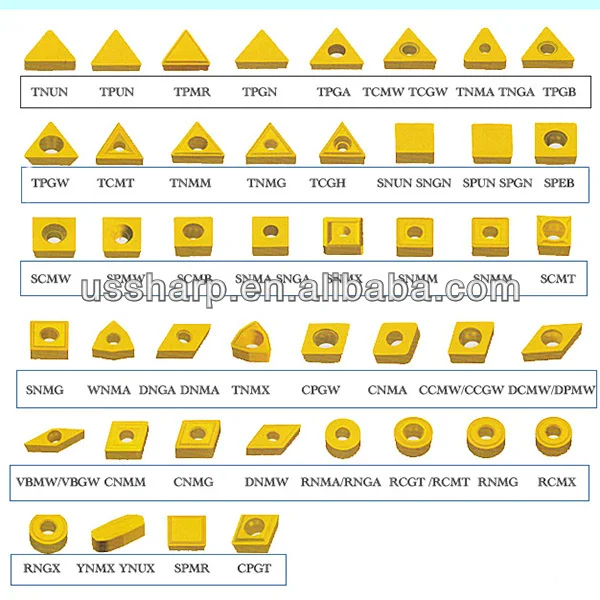

Lathe Insert Chart

Lathe Insert Chart - Charts below for definitions of values: Web printable iso insert designations chart. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. These charts show the ansi and iso designations for turning indexable inserts. There are many parameters to consider when choosing a turning insert. Indexable inserts ansi designations for size and shape keywords: Web number of 1/8's on inserts 1/4 than 1/4 i.c. Number of 1/16's on inserts less. Click the code letter or their description links in the example. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. There are a variety of insert shapes available, but the general note is use wider inserts for simple geometry and roughing passes, since they have more durability than a more narrow cutting tool, which. Indexable inserts,iso,standards,cutting tools created date: Web number of 1/8's on inserts 1/4 than 1/4 i.c. Download your key to understanding the insert code system! Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. There are many parameters to consider when choosing a turning insert. Web how to choose correct turning insert. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. These charts show the ansi and iso designations for turning indexable inserts. Web regardless. Number of 1/16's on inserts less. Polished high positive rake grade c23j inserts are designed for aluminum, copper and plastics use tialn coated grade 323f for finishing most materials including stainless, titanium & hardened steels 45rc + description l a r t. Web printable iso insert designations chart. There are many parameters to consider when choosing a turning insert. Indexable. Web number of 1/8's on inserts 1/4 than 1/4 i.c. Click the code letter or their description links in the example. Charts below for definitions of values: Polished high positive rake grade c23j inserts are designed for aluminum, copper and plastics use tialn coated grade 323f for finishing most materials including stainless, titanium & hardened steels 45rc + description l. There are a variety of insert shapes available, but the general note is use wider inserts for simple geometry and roughing passes, since they have more durability than a more narrow cutting tool, which is needed for complicated or intricate parts. Click the code letter or their description links in the example. Web use this turning insert designation system guide. There are a variety of insert shapes available, but the general note is use wider inserts for simple geometry and roughing passes, since they have more durability than a more narrow cutting tool, which is needed for complicated or intricate parts. Indexable inserts iso designations for size and shape keywords: Web how to choose correct turning insert. Web printable iso. These charts show the ansi and iso designations for turning indexable inserts. Polished high positive rake grade c23j inserts are designed for aluminum, copper and plastics use tialn coated grade 323f for finishing most materials including stainless, titanium & hardened steels 45rc + description l a r t. Web number of 1/8's on inserts 1/4 than 1/4 i.c. There are. Web how to choose correct turning insert. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Download your key to understanding the insert code system! These charts show the ansi and iso designations for turning indexable inserts. Number of 1/16's on inserts less. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. Click the code letter. Indexable inserts ansi designations for size and shape keywords: There are a variety of insert shapes available, but the general note is use wider inserts for simple geometry and roughing passes, since they have more durability than a more narrow cutting tool, which is needed for complicated or intricate parts. Charts below for definitions of values: There are many parameters to consider when choosing a turning insert. These charts show the ansi and iso designations for turning indexable inserts. Download your key to understanding the insert code system! Web how to choose correct turning insert. Indexable inserts iso designations for size and shape keywords: Web printable iso insert designations chart. Web regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Indexable inserts,iso,standards,cutting tools created date: Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Web number of 1/8's on inserts 1/4 than 1/4 i.c.

Lathe Insert Identification Chart

Carbide Turning Inserts Chart

Lathe Insert Identification Chart

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco

lathe carbide insert chart Conomo.helpapp.co

TNMG inserts Pesquisa Google Perkakas

Selecting Carbide Inserts for Metalworking Kennametal

Lathe Tool Insert Chart

10pc TCMT 110204 110208 Turning Boring Indexable Lathe Carbide Inserts

Toollink Co., Ltd. Shape&Size Toollink Co., Ltd.

Click The Code Letter Or Their Description Links In The Example.

Web Use This Turning Insert Designation System Guide To Learn The Name Of The Turning Insert You Need Based On An Existing Inserts Specifications, Or As A Handy Reference Guide That Explains Your Inserts' Specifications Based On Its Name.

Polished High Positive Rake Grade C23J Inserts Are Designed For Aluminum, Copper And Plastics Use Tialn Coated Grade 323F For Finishing Most Materials Including Stainless, Titanium & Hardened Steels 45Rc + Description L A R T.

Number Of 1/16'S On Inserts Less.

Related Post: