Metal Stud Size Chart

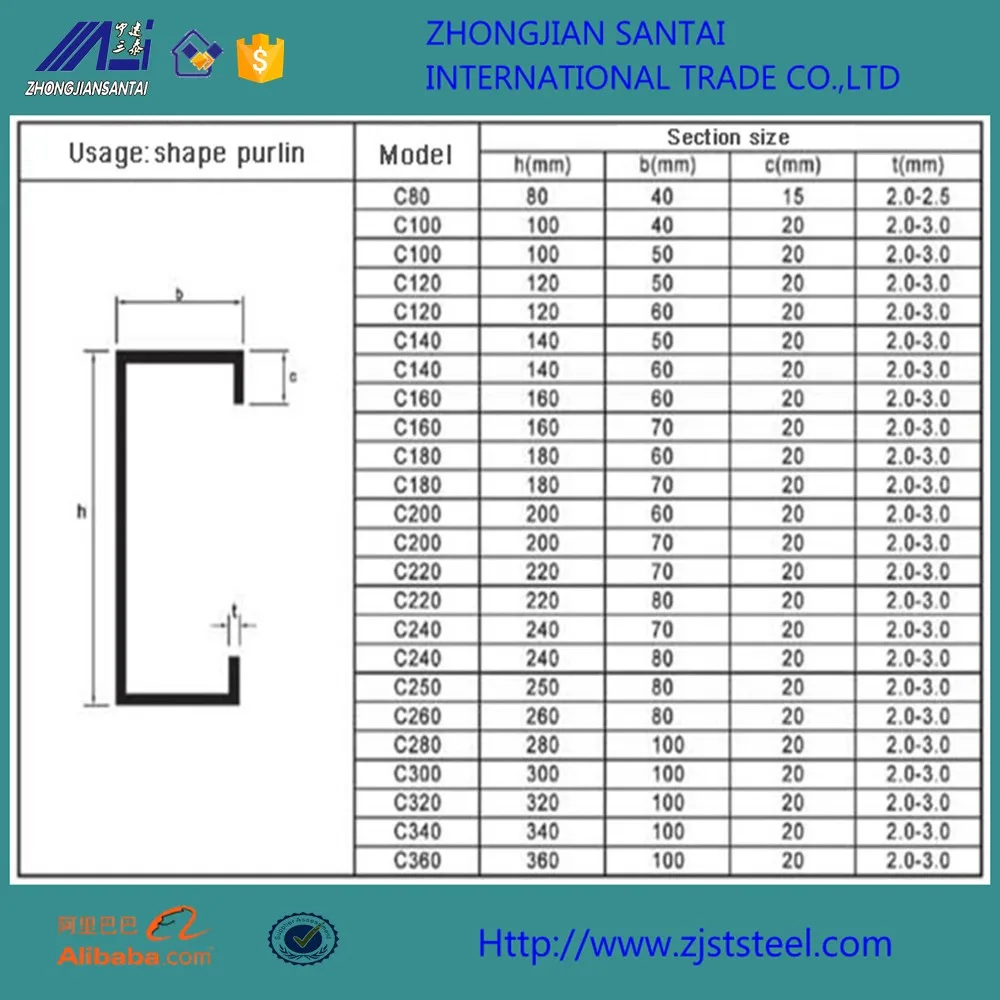

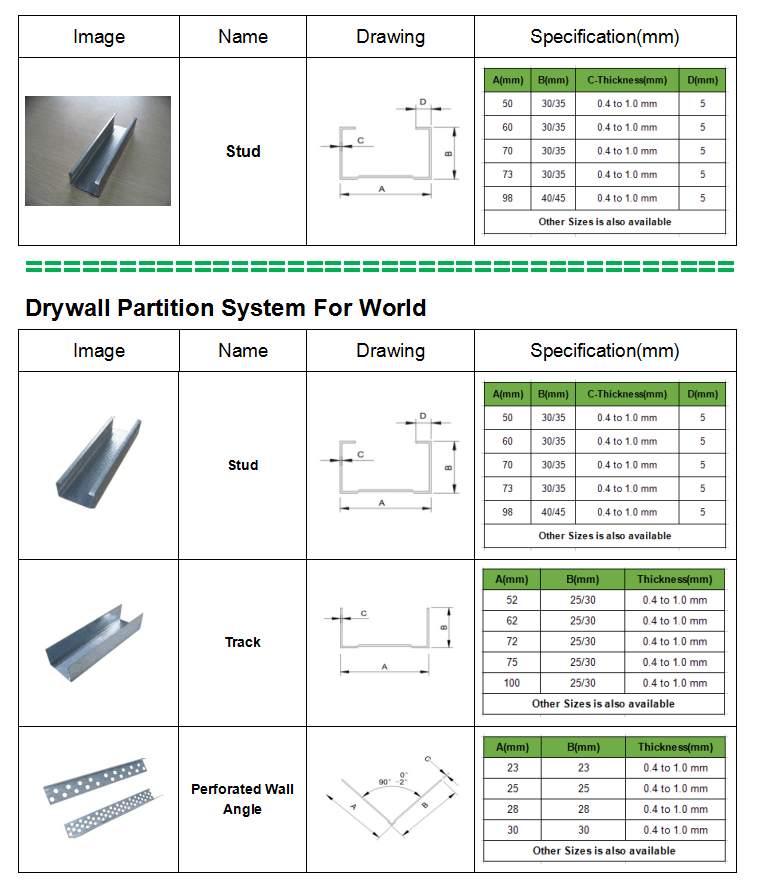

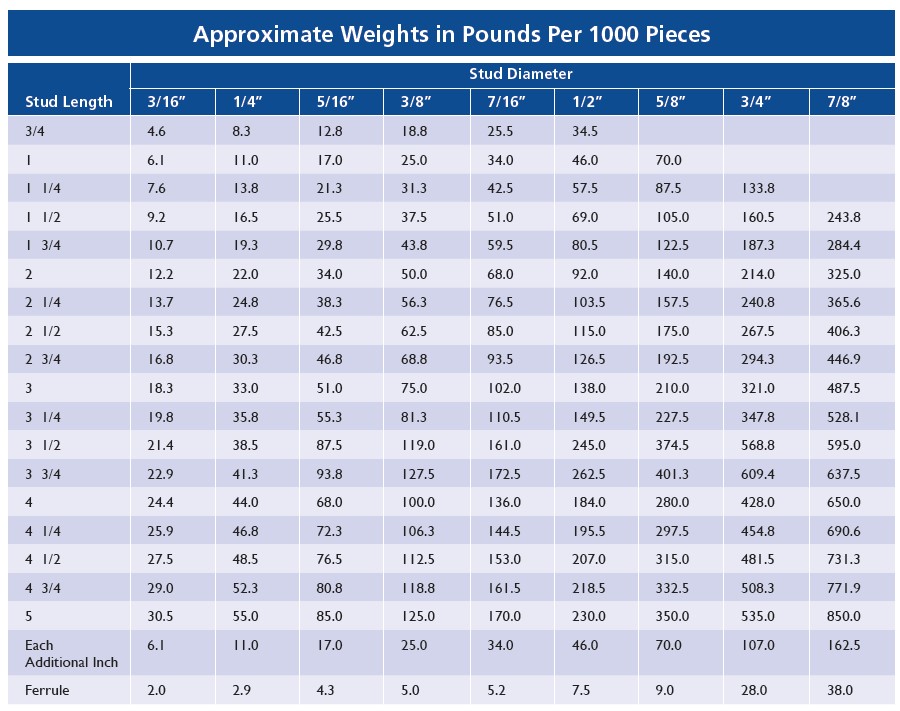

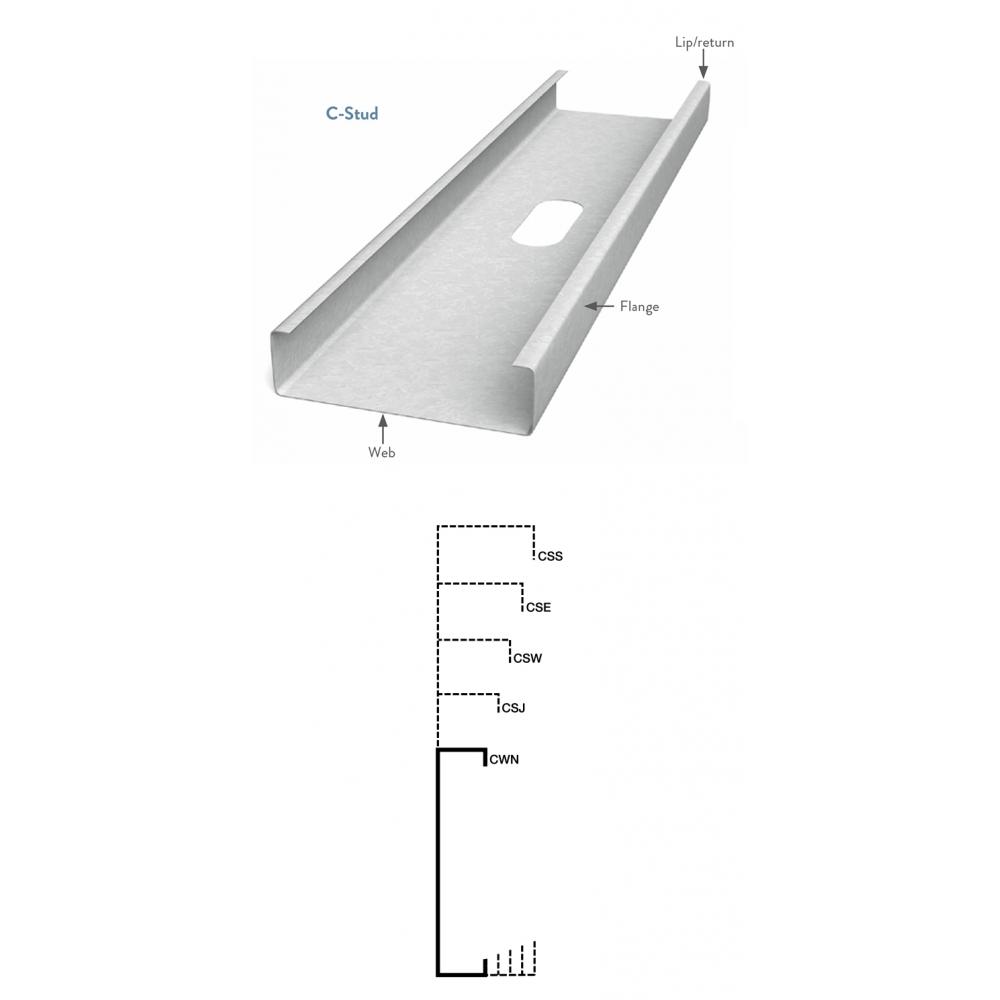

Metal Stud Size Chart - The hemming also stiffens the angle significantly. It is important to consider the thickness of the frame, the size of the webbing, and the size of the flange and lip. Residential construction predominantly employs 25 to 20 gauge, whereas commercial projects often opt for the thicker 20. Web metal stud manufacturers are required to stamp the stud size and gauge on each product. Cut one stud to size and use that, along with a level, to mark the location of the top plate at both ends, and snap a line to guide placement. Web metal stud sizes. They recommend a maximum spacing of 24 inches on center for metal studs. Combined with a layer of 5/8 gypsum wall board on both sides will give a 4 7/8 thick wall. Consider the size of the building before choosing the ideal size. Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated. The hemming also stiffens the angle significantly. Web metal stud manufacturers are required to stamp the stud size and gauge on each product. Standard widths for metal studs are 1 ⅝”, 2 ½”, 3 ⅝”. Web cut and install metal studs: Web the gauges typically used for steel studs range from 25 gauge, being the thinnest, to 16 gauge, the. Web metal stud sizes vary in width, thickness, and depth. Standard widths for metal studs are 1 ⅝”, 2 ½”, 3 ⅝”. To create longer walls, overlap metal studs at their ends and connect them with screws. [email protected] allsteel & gypsum products inc phone: Web metal stud size chart. They also vary in thickness, from 14 to 26 gauge. Measure and cut metal studs according to the wall height. 6”, 8”, 10” and 12”. Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated. Web there are many different metal stud sizes to choose from, which vary in width, thickness, and. 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68. Web there are many different metal stud sizes to choose from, which vary in width, thickness, and depth. Web the international building code (ibc) and american iron and steel institute (aisi) provide guidelines for which metal stud floor joists to use and how to space them out. Measure and cut. Secure them vertically between the top and bottom track channels using screws and a level for alignment. In general, the capacity of a stud depends on many variables — stud size, height, gauge, bracing condition, and lateral load. The width is measured from the outer edge to the opposite outer edge. Webbing in metal studs is the space in between. Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated. 6”, 8”, 10” and 12”. The hemming also stiffens the angle significantly. Web there are various steel studs for both residential and commercial use. Secure them vertically between the top and bottom track channels using screws and a level for alignment. Building a large structure requires thick metal studs with a wide web size. Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated. 5 end reactions must be checked for web crippling separately. The hemming also stiffens the angle significantly. Web metal stud manufacturers are required to stamp the stud size and. Secure them vertically between the top and bottom track channels using screws and a level for alignment. The flange is the portion of the stud that provides a larger surface area for attaching drywall or other finishing materials. Different manufacturers fabricate metal studs of similar sizes, plus some with unique characteristics. This website also provides you with more detailed information. Hemmed angle has edges that are bent over the flanges to make a smooth edge that is less sharp and easier to handle. Shaftwall is used when only one side of the wall is accessible, as in mechanical shafts where there is no floor on one side of the wall. Consider the size of the building before choosing the ideal. Standard widths for metal studs are 1 ⅝”, 2 ½”, 3 ⅝”. Web clarkdietrich studs are made in a variety of flange widths to meet different applications. Consider the size of the building before choosing the ideal size. Web metal stud sizes. While it’s always good to go with an engineered design there are tables for metal stud framing that. Cut one stud to size and use that, along with a level, to mark the location of the top plate at both ends, and snap a line to guide placement. Web the international building code (ibc) and american iron and steel institute (aisi) provide guidelines for which metal stud floor joists to use and how to space them out. Combined with a layer of 5/8 gypsum wall board on both sides will give a 4 7/8 thick wall. Different manufacturers fabricate metal studs of similar sizes, plus some with unique characteristics. Shaftwall is used when only one side of the wall is accessible, as in mechanical shafts where there is no floor on one side of the wall. Web when to use certain metal stud sizes. Hemmed angle is easier and safer to work with, thus increasing productivity. “b” next, the name may include information about the flange size. Measure and cut metal studs according to the wall height. Web the full height of the stud. Unlike wood, steel studs are reliably straight. Web 4 / 13. Web standard metal stud sizes are 1 ⅝, 2 ½, 3 ⅝, 4, and 6 inches. Web steel framing studs and track. While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel framing based on existing data out there. [email protected] allsteel & gypsum products inc phone:

Metal Stud Size Chart Ps1200 steel stud track machine jobsite

Standard Metal Stud Sizes Chart

Metal Stud Standard Size

Standard Metal Stud Sizes Chart

Steel Stud Sizes Chart

Standard Metal Stud Sizes Chart

Arc Weld Studs Complete Stud Weld

Standard Metal Stud Sizes Chart

Standard Metal Stud Sizes Chart

Metal Stud Dimensions Chart

Web There Are Various Steel Studs For Both Residential And Commercial Use.

Consider The Size Of The Building Before Choosing The Ideal Size.

Don’t Worry About Cutting Your Studs To Fit Perfectly.

5 End Reactions Must Be Checked For Web Crippling Separately.

Related Post: