Knurling Pattern

Knurling Pattern - Web knurling is a machining process that involves creating a patterned texture on a workpiece's surface, typically for added grip or aesthetic appeal. Web knurling is a process used in machining to create a textured pattern on the surface of a workpiece. It is mostly performed on round or. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Web knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Web this article explains the concept, types, process flow of knurling and explains the different types and most common defects that occur during the knurling process. Knurling is done to increase the friction on a surface, and is. Web the knurled definition is a process to roll patterns of straight, rhombus, or spherical shape into work piece, which can be conducted on manipulative tools or. Web knurling is a manufacturing operation, performed on a lathe, that copies a pattern from a knurling wheel onto a round workpiece. Web knurling is one of these further processing cycles. Web in manufacturing, knurling is a finishing process used to create any combination of horizontal, vertical or crossing lines on the surface of a workpiece. Web knurling is a process used in machining to create a textured pattern on the surface of a workpiece. It is mostly performed on round or. Web this article explains the concept, types, process flow. Knurling can also refer to. It's achieved by pressing a. It is mainly used for: Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Knurling uses the tool to. Monitor tool wear and replace as needed. Web knurling refers to a finishing process that makes patterns of concave and convex contours on the surface of the machine part. Web knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Web knurling is a manufacturing process that deforms a workpiece,. Web knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Web knurling is a manufacturing process where geometric patterns roll onto a material. Web barbell knurling is the crosshatch pattern on the shaft of olympic barbells that is intended to increase friction between your hands. Web the knurled definition is a process to roll patterns of straight, rhombus, or spherical shape into work piece, which can be conducted on manipulative tools or. Web knurling is one of these further processing cycles. Knurling can also refer to. In this article, you will. Web in manufacturing, knurling is a finishing process used to create any combination of. Web knurling is one of these further processing cycles. This is achieved by a rotating tool that. Web in manufacturing, knurling is a finishing process used to create any combination of horizontal, vertical or crossing lines on the surface of a workpiece. Learn tools, techniques, patterns, and expert tips to elevate your knurling project today! It is mostly performed on. Knurling uses the tool to. It is done by using hardened metal wheels with special. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Web this article explains the concept, types, process flow of knurling and explains the different types and most common defects that occur during. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. Monitor tool wear and replace as needed. Web knurling is the process of creating a pattern on a workpiece to improve the visual appearance or to create a better grip on the part. Web choose the appropriate knurling. As such, it offers attractive textured finishes for various custom parts by making patterns like crests and troughs on. Learn tools, techniques, patterns, and expert tips to elevate your knurling project today! It is mainly used for: Web knurling is a machining process that involves creating a patterned texture on a workpiece's surface, typically for added grip or aesthetic appeal.. Web knurling is a manufacturing operation, performed on a lathe, that copies a pattern from a knurling wheel onto a round workpiece. Web the knurled definition is a process to roll patterns of straight, rhombus, or spherical shape into work piece, which can be conducted on manipulative tools or. Knurling is done to increase the friction on a surface, and. Web knurling is a manufacturing process used to create a textured pattern on the surface of a cylindrical or flat workpiece, typically made of materials like metal,. It is typically done on a lathe, which is a machine tool that. Web knurling is one of these further processing cycles. Web knurling is a manufacturing process where geometric patterns roll onto a material. Knurling uses the tool to. Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Web knurling is a manufacturing operation, performed on a lathe, that copies a pattern from a knurling wheel onto a round workpiece. It is done by using hardened metal wheels with special. Web knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Web choose the appropriate knurling pattern and tool. Web knurling refers to a finishing process that makes patterns of concave and convex contours on the surface of the machine part. In this article, you will. It's achieved by pressing a. Monitor tool wear and replace as needed. Web the knurled definition is a process to roll patterns of straight, rhombus, or spherical shape into work piece, which can be conducted on manipulative tools or. Web this article explains the concept, types, process flow of knurling and explains the different types and most common defects that occur during the knurling process.

How To Make Knurling Solidworks Tutorial YouTube

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

How to Show Part Knurling in SOLIDWORKS Part 1

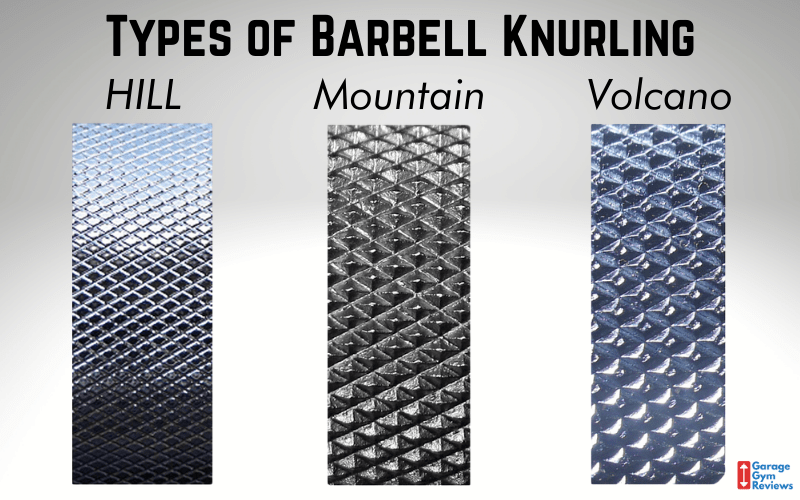

What is Barbell Knurling and Why It Matters Garage Gym Reviews

knurling operation? Purpose of knurling 5 knurl patterns knurling

Knurling.jpg (720×1200) Pattern design

Knurled pattern on a flat surface — Onshape

seamless knurling Wall texture design, Fabric textures, Charcoal

Why cut knurling patterns is the dinosaur of die casting

How to make knurling in ProE? GrabCAD Tutorials

It Is Mostly Performed On Round Or.

Learn Tools, Techniques, Patterns, And Expert Tips To Elevate Your Knurling Project Today!

Web Knurling Is A Process Used To Create A Pattern On The Surface Of A Material By Displacing Or Deforming The Surface.

Web In The Following Sections, You’ll Learn About K Nurling Calculations And Formulas, The Different Types Of Knurling And Their Applications, Best Practices For.

Related Post: