Mold Design

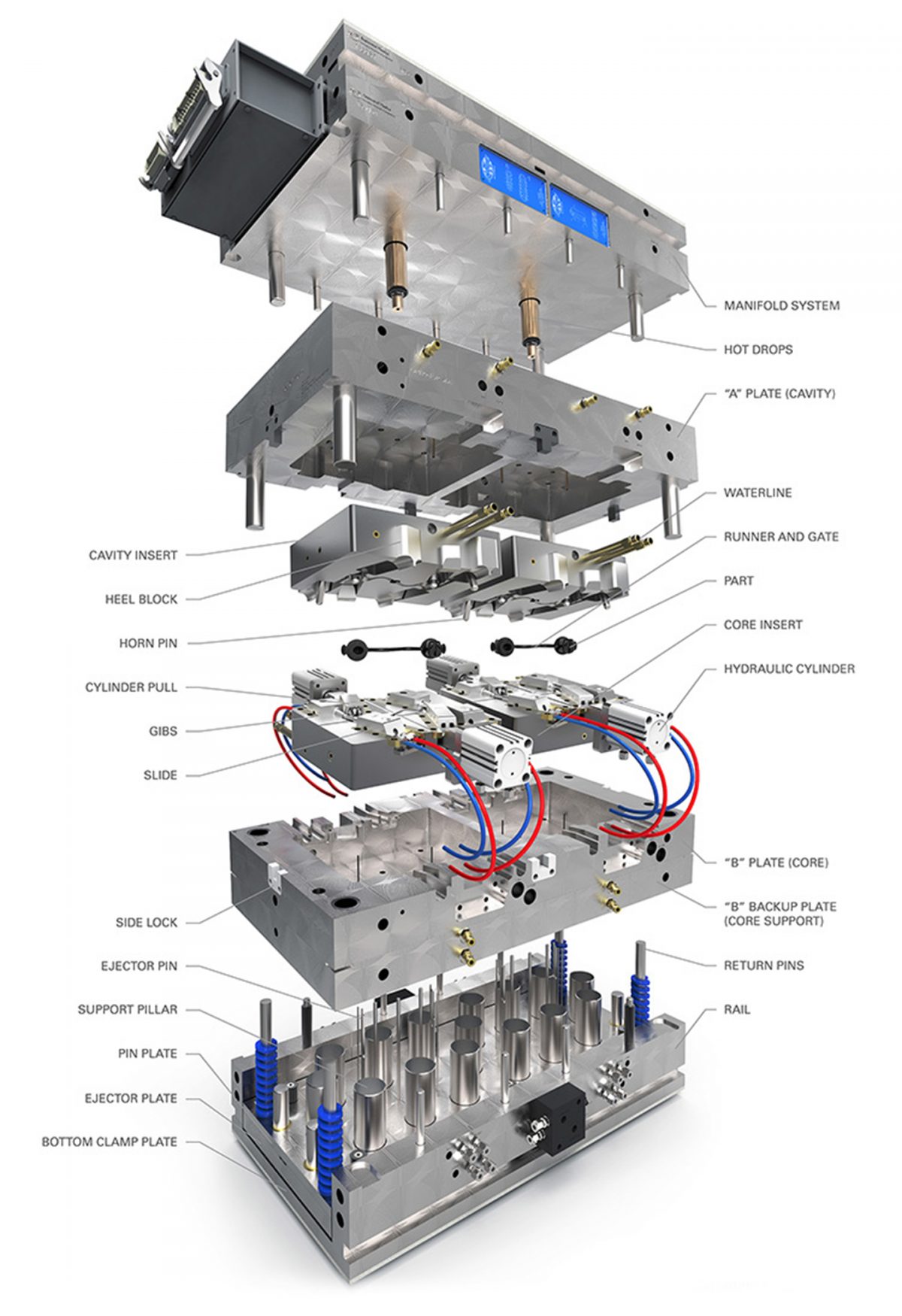

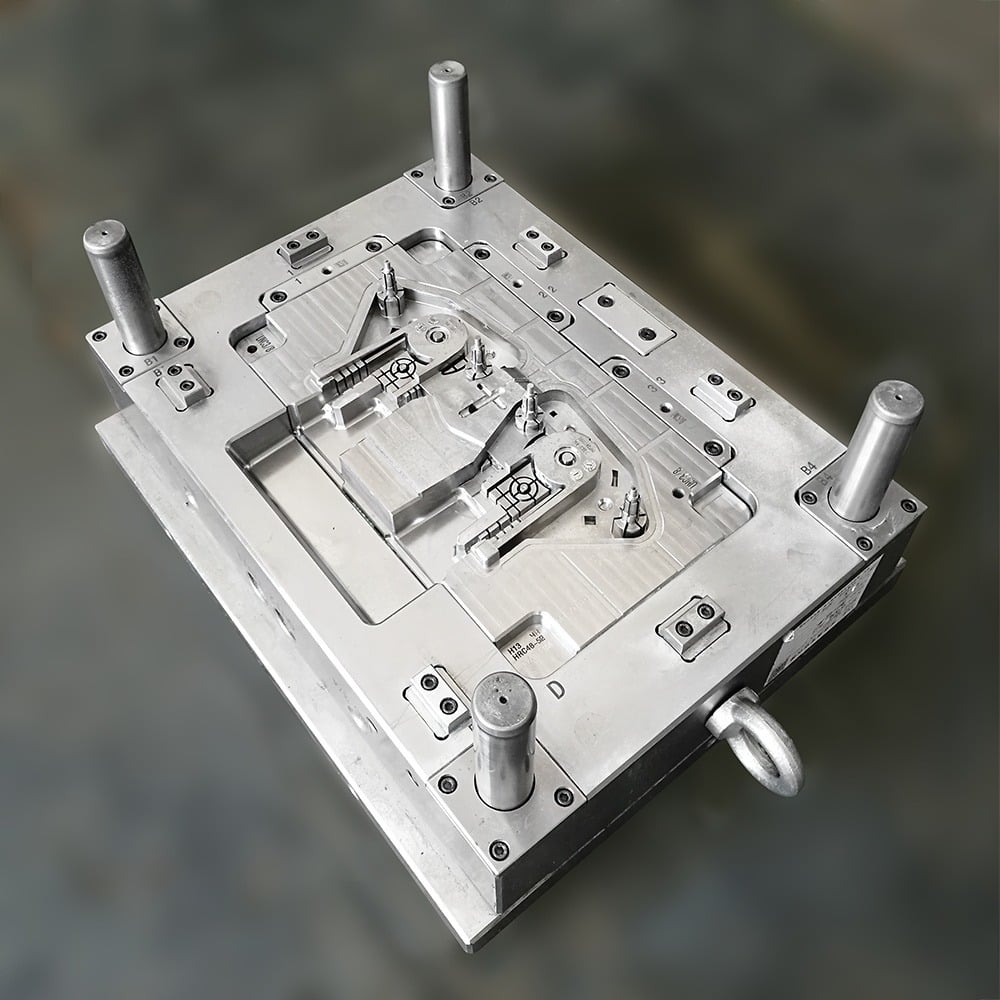

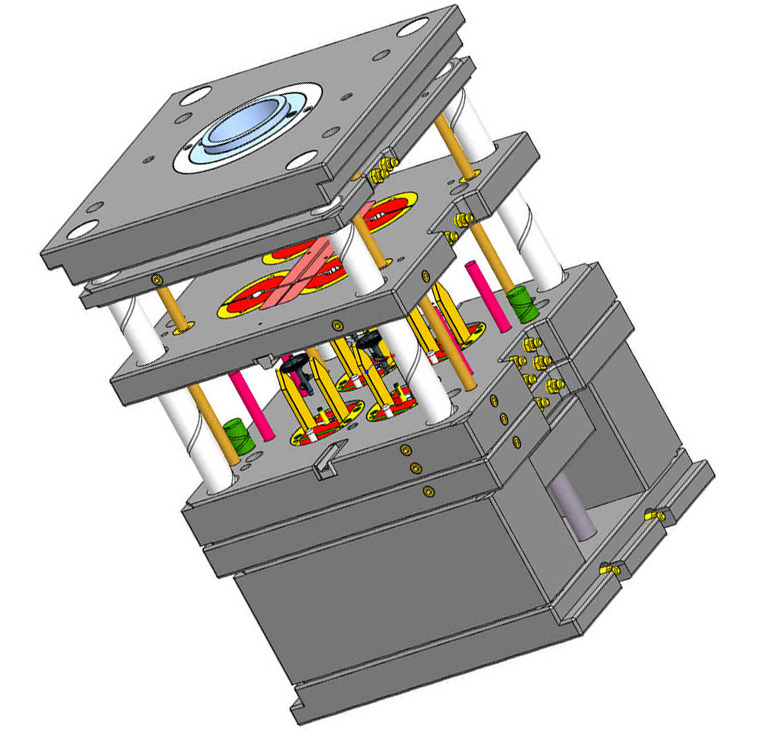

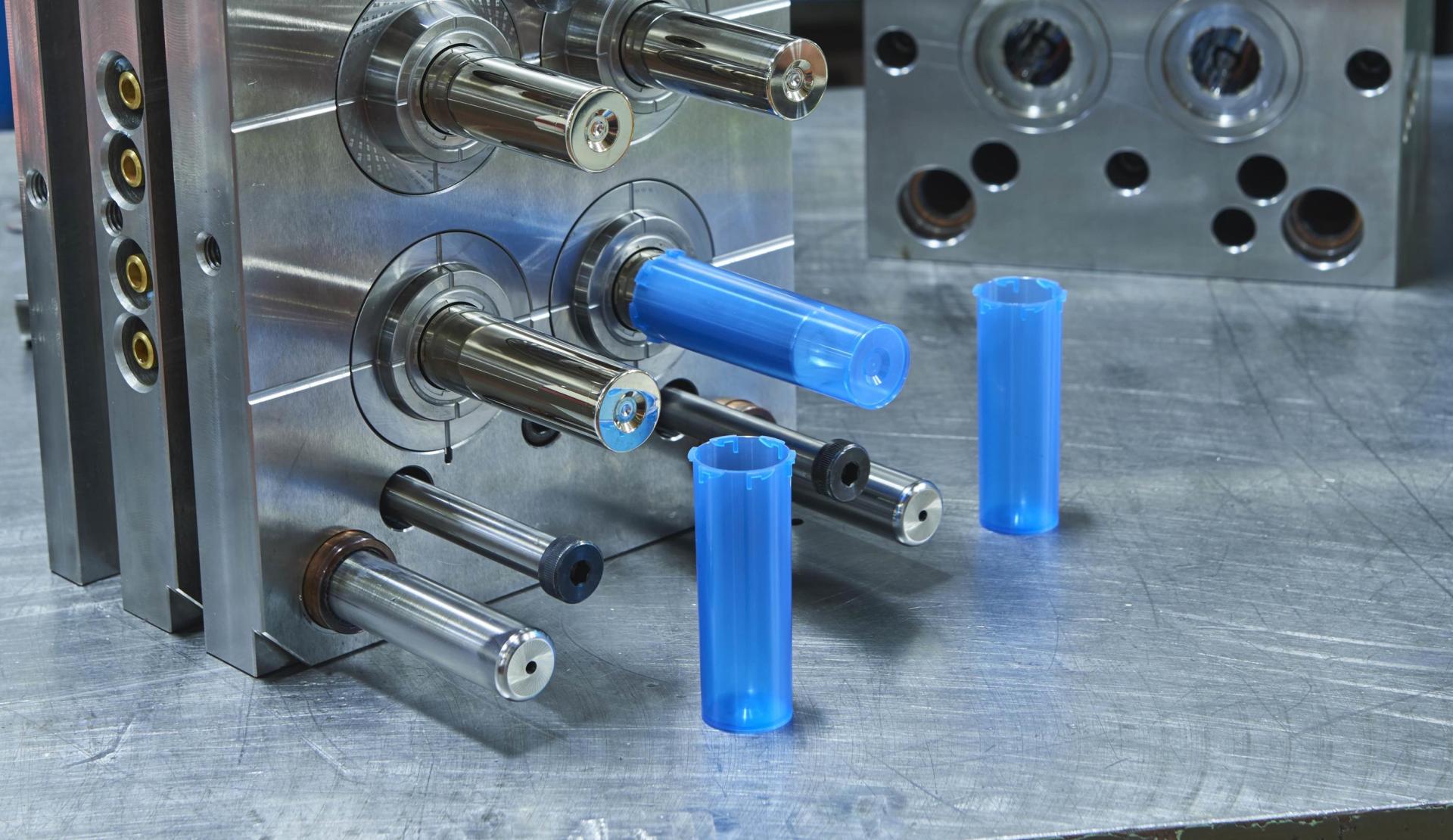

Mold Design - This involves considering various factors such as part geometry, material selection, cooling system design, and ejection mechanisms. Download for free the pdf version of the injection molding manufacturing and design guide. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. The design process involves numerous considerations, from material selection and wall thickness to the location of gates and ejector pins. Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. This tip offers advice for helping your design. Web basics of injection molding design. Web injection mold design is a complex process that requires a deep understanding of the properties of different materials, the mechanics of the molding machine, and the functional requirements of the final product. Web a few key mold design strategies can go a long way in improving your mold building operations and customer support. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. Web a few key mold design strategies can go a long way in improving your mold building operations and customer support. Web learn the basics to the injection molding process, including: Download for free the pdf version of the injection molding manufacturing and design guide. Web injection mold design is a complex process that requires a deep understanding of the. This involves considering various factors such as part geometry, material selection, cooling system design, and ejection mechanisms. Web basics of injection molding design. Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. The design process involves numerous considerations, from material selection and. The design process involves numerous considerations, from material selection and wall thickness to the location of gates and ejector pins. Web the process taken when designing a mold depends on the plastic part to be molded. This tip offers advice for helping your design. Web basics of injection molding design. The process begins with analyzing the plastic part, designing for. Download for free the pdf version of the injection molding manufacturing and design guide. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. This involves considering various factors such as part geometry, material selection, cooling system design, and ejection mechanisms. Web injection mold design is a complex process that. Web learn the basics to the injection molding process, including: The design process involves numerous considerations, from material selection and wall thickness to the location of gates and ejector pins. This tip offers advice for helping your design. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. Web basics. The success of a mold manufacturer boils down to its ability to deliver high quality products at the. Web basics of injection molding design. The design process involves numerous considerations, from material selection and wall thickness to the location of gates and ejector pins. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design. Web a few key mold design strategies can go a long way in improving your mold building operations and customer support. Web learn the basics to the injection molding process, including: Web injection mold design is a complex process that requires a deep understanding of the properties of different materials, the mechanics of the molding machine, and the functional requirements. The success of a mold manufacturer boils down to its ability to deliver high quality products at the. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. The design process involves numerous considerations, from material selection and wall thickness to the location of gates and ejector pins. Web the. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. Web the process taken when designing a mold depends on the plastic part to be molded. The process. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. How it works, design principles, materials, and quality systems. This involves considering various factors such as part geometry, material selection, cooling system design, and ejection. The success of a mold manufacturer boils down to its ability to deliver high quality products at the. Download for free the pdf version of the injection molding manufacturing and design guide. Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. Web injection mold design is a complex process that requires a deep understanding of the properties of different materials, the mechanics of the molding machine, and the functional requirements of the final product. Web basics of injection molding design. This tip offers advice for helping your design. Web the process taken when designing a mold depends on the plastic part to be molded. The process begins with analyzing the plastic part, designing for manufacturing, cad, mold flow analysis, design confirmation, and mold building. How it works, design principles, materials, and quality systems. Web learn the basics to the injection molding process, including:

Unscrewing mold design Mould design, Plastic injection molding

Anatomy of a Mold PTI Plastic Injection Molding

Mold Design Tutorial Moldmaking Resource

Injection Mold Design With Complicated Mechanisms UPMOLD

Injection Mold Design Why Simulation is Important

3D INJECTION & DIE CAST MOLD DESIGN

The Basic Process Of Injection Molding Mold Design

Inhouse mold making design for precision plastics

Basics of Injection Molding Design 3D Systems

This mold was built for a large tier one automotive supplier. The part

Web A Few Key Mold Design Strategies Can Go A Long Way In Improving Your Mold Building Operations And Customer Support.

The Design Process Involves Numerous Considerations, From Material Selection And Wall Thickness To The Location Of Gates And Ejector Pins.

This Involves Considering Various Factors Such As Part Geometry, Material Selection, Cooling System Design, And Ejection Mechanisms.

Related Post: