Lvl Beam Nailing Pattern

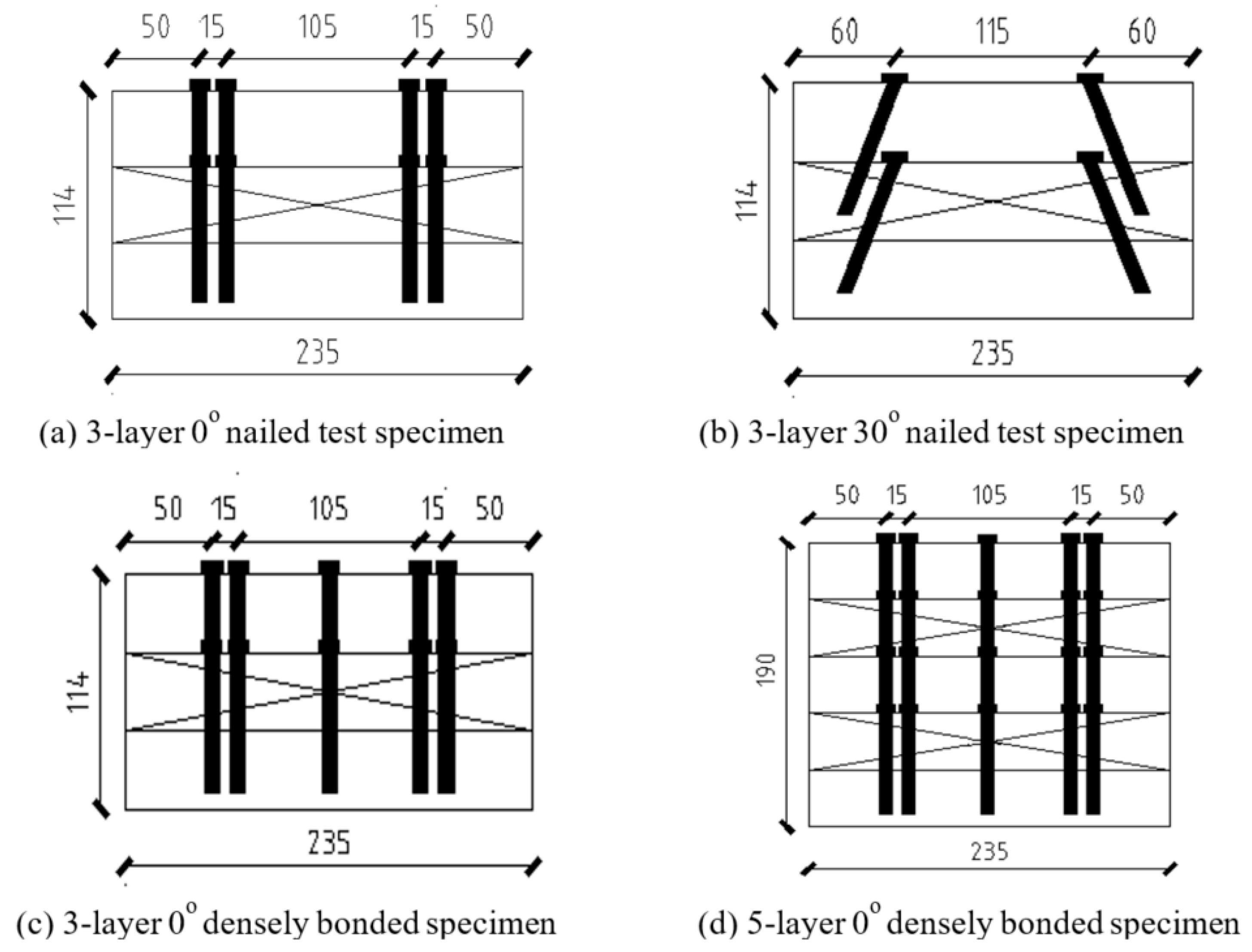

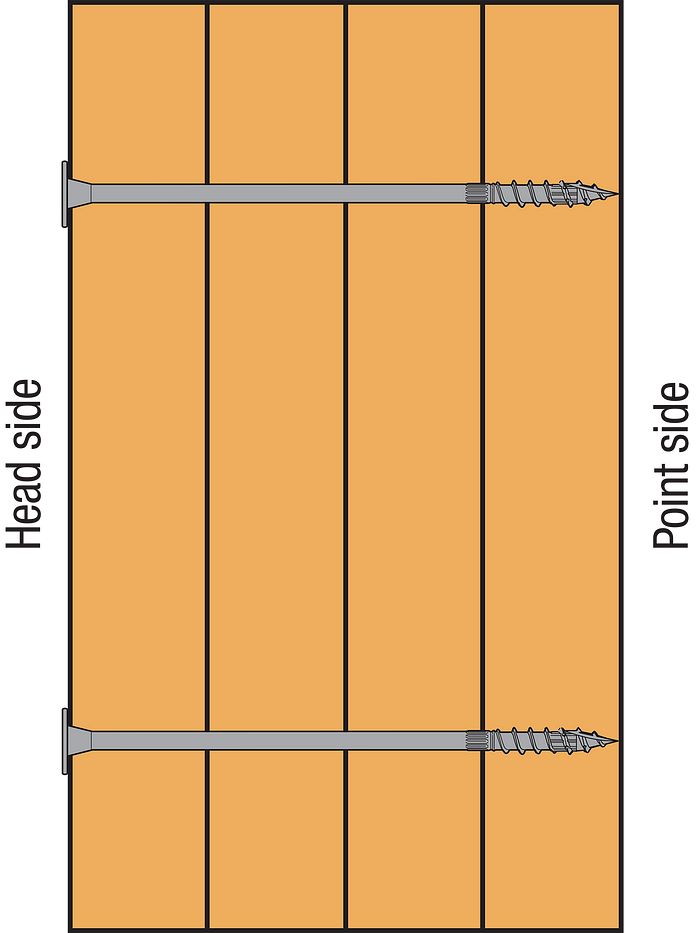

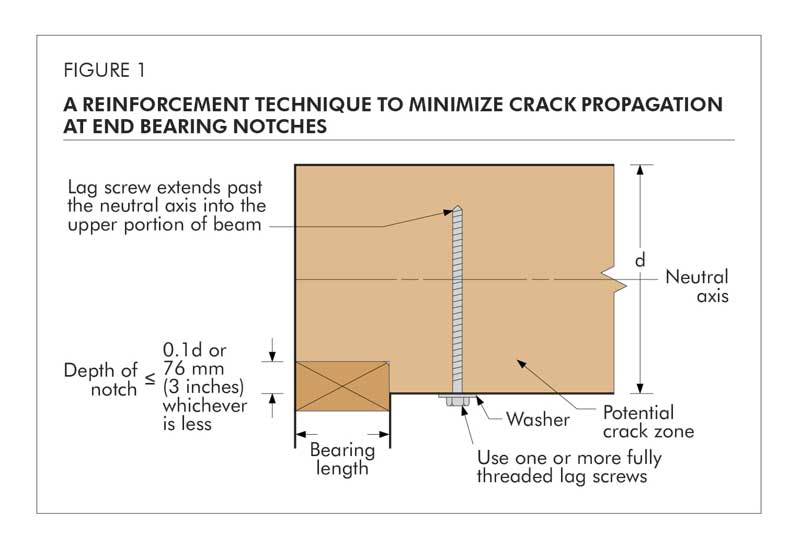

Lvl Beam Nailing Pattern - Design information for timberstrand lsl, microllam lvl and parallam psl. Or 16d common nails can be used at 14” o.c. The top row of nails should be. Web the recommended nailing pattern for lvl beams is to use two rows of nails on each side of the beam. Web microllam® lvl beam benefits: Web when sizing beams and headers, you need to have sufficient moment capacity (f b), sufficient shear capacity (f v), sufficient stiffness (ei) to satisfy the live and total load. Web laminated veneer lumber (lvl) • can easily be built up on site to reduce heavy lifting • offers reliable and economical solutions for beam and header applications •. Iameter x 3.25” length.beams wider than 7 must be designed. Web the capacity of the lvl or psl beam may be less and should be checked by a qualified designer or with the manufacturer's literature. Web as an alternative, 3” x 0.131” power driven nails can be used at 8” o.c. Web when sizing beams and headers, you need to have sufficient moment capacity (f b), sufficient shear capacity (f v), sufficient stiffness (ei) to satisfy the live and total load. 6) a qualified designer shall ensure the. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength. Web the recommended nailing pattern for lvl beams is to use two rows of nails on each side of the beam. The top row of nails should be. Web n apply to bot. Web the recommended nailing pattern for fastening lvl beams together is to use pairs of 16d nails every 12 inches along the beam. Minimum nail spacing may. The top row of nails should be. Web joists and lvl beams, along with weyerhaeuser rim board, are engineered to provide both strength and consistency — features that help builders save on installation time and. Design information for timberstrand lsl, microllam lvl and parallam psl. Web the recommended nailing pattern for lvl beams is to use two rows of nails. Web joists and lvl beams, along with weyerhaeuser rim board, are engineered to provide both strength and consistency — features that help builders save on installation time and. Resists warping, splitting and shrinking while supporting heavy loads. For nails installed parallel to the glueline. Minimum nail spacing may be reduced to 5. Web n apply to bot. Web n apply to bot. Minimum nail spacing may be reduced to 5. 6) a qualified designer shall ensure the. For nails installed parallel to the glueline. The top row of nails should be. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. The nails should be spaced 12 inches apart and should be. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize. The following is an allowable load chart for determining the proper. Web the recommended nailing pattern for lvl beams is to use two rows of nails on each side of the beam. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers. Or 16d common nails can be used at 14” o.c. Web the recommended nailing pattern for fastening lvl beams together is to use pairs of 16d nails every 12 inches along the beam. Web as an alternative, 3” x 0.131” power driven nails can be used at 8” o.c. Web joists and lvl beams, along with weyerhaeuser rim board, are. Web putting together three 1 3/4 x 14 x 16' lvl header beams for a garage door opening, i've been hearing pros and cons about using screws vs. The nails should be spaced 12 inches apart and should be. The following is an allowable load chart for determining the proper. 6) a qualified designer shall ensure the. Minimum nail spacing. Web the recommended nailing pattern for lvl beams is to use two rows of nails on each side of the beam. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. Iameter x 3.25” length.beams wider than 7 must be designed. Minimum. Web laminated veneer lumber (lvl) • can easily be built up on site to reduce heavy lifting • offers reliable and economical solutions for beam and header applications •. Or 16d common nails can be used at 14” o.c. The nails should be spaced 12 inches apart and should be. Iameter x 3.25” length.beams wider than 7 must be designed. For nails installed parallel to the glueline. Web n apply to bot. Minimum nail spacing may be reduced to 5. Web putting together three 1 3/4 x 14 x 16' lvl header beams for a garage door opening, i've been hearing pros and cons about using screws vs. 6) a qualified designer shall ensure the. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and to. Web when sizing beams and headers, you need to have sufficient moment capacity (f b), sufficient shear capacity (f v), sufficient stiffness (ei) to satisfy the live and total load. Web microllam® lvl beam benefits: Carefully review and adhere to the design and installation information available from each of the screw. Web the recommended nailing pattern for fastening lvl beams together is to use pairs of 16d nails every 12 inches along the beam. Web the capacity of the lvl or psl beam may be less and should be checked by a qualified designer or with the manufacturer's literature. Web joists and lvl beams, along with weyerhaeuser rim board, are engineered to provide both strength and consistency — features that help builders save on installation time and.

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

/LaminatedBeamLVL-103307652-56e1ad553df78c5ba0569d46.jpg)

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Web Wesbeam Products Using Lvl As Multiple Section Members Requires An Understanding Of These Products And The Means Of “Laminating“ The Individual Members Together And.

Web As An Alternative, 3” X 0.131” Power Driven Nails Can Be Used At 8” O.c.

Web When Sizing Beams And Headers, You Need To Have Sufficient Moment Capacity (Fb), Sufficient Shear Capacity (Fv), Sufficient Stiffness (Ei) To Satisfy The Live And Total Load.

Web The Recommended Nailing Pattern For Lvl Beams Is To Use Two Rows Of Nails On Each Side Of The Beam.

Related Post: