Mig Welding Amperage Chart

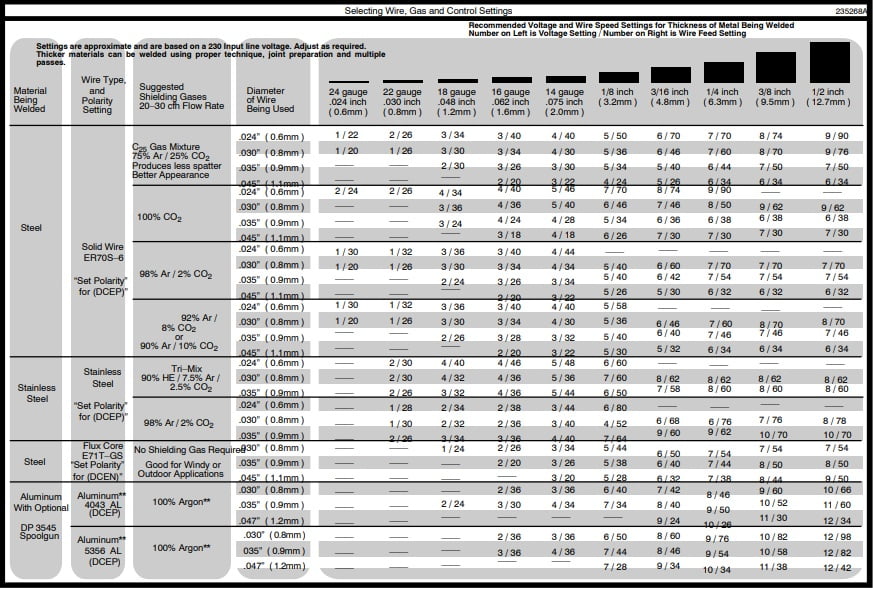

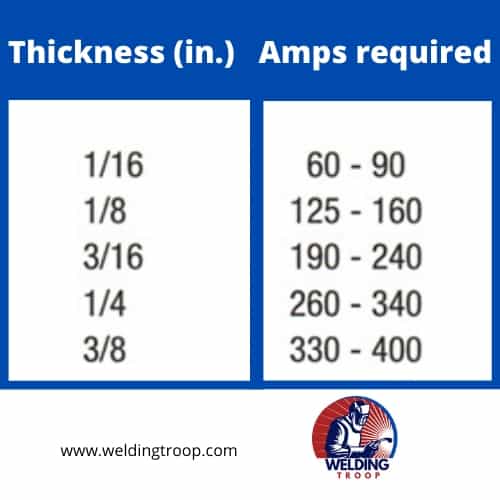

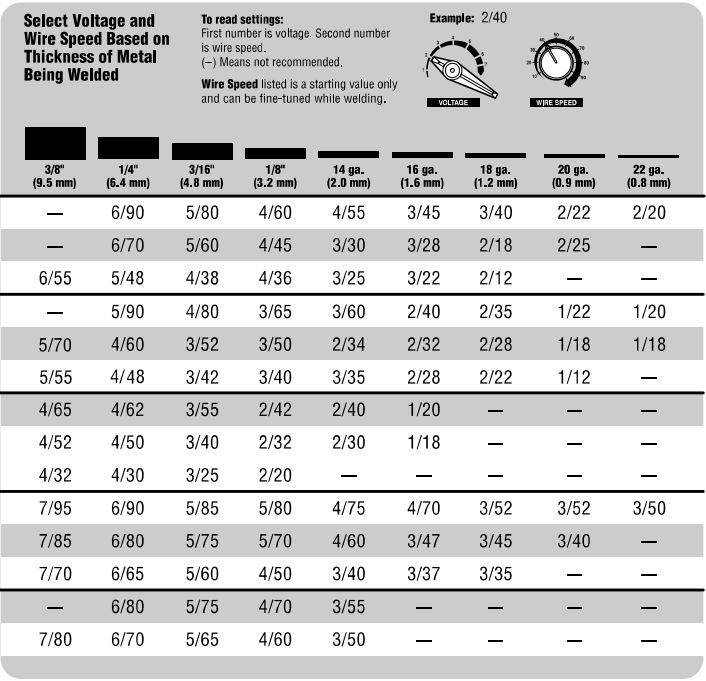

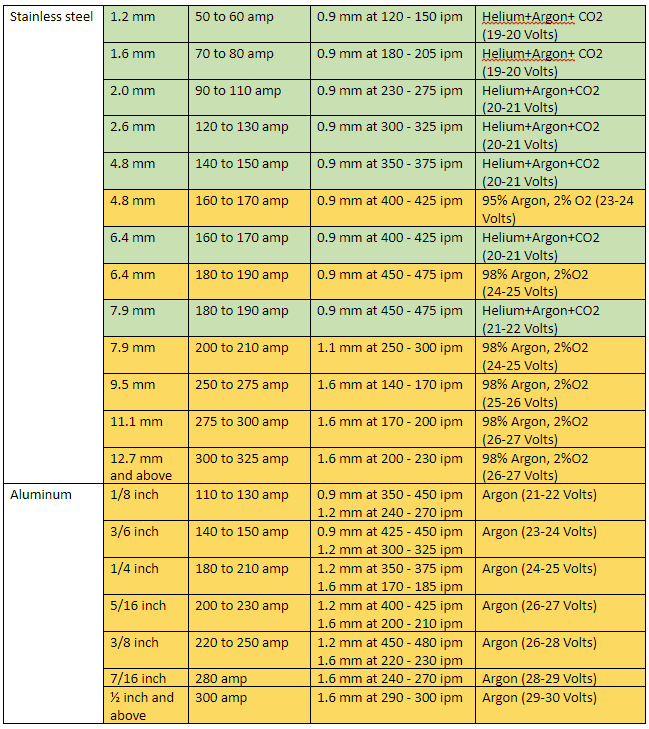

Mig Welding Amperage Chart - Mig welding, also called metal inert gas, is widely used and practiced in various industrial zones to weld different metals, and multiple shielding gasses are used to complete its process. Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. Wire speed controls amperage as well as the amount of weld penetration. As we go along, you’ll learn how to balance voltage. There might be variations with the settings depending on the manufacturer. But before using these values, we suggest that you have a decent understanding of your preferred metal. That would mean that 75 to 80 amps would be a good setting to start out on for mild steel that is 2mm in thickness. To help determine the proper amperage for your needs, use the chart above or a calculator to determine power and feed speed. The estimates will appear in a table (above) after you have filled in the form. Also, consider the amperage settings and the task at hand. Web quick guide for selecting mig wire size and welder amperage for your application. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web set the wire feed speed. The estimates will appear in a table (above) after you have filled in the form. Also, consider the amperage settings and the task. Also, consider the amperage settings and the task at hand. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Check with your machine manufacturer for any information that may pertain to your welding system. Table of wire speed for mig welding. Web setting the amperage on a. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. Welds thinner materials (22 gauge) than flux cored wires. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding. Web set the welding machine to constant voltage mode and adjust the voltage & amperage according to the recommended settings shown in the below chart for the metal and wire being used. Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. There might be variations with the settings depending. But before using these values, we suggest that you have a decent understanding of your preferred metal. Welding amperage is the measure of the electrical current used during the welding process. The estimates will appear in a table (above) after you have filled in the form. Also, consider the amperage settings and the task at hand. Information about default weld. Once you determine these three main variables, you can set your welding machine and start. Web set the welding machine to constant voltage mode and adjust the voltage & amperage according to the recommended settings shown in the below chart for the metal and wire being used. Table of wire speed for mig welding. Information about default weld parameters and. But before using these values, we suggest that you have a decent understanding of your preferred metal. What material are you welding? Web quick guide for selecting mig wire size and welder amperage for your application. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web set the wire feed speed. Adjust the wire feed speed. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. That is the reason that makes the mig welding technique settings the essential operation to provide quality weld on the spot. But before using these values, we suggest that you have a. The estimates will appear in a table (above) after you have filled in the form. Wire speed controls amperage as well as the amount of weld penetration. Web set the welding machine to constant voltage mode and adjust the voltage & amperage according to the recommended settings shown in the below chart for the metal and wire being used. Web. Welds thinner materials (22 gauge) than flux cored wires. Adjust the wire feed speed. Welding amperage is the measure of the electrical current used during the welding process. Once you determine these three main variables, you can set your welding machine and start. Web miller mig welding settings charts. Web miller mig welding settings charts. Before tackling any mig welding application, look at the charts and tips below. Welding amperage is the measure of the electrical current used during the welding process. Also, consider the amperage settings and the task at hand. What material are you welding? Web a mig welding amperage chart is a guide that helps you determine the right amperage to set your welding machine to when welding a specific type of material. Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web these settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web in this article, we are going to take a look at how to set up a mig welder along with various other information like how to set up wire welder with gas, metal inert gas welding procedure, what is gmaw welding used for, etc. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Once you determine these three main variables, you can set your welding machine and start. Web set the welding machine to constant voltage mode and adjust the voltage & amperage according to the recommended settings shown in the below chart for the metal and wire being used. Web set the wire feed speed. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel.

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG Welding Wire Output Amperage & Selection Chart

Mig Welding Amps To Metal Thickness Chart

Mig Welding Amps To Metal Thickness Chart

How Many Amps Do I REALLY Need for a MIG Welder >> 200300 Amps?

Mig Welding Setting Chart

Aluminum Mig Welding Amperage Chart

MIG welder settings explained Amperage & Wire Speed

Aluminum Mig Welding Amperage Chart

A MIG Welding Amps to Metal Thickness Chart Welding Mastermind

Stainless Steel And Aluminium Amps Chart.

As We Go Along, You’ll Learn How To Balance Voltage.

Web A Mig Welding Wire Speed Chart Offers Insights Into Appropriate Wire Speeds For Various Material Thicknesses And Types In Mig Welding.

Wire Speed Controls Amperage As Well As The Amount Of Weld Penetration.

Related Post: