Mig Welding Gas Flow Rate Chart Lpm

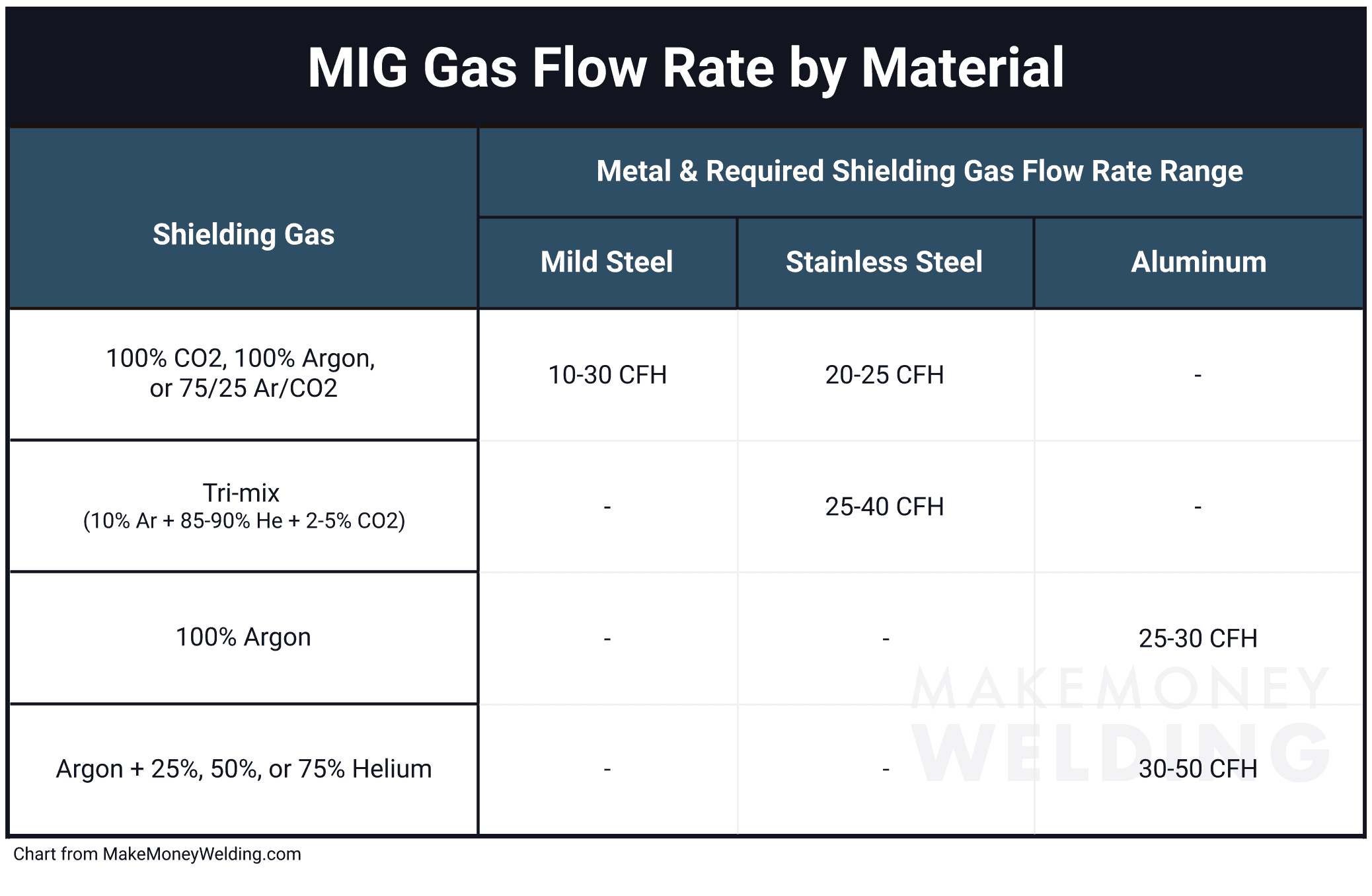

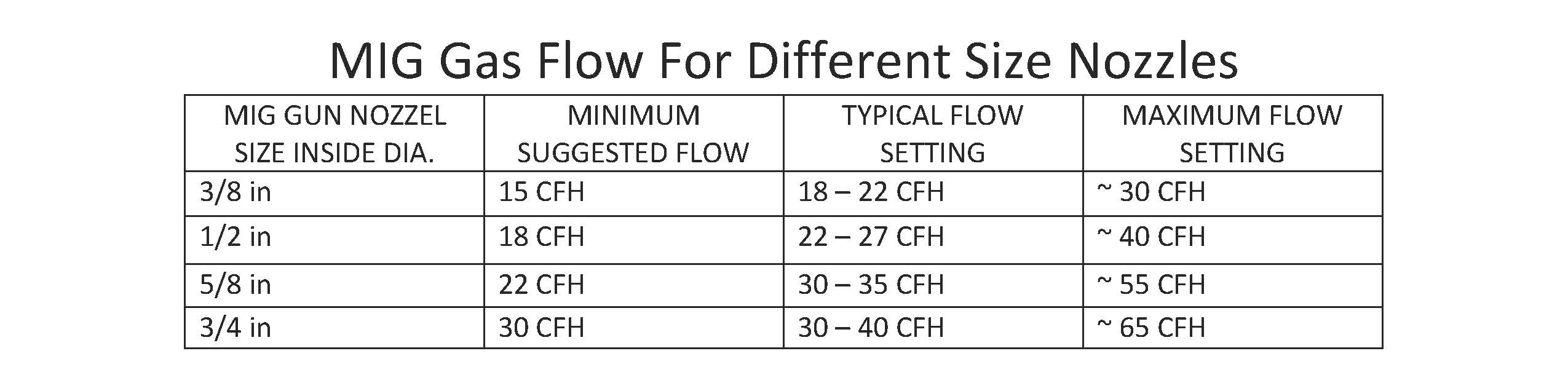

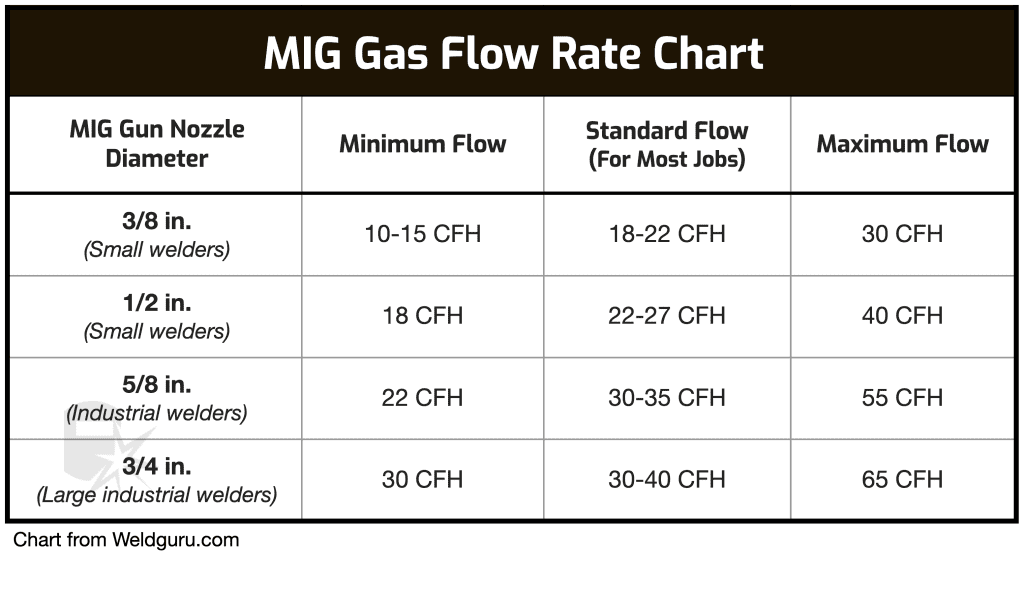

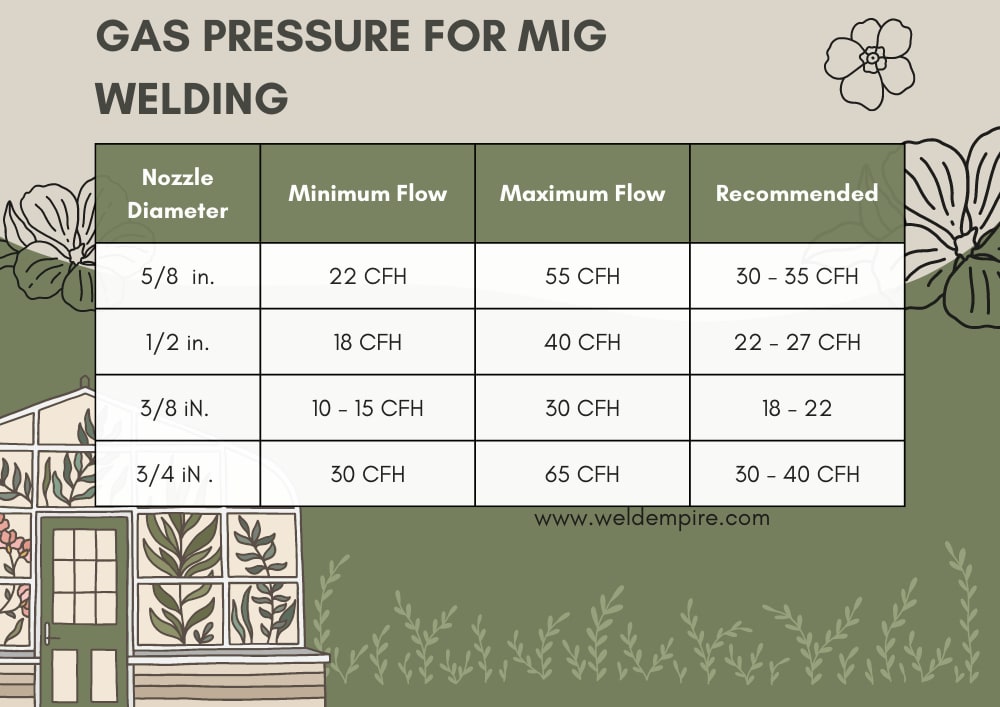

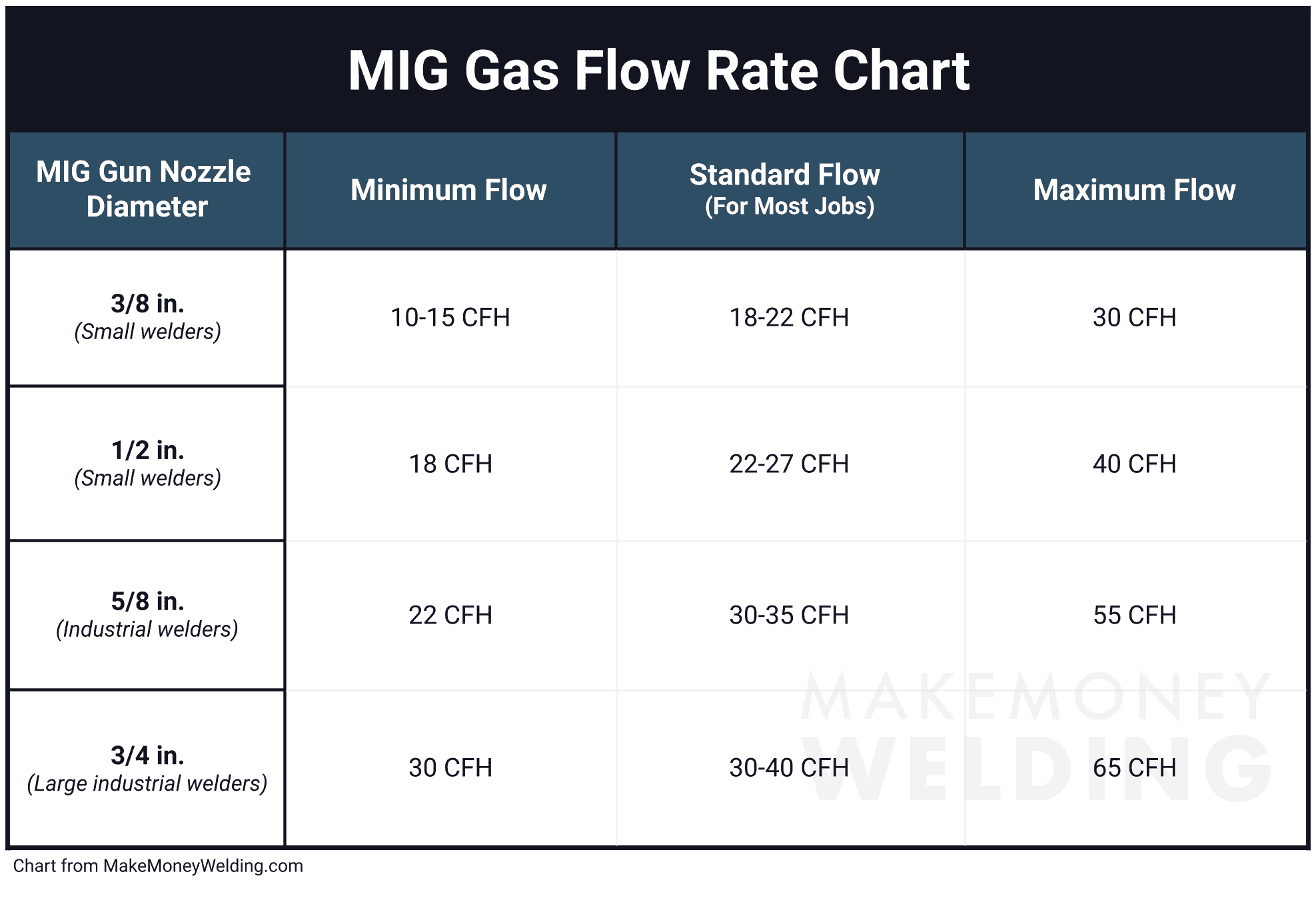

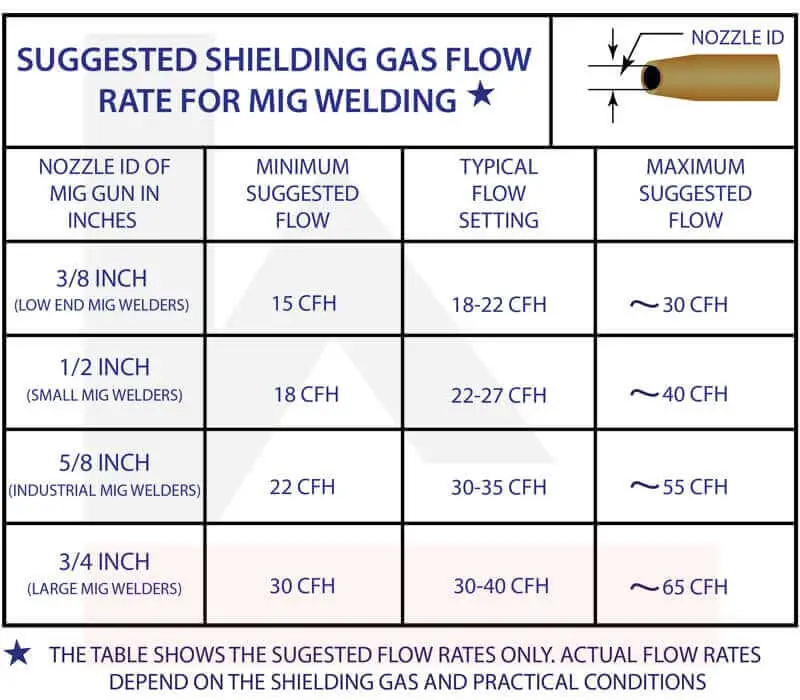

Mig Welding Gas Flow Rate Chart Lpm - Web i run at 6 to 8 lpm in the workshop, my welding is 99% on the flat with easy access and that means perfect torch angle so the gas is going where it is supposed to,. Web aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. This increased shielding helps maintain the material’s corrosion. Web i recommend using a minimum gas flow rate of 20 cubic feet per hour, depending on the thickness of your weld. The gas pressure in the hose going into a wire feeder/welder, while welding, typically varies from 3 to 8 psi. Web shielding gas use can be calculated based on the flow rate (scfh) used during production and the hours of welding needed to complete the job as follows: Web typical gas flow when mig welding varies for different inside nozzle diameters. Web you want around 10 lpm at the torch shroud so as long as there's no leaks between the flow meter and torch, set the flow meter at 10 lpm. On this gauge, near the scale, two entities. Web to figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Web the correct gas flow rate for a mig will depend on a number of factors: Web typical gas flow when mig welding varies for different inside nozzle diameters. Web the correct gas flow rate in mig welding ranges between 15 to 25 cfh. This increased shielding helps maintain the material’s corrosion. Web shielding gas use can be calculated based. Web i recommend using a minimum gas flow rate of 20 cubic feet per hour, depending on the thickness of your weld. Want to learn more about welding gas burn times and. The gas pressure in the hose going into a wire feeder/welder, while welding, typically varies from 3 to 8 psi. The diameter of the gas shroud. Web min. Web shielding gas use can be calculated based on the flow rate (scfh) used during production and the hours of welding needed to complete the job as follows: But make sure to take into account the different variables while selecting the flow rate. Welding gas cylinder exchange and burn times. Web the correct gas flow rate in mig welding ranges. Web using a regulator flowmeter or flowgauge regulator is essential for welding because it’s necessary to know the cubic feet per hour or litres per minute a gas is. Web min & max mig gas flow rate chart. Web you want around 10 lpm at the torch shroud so as long as there's no leaks between the flow meter and. Web i run at 6 to 8 lpm in the workshop, my welding is 99% on the flat with easy access and that means perfect torch angle so the gas is going where it is supposed to,. Welding gas cylinder exchange and burn times. Web setting mig shielding gas flow rates: Web typical gas flow when mig welding varies for. The gas pressure in the hose going into a wire feeder/welder, while welding, typically varies from 3 to 8 psi. Web to figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Web shielding gas use can be calculated based on. Web the flow rate of argon gas is measured in litres per minute (lpm), using a gauge which is attached at top of the cylinder. Web aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. Web min & max mig gas flow rate chart. Web using a regulator flowmeter. But make sure to take into account the different variables while selecting the flow rate. This increased shielding helps maintain the material’s corrosion. Web the flow rate of argon gas is measured in litres per minute (lpm), using a gauge which is attached at top of the cylinder. Web using a regulator flowmeter or flowgauge regulator is essential for welding. The graph below illustrates the minimum and maximum flow rates for typical mig diameters. Web setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding. Web i run at 6 to 8 lpm in the workshop, my welding is 99% on the flat with easy. Welding gas cylinder exchange and burn times. But make sure to take into account the different variables while selecting the flow rate. This increased shielding helps maintain the material’s corrosion. Web using a regulator flowmeter or flowgauge regulator is essential for welding because it’s necessary to know the cubic feet per hour or litres per minute a gas is. The. Web i recommend using a minimum gas flow rate of 20 cubic feet per hour, depending on the thickness of your weld. Welding gas cylinder exchange and burn times. The gas pressure in the hose going into a wire feeder/welder, while welding, typically varies from 3 to 8 psi. Web to figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Web you want around 10 lpm at the torch shroud so as long as there's no leaks between the flow meter and torch, set the flow meter at 10 lpm. Web the flow rate of argon gas is measured in litres per minute (lpm), using a gauge which is attached at top of the cylinder. The diameter of the gas shroud. This increased shielding helps maintain the material’s corrosion. Web typical gas flow when mig welding varies for different inside nozzle diameters. Web the correct gas flow rate in mig welding ranges between 15 to 25 cfh. Want to learn more about welding gas burn times and. Web setting mig shielding gas flow rates: Use this web page to find information about setting mig shielding gas flow rates, reducing waste and improving weld. Web i run at 6 to 8 lpm in the workshop, my welding is 99% on the flat with easy access and that means perfect torch angle so the gas is going where it is supposed to,. Web aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. But make sure to take into account the different variables while selecting the flow rate.

MIG Welding Gas Pressure Settings

MIG Welding Gas Pressure Settings (with Charts), 42 OFF

Mig Welding Gas Flow Rate Chart

MIG Welding Gas Pressure Settings (with Charts)

MIG Welding Gas Pressure Settings (with Charts)

Mig Welding Gas Flow Rate Chart

MIG Welding Gas Pressure Settings

How to Optimize MIG Welding Shielding Gas Pressure

Mig Welding Gas Flow Rate Chart

Mig Welding Gas Pressure Chart A Visual Reference of Charts Chart Master

Web The Correct Gas Flow Rate For A Mig Will Depend On A Number Of Factors:

On This Gauge, Near The Scale, Two Entities.

The Graph Below Illustrates The Minimum And Maximum Flow Rates For Typical Mig Diameters.

Web Unlike Oxyfuel Welding And Cutting, Mig Gas Flow Rates Are Very Low.

Related Post: