Lvl Nail Pattern

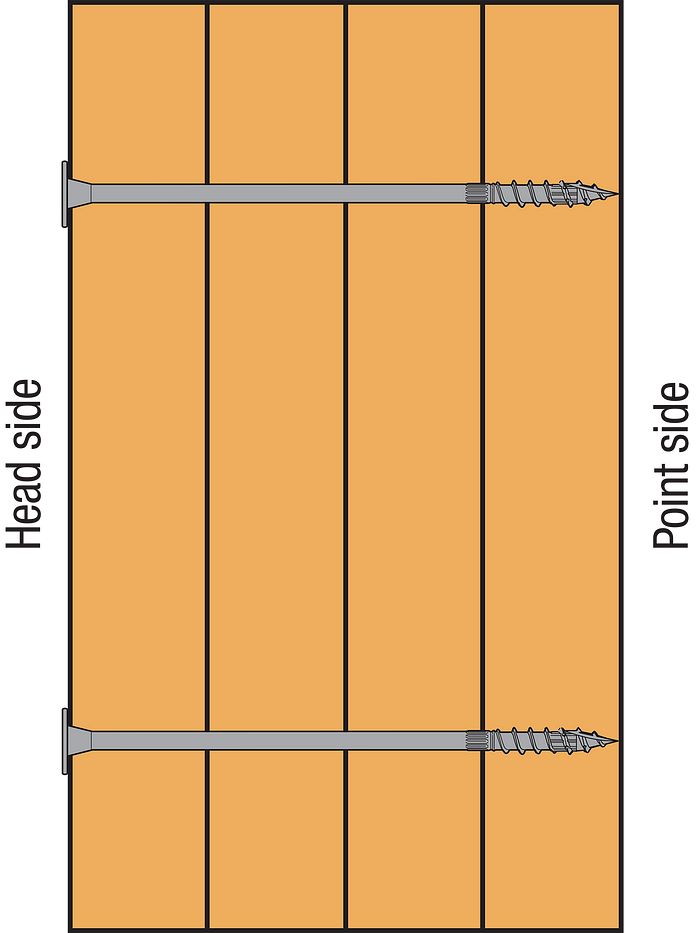

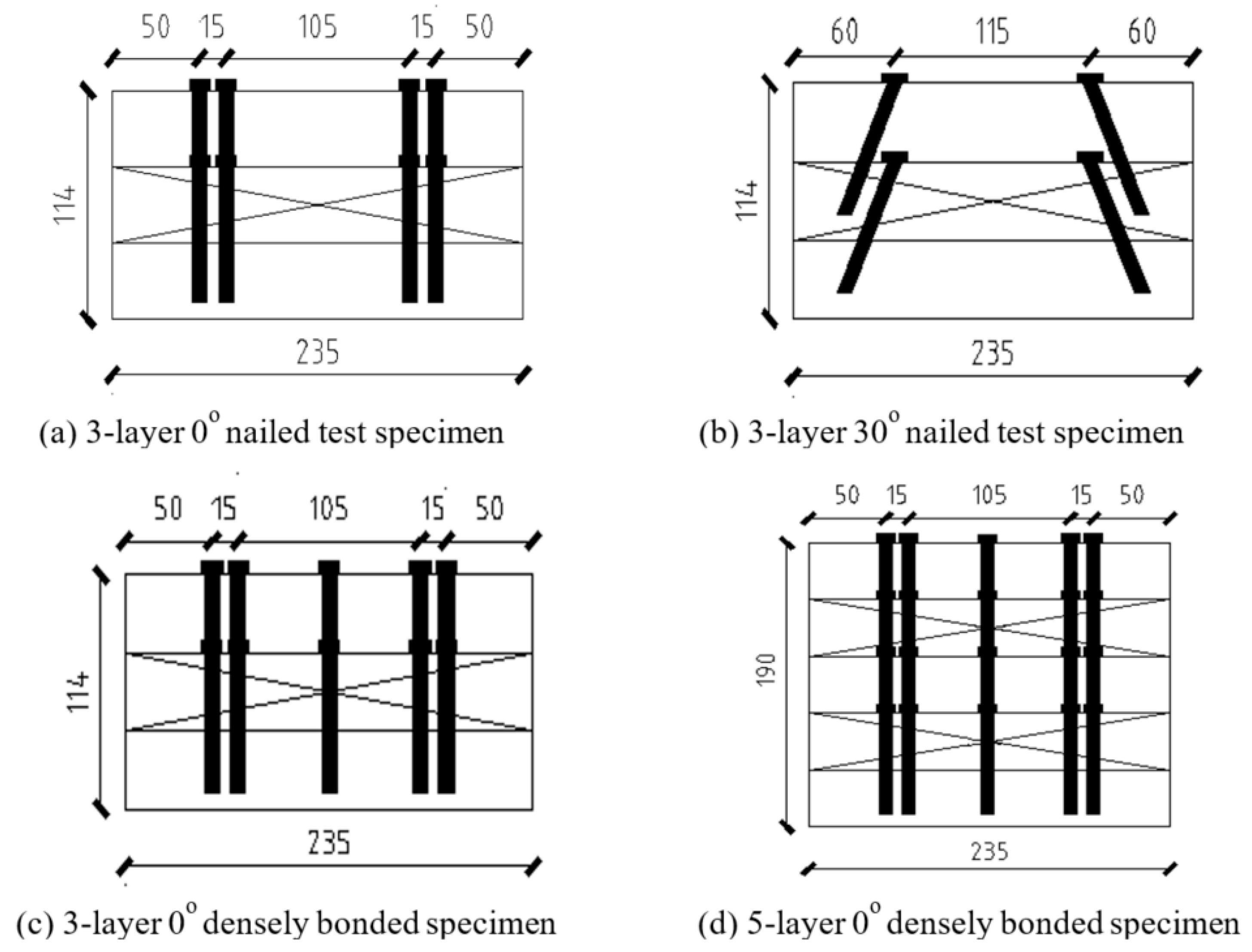

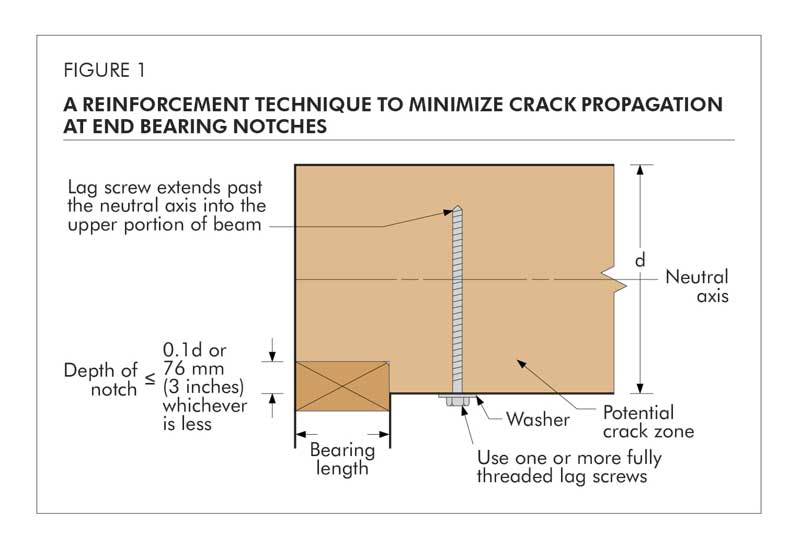

Lvl Nail Pattern - Web microllam® lvl beam benefits: The top row of nails should be. Web the recommended nailing pattern for lvl beams is to use two rows of nails on each side of the beam. Nail spacing, nail pattern, how many and how to join & fix b. All products have face, back and. (add 1 row for 16d sinkers). Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Web 3) fastening with nails. Web joists and lvl beams, along with weyerhaeuser rim board, are engineered to provide both strength and consistency — features that help builders save on installation time and. Web nailing pattern on a 9 1/2 inch lvl? Web i drew up this portal frame detail to show the nailing pattern per code so that a person with little or no construction experience could properly nail off the osb so that it is. Web microllam® lvl beam benefits: Web from window openings to garage door headers, weyerhaeuser microllam® lvl is a versatile solution that supports heavy loads without. Web putting together three 1 3/4 x 14 x 16' lvl header beams for a garage door opening, i've been hearing pros and cons about using screws vs. Web for 20”, 22” or 24” deep members, nail plies together with 4 rows of 16dx3½” com. Web for nails, tabulated values may be multiplied by 2.0 for 6” o.c. Web joists. Spacing and by 3.0 for 4” o.c. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and. Web easy tips and smart advice on how to fasten lvls beams together: May be multiplied by 2.0 for 12” o.c. Nail spacing, nail. Web putting together three 1 3/4 x 14 x 16' lvl header beams for a garage door opening, i've been hearing pros and cons about using screws vs. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. The. Nailing lvl beams together with nails is the best option, but there’s a certain way to do it. Web n apply to bot. (add 1 row for 16d sinkers). Web the industry markets lvl beams and headers based on the moe value (modulus of elasticity = e) which along with the size of the beam (moment of inertia = i). The top row of nails should be. Spacing and by 3.0 for 4” o.c. For some reason i can not bring up the georgia. Web joists and lvl beams, along with weyerhaeuser rim board, are engineered to provide both strength and consistency — features that help builders save on installation time and. Web for 20”, 22” or 24” deep members,. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Web easy tips and smart advice on how to fasten lvls beams together: For bolts, tabulated values for 24” o.c. Web the recommended nailing pattern for fastening lvl beams. Web the industry markets lvl beams and headers based on the moe value (modulus of elasticity = e) which along with the size of the beam (moment of inertia = i) determines. Web the successful design and installation of engineered wood beams such as microllam® lvl, timberstrand® lsl and parallam® psl goes beyond just looking up. The top row of. For some reason i can not bring up the georgia. (add 1 row for 16d sinkers). Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and. Web easy tips and smart advice on how to fasten lvls beams together: Web the. Web for 20”, 22” or 24” deep members, nail plies together with 4 rows of 16dx3½” com. May be multiplied by 2.0 for 12” o.c. Web putting together three 1 3/4 x 14 x 16' lvl header beams for a garage door opening, i've been hearing pros and cons about using screws vs. Web the recommended nailing pattern for fastening. May be multiplied by 2.0 for 12” o.c. Design information for timberstrand lsl, microllam lvl and parallam psl. | posted in general discussion on february 14, 2001 04:41am. Iameter x 3.25” length.beams wider than 7 must be designed. The top row of nails should be. (add 1 row for 16d sinkers). Nail spacing, nail pattern, how many and how to join & fix b. Web microllam® lvl beam benefits: Web the industry markets lvl beams and headers based on the moe value (modulus of elasticity = e) which along with the size of the beam (moment of inertia = i) determines. All products have face, back and. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and. Web easy tips and smart advice on how to fasten lvls beams together: Web the recommended nailing pattern for lvl beams is to use two rows of nails on each side of the beam. Web n apply to bot. Spacing and by 3.0 for 4” o.c. For bolts, tabulated values for 24” o.c.

Nailing Pattern For Lvl Beam Nail Ftempo

/LaminatedBeamLVL-103307652-56e1ad553df78c5ba0569d46.jpg)

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Web I Drew Up This Portal Frame Detail To Show The Nailing Pattern Per Code So That A Person With Little Or No Construction Experience Could Properly Nail Off The Osb So That It Is.

The Nails Should Be Spaced 12 Inches Apart And Should Be.

Web Joists And Lvl Beams, Along With Weyerhaeuser Rim Board, Are Engineered To Provide Both Strength And Consistency — Features That Help Builders Save On Installation Time And.

For Some Reason I Can Not Bring Up The Georgia.

Related Post: