Machining Design

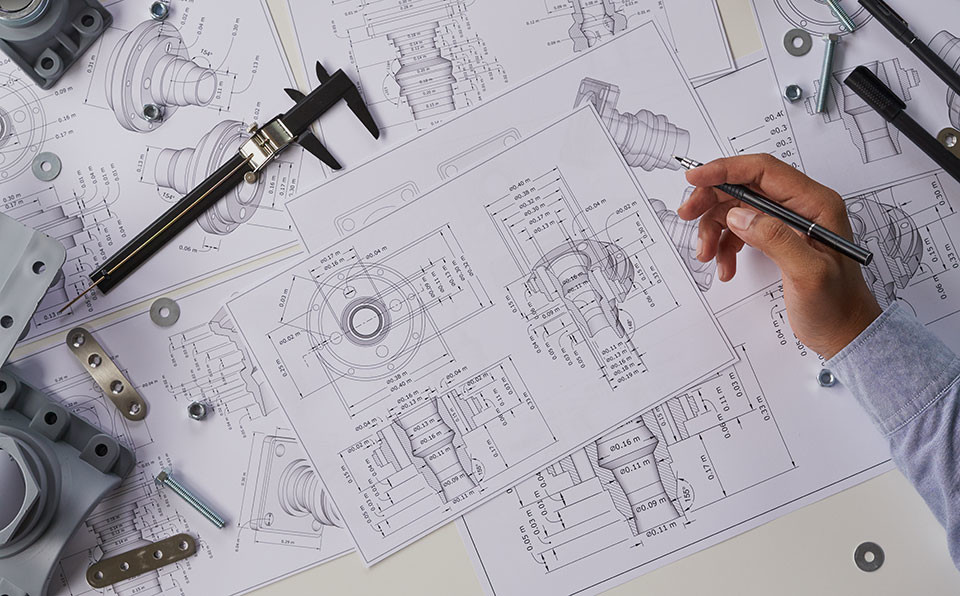

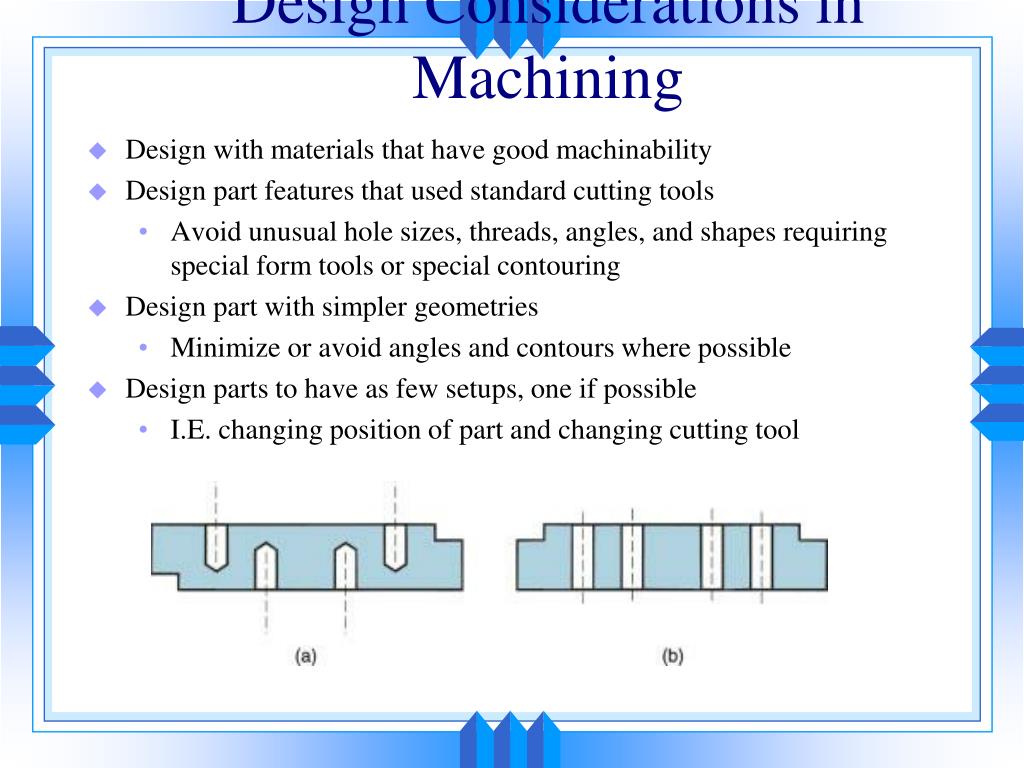

Machining Design - During an inspection of your firm located at 410 conselyea. Download our guide for cnc manufacturability recommendations to optimize your designs, reduce machining time, and lower your costs. It involves the application of engineering principles, scientific knowledge, and practical considerations to design machines that fulfill specific purposes. As 9100 d / iso 9001:2015 certified. From general best practices to bespoke tips for different cnc operations, we’re diving into how to sculpt your designs for peak cnc performance. There are a few easy steps you can take to optimize your designs for computer numerical control (cnc) machining. Here’s a short list of design factors to prioritize for cnc machinability. Web in this complete guide to designing for cnc machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. Amco international manufacturing & design, inc. Web cnc machining’s goal is precision, and feature tolerances can be as small as ±0.001 in. Drilling, milling, turning, and advanced tips. Web cnc machining’s goal is precision, and feature tolerances can be as small as ±0.001 in. When it comes to a material consideration, the speed of machining, material hardness, and finishing aesthetics are all critical in design for cnc. During an inspection of your firm located at 410 conselyea. These composites were used to. Simply complete our online form. From design for machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. This process accelerates the design and review process, and increases efficiency while reducing costs. Here’s a short list of design factors to prioritize for cnc machinability. Web design cnc parts for seamless machining with large diameters using. Central florida’s leading precision cnc shop. The share of modern semiconductor manufacturing capacity located in the u.s. We are happy to provide you with a custom quote! In this guide, we unravel the secrets of cnc machining design. Web in july 2022, congress passed the chips act of 2022 to strengthen domestic semiconductor manufacturing, design and research, fortify the economy. Web large format additive manufacturing (lfam) is defined as those am technologies that enable the production of parts larger than 1 m³ [1]. Web for more than 30 years, electronic design and manufacturing (edm) of lynchburg, virginia, has been solving engineering and manufacturing challenges in the electronic manufacturing services (ems) industry. Web ak machining is a family owned and operated. Has eroded from 37% in 1990 to 12% today,. 6 ways to optimize part design for cnc machining. From design for machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. Here’s a short list of design factors to prioritize for cnc machinability. It can be performed on almost any material from expanded polyurethane foam. Air force research laboratory to produce an innovative additive manufacturing, or am, machine. It involves the application of engineering principles, scientific knowledge, and practical considerations to design machines that fulfill specific purposes. Web how to design for cnc machining. Simply complete our online form. Web large format additive manufacturing (lfam) is defined as those am technologies that enable the production. A computer uses programming codes to direct machine tools to chip at (subtract) a material. Here’s a short list of design factors to prioritize for cnc machinability. In this guide, we unravel the secrets of cnc machining design. 6 ways to optimize part design for cnc machining. Our entire process, from quoting to physical cutting in a mill—more commonly known. Web digitalization, through the creation of digital twins, will let enterprises design and simulate their physical processes before constructing a physical replica. We are happy to provide you with a custom quote! Web large format additive manufacturing (lfam) is defined as those am technologies that enable the production of parts larger than 1 m³ [1]. In this guide, we unravel. From general best practices to bespoke tips for different cnc operations, we’re diving into how to sculpt your designs for peak cnc performance. From concept to production, we can engineer and design customized parts to suit your needs. Central florida’s leading precision cnc shop. Machining experts advise against using tool sizes less than 20 points when cnc machining texts on. This is until the material forms the input designed part. Air force research laboratory to produce an innovative additive manufacturing, or am, machine. Web digitalization, through the creation of digital twins, will let enterprises design and simulate their physical processes before constructing a physical replica. You can save significant time and cost by checking your design against this list before. The share of modern semiconductor manufacturing capacity located in the u.s. Web don’t let design for manufacturing be an afterthought. Air force research laboratory to produce an innovative additive manufacturing, or am, machine. From general best practices to bespoke tips for different cnc operations, we’re diving into how to sculpt your designs for peak cnc performance. Web design for cnc machining. A computer uses programming codes to direct machine tools to chip at (subtract) a material. Web digitalization, through the creation of digital twins, will let enterprises design and simulate their physical processes before constructing a physical replica. Web cnc machining’s goal is precision, and feature tolerances can be as small as ±0.001 in. Web it’s an art form, requiring a keen eye for design and a deep understanding of the process. We are happy to provide you with a custom quote! Web concurrent technologies corporation, or ctc, has received a contract from the u.s. Web ak machining is a family owned and operated precision machine shop specializing in cnc milling and turning and quick deliveries. It can be performed on almost any material from expanded polyurethane foam to nickel superalloys. During an inspection of your firm located at 410 conselyea. Web generally speaking, computer numerical control (cnc) machining is a deduction manufacturing technique that produces finished parts by removing layers from solid blocks called blanks. From concept to production, we can engineer and design customized parts to suit your needs.

CNC Machining How to design parts for CNC machining?

Amormino Machining & Design

Precision Machining Freedom Manufacturing Inc. York PA

What is CNC Machining? Denver Manufacturing CNC Manufacturing

How to design parts for CNC machining 3D Hubs

3 Aspects of CNC Machining Parts That You Should Know • Aerostar

Custom Precision Machining & Part Design From Prototyping to

15 Machining Design Guidelines for Beginners (2023) »

PPT Machining Family of Material Removal Processes PowerPoint

2D Technical Drawings CNC Machining Service

Web We’ve Gathered Some Best Practices For You To Keep In Mind While Designing Your Product, Separated Into 4 Sections:

When 3D Simulations Are Connected To The Physical World Using Universal Scene.

These Composites Were Used To Print A Luminaire Utilising A Biomimetic Approach And Parametric Design, Showcasing How New Materials And Innovative Product Design Can Be Integrated To.

In This Guide, We Unravel The Secrets Of Cnc Machining Design.

Related Post: