Mawp Vs Design Pressure

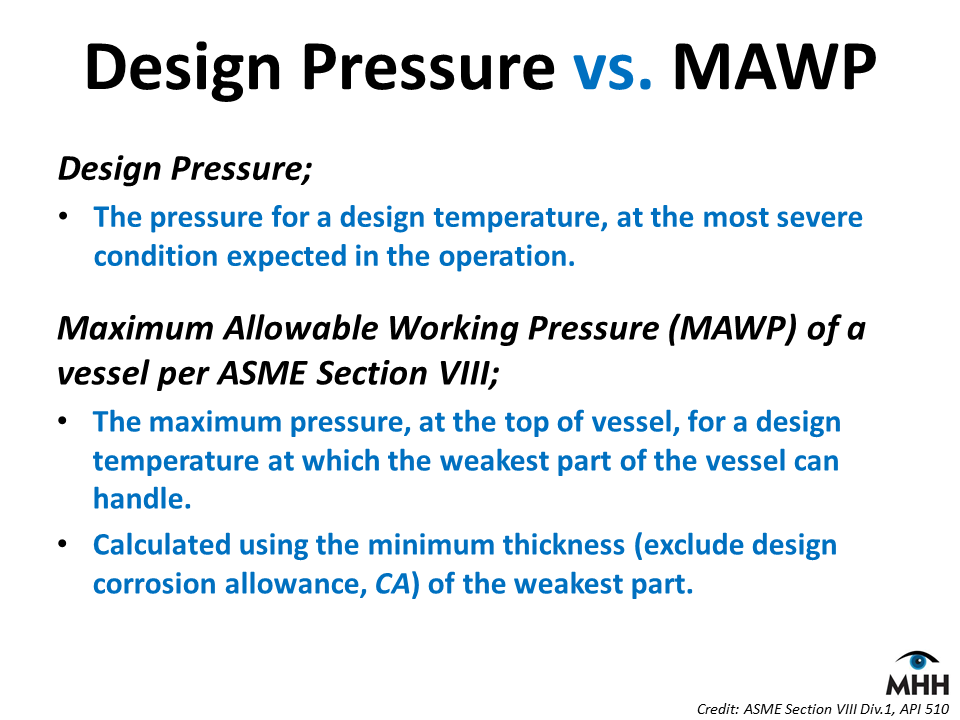

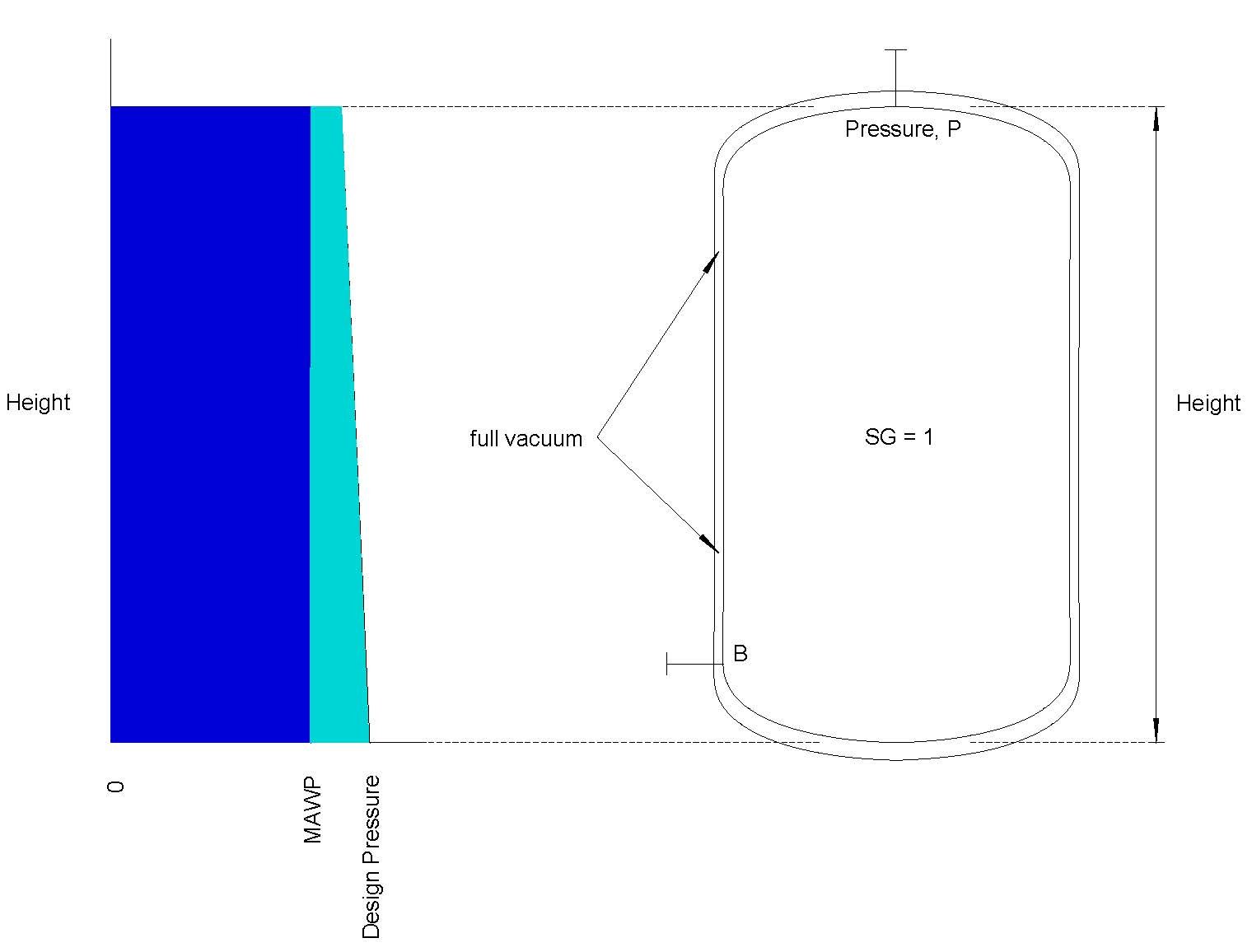

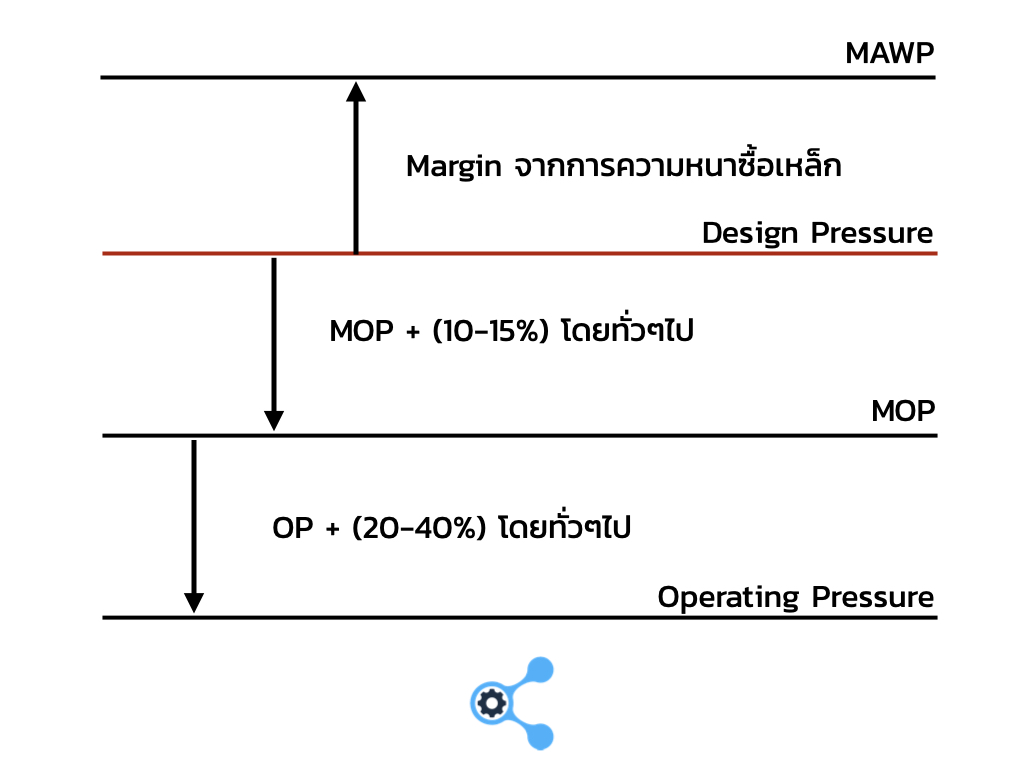

Mawp Vs Design Pressure - Vessel was designed to asme section viii div. Web the mawp is the pressure stamped on the pressure equipment, and the pressure that must not be exceeded in operation. It is almost always higher than the design pressure. Refused to stamp anything other than the design pressure on the nameplate mawp section. Design pressure is the pressure a pressurized item is designed to, and is higher than any expected operating pressures. Web mawp is a safety limit that should not be exceeded, while design pressure is a starting point for the vessel’s design and can be adjusted based on other factors, such as safety regulations and cost. Therefore, the key difference between the two is that design pressure is the maximum pressure equipment is designed to withstand. The design pressure and the coincident design All data should be transmitted to the fabricator. A vessel may have multiple design pressures with coincident design temperatures. This should be below mawp and based on company standards can vary from 10% to 25% above the maximum operating pressure of the system. After several discussions, our fabricator said their a.i. All data should be transmitted to the fabricator. Design pressure is the pressure a pressurized item is designed to, and is higher than any expected operating pressures. Mawp. Vessel was designed to asme section viii div. Web the code calculations showed an actual vessel mawp to be much higher (~140 psig). After several discussions, our fabricator said their a.i. Web the mawp is the pressure stamped on the pressure equipment, and the pressure that must not be exceeded in operation. Web one of the main differences between maximum. Vessel was designed to asme section viii div. This should be below mawp and based on company standards can vary from 10% to 25% above the maximum operating pressure of the system. Therefore, the key difference between the two is that design pressure is the maximum pressure equipment is designed to withstand. It is almost always higher than the design. Web mawp vs design pressure. Refused to stamp anything other than the design pressure on the nameplate mawp section. All data should be transmitted to the fabricator. Web in short, the mawp is always set lower than the design pressure to prevent equipment failure or damage. A vessel may have multiple design pressures with coincident design temperatures. All data should be transmitted to the fabricator. Web in short, the mawp is always set lower than the design pressure to prevent equipment failure or damage. Web mawp vs design pressure. Web the code calculations showed an actual vessel mawp to be much higher (~140 psig). After several discussions, our fabricator said their a.i. The design pressure and the coincident design Web mawp is a safety limit that should not be exceeded, while design pressure is a starting point for the vessel’s design and can be adjusted based on other factors, such as safety regulations and cost. Web the code calculations showed an actual vessel mawp to be much higher (~140 psig). “the pressure. The psv set pressure is based on design pressure, and it can be equal to the mawp but not higher. It is almost always higher than the design pressure. Refused to stamp anything other than the design pressure on the nameplate mawp section. After several discussions, our fabricator said their a.i. Web calculation of maximum allowable working pressure (mawp) the. Therefore, the key difference between the two is that design pressure is the maximum pressure equipment is designed to withstand. It is almost always higher than the design pressure. Mawp is the highest pressure at which the equipment may be operated at its design temperature. Web in short, the mawp is always set lower than the design pressure to prevent. Web one of the main differences between maximum allowable working pressure and design pressure is that the latter one is always equal or less than the mawp of the vessel or equipment. Web mawp vs design pressure. Design pressure is the pressure a pressurized item is designed to, and is higher than any expected operating pressures. A vessel may have. Refused to stamp anything other than the design pressure on the nameplate mawp section. All data should be transmitted to the fabricator. Web mawp is a safety limit that should not be exceeded, while design pressure is a starting point for the vessel’s design and can be adjusted based on other factors, such as safety regulations and cost. This should. Web one of the main differences between maximum allowable working pressure and design pressure is that the latter one is always equal or less than the mawp of the vessel or equipment. The design pressure and the coincident design The psv set pressure is based on design pressure, and it can be equal to the mawp but not higher. Therefore, the key difference between the two is that design pressure is the maximum pressure equipment is designed to withstand. Whereas a vessel’s mawp is the highest level of pressure it could be exposed to, the design pressure is the highest level of pressure it should be exposed to in normal operating conditions. After several discussions, our fabricator said their a.i. A vessel may have multiple design pressures with coincident design temperatures. Web mawp is a safety limit that should not be exceeded, while design pressure is a starting point for the vessel’s design and can be adjusted based on other factors, such as safety regulations and cost. Web in short, the mawp is always set lower than the design pressure to prevent equipment failure or damage. Refused to stamp anything other than the design pressure on the nameplate mawp section. It is almost always higher than the design pressure. This should be below mawp and based on company standards can vary from 10% to 25% above the maximum operating pressure of the system. Mawp is the highest pressure at which the equipment may be operated at its design temperature. All data should be transmitted to the fabricator. Vessel was designed to asme section viii div. Design pressure is the pressure a pressurized item is designed to, and is higher than any expected operating pressures.

MHH Place for Knowledge Sharing with Happiness

CRNs, MAWP & Design Pressure Cammar Corporation

Difference Between MAWP and Design Pressure in short YouTube

Design Pressure Vs MAWP (API, ASME) AMARINE

ข้อแตกต่างของ MAWP, Design pressure, และ Operating pressure

What is Operating pressure, Design Pressure, MAWP,MOP Design Hub

What is MAWP & How to calculate MAWP? Part 5 Design Hub YouTube

What is MAWP, Design ,Operating & Hydrotest Pressure ? YouTube

MAWP vs Design Pressure Overpressure & Accumulation Operating P

Design and Working Pressure Download Scientific Diagram

“The Pressure Authorized On The Design Registration Or A Lesser Pressure As Indicated On The Manufacturer’s Data Report.

Web Mawp Vs Design Pressure.

Web Calculation Of Maximum Allowable Working Pressure (Mawp) The Mawp Is Not The Same As The Design Pressure.

Web The Code Calculations Showed An Actual Vessel Mawp To Be Much Higher (~140 Psig).

Related Post: