Mig Welder Settings Chart

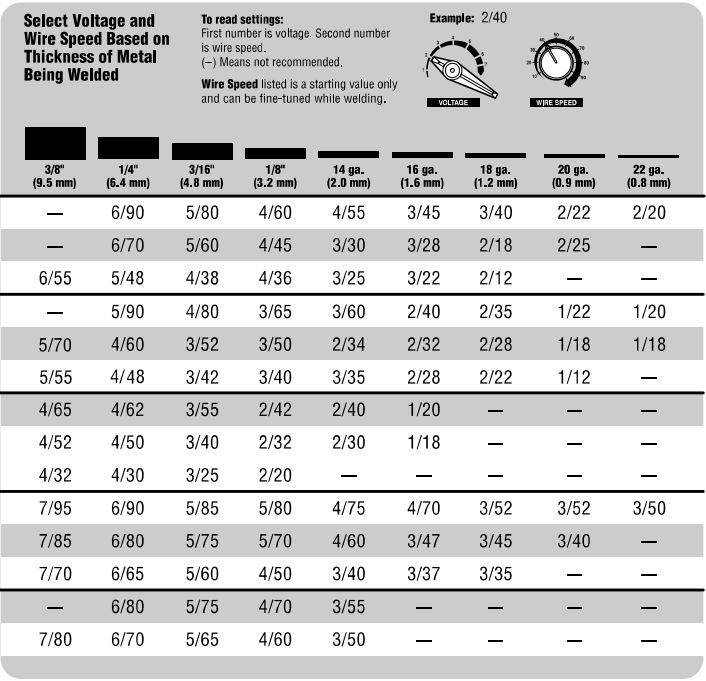

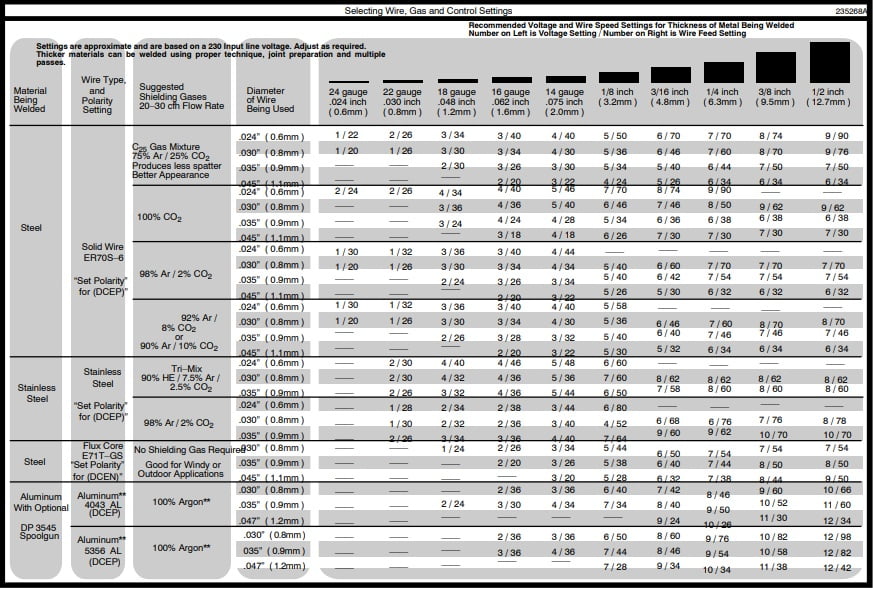

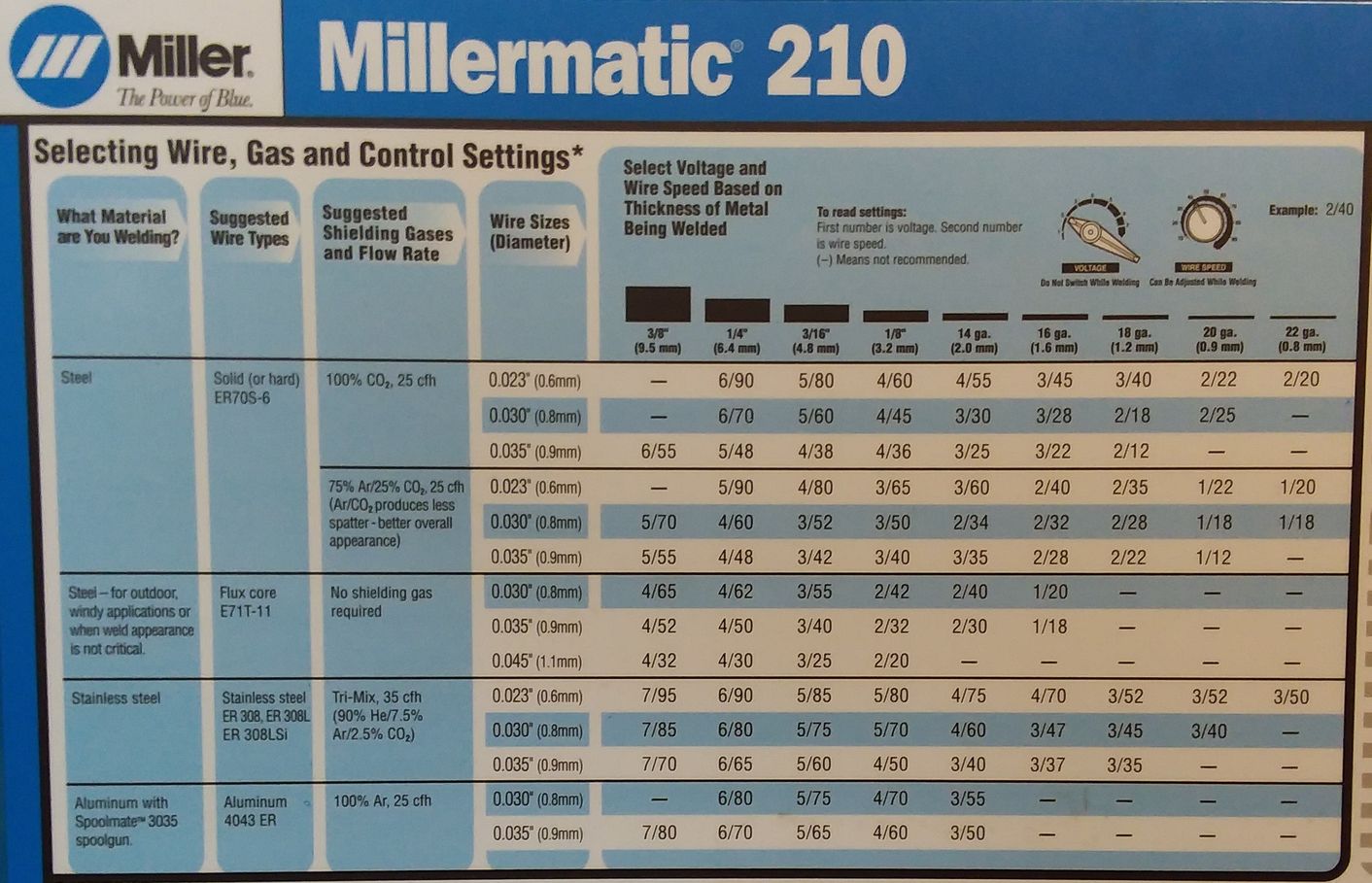

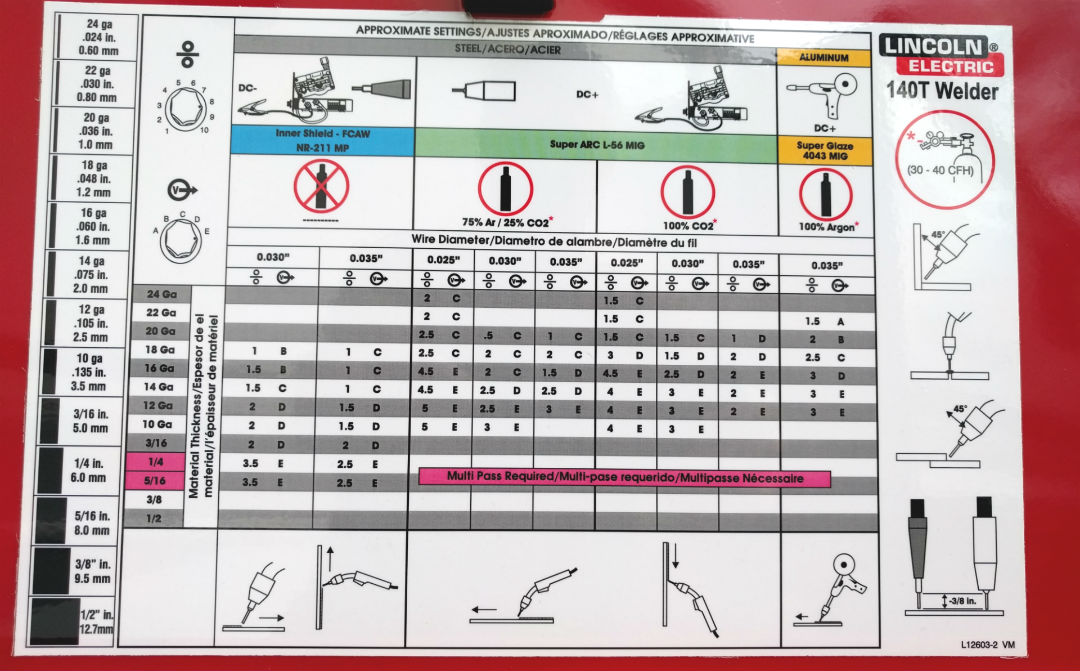

Mig Welder Settings Chart - Web the two main settings on a mig welder are wire speed and voltage. The mig welder has a proper setting for that. The same is the case for joining mild steel; Now, to get good results, follow the below lines. Two separate knobs control these on most mig welders. The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. However, not all welders use the same settings, so you should read your welder’s manual. Web using the correct mig welding settings can make or break the quality of your finished product. Now, to get good results, follow the below lines. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. However, not all welders use the same settings, so you should read your welder’s manual. Two separate knobs control these on most. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Now, to get good results, follow the below lines. Web the chart below shows minimum and maximum gas flow rates for standard mig nozzle diameters for argon mixtures and co 2. These settings determine the heat, wire. Use these tips to get the best mig welds. Now, to get good results, follow the below lines. What material are you welding? The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage. Now, to get good results, follow the below lines. The same is the case for joining mild steel; But there, each of the metal joining processes required different settings. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. There are many mig setting charts. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. There are many mig setting charts available from manufacturers that all vary. Use these tips to get the. Web mig welding is called metal inert gas and is used to join different metals. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Use these tips to get the best mig welds. Now, to get good results, follow the below lines. But there,. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. The same is the case for joining mild steel; Web mig welding is called metal inert gas and is used to join different metals. Web the welding chart that comes with your machine undoubtedly provides the best. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Two separate knobs control these on most mig welders. Use these tips to get the best mig welds. Web the welding. Web the welding chart that comes with your machine undoubtedly provides the best guidelines for the welding start. What material are you welding? These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. The mig welder has a proper setting for that. Web using the correct mig welding settings can make or break the quality of. The same is the case for joining mild steel; The mig welder has a proper setting for that. Web using the correct mig welding settings can make or break the quality of your finished product. Use these tips to get the best mig welds. What material are you welding? But there, each of the metal joining processes required different settings. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Web the two main settings on a mig welder are wire speed and voltage. Now, to get good results, follow the below lines. There are many mig setting charts available from manufacturers that all vary. The most common metals welded with the mig process include mild steel, stainless steel, and aluminum. Two separate knobs control these on most mig welders. However, not all welders use the same settings, so you should read your welder’s manual.

MIG Welder Settings Explained (with Chart) Weld Guru

Mig Welding Setting Chart

aluminum mig welding settings chart

Mig Welding Setting Chart

Mig Welding Settings Chart

How To MIG Weld Aluminum Beginners Guide (with Chart)

Best Welder for Beginners? 19 Smart Reasons for MIG • WelditU

Mig Welder Chart Settings

Mig Welder Settings Chart Pdf

Welding Settings For Mig Welders

Web The Chart Below Shows Minimum And Maximum Gas Flow Rates For Standard Mig Nozzle Diameters For Argon Mixtures And Co 2.

Web The Welding Chart That Comes With Your Machine Undoubtedly Provides The Best Guidelines For The Welding Start.

Web Mig Welding Is Called Metal Inert Gas And Is Used To Join Different Metals.

To Ensure Optimal Results, Select The Appropriate Gauge Thickness And Refer To The Corresponding Joint Gap, Wire Diameter, Amperage, And Voltage Setting For Your Weld.

Related Post: