Lug Nut Tightening Pattern

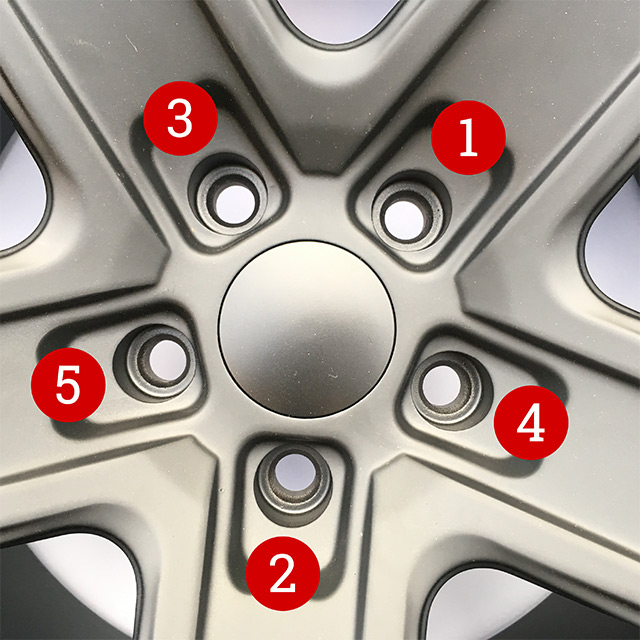

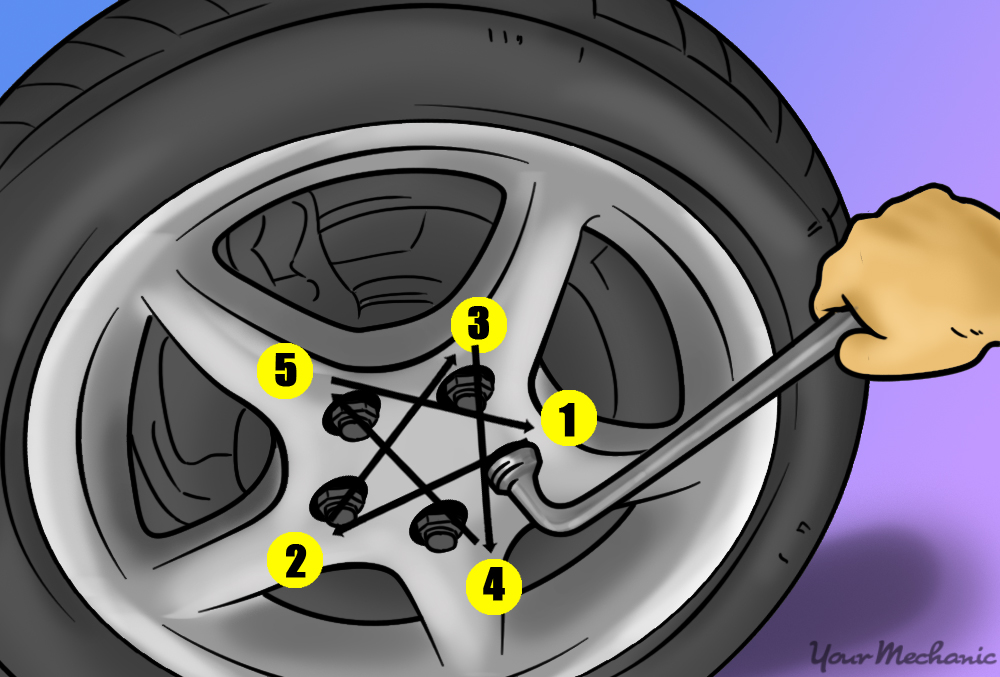

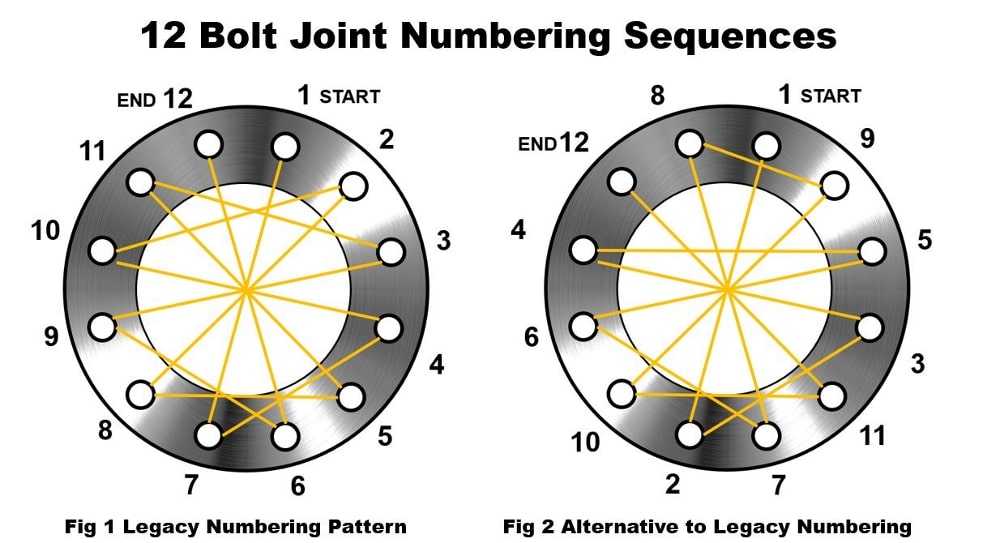

Lug Nut Tightening Pattern - This pattern is essential for evenly distributing force across the wheel, which helps prevent issues like wheel imbalance or warped brake rotors. Web after setting the torque wrench to the specification in the owner’s manual or repair manual, there are three steps to tighten lug nuts properly: This is the safest way of removing the lug nut as well as the least likely to damage the wheel. Put the lug nut into place around the bolt and position the torque stick over its head. Wheel and tire fitment data. Replace damaged studs or nuts. This pattern helps to evenly distribute the torque and ensures proper wheel alignment. Follow the tightening and loosening pattern shown below. Be careful to tighten to the manufacturer's specifications. This process is done to ensure your wheels are stable and not misaligned. This pattern is essential for evenly distributing force across the wheel, which helps prevent issues like wheel imbalance or warped brake rotors. This is the safest way of removing the lug nut as well as the least likely to damage the wheel. The graphic below shows the three common bolt patterns and tightening sequences, appropriate for. Whenever a car’s wheel. If the wheel is not a 5 lug nut wheel, then use the proper tightening pattern listed in the image below. Next, on the other end of the torque stick, use the impact wrench to turn the lug nut into position. Web 5 easy steps to select and install the proper lug nuts for your vehicle's aftermarket wheels. This pattern. Web tighten all lug nuts to full specification using the star pattern. Web however, you should always check and make sure the wheel stud threads and lug nuts are free from corrosion and debris to get the right torque value and prevent them from seizing. Web after setting the torque wrench to the specification in the owner’s manual or repair. Then put on the lug nuts and tighten them finger tight. Web what is tightening the wheel lug nuts all about? This lug nut guide covers all you need, including torque specs. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. This is the safest. Next, on the other end of the torque stick, use the impact wrench to turn the lug nut into position. Web the first time you tighten your lug nuts is when your car is still in the air before you drop it down. This diagram will show you what order to tighten your lug nuts. Our guide focuses on achieving. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Start by tightening the lug nuts in a star pattern to slightly more than hand tight to seat the wheel while it is still on the jack stands. Replace damaged studs or nuts.. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Whenever a car’s wheel has been taken off, it should be replaced and the lug nuts properly tightened. This lug nut guide covers all you need, including torque specs. Then put on the. The steel part oxidizes (otherwise known as rusts). Web the proper way to tighten lug nuts is to first put the tire onto the studs with the vehicle jacked up. This lug nut guide covers all you need, including torque specs. Web what is tightening the wheel lug nuts all about? Web using the torque wrench and the manufacturer's recommended. That makes the steel expand, distorting the shape of the cosmetic cap, so it's no longer the right fit with your lug nut wrench. The steel part oxidizes (otherwise known as rusts). Be careful to tighten to the manufacturer's specifications. Follow the tightening and loosening pattern shown below. Web it is also important to tighten lug nuts or bolts incrementally. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. The torque specification for your vehicle is based on clean dry threads. Use a breaker bar to give yourself as much torque on the stuck lug nut as possible, positioning it so you. Start by tightening the lug nuts in a star pattern to slightly more than hand tight to seat the wheel while it is still on the jack stands. The torque specification for your vehicle is based on clean dry threads. Original equipment and alternative options. Next, on the other end of the torque stick, use the impact wrench to turn the lug nut into position. Web 5 easy steps to select and install the proper lug nuts for your vehicle's aftermarket wheels. Tighten the lug nuts using an impact wrench and your lowest number torque stick. Put the lug nut into place around the bolt and position the torque stick over its head. Web the proper way to tighten lug nuts is to first put the tire onto the studs with the vehicle jacked up. This diagram will show you what order to tighten your lug nuts. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web the first time you tighten your lug nuts is when your car is still in the air before you drop it down. Many workshops simply use air wrenches that frequently over tighten the lug nuts. This is the safest way of removing the lug nut as well as the least likely to damage the wheel. This pattern helps to evenly distribute the torque and ensures proper wheel alignment. This reduces the likelihood of things shifting and flexing, which means that the nuts will stay tight even after you torque them. If the wheel is not a 5 lug nut wheel, then use the proper tightening pattern listed in the image below.

Wheel Bolt Patterns & Typical Lug Nut Torque Specifications Quadratec

How to Change a Tire on an RV? Les Schwab

How to Diagnose and Repair Noisy Brakes YourMechanic Advice

How To Quickly & Safely Change A Flat Tire Using The CrissCross Lug

Why is Wheel Lug Nut Torque Important? LEARN ABOUT TPMS

6 lug tightening sequence World

/stp-500-481503701-5c4f9fc8c9e77c00014afc8f.jpg)

Wheel Lug Nut Tightening Order by Bolt Pattern

How to Tighten Lug Nuts YourMechanic Advice

How to Install New Rotors YourMechanic Advice

Lug Bolt Tightening Sequence And Bolt Torque Chart Method Statement Hq

Web After Setting The Torque Wrench To The Specification In The Owner’s Manual Or Repair Manual, There Are Three Steps To Tighten Lug Nuts Properly:

Web Wheel Size, Pcd, Offset, And Other Specifications Such As Bolt Pattern, Thread Size (Thd), Center Bore (Cb), Trim Levels For Toyota Yaris Xp150 Facelift [2017.

Wheel And Tire Fitment Data.

Web What Is Tightening The Wheel Lug Nuts All About?

Related Post: