Most Effective Wind Turbine Blade Design

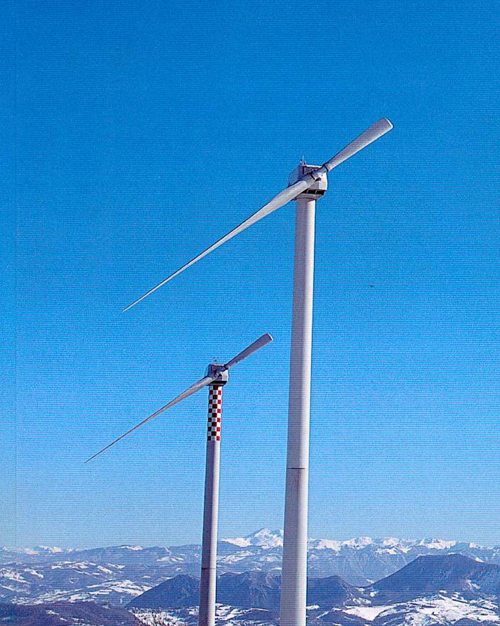

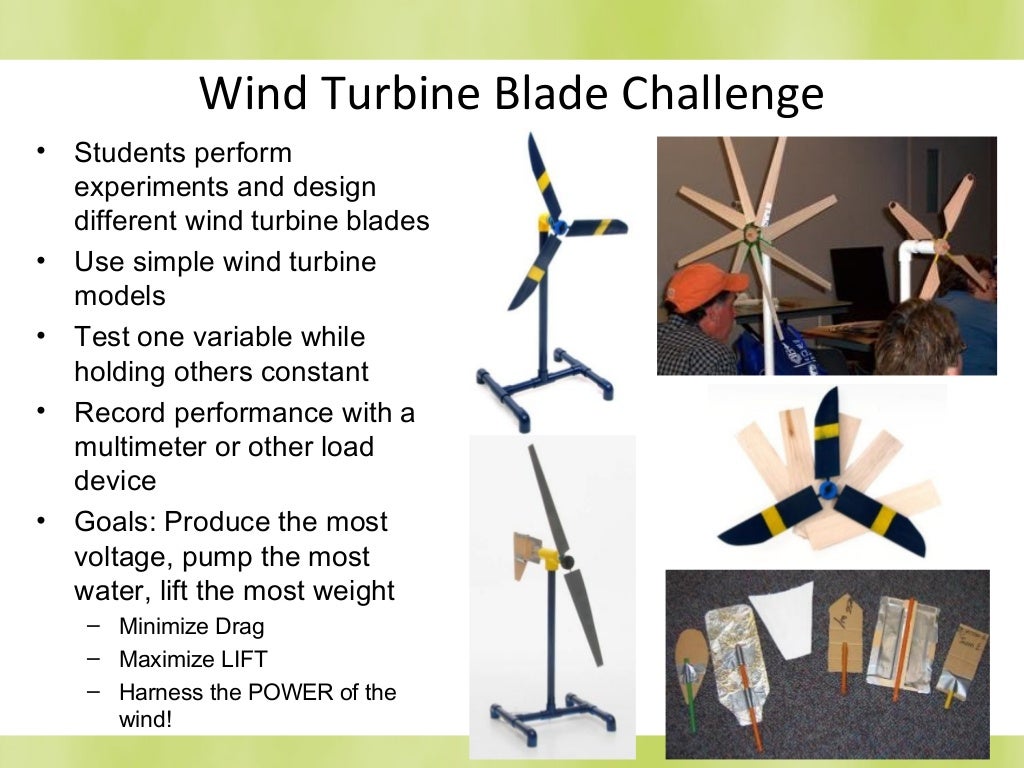

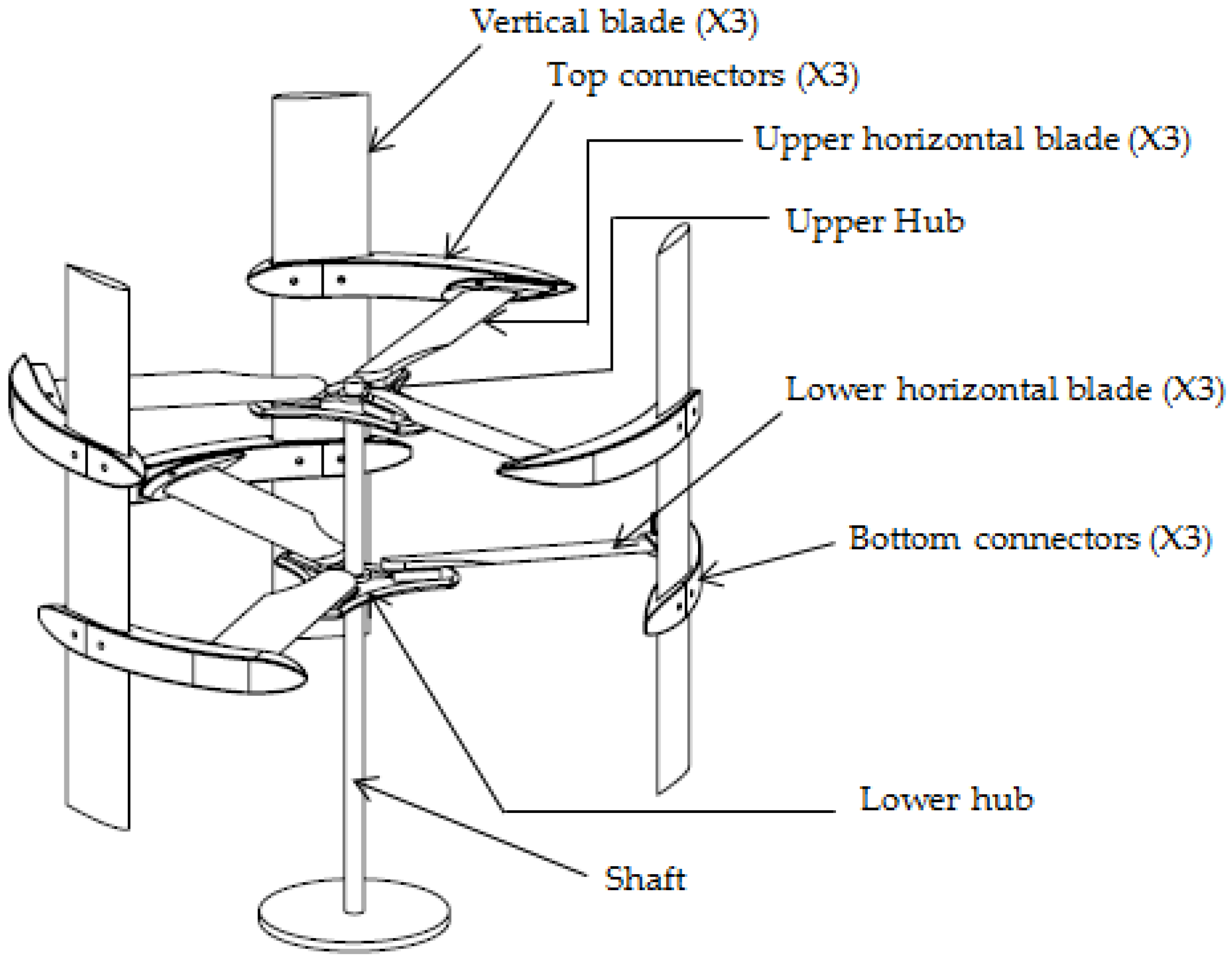

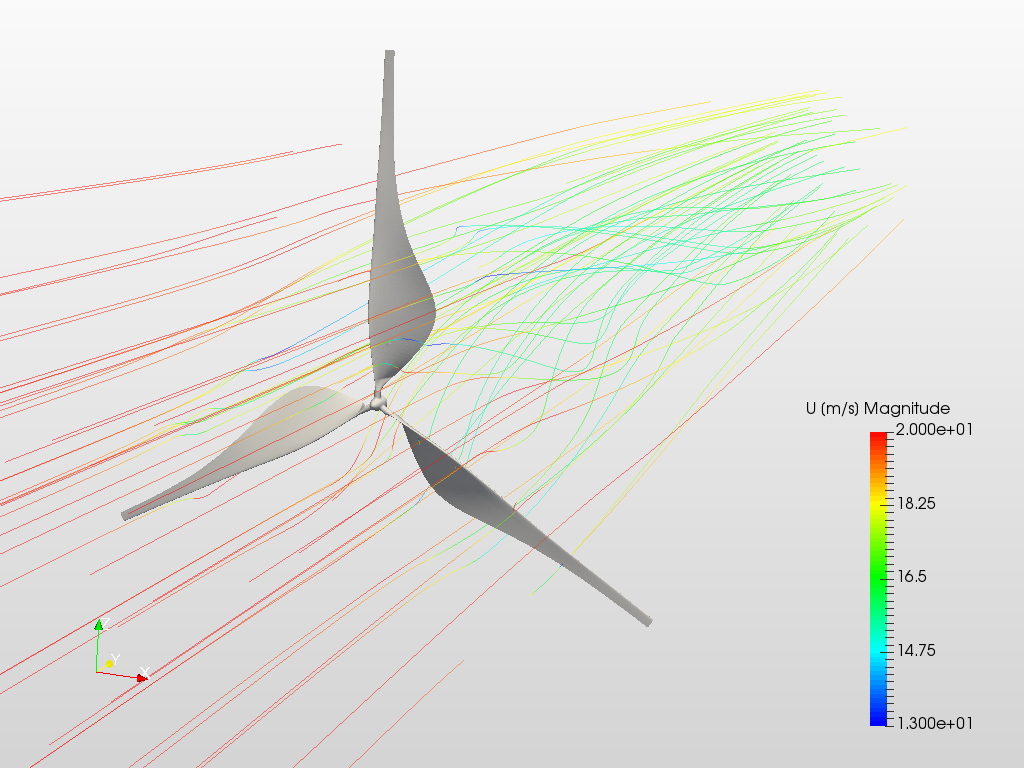

Most Effective Wind Turbine Blade Design - Web in this paper we analyzed the main features of vertical vawt and horizontal hawt axis wind turbines. Lm wind power’s technology plays a central role in the creation of each wind turbine blade type. Demonstrate a bionic design for wind turbine blades based on features of the wings and feathers of a bird. And reliability comes from experience. To increase the power generating capacity of a turbine, blades must grow in length (power captured by a turbine is proportional to the square of blade length). Web floating offshore wind turbines (fowts) experience unbalanced loads and platform motion due to the coupling of variable wind and wave loads, which leads to output power fluctuation and increased fatigue loads. This paper introduces a new blade pitch control strategy for fowts that combines fuzzy logic with a linear quadratic regulator. This makes full use of the characteristics of lightweight, high strength, and strong corrosion. Larger swept area ⇒ larger power capture. Web hawt’s are generally designed with three blades, as it is the most effective design in terms of cost per blade and electric power generation (“the performance evaluation of horizontal axis wind turbine torque and mechanical power generation affected by the number of. Web learn about wind power and how to optimize your wind turbine blade design with our online wind turbine simulator tool from simscale. Web floating offshore wind turbines (fowts) experience unbalanced loads and platform motion due to the coupling of variable wind and wave loads, which leads to output power fluctuation and increased fatigue loads. Wind power technology has an. Web in conventional wind turbines, the blades spin a shaft that is connected through a gearbox to the generator. In this article, we will delve into the world of wind turbine blade technology, exploring how design choices can enhance efficiency. Web gao et al. Demonstrate a bionic design for wind turbine blades based on features of the wings and feathers. To increase the power generating capacity of a turbine, blades must grow in length (power captured by a turbine is proportional to the square of blade length). Web the simplicity and functionality of the modular design and simulation system enabled it to be conveniently integrated with the parallel differential evolution algorithms that were used to produce an efficient blade configuration. In the initial part of the study the flow around two airfoil sections cut along the wing turbine blade and for a wind speed of 10m/s is simulated using cfd. Higher tower ⇒ higher wind speed because of vertical shear. Web gao et al. To increase the power generating capacity of a turbine, blades must grow in length (power captured. This makes full use of the characteristics of lightweight, high strength, and strong corrosion. Getting onshore or offshore wind energy at various speeds around the globe needs reliable turning blades. The reliability of wind blades comes from skills in producing them. Web the design process for wind turbine blades involves the use of computational fluid dynamics (cfd) codes, such as. Web in this paper we analyzed the main features of vertical vawt and horizontal hawt axis wind turbines. From the results, it was found that the stress. However, other turbine and blade shapes may be better designed for production and durability in certain environmental conditions. Getting onshore or offshore wind energy at various speeds around the globe needs reliable turning. Web the three blade turbine has been widely adopted as the most efficient design to meet environmental, commercial and economic constraints and therefore dominates today’s large scale wind turbine industry. However, other turbine and blade shapes may be better designed for production and durability in certain environmental conditions. In this article, we will delve into the world of wind turbine. Size grows more than power rating. The complex failure characteristics of the skin were studied in detail and a driving relationship was obtained. Getting onshore or offshore wind energy at various speeds around the globe needs reliable turning blades. In this article, we will delve into the world of wind turbine blade technology, exploring how design choices can enhance efficiency.. However, other turbine and blade shapes may be better designed for production and durability in certain environmental conditions. Today modern hawt use all the available progress in modern aviation engineering related to blades structure, pitch control, transmissions, and it. Larger swept area ⇒ larger power capture. Web the design process for wind turbine blades involves the use of computational fluid. In this article, we will delve into the world of wind turbine blade technology, exploring how design choices can enhance efficiency. However, other turbine and blade shapes may be better designed for production and durability in certain environmental conditions. Web in conventional wind turbines, the blades spin a shaft that is connected through a gearbox to the generator. Web the. Web the design process for wind turbine blades involves the use of computational fluid dynamics (cfd) codes, such as windse, to simulate wind turbine or wind farm performance, optimize designs, and quantify uncertainty. Claims of superior performance by alternate technologies accompanied by requests. Web the three blade turbine has been widely adopted as the most efficient design to meet environmental, commercial and economic constraints and therefore dominates today’s large scale wind turbine industry. From the results, it was found that the stress. 5 shows the design case of retired wind turbine blades used as structural materials in the marine field. Wind power technology has an important role in. Size grows more than power rating. Web gao et al. Web floating offshore wind turbines (fowts) experience unbalanced loads and platform motion due to the coupling of variable wind and wave loads, which leads to output power fluctuation and increased fatigue loads. To increase the power generating capacity of a turbine, blades must grow in length (power captured by a turbine is proportional to the square of blade length). In the initial part of the study the flow around two airfoil sections cut along the wing turbine blade and for a wind speed of 10m/s is simulated using cfd. This makes full use of the characteristics of lightweight, high strength, and strong corrosion. The reliability of wind blades comes from skills in producing them. Web the design optimization of the blades is the most important stage to maximize efficiency production. Aerodynamic characteristics of the blades are critical components that have a large influence on the performance of the turbine. Web design improvements to windpower turbine blades should increase their efficiency and performance, trim the cost of harvesting the wind, and keep it competitive with fossil fuels.

Wind Turbine Blade Design Engineering's Advice

Different Types Of Wind Turbine Blades

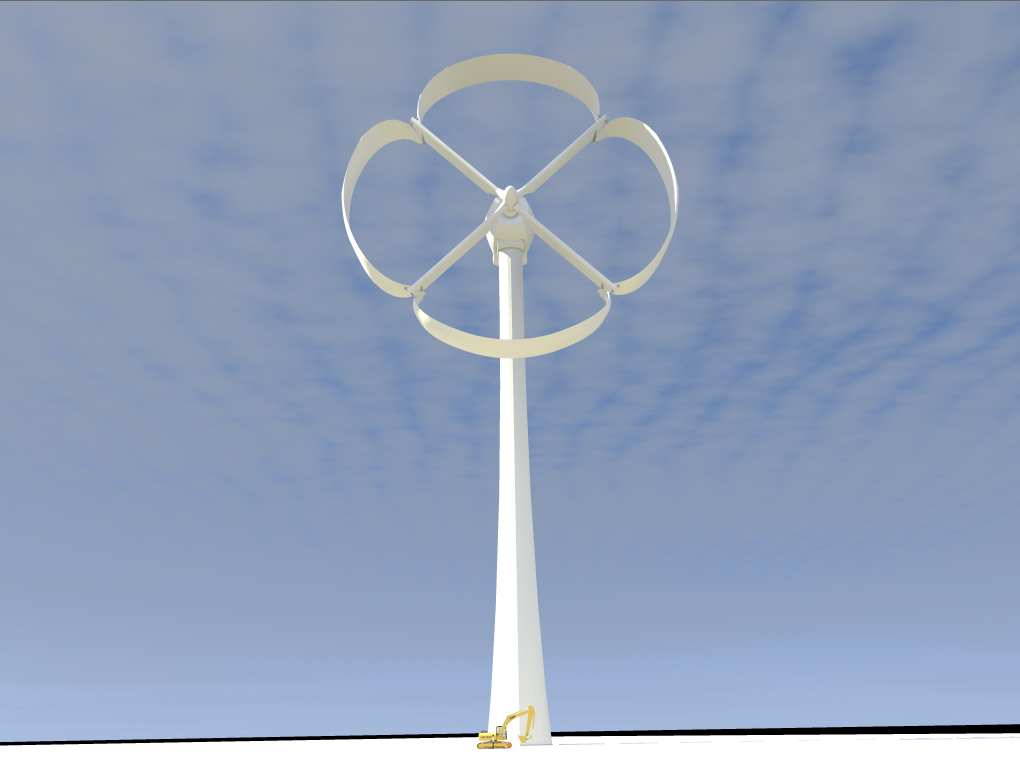

GEDAYC Wind Turbine 300 More Efficient

How to Design Wind Turbine Blade Geometry for Optimal Aerodynamic

Energies Free FullText Wind Turbine Blade Design HTML

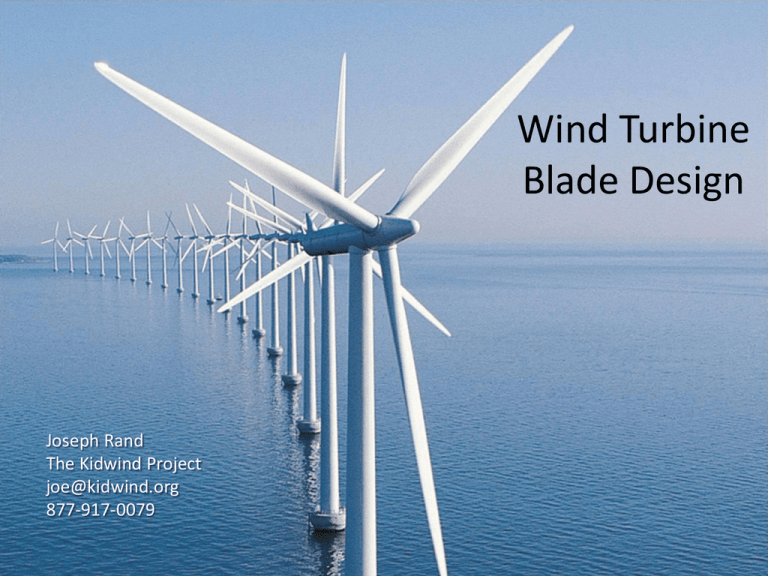

Wind Turbine Blade Design

Wind turbine blade design

GEDAYC Wind Turbine 300 More Efficient Create the Future Design Contest

Wind Turbine Blade Design Engineering's Advice

Wind turbine blade design calculations Renewable energy

Larger Swept Area ⇒ Larger Power Capture.

This Paper Introduces A New Blade Pitch Control Strategy For Fowts That Combines Fuzzy Logic With A Linear Quadratic Regulator.

Find Out How Wind Turbine Blades Are Designed And The Aerodynamics And Science Of Turbine Blade Movement.

Web The Best In Wind Turbine Blade Design.

Related Post: