Knurling Patterns

Knurling Patterns - This moving of the workpiece material creates the knurled pattern. It can also be used for identification and securing purposes. Web knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Choosing the right workpiece material Web knurling is a manufacturing process where geometric patterns roll onto a material. Web knurling is a process used in machining to create a textured pattern on the surface of a workpiece. The patterns are created by cutting or forming the surface material. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. As such, it offers attractive textured finishes for various custom parts by making patterns like crests and troughs on machined parts. Knurling can also refer to material that has a knurled pattern. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. Web knurling is a machining process that involves creating a patterned texture on a workpiece's surface, typically for added grip or aesthetic appeal. It is typically done on a lathe, which is a machine tool. Learn about the various tools and techniques for knurling and tips for successful knurling. Web knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Web master the art of knurling with our comprehensive guide. Web knurling defined knurling is a manufacturing process that involves impressing. Web knurling is a machining process that involves creating a patterned texture on a workpiece's surface, typically for added grip or aesthetic appeal. Web knurling is a manufacturing process used to create a textured pattern on the surface of a cylindrical or flat workpiece, typically made of materials like metal, plastic, or wood. This article explains what is knurling, exploring. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. Web knurling is a process used in machining to create a textured pattern on the surface of a workpiece. This moving of the workpiece material creates the knurled pattern. In this article, you will learn about the knurling process, common. This increases friction, enhances aesthetics, prevents slipping, and strengthens the surface. Knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Knurling can also refer to material that has a knurled pattern. Choosing the right workpiece material Knurling uses the tool to displace material. Web knurling refers to a finishing process that makes patterns of concave and convex contours on the surface of the machine part. Here’s a breakdown of the process: This rough textured pattern enhances a part’s aesthetics and increases friction on its surface to facilitate grip. Web knurling is one of these further processing cycles. This increases friction, enhances aesthetics, prevents. Web knurling is a process used in machining to create a textured pattern on the surface of a workpiece. Web knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Choosing the right workpiece material Knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. This rough textured pattern enhances a part’s aesthetics and increases friction on its surface. Three common knurl patterns are: Learn about the various tools and techniques for knurling and tips for successful knurling. Web knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface. Web knurling is the process of creating a pattern on a workpiece to improve the visual appearance. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. It is done by using hardened metal wheels with special shapes to enhance the workpiece’s appearance and provide a better grip. Web master the art of knurling with our comprehensive guide. Web the knurling technique involves using specialized knurling wheels. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. Web knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Here’s a breakdown of the process: Web knurling is a manufacturing process used to create a textured pattern on the surface of a cylindrical or flat workpiece, typically made of materials like metal, plastic, or wood. Knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. This moving of the workpiece material creates the knurled pattern. Learn about the various tools and techniques for knurling and tips for successful knurling. Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Web the knurling technique involves using specialized knurling wheels to create specific patterns on the surface of a workpiece. The purpose of knurling is to improve the grip or enhance the appearance of the object, making it easier to handle or manipulate by hand. A texture or pattern is obtained by cutting, extruding a workpiece’s surface, and so on. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. Web in the following sections, you’ll learn about k nurling calculations and formulas, the different types of knurling and their applications, best practices for accurate knurling specifications, common mistakes to avoid, and how to use solidworks for knurling design and simulation. Different patterns require various knurling. The patterns are created by cutting or forming the surface material.

Knurling designs

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

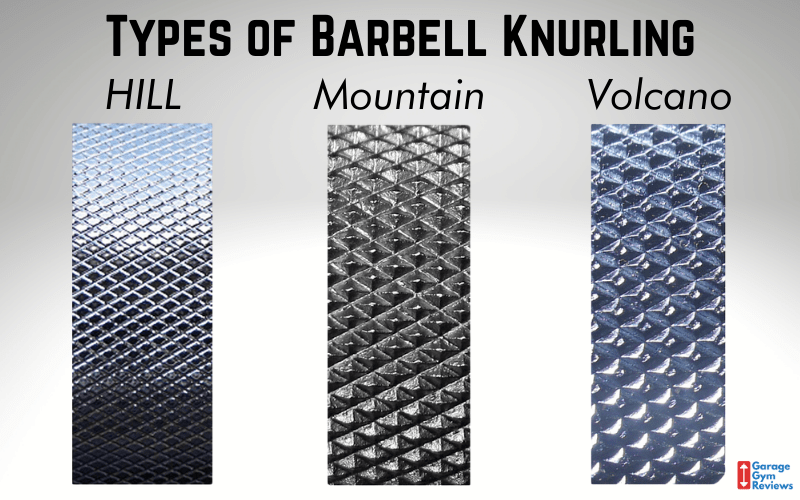

The 3 Types of Barbell Knurling and What It Means for Your Grip

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

knurling operation? Purpose of knurling 5 knurl patterns knurling

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Knurling.jpg (720×1200) Pattern design

Knurling designs

knurling patterns Google keresés Knurled metal, Metal texture

Web Knurling Is A Process Used In Machining To Create A Textured Pattern On The Surface Of A Workpiece.

It Can Also Be Used For Identification And Securing Purposes.

Web Knurling Is The Process Of Creating A Pattern On A Workpiece To Improve The Visual Appearance Or To Create A Better Grip On The Part.

Web Knurling Is A Manufacturing Process, Typically Conducted On A Lathe, Whereby A Pattern Of Straight, Angled Or Crossed Lines Is Rolled Into The Material.

Related Post: