Medical Device Design Control

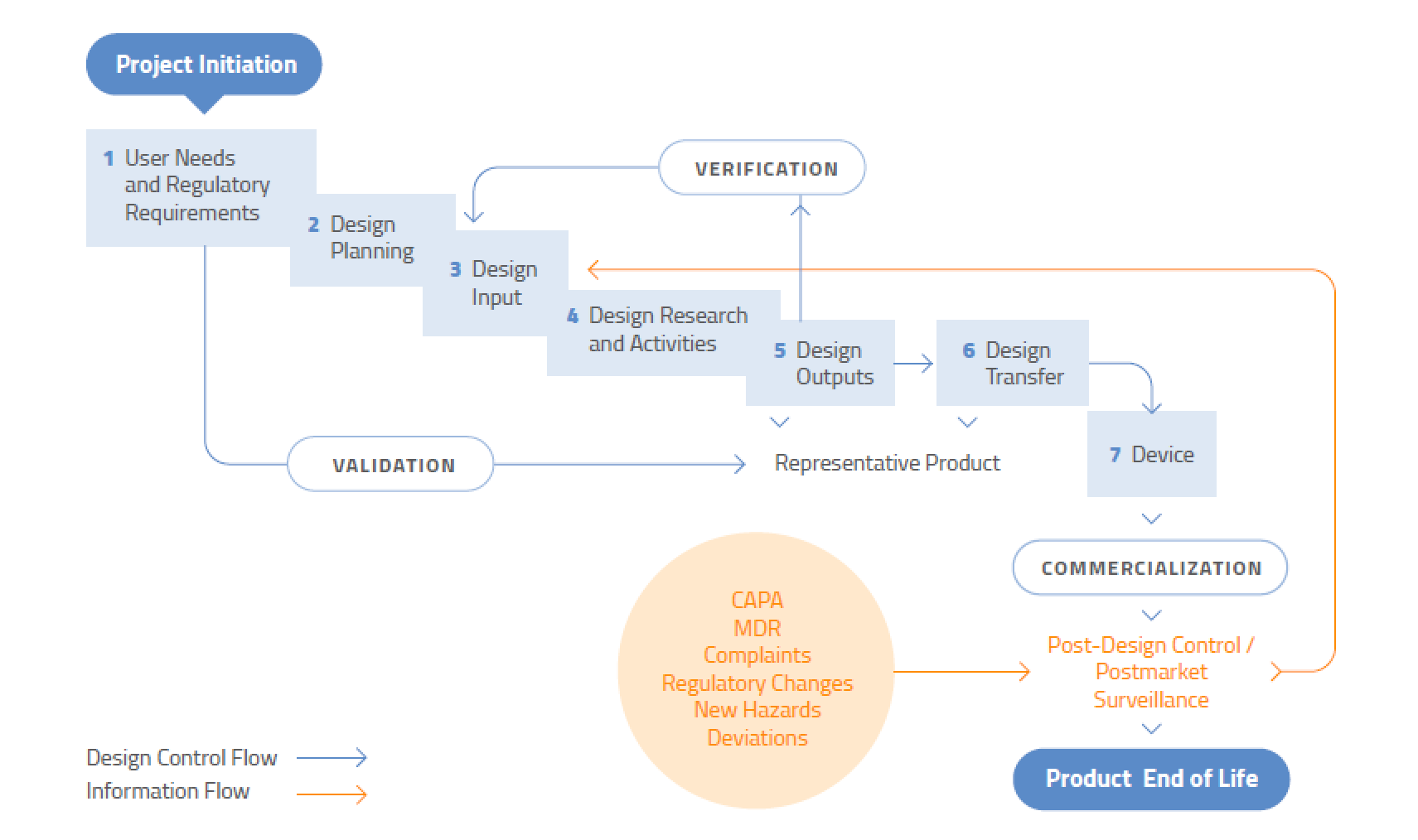

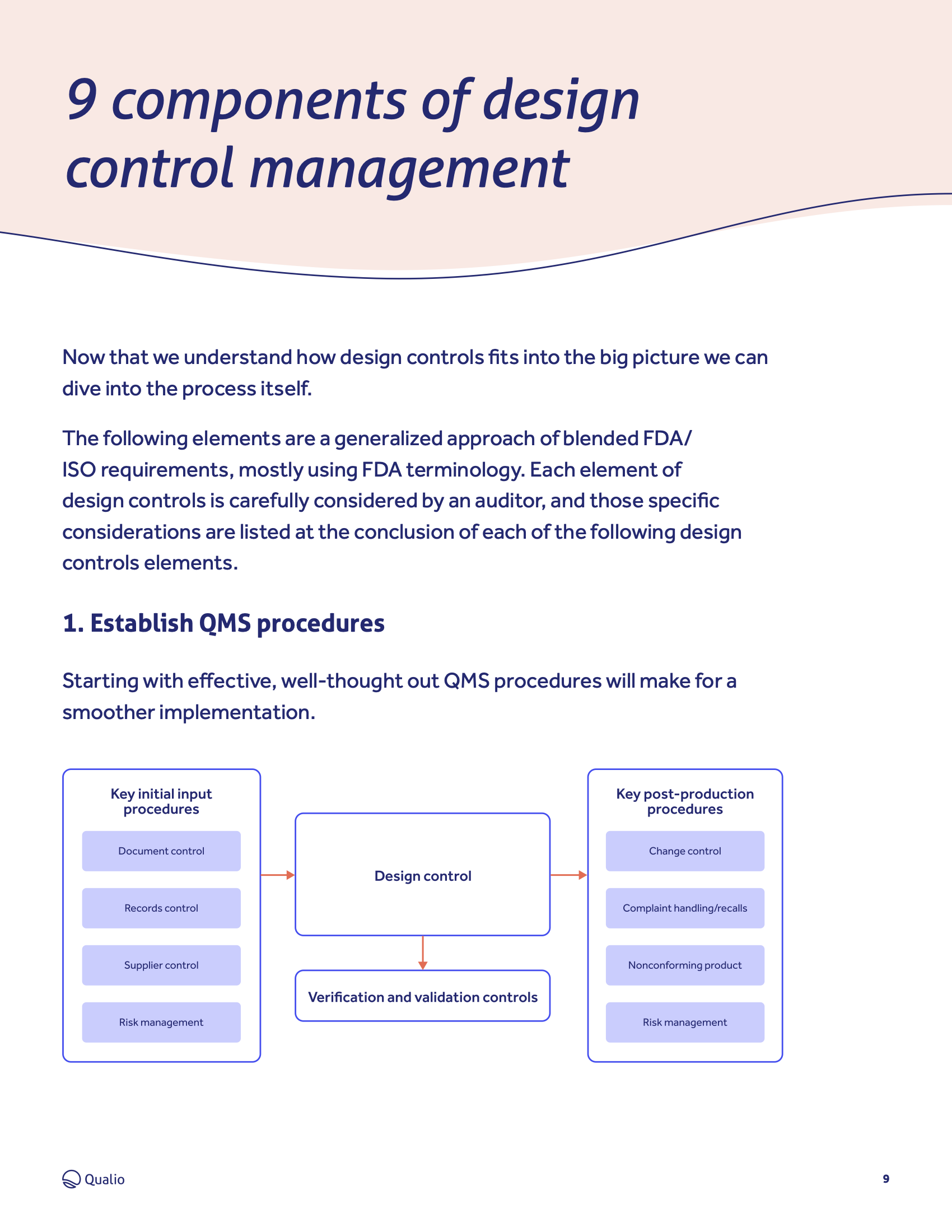

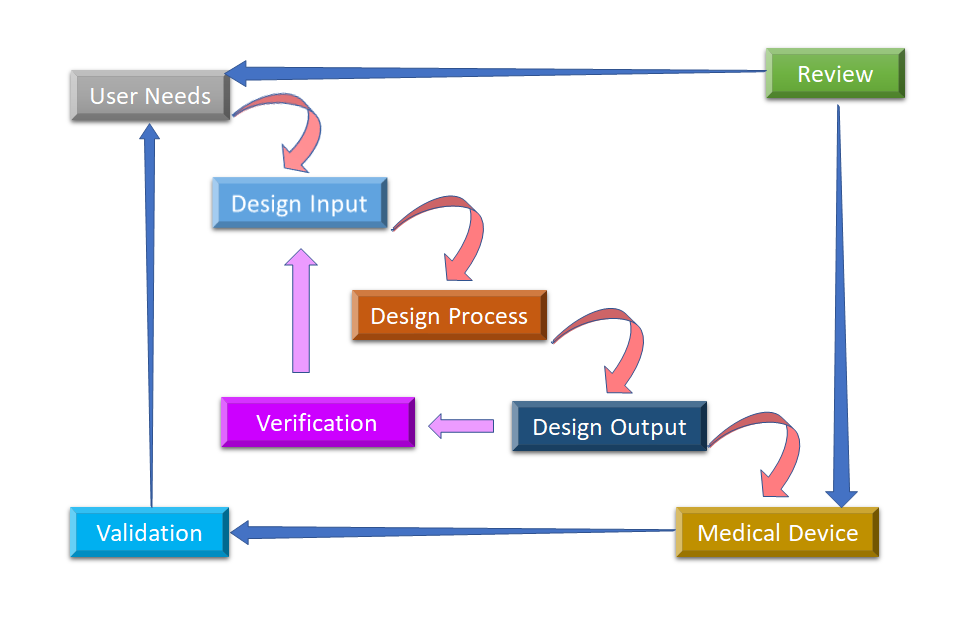

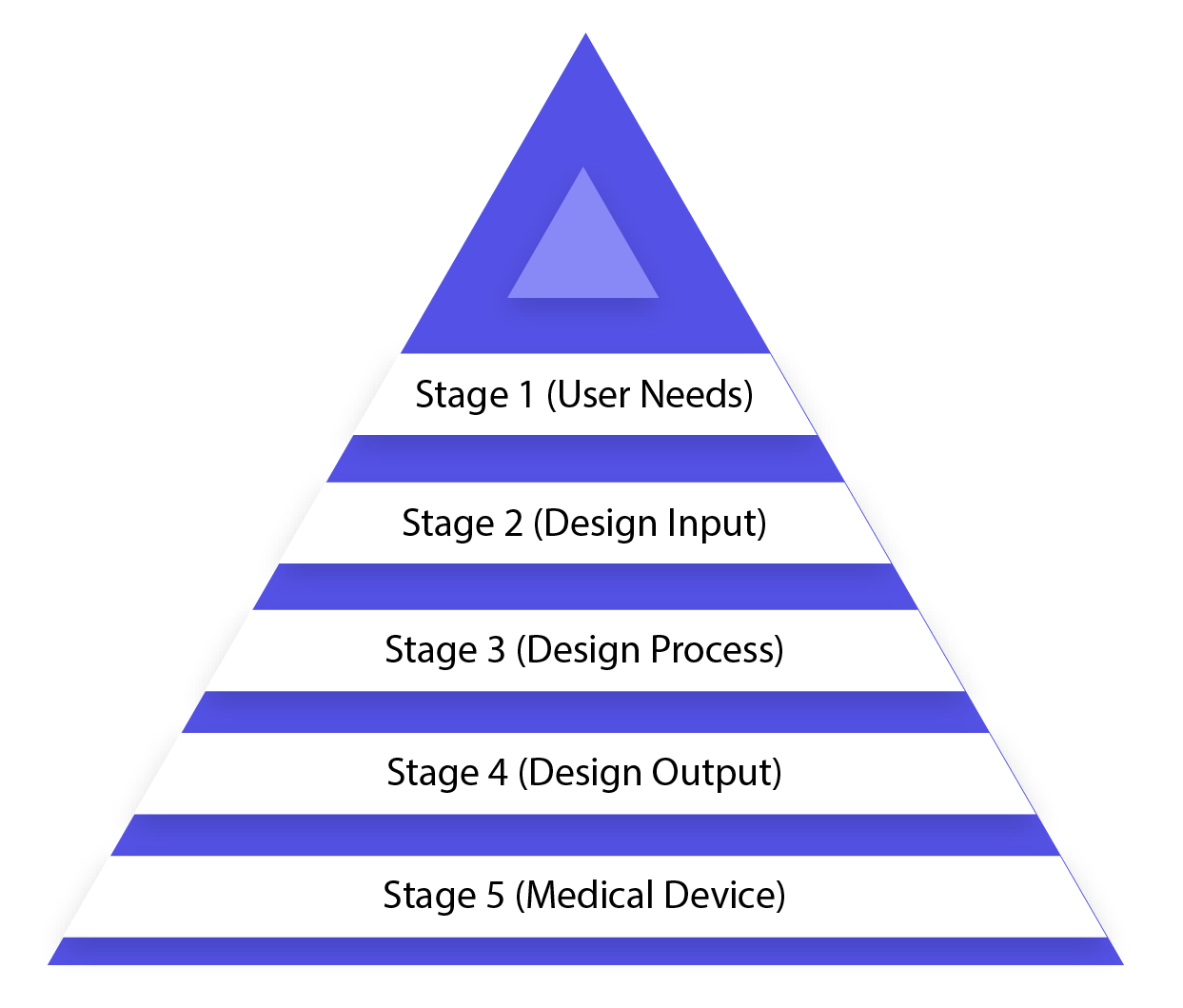

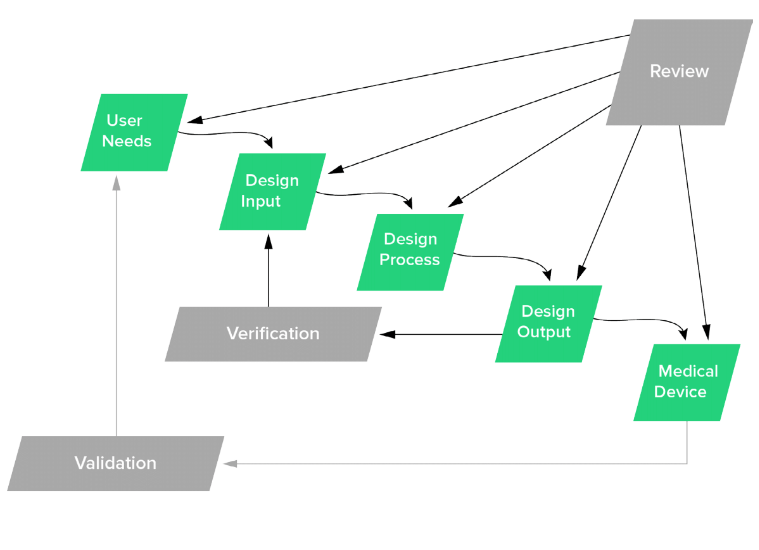

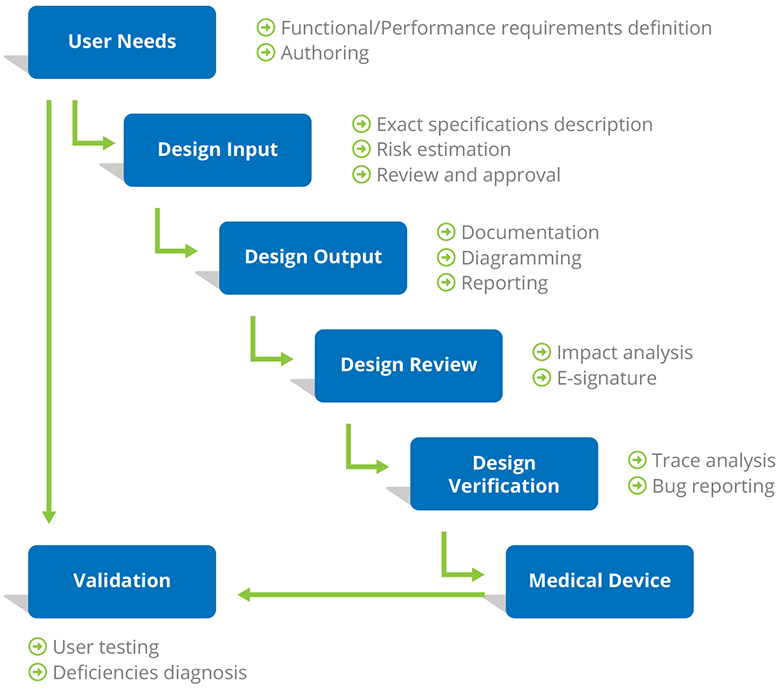

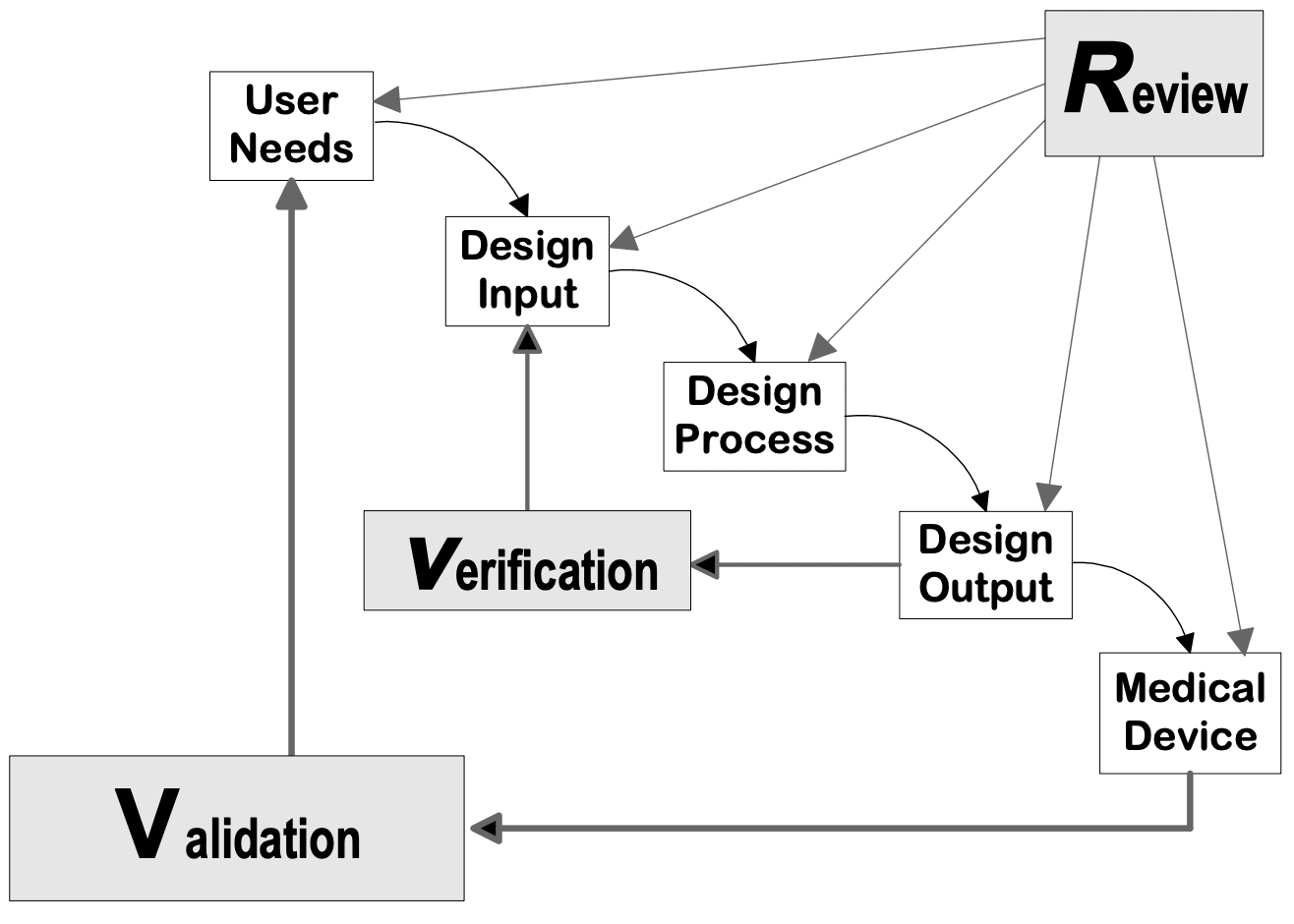

Medical Device Design Control - Web safe medical device act of 1990 authorized fda to add design controls to the current good manufacturing practice (cgmp) requirements for medical devices. Web design controls play a crucial role in the medical device development process by providing a systematic approach to manage risks, design requirements, and verification and validation activities. Why your design outputs need to be more than a drawing and their relationship to your dmr. Web you'll learn about design outputs, device master record (dmr), design verification and validation (v&v), design transfer and regulatory submissions. Web design controls demonstrate our medical devices are safe, effective, and meet the indications for use. Web design controls for medical devices are, in short, a series of structured requirements that facilitate a compliant design and development process. Each control details what’s required for compliance, and provides structure and clarity around a manufacturer’s processes and procedures. Web this documentation process is widely known as “design controls” and its purpose is to ensure that medical devices meet user needs, intended uses, and specified requirements. Plus best practices for implementing design controls as productively as possible. Let's explore the key elements of iso 13485 that will help you manage the process effectively. They act as 'checkpoints', in place to ensure your device is safe and effective when brought to market. Web design controls demonstrate our medical devices are safe, effective, and meet the indications for use. Each control details what’s required for compliance, and provides structure and clarity around a manufacturer’s processes and procedures. Let's explore the key elements of iso 13485. Each control details what’s required for compliance, and provides structure and clarity around a manufacturer’s processes and procedures. Design controls apply to the design of the product and associated manufacturing processes. Web design controls play a crucial role in the medical device development process by providing a systematic approach to manage risks, design requirements, and verification and validation activities. Plus. Design controls apply to the design of the product and associated manufacturing processes. Plus best practices for implementing design controls as productively as possible. Web you'll learn about design outputs, device master record (dmr), design verification and validation (v&v), design transfer and regulatory submissions. The quality system (qs) regulation became. Each control details what’s required for compliance, and provides structure. Web design controls play a crucial role in the medical device development process by providing a systematic approach to manage risks, design requirements, and verification and validation activities. Web safe medical device act of 1990 authorized fda to add design controls to the current good manufacturing practice (cgmp) requirements for medical devices. Design controls apply to the design of the. Design controls apply to the design of the product and associated manufacturing processes. Let's explore the key elements of iso 13485 that will help you manage the process effectively. Plus best practices for implementing design controls as productively as possible. They act as 'checkpoints', in place to ensure your device is safe and effective when brought to market. Web design. Web safe medical device act of 1990 authorized fda to add design controls to the current good manufacturing practice (cgmp) requirements for medical devices. Web you'll learn about design outputs, device master record (dmr), design verification and validation (v&v), design transfer and regulatory submissions. The quality system (qs) regulation became. Let's explore the key elements of iso 13485 that will. Web safe medical device act of 1990 authorized fda to add design controls to the current good manufacturing practice (cgmp) requirements for medical devices. Design controls apply to the design of the product and associated manufacturing processes. Web this documentation process is widely known as “design controls” and its purpose is to ensure that medical devices meet user needs, intended. Web you'll learn about design outputs, device master record (dmr), design verification and validation (v&v), design transfer and regulatory submissions. With this guide, i plan to share valuable insights to explain what design controls are, how to address them, and how they benefit your medical device product development efforts. Why your design outputs need to be more than a drawing. Why your design outputs need to be more than a drawing and their relationship to your dmr. With this guide, i plan to share valuable insights to explain what design controls are, how to address them, and how they benefit your medical device product development efforts. Web design controls for medical devices are, in short, a series of structured requirements. Web this documentation process is widely known as “design controls” and its purpose is to ensure that medical devices meet user needs, intended uses, and specified requirements. Web design controls play a crucial role in the medical device development process by providing a systematic approach to manage risks, design requirements, and verification and validation activities. With this guide, i plan. Web design controls for medical devices are, in short, a series of structured requirements that facilitate a compliant design and development process. Let's explore the key elements of iso 13485 that will help you manage the process effectively. Web design controls demonstrate our medical devices are safe, effective, and meet the indications for use. With this guide, i plan to share valuable insights to explain what design controls are, how to address them, and how they benefit your medical device product development efforts. Plus best practices for implementing design controls as productively as possible. Web the us fda identifies design controls that medical device manufacturers must incorporate under their qms when developing new products, or modifying existing ones. Web here’s a plain and simple version of design controls for medical device development to help you understand fda design controls for medical devices. Web this documentation process is widely known as “design controls” and its purpose is to ensure that medical devices meet user needs, intended uses, and specified requirements. The quality system (qs) regulation became. Web you'll learn about design outputs, device master record (dmr), design verification and validation (v&v), design transfer and regulatory submissions. Web safe medical device act of 1990 authorized fda to add design controls to the current good manufacturing practice (cgmp) requirements for medical devices. Each control details what’s required for compliance, and provides structure and clarity around a manufacturer’s processes and procedures.

Medical Device Design and Developement. Validation. Regulation. Control

Basics of Medical Device Design Controls What, Why, and How Oriel

Ultimate guide to medical device design controls

An Intelligent Approach to Design Control for Medical Devices Siemens

Medical Device Design The Essential, StepbyStep Guide

FDA Design Control The Ultimate Guide For Medical Device Companies

The Ultimate Guide To Design Controls For Medical Device Companies

A Guide To Fda Design Controls For Your Medical Devic vrogue.co

A guide to FDA Design Controls for your medical device

.webp?width=750&height=590&name=Medical Device Development Design Control (1).webp)

Medical Device Development Guide

They Act As 'Checkpoints', In Place To Ensure Your Device Is Safe And Effective When Brought To Market.

Design Controls Apply To The Design Of The Product And Associated Manufacturing Processes.

Why Your Design Outputs Need To Be More Than A Drawing And Their Relationship To Your Dmr.

Web Design Controls Play A Crucial Role In The Medical Device Development Process By Providing A Systematic Approach To Manage Risks, Design Requirements, And Verification And Validation Activities.

Related Post: