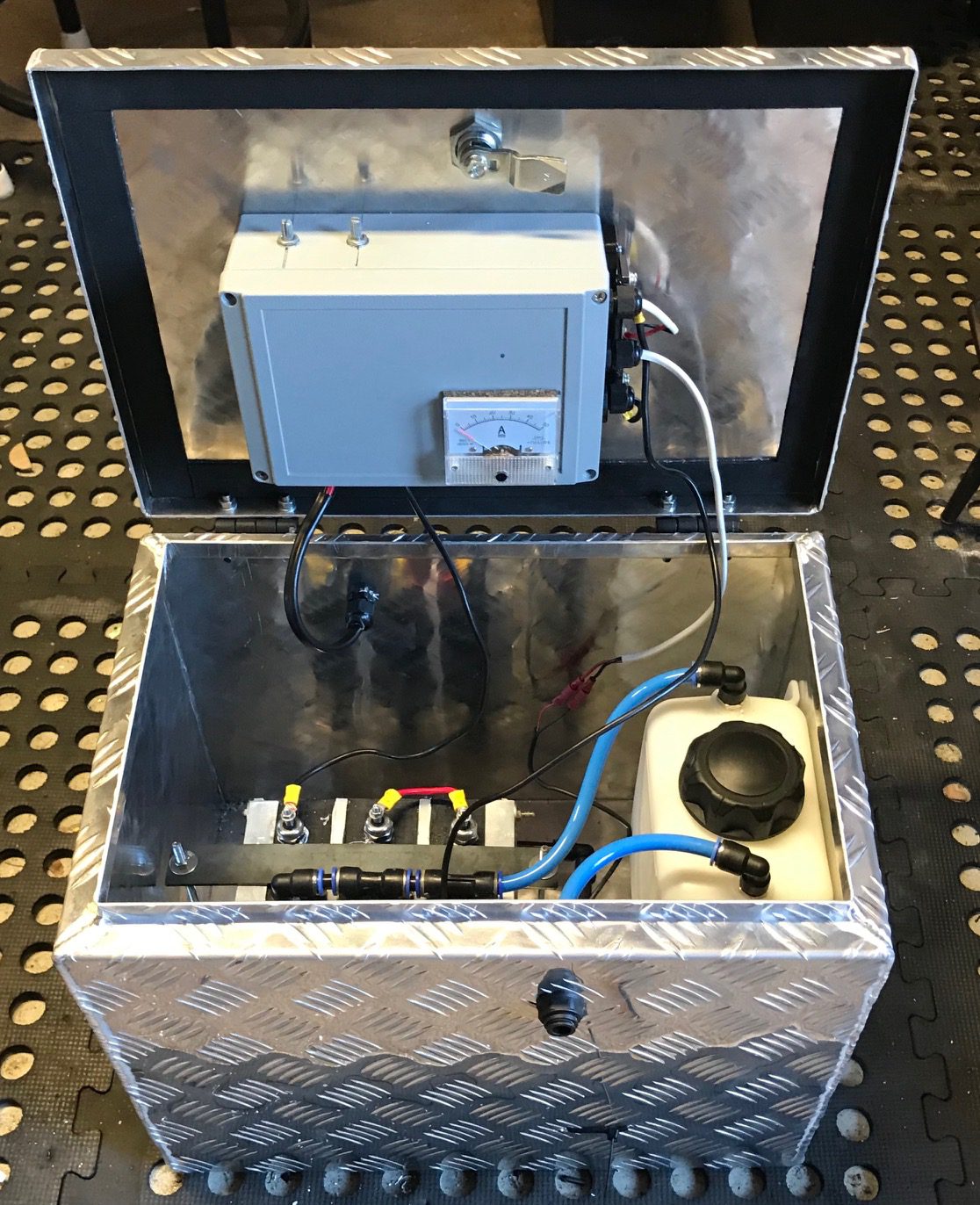

HHO Generator Plans postage 20 Hydrogen kit

HHO Generator Design. Download Scientific Diagram

Hho Most Efficient Hho Cell Design

Hho Electrode Generator Material Made Of Aluminum And Brass.

Web Measuring 389'9 (118.80 Meters), Project 821 Is The Largest Motor Yacht Ever To Launch In The Netherlands.

Select Generator From The Chart Below.

Key Parameters Consideredin This Study Includeelectrode Area, Electrodes Spacing, Electrodesurface Conditioning, And Electrode Configuration As Well As The Efficiency Of Thegenerator.

Related Post: