Mig Welder Amp Chart

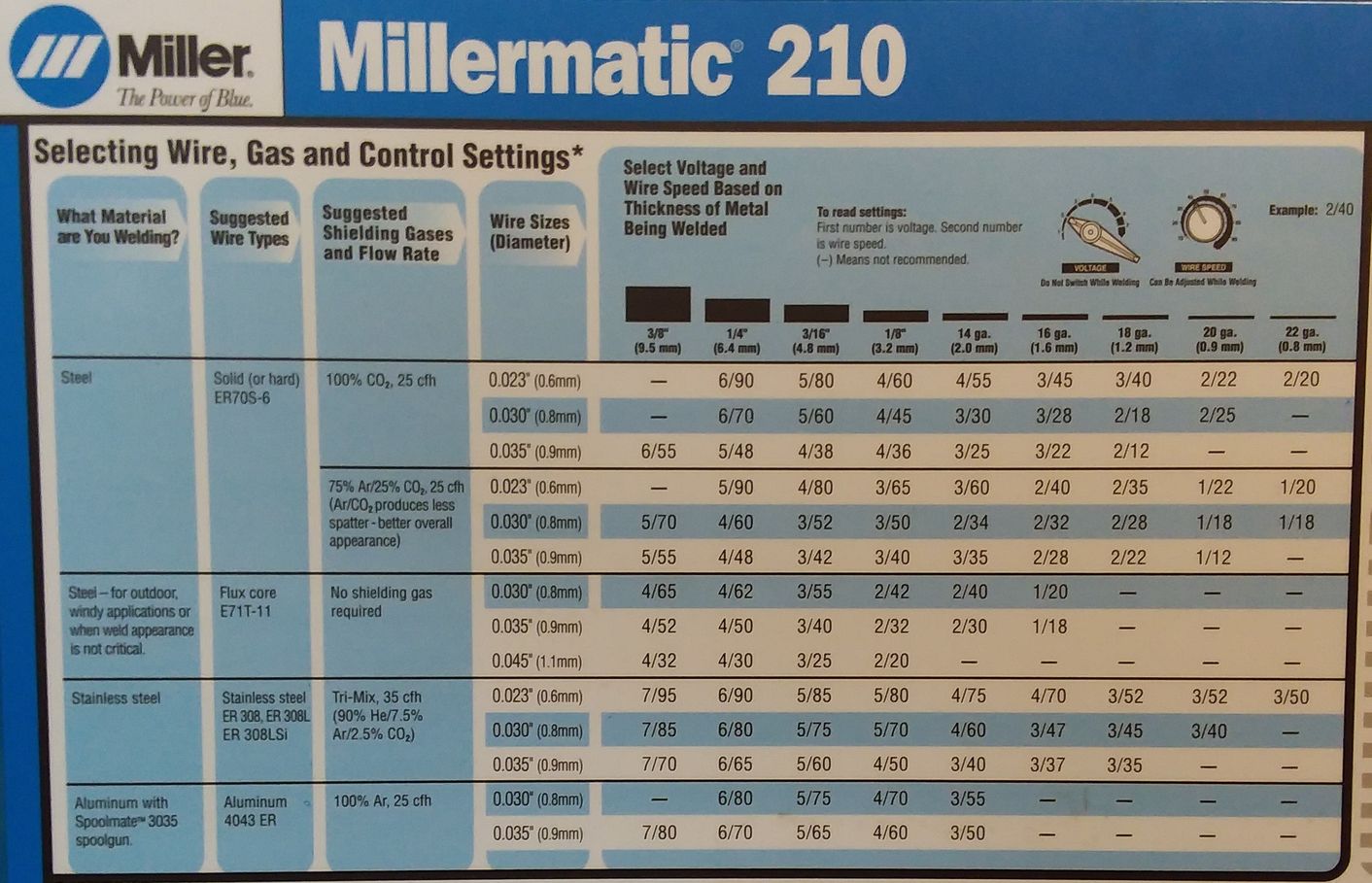

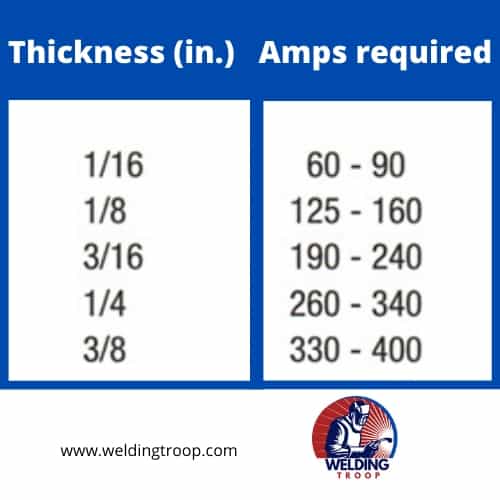

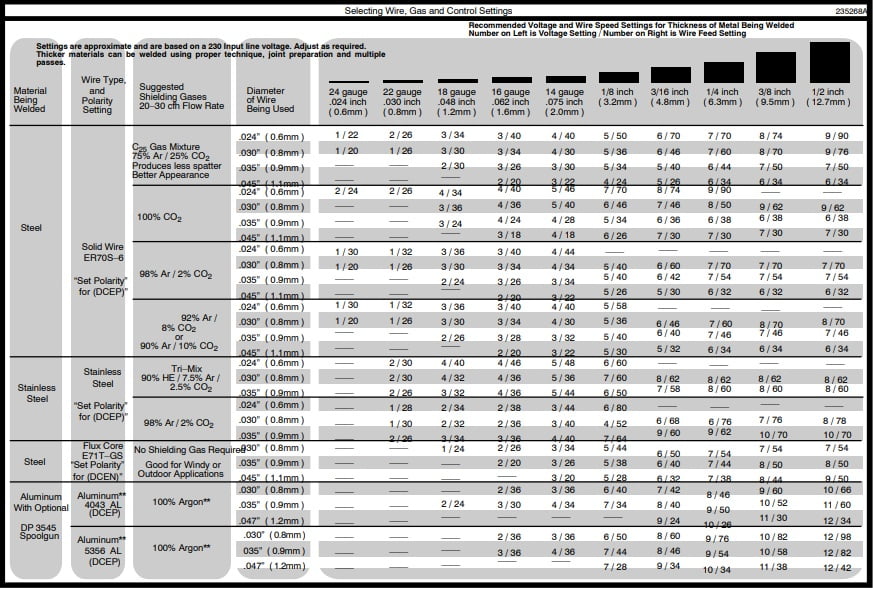

Mig Welder Amp Chart - Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web quick guide for selecting mig wire size and welder amperage for your application. Numbers are approximate but should be damn close. To help determine the proper amperage for your needs,. Web download the app version of the weld setting calculator for easy reference! Web how many amps do you really need for a mig welder? Check with your machine manufacturer for any information that may pertain to your welding. These figures can be found from manufacturer or retailers' specs. There are many mig setting charts available from manufacturers that all vary. Wire speed controls amperage as well as the amount of weld penetration. Web this is a mig welding chart provided by the lincoln electric the welding chart that comes with your machine undoubtedly provides the best guidelines for the. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. You may need to dial them in, depending on your setup.. Always test your settings on a scrap piece of metal. Web how many amps do you really need for a mig welder? Web set the wire feed speed. You may need to dial them in, depending on your setup. It aids in the optimal setting. Web how many amps do you really need for a mig welder? Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. In average you need 140 amps for 115 volts welders in order to weld up to ¼” thick steel and around 200 amps for 220. Numbers are approximate. Always test your settings on a scrap piece of metal. Wire speed controls amperage as well as the amount of weld penetration. To help determine the proper amperage for your needs,. These settings determine the heat, wire deposition rate, and. Web the chart provides a visual representation of the required settings, making it easy for welders to select the right. Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Check with your machine manufacturer for any information that may pertain to your welding. Web mig wire amperage chart. But before using these values, we. You may need to dial them in, depending on your setup. Web how to use the calculator. Web mig wire amperage chart. These settings determine the heat, wire deposition rate, and. There are many mig setting charts available from manufacturers that all vary. To help determine the proper amperage for your needs,. Web quick guide for selecting mig wire size and welder amperage for your application. Welds thinner materials (22 gauge) than flux cored wires. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web lincoln mig welding settings charts. Web a mig welding amperage chart is a guide that helps you determine the. But before using these values, we suggest that you have a decent. These figures can be found from manufacturer or retailers' specs. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web mig wire amperage chart. Welds thinner materials (22 gauge) than flux cored wires. To help determine the proper amperage for your needs,. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web quick guide for selecting mig wire size and welder amperage for your application. Web how many amps do you really need for a mig welder? Web there. Here's a handy chart i came up with to help all you wire feeders out there. Web quick guide for selecting mig wire size and welder amperage for your application. These settings determine the heat, wire deposition rate, and. Numbers are approximate but should be damn close. Web a mig welding amperage chart is a guide that helps you determine. Numbers are approximate but should be damn close. These figures can be found from manufacturer or retailers' specs. But before using these values, we. Web quick guide for selecting mig wire size and welder amperage for your application. You may need to dial them in, depending on your setup. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. To help determine the proper amperage for your needs,. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Web a mig welding amperage chart is a guide that helps you determine the right amperage to set your welding machine to when welding a specific type of material. Web download the app version of the weld setting calculator for easy reference! Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. Web what material are you welding? In average you need 140 amps for 115 volts welders in order to weld up to ¼” thick steel and around 200 amps for 220. For example a sip migmate 130 has a minimum output current of 25 amps, maximum. There are many mig setting charts available from manufacturers that all vary. Web lincoln mig welding settings charts.

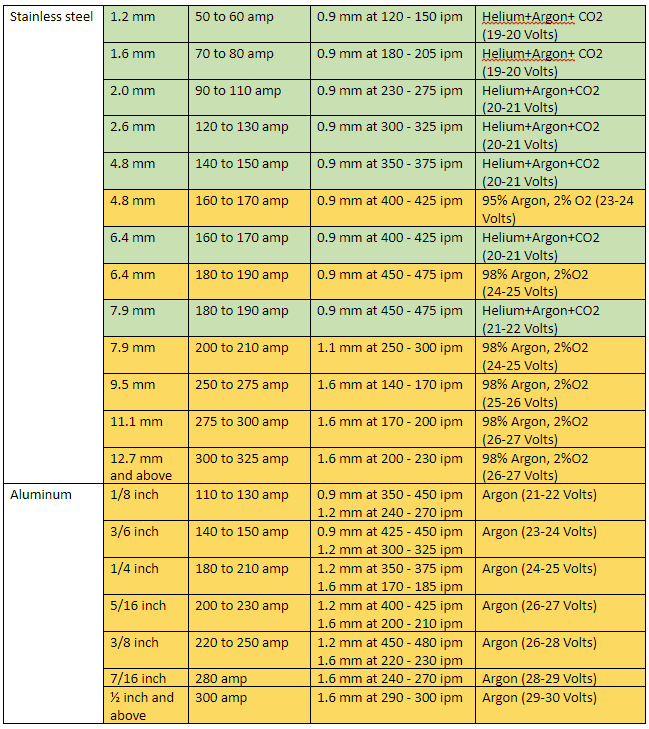

Mig Welding Amps To Metal Thickness Chart

Mig welder options, Old machine vs new MIG Welding Forum

MIG Welding Wire Output Amperage & Selection Chart

Aluminum Mig Welding Amperage Chart

Aluminum Mig Welding Amperage Chart

A MIG Welding Amps to Metal Thickness Chart Welding Mastermind

MIG Welder makerhub

MIG welder settings explained Amperage & Wire Speed

How Many Amps Do I REALLY Need for a MIG Welder >> 200300 Amps?

Mig Welding Amps To Metal Thickness Chart

Web Here Is A Chart Showing The Wire Speed And Voltage Speed Settings That Suit Lincoln Mig Welders.

Web The Chart Provides A Visual Representation Of The Required Settings, Making It Easy For Welders To Select The Right Amperage, Depending On The Material, Joint Type,.

Check With Your Machine Manufacturer For Any Information That May Pertain To Your Welding.

These Settings Determine The Heat, Wire Deposition Rate, And.

Related Post: