Labyrinth Seal Design

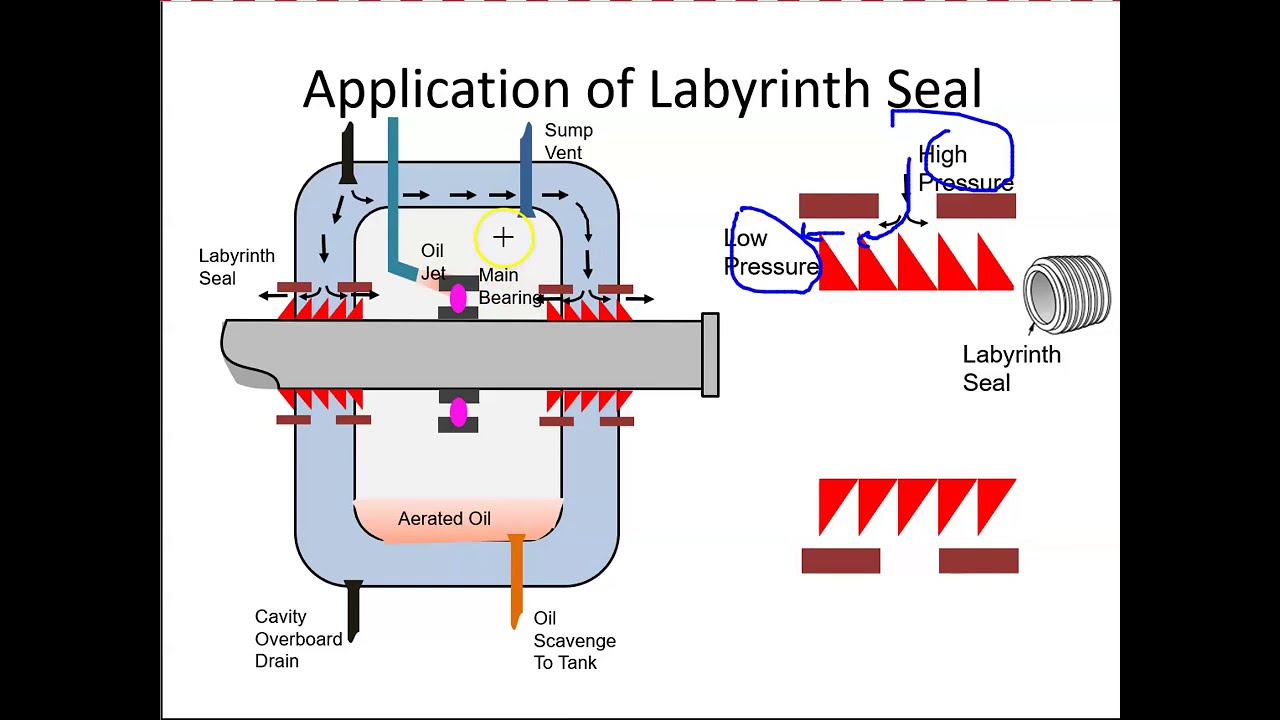

Labyrinth Seal Design - Web labyrinth seals are designed to function extremely well protecting sensitive components like bearings from both liquid and airborne particulates. This includes dirty or dusty environments and applications with splashing liquids. Web key design parameters that influence each seal performance include seal geometry, drag characteristics of the stator and rotor surfaces; It is used to prevent leakage of fluids or gases between rotating and stationary parts. This unique design keeps contaminants out and ensures the inner and outer rings of the seal stay inseparable. An example of such a seal is sometimes found within an axle's bearing to help prevent the leakage of the oil lubricating the bearing. An example of such a seal is sometimes found within an axle 's bearing to help prevent the leakage of the oil lubricating the bearing. Several types of standard labyrinth seals exist. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage flow compressibility. Web a labyrinth seal is a type of mechanical seal. Typical designs incorporate a set of rings, or maze, with seal components in extremely close proximity to capture. This includes dirty or dusty environments and applications with splashing liquids. It is used to prevent leakage of fluids or gases between rotating and stationary parts. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage. This includes dirty or dusty environments and applications with splashing liquids. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage flow compressibility. An example of such a seal is sometimes found within an axle's bearing to help prevent the leakage of the oil lubricating the bearing. It is used to prevent leakage of. Web key design parameters that influence each seal performance include seal geometry, drag characteristics of the stator and rotor surfaces; Web standard labyrinth seals. An example of such a seal is sometimes found within an axle's bearing to help prevent the leakage of the oil lubricating the bearing. This includes dirty or dusty environments and applications with splashing liquids. It. Web a labyrinth seal is a type of mechanical seal. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage flow compressibility. Web key design parameters that influence each seal performance include seal geometry, drag characteristics of the stator and rotor surfaces; An example of such a seal is sometimes found within an axle. Web standard labyrinth seals. An example of such a seal is sometimes found within an axle 's bearing to help prevent the leakage of the oil lubricating the bearing. Typical designs incorporate a set of rings, or maze, with seal components in extremely close proximity to capture. Web a labyrinth seal is a type of mechanical seal that provides a. Web standard labyrinth seals. Web a labyrinth seal is a type of mechanical seal that provides a tortuous path to help prevent leakage. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage flow compressibility. It is used to prevent leakage of fluids or gases between rotating and stationary parts. An example of such. Web standard labyrinth seals. Web a labyrinth seal is a type of mechanical seal. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage flow compressibility. An example of such a seal is sometimes found within an axle 's bearing to help prevent the leakage of the oil lubricating the bearing. Several types of. An example of such a seal is sometimes found within an axle 's bearing to help prevent the leakage of the oil lubricating the bearing. Web labyrinth seals are designed to function extremely well protecting sensitive components like bearings from both liquid and airborne particulates. Typical designs incorporate a set of rings, or maze, with seal components in extremely close. Several types of standard labyrinth seals exist. Web standard labyrinth seals. Typical designs incorporate a set of rings, or maze, with seal components in extremely close proximity to capture. Such seals can be found in centrifugal and axial flow gas compressors, steam turbines, hot gas expanders, and aircraft jet engines. Web labyrinth seals are designed to function extremely well protecting. Typical designs incorporate a set of rings, or maze, with seal components in extremely close proximity to capture. Several types of standard labyrinth seals exist. Web standard labyrinth seals. Such seals can be found in centrifugal and axial flow gas compressors, steam turbines, hot gas expanders, and aircraft jet engines. Web a labyrinth seal is a type of mechanical seal. Web a labyrinth seal is a type of mechanical seal that provides a tortuous path to help prevent leakage. Web a labyrinth seal is a type of mechanical seal. Web standard labyrinth seals. Such seals can be found in centrifugal and axial flow gas compressors, steam turbines, hot gas expanders, and aircraft jet engines. This includes dirty or dusty environments and applications with splashing liquids. Web labyrinth seals are designed to function extremely well protecting sensitive components like bearings from both liquid and airborne particulates. An example of such a seal is sometimes found within an axle 's bearing to help prevent the leakage of the oil lubricating the bearing. And operating parameters such as inlet pressure, temperature, swirl, seal pressure ratio, fluid viscosity, and leakage flow compressibility. It is used to prevent leakage of fluids or gases between rotating and stationary parts. Typical designs incorporate a set of rings, or maze, with seal components in extremely close proximity to capture. An example of such a seal is sometimes found within an axle's bearing to help prevent the leakage of the oil lubricating the bearing. Web key design parameters that influence each seal performance include seal geometry, drag characteristics of the stator and rotor surfaces;

Custom, superior non contact seal design Labyrinth Seal Oz Seals

Custom, superior non contact seal design Labyrinth Seal Oz Seals

Custom, superior non contact seal design Labyrinth Seal Oz Seals

Custom, superior non contact seal design Labyrinth Seal Oz Seals

Labyrinth Seals and Clearance Seals Selection Guide Types, Features

Oz Labyrinth seal Oz Seals Pty Ltd

Custom, superior non contact seal design Labyrinth Seal Oz Seals

Labyrinth Seal YouTube

![Labyrinth seal [51]. Download Scientific Diagram](https://www.researchgate.net/publication/324611517/figure/download/fig5/AS:617311803297793@1524190011945/Labyrinth-seal-51.png)

Labyrinth seal [51]. Download Scientific Diagram

What are labyrinth seals for bearings?

Several Types Of Standard Labyrinth Seals Exist.

This Unique Design Keeps Contaminants Out And Ensures The Inner And Outer Rings Of The Seal Stay Inseparable.

Web A Labyrinth Seal Is A Type Of Mechanical Seal That Provides A Tortuous Path To Help Prevent Leakage.

Related Post: