Mig Voltage Chart

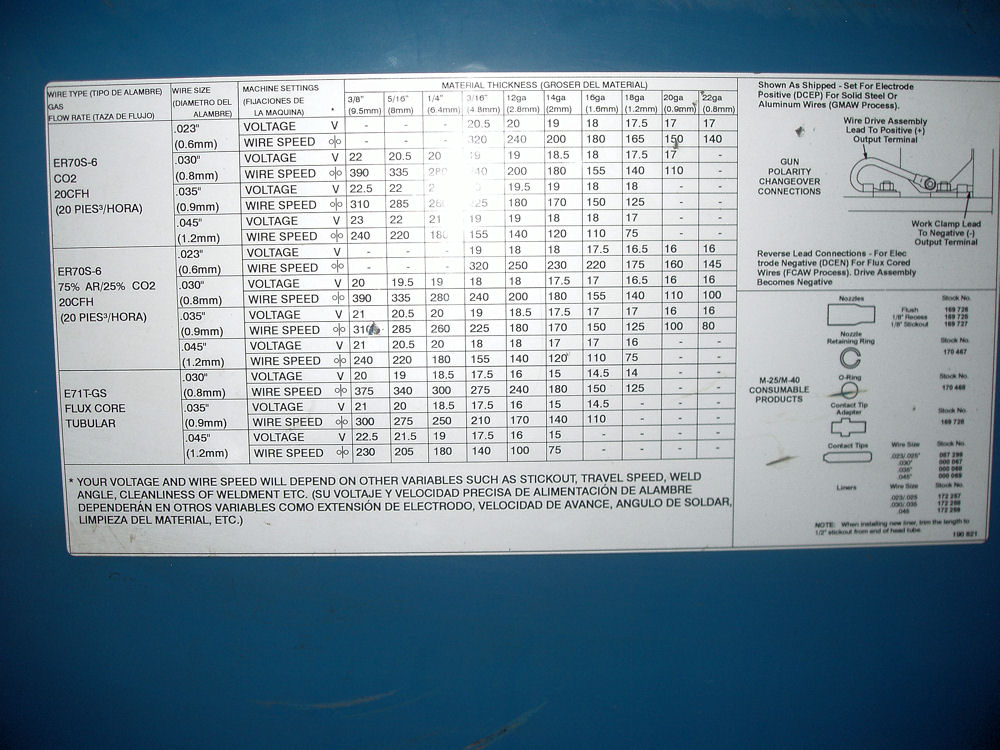

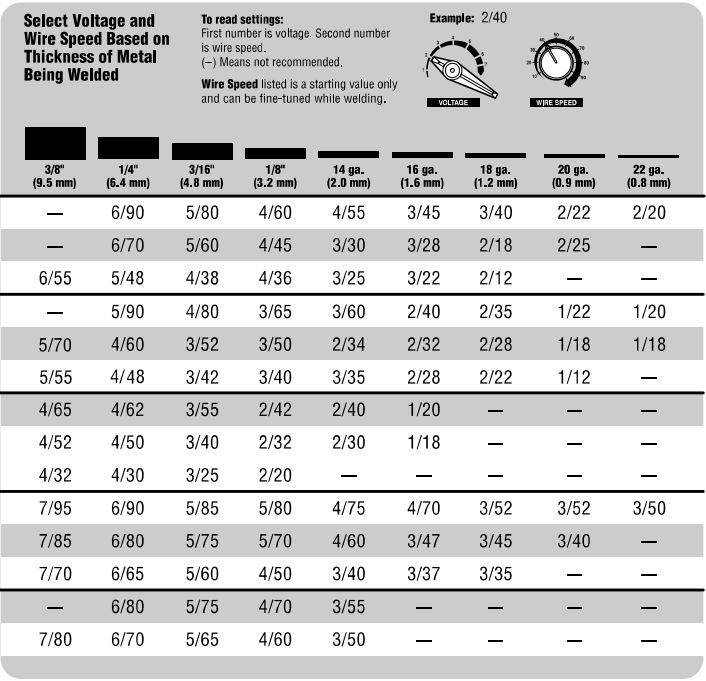

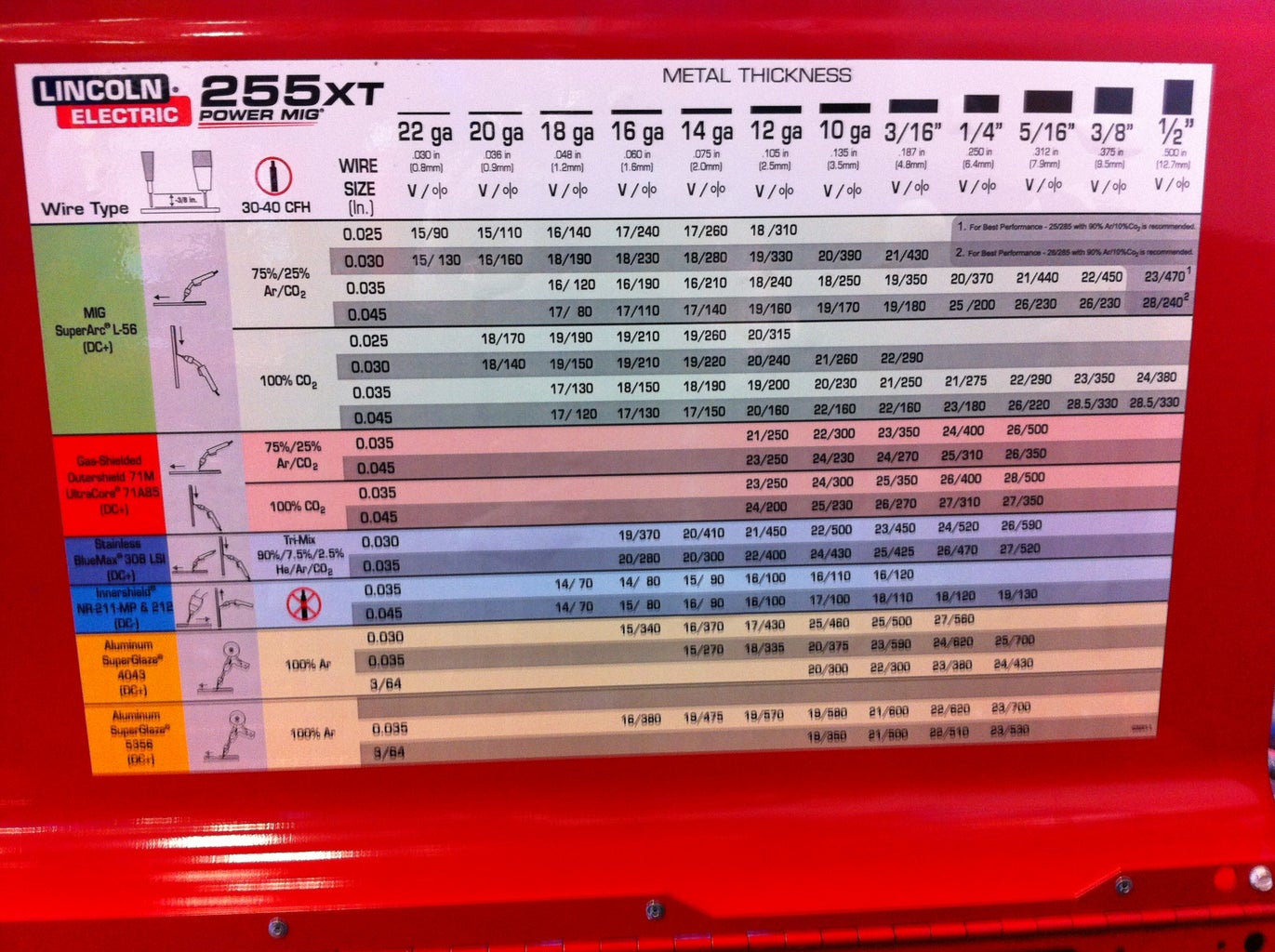

Mig Voltage Chart - Web here is a chart showing the wire speed and voltage speed settings required for various tasks. 75% argon / 25% co 2 is better on thin steels,. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Too much arc length makes a very flat bead and the undercut possibility. Co 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. Web a longer arc (more voltage) produces a flatter, wider bead. Web the wire feed speed and voltage for 1/8 inch thick steel will be lower than for 1/4 inch thick steel. Web master mig welding! Read and understand the safety data sheets. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. ⚡️ this guide unlocks the secrets of voltage & wire speed settings (usa). But before using these values, we suggest. Web a longer arc (more voltage) produces a flatter, wider bead. The proper and correct settings depend on your mig welder machine and the thickness of the mild steel you are working. If no chart, manual or specifications are available. Find perfect settings for your materials & achieve strong, clean. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Co 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. But before using these values, we suggest that. But before using these values, we suggest that you have a decent understanding. Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web a mig welding wire speed and voltage chart provide essential settings based on material thickness and wire diameter. Web there are various criteria to consider when setting your. Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. If no chart, manual or specifications are available for setting the correct voltage, you can try. These settings determine the heat, wire deposition rate, and. Web shielding gas & voltage range: But before using these values, we suggest that you have a. If no chart, manual or specifications are available for setting the correct voltage, you can try. Too much arc length makes a very flat bead and the undercut possibility. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web settings for the amperage and voltage: Web. Read and understand the safety data sheets. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. In this video i will walk you through the process of adjusting your. Web lincoln mig welding settings charts. ⚡️ this guide unlocks the secrets of voltage & wire speed. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web what material are you welding? Web shielding gas & voltage range: Co 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. Too much arc length makes a very flat bead and the undercut. Too much arc length makes a very flat bead and the undercut possibility. But before using these values, we suggest that you have a decent. Find perfect settings for your materials & achieve strong, clean. Web here is a chart showing the wire speed and voltage speed settings required for various tasks. If no chart, manual or specifications are available. 75% argon / 25% co 2 is better on thin steels,. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. In this video i will walk you through. Web the wire feed speed and voltage for 1/8 inch thick steel will be lower than for 1/4 inch thick steel. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web here is a chart showing the wire speed and voltage speed settings that suit lincoln. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: To get the voltage straight,. Web master mig welding! Web here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. But before using these values, we suggest. Web shielding gas & voltage range: If no chart, manual or specifications are available for setting the correct voltage, you can try. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web settings for the amperage and voltage: Find perfect settings for your materials & achieve strong, clean. Web lincoln mig welding settings charts. Web a mig welding wire speed and voltage chart provide essential settings based on material thickness and wire diameter. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web a longer arc (more voltage) produces a flatter, wider bead. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web here is a chart showing the wire speed and voltage speed settings required for various tasks.

What is Amps and Volts in welding? Jasic Blog

Mig Welding Voltage Chart

242 MIG Settings Chart Metalworking Metals

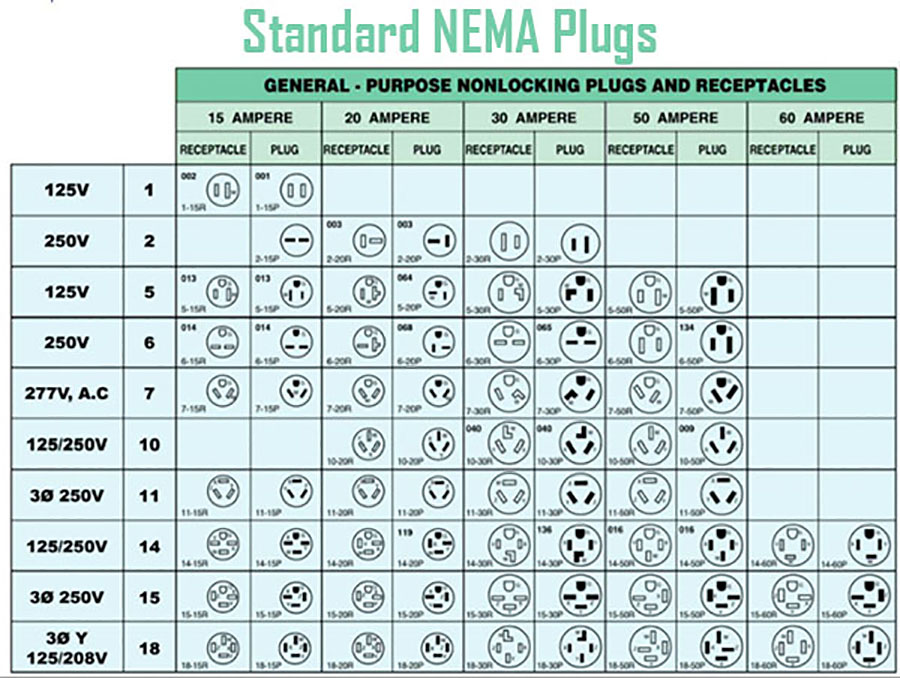

MIG Welder Voltage Selection 120 Volt or 240 Volt

MIG Welder Machine SetUp Voltage and Wire Feed Speed Guidelines and

Mig Welding Setting Chart

Mig Voltage Setting Chart

Mig Welding Voltage And Current Chart

How To MIG Weld Aluminum Beginners Guide (with Chart)

Basics of MIG Welding 17 Steps (with Pictures) Instructables

Web There Are Various Criteria To Consider When Setting Your Mig Weld Controls, Including Materials, Metal Thickness, Shielding Gas, Electrode Wires, And Amperage.

But Before Using These Values, We Suggest That You Have A Decent Understanding.

Too Much Arc Length Makes A Very Flat Bead And The Undercut Possibility.

Co 2 Gas Is Economical And Has Deeper Penetration On Steel, But May Be Too Hot For Thin Metal.

Related Post: