Mold Injection Design

Mold Injection Design - This comprehensive guide covers key design considerations and best practices for optimizing injection molded parts for manufacturability. Web injection molding is a manufacturing process used for the mass production of identical plastic parts. This manual, a guide to polyolefin injection molding, contains general information concerning materials, methods and equipment for producing high quality, injection molded, polyolefin products at optimum production rates. It’s a method of plastic injection where molten plastic is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of modeled plastic parts. Series versus parallel mold cooling designs. Material selection and part complexity. Web used plastics for injection molding. Web learn how to design the most common features encountered in injection molded parts with these practical guidelines. How to verify turbulent flow. Major factors affecting the cost of injection molding. This comprehensive guide covers key design considerations and best practices for optimizing injection molded parts for manufacturability. How to verify turbulent flow. Applications range from containers and packaging with living hinges to medical applications, toys, displays, overcaps and hangers. Web injection molding, also known as injection moulding, is a manufacturing method that involves injecting molten material into a mold to. Web before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Web what is injection molding? Web injection molded parts design overview. Master the basic principles of the technology and learn quickly actionable design tips that save time & cut costs. How to verify turbulent flow. Web injection molding, also known as injection moulding, is a manufacturing method that involves injecting molten material into a mold to produce various products. This tip offers advice for helping your design. This versatile, automated process delivers precision, speed, and affordability. Web used plastics for injection molding. Web injection molding is a manufacturing process used for the mass production of. When it comes to plastic part production, there is no manufacturing method that comes close to the popularity of injection molding. Web injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a specific shape or design. It’s a method of plastic injection where molten plastic is inserted into a mold to produce. Applications range from containers and packaging with living hinges to medical applications, toys, displays, overcaps and hangers. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. This manual, a guide to polyolefin injection molding, contains general information concerning materials, methods and equipment for producing high quality, injection molded, polyolefin products at optimum production rates.. It’s a method of plastic injection where molten plastic is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of modeled plastic parts. This comprehensive guide covers key design considerations and best practices for optimizing injection molded parts for manufacturability. In this video, you’ll learn the fund. Web injection molding,. Master the basic principles of the technology and learn quickly actionable design tips that save time & cut costs. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. Web injection molding revolutionized mass production of detailed plastic parts across countless industries. Plastic products were primarily limited to phenolics, polystyrene, and other thermosets. Web the. Web learn how to design the most common features encountered in injection molded parts with these practical guidelines. Plastic products were primarily limited to phenolics, polystyrene, and other thermosets. It’s a method of plastic injection where molten plastic is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of modeled. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. How to verify turbulent flow. Web injection molding is a manufacturing process used for the mass production of identical plastic parts. Mold tear down and assembly. Material selection and part complexity. Applications range from containers and packaging with living hinges to medical applications, toys, displays, overcaps and hangers. This versatile, automated process delivers precision, speed, and affordability. It melts plastic and injects it into molds to fabricate the products we rely on every day. Web used plastics for injection molding. S to achieve its full potential. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. Web injection molding design guide. Web injection molding is a manufacturing process used for the mass production of identical plastic parts. Web injection molding revolutionized mass production of detailed plastic parts across countless industries. Web injection molding design: This process is used to design a variety of utensils, packaging, toys, and many other objects. Use them to improve the functionality of your designs, while still complying with the basic design rules. Plastic products were primarily limited to phenolics, polystyrene, and other thermosets. Web in injection molding, the part design dictates the mold design, which in turn, influences cycle times, production costs, and the longevity of the mold itself. The injection molding design guidelines provided in this glossary can provide you with general rules for proper design. Web learn how to select the right material for your injection molding design with this technical overview of thermoplastic resins. This versatile, automated process delivers precision, speed, and affordability. Web the basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold. Web injection molded plastics have revolutionized design, innovation, and manufacturing in the 20th century. It’s a method of plastic injection where molten plastic is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of modeled plastic parts. It melts plastic and injects it into molds to fabricate the products we rely on every day.

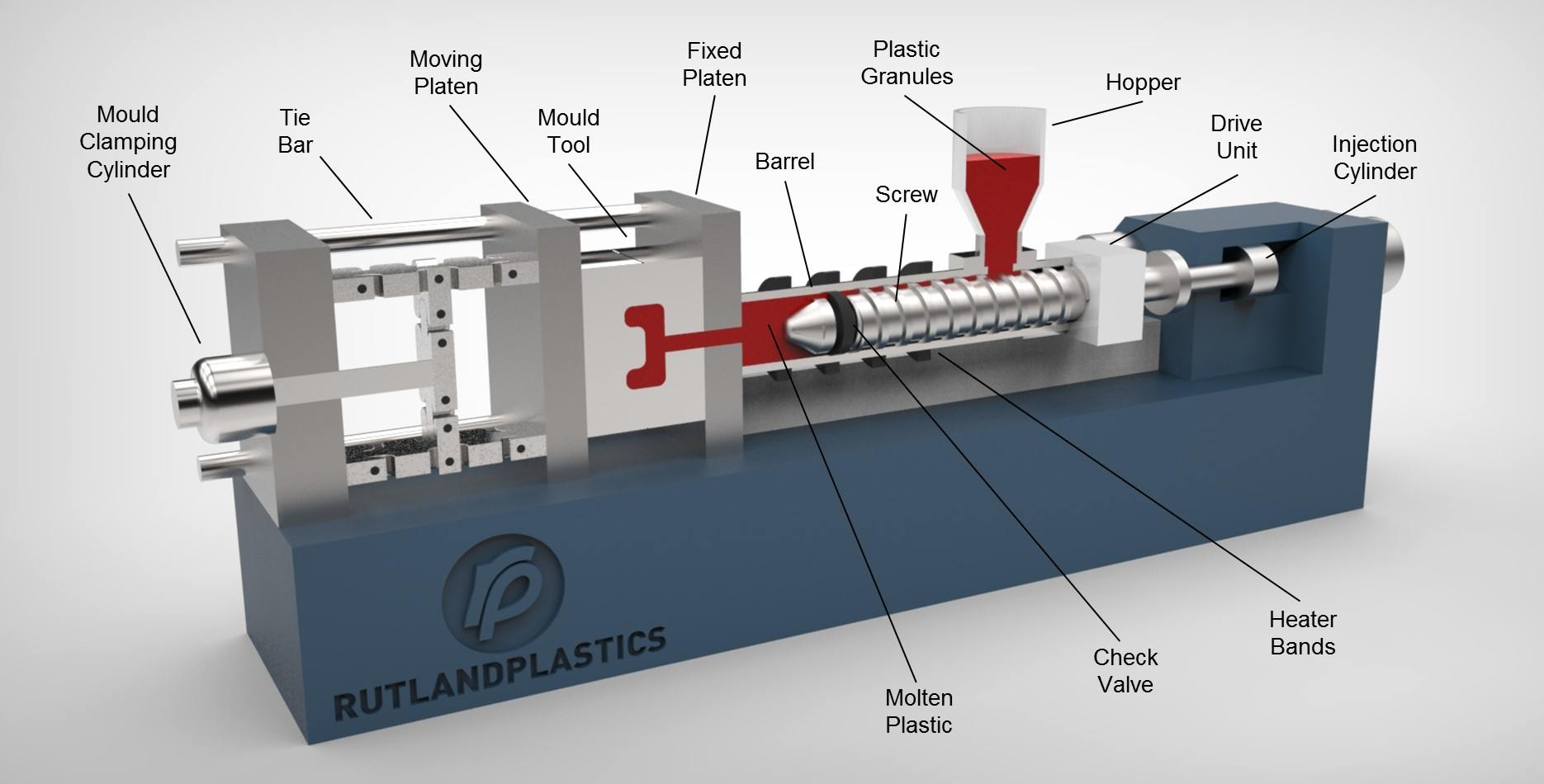

What is Injection Molding and How Does it Work Definition & Working

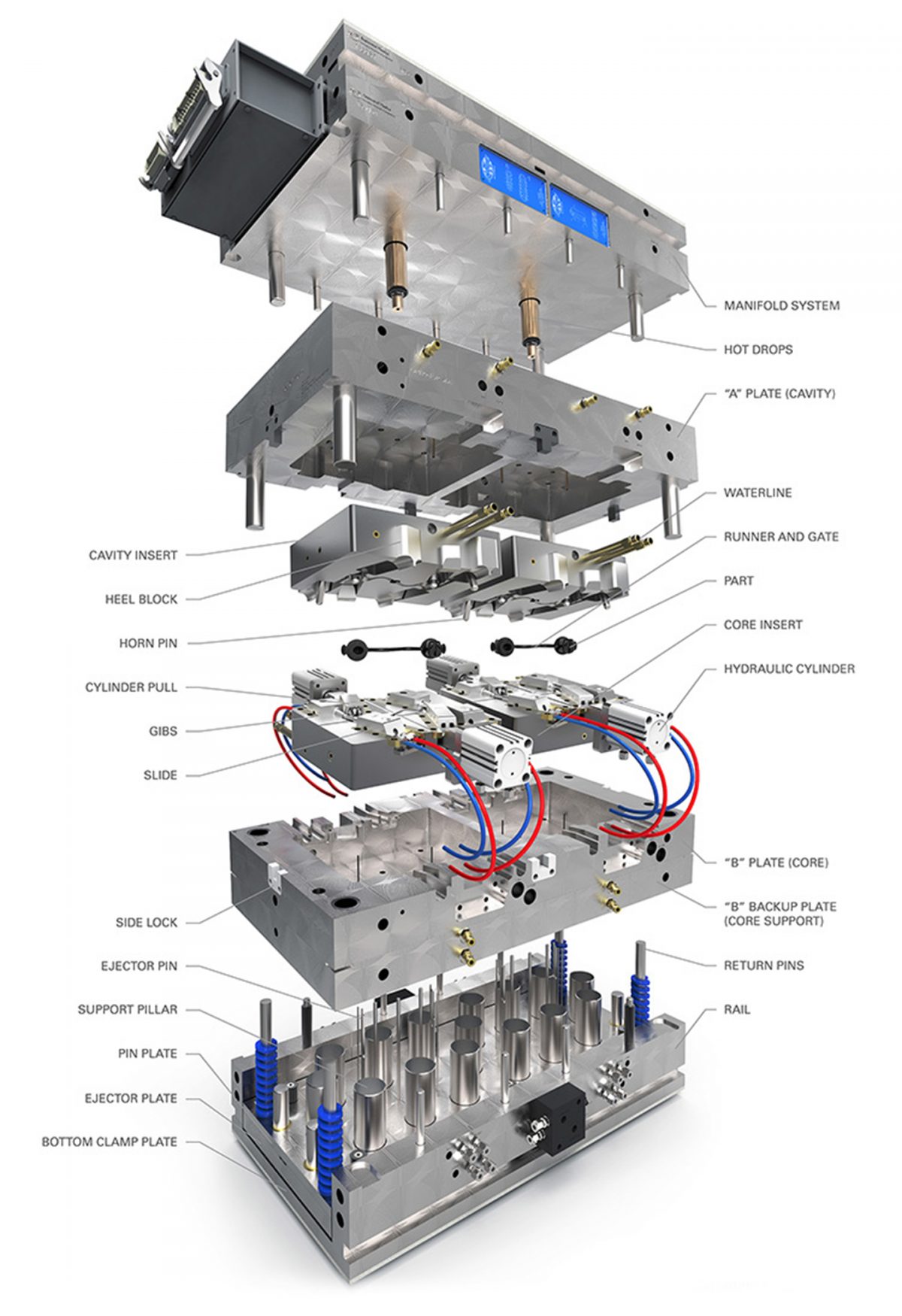

Anatomy of a Mold PTI Plastic Injection Molding

Injection Mold Design Why Simulation is Important

One Picture to Understand the Structure of an Injection Mold

How does injection moulding work Rutland Plastics

![]()

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

Injection Molding Design Guidelines

Injection Molding 101 How It Works Peterman Design Firm

How to Design an Injection Mold 3D Insider

Injection Molding Design Validation Medical Device Biopolymers

Web Learn How To Design The Most Common Features Encountered In Injection Molded Parts With These Practical Guidelines.

The Design Of The Mold, As Well As The Part Being Molded, Has A Significant Impact On The Success Of The Process.

Major Factors Affecting The Cost Of Injection Molding.

How To Verify Turbulent Flow.

Related Post: