Joint Design

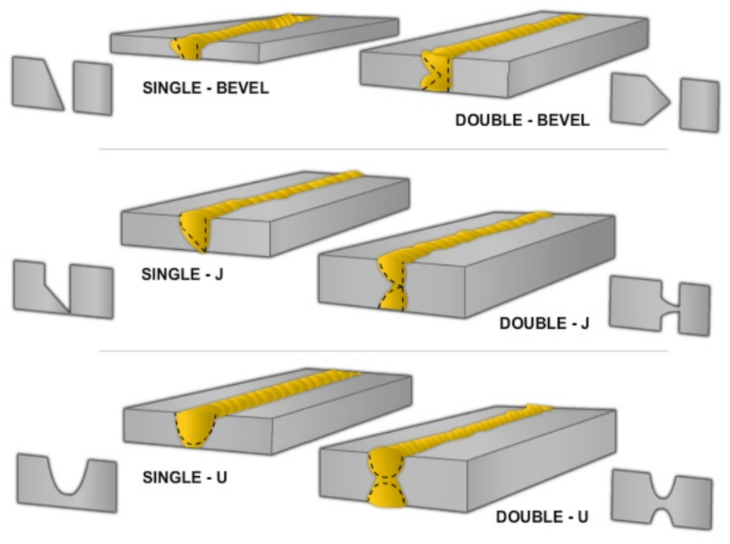

Joint Design - Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Web the aim of joint design is to obtain maximum strength for a given area of a bond. Guidance is provided for general bolted joint design, computation of preload. Web bolted joints = connectors, impact many parts: The fastener positions are often patterned uniformly because of the ease of developing simple linear patterns in cad programs. Web joints represent one of the greatest challenges in the design of structures in general and in composite structures in particular. Web design of joints and bearing rails. Web the fusion of motor, gear and sensors into a highly integrated, mechatronic joint module has several advantages for the whole system, including high power density, good. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Web several methods for the design and analysis of bolted joint connections are presented. Joints should be specifically designed for use with structural adhesives. Web joint layout guidelines • what you should do: Web several methods for the design and analysis of bolted joint connections are presented. Web design of joints and bearing rails. Although it may be tempting to use joints intended for other fastening methods, adhesives require joints of a special design. Web joint design is a very critical step in part design. Web design of joints and bearing rails. Guidance is provided for general bolted joint design, computation of preload. Web joints represent one of the greatest challenges in the design of structures in general and in composite structures in particular. Web the fusion of motor, gear and sensors into a. Web learn how to design joints for pavement structures to minimize cracking, deflection, stresses and roughness. Each technique has its pros and cons, and knowing. These effects result from the way the joint is loaded, as well as how the joint responds to the load. Web bolted joints = connectors, impact many parts: Web the design of the adhesive joint. Web the five basic joint designs are typically welded with the tig process using either a groove or a fillet weld. Web lecture presentation on bolted joints, stiffness, loading, torque, friction, and preload. The reason for this is that joints entail interruptions of. Web as engineers we design bolted and riveted joints that include multiple fasteners. The more complex the. Web lecture presentation on bolted joints, stiffness, loading, torque, friction, and preload. Joints should be specifically designed for use with structural adhesives. Web several methods for the design and analysis of bolted joint connections are presented. Web joint layout guidelines • what you should do: Web several methods for the design and analysis of bolted joint connections are presented. The characteristics of joints between a machine's components are strong functions of the components themselves, and the. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Some of the various load types include tensile, shear and bending. Web joints represent one of the greatest challenges in the. The first is to provide useful details to commanders and planners on joint operational design and its interaction with the joint operation planning process. Web joints represent one of the greatest challenges in the design of structures in general and in composite structures in particular. Web several methods for the design and analysis of bolted joint connections are presented. Web. Guidance is provided for general bolted joint design, computation of preload. Joints should be specifically designed for use with structural adhesives. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Each technique has its pros and cons, and knowing. Web joint design is a very critical step. The more complex the demands on and design of a human. Web the fusion of motor, gear and sensors into a highly integrated, mechatronic joint module has several advantages for the whole system, including high power density, good. Groove welds are those made into a prepared joint to get deeper. The fastener positions are often patterned uniformly because of the. Web the aim of joint design is to obtain maximum strength for a given area of a bond. Web several methods for the design and analysis of bolted joint connections are presented. The first is to provide useful details to commanders and planners on joint operational design and its interaction with the joint operation planning process. Joints should be specifically. The first is to provide useful details to commanders and planners on joint operational design and its interaction with the joint operation planning process. Web several methods for the design and analysis of bolted joint connections are presented. The joints were designed to put all the loading in shear and reduce stress concentrations. Web learn about the principles of joint design from the brazing and metal joining experts at lucas milhaupt. Web as engineers we design bolted and riveted joints that include multiple fasteners. This is largely a matter of. Composite connections (p213/98), which provides design guidance for moment resisting composite end plate connections. Web joints in steel construction: Web the fusion of motor, gear and sensors into a highly integrated, mechatronic joint module has several advantages for the whole system, including high power density, good. Web let’s break down joint design basics and look at different ways to do it, like welding, bolting, and gluing things together. The more complex the demands on and design of a human. Web lecture presentation on bolted joints, stiffness, loading, torque, friction, and preload. The fastener positions are often patterned uniformly because of the ease of developing simple linear patterns in cad programs. Web the design of the adhesive joint will play a significant factor in determining how it will survive service loads. Web learn how to design joints for pavement structures to minimize cracking, deflection, stresses and roughness. Joints should be specifically designed for use with structural adhesives.

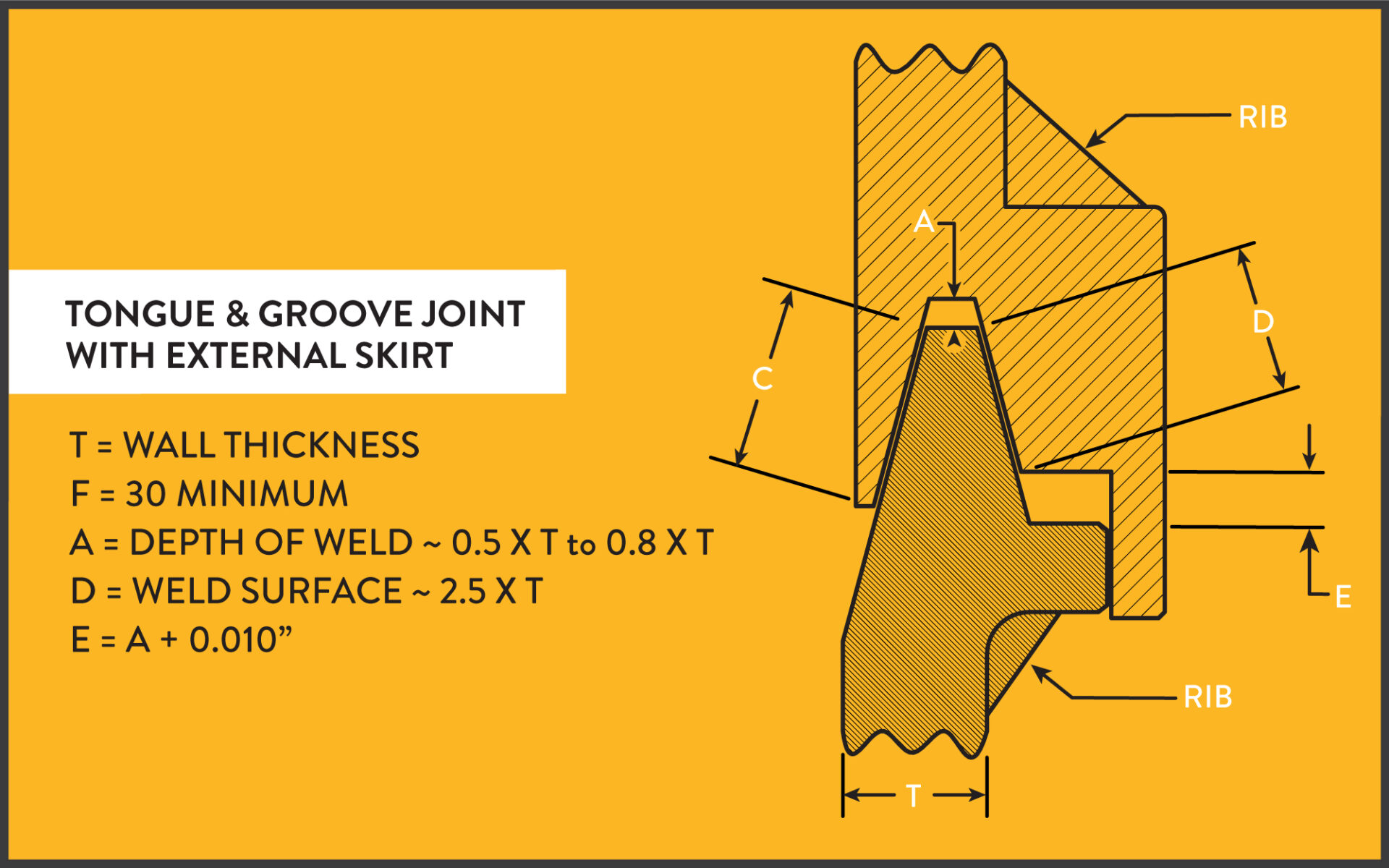

Spin Welding Joint Design Guidelines

Construction Joint Design and Considerations YouTube

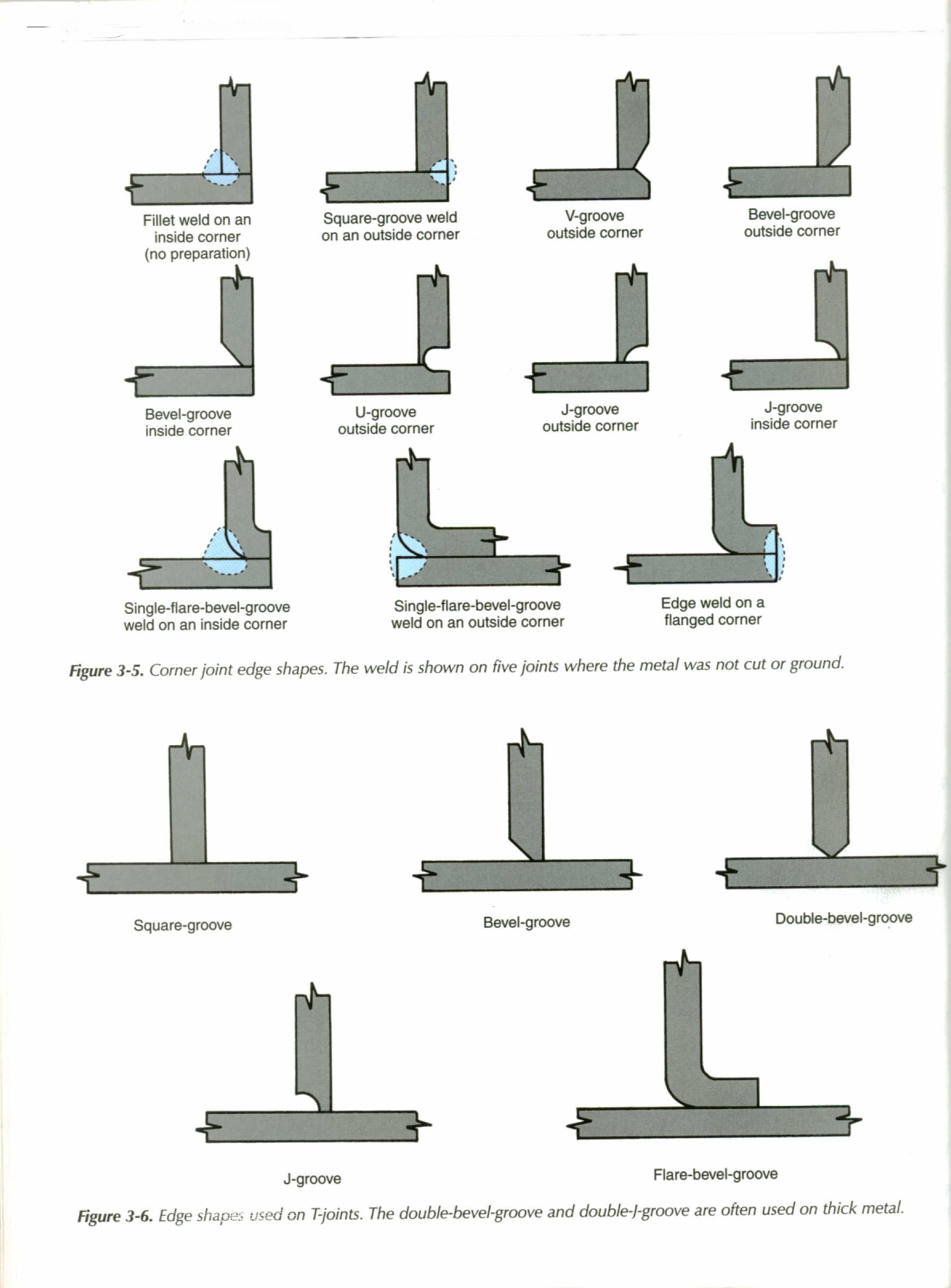

Welding joints Engineers Gallery

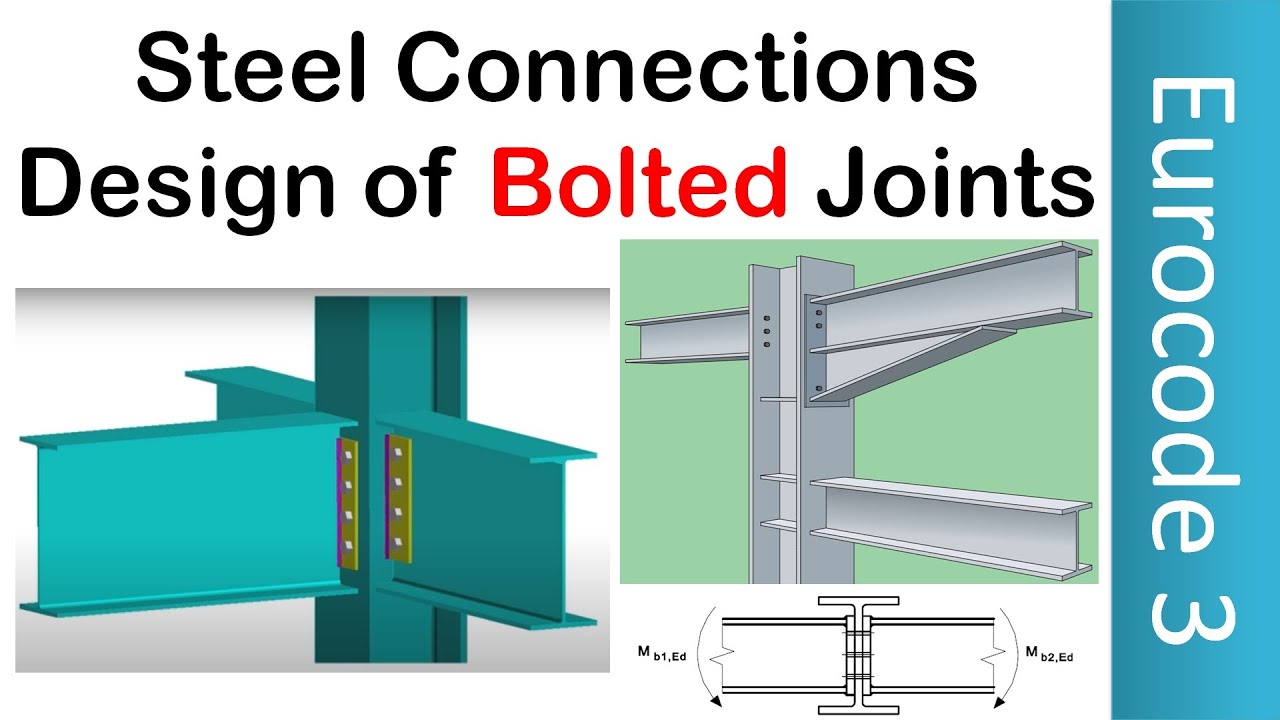

Design of Joints in Steel and Composite Structures Eurocode 3 Design

Guide to Welding Joint Types and Parts WelditU

Types of Joints Annenberg Learner

Design of Welded JointsTypes of Welded jointFundamental of Machine

Steel Connections Bolted Joint Design Pinned Joints Rigid Joints

Knuckle Joint Design Procedure,Problems Questions

Design Of Structural Steel Joints Design Talk

Loads Can Be Applied To Bolted Joints In A Number Of Different Ways, Each Of Which Produces Unique Effects On The Joint.

Web The Aim Of Joint Design Is To Obtain Maximum Strength For A Given Area Of A Bond.

Guidance Is Provided For General Bolted Joint Design, Computation Of Preload.

Loads Can Be Applied To Bolted Joints In A Number Of Different Ways, Each Of Which Produces Unique Effects On The Joint.

Related Post: