Jig And Fixture Design

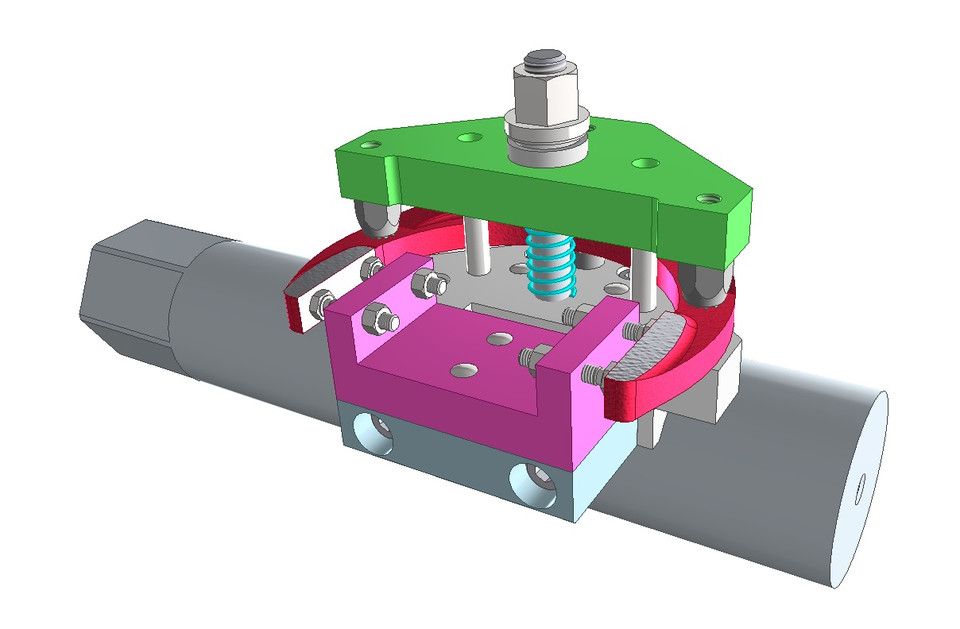

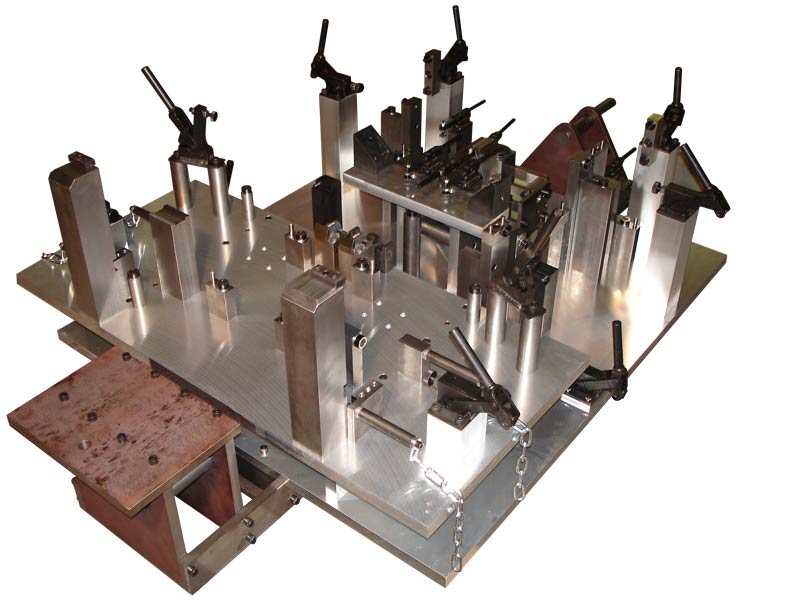

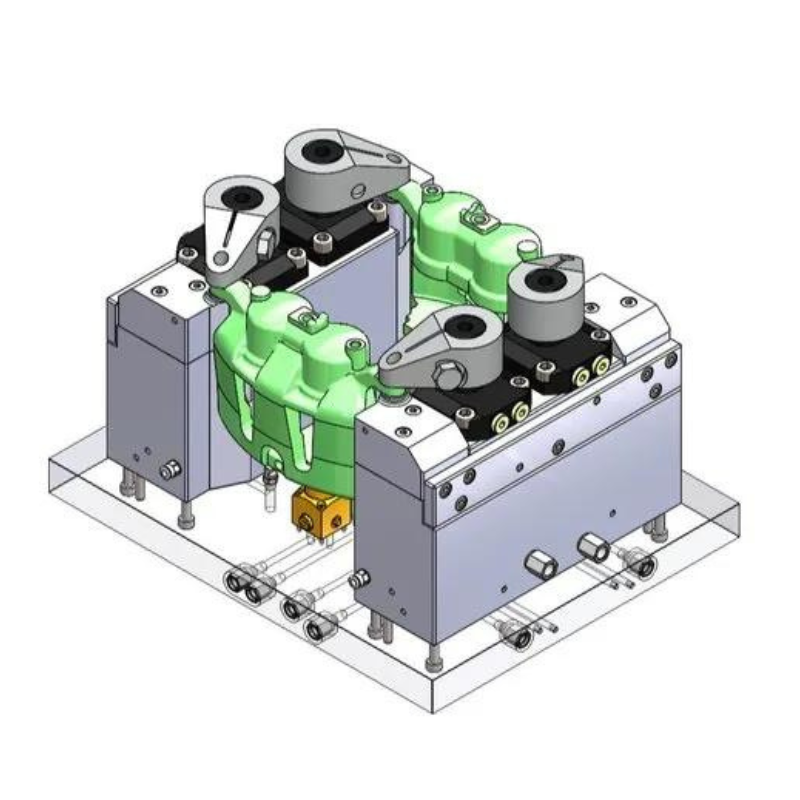

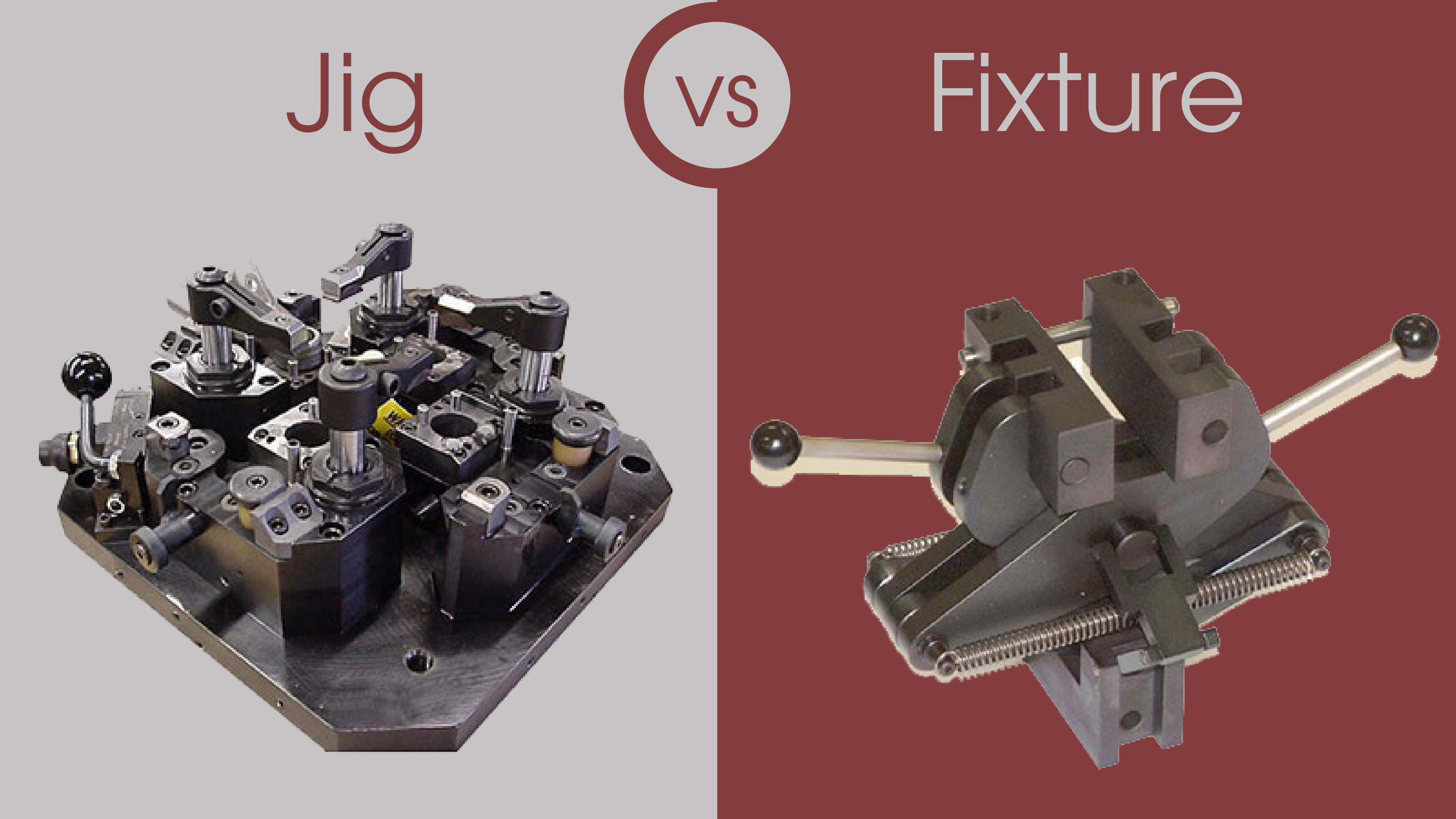

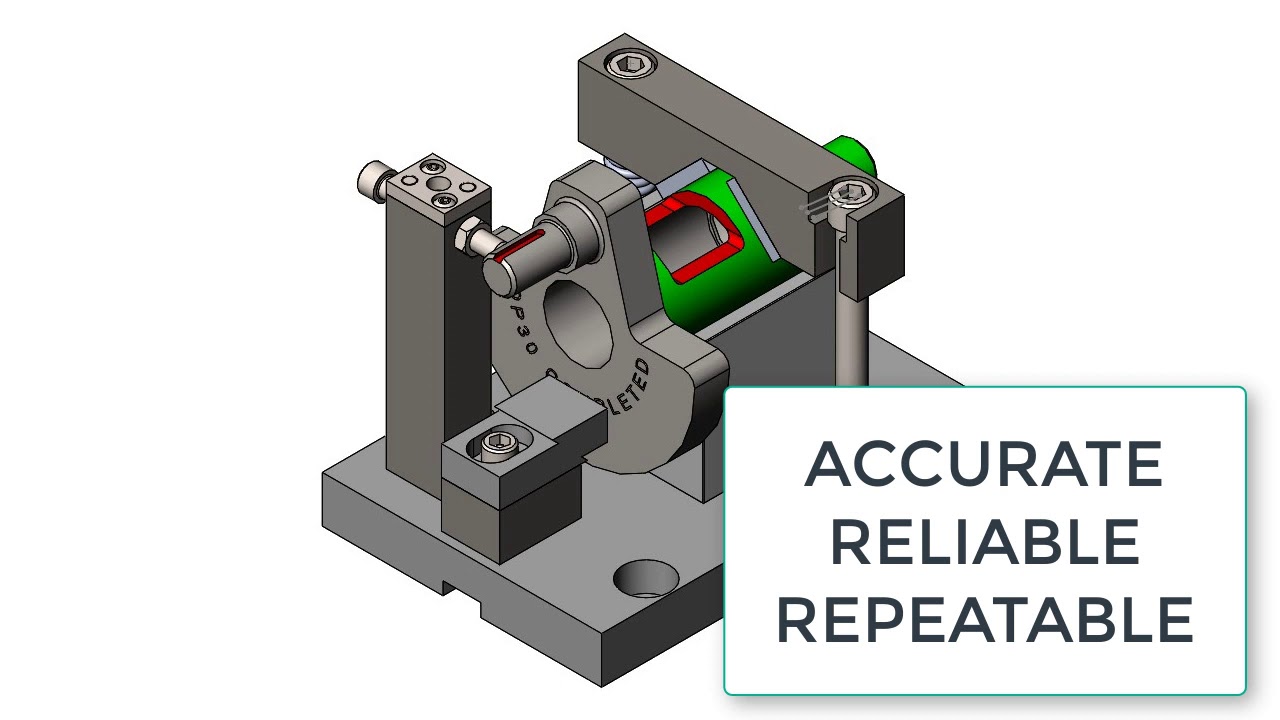

Jig And Fixture Design - We integrate features to ensure a complete test solution that performs your tests the way you need it done. Web design pcb test fixtures to your needs. Web in this article, we'll explore the importance of jigs and fixtures, their types, applications, design principles and much more. On the other hand, fixtures maintain a workpiece steady in a defined position, orientation, or location rather than guiding a cutting tool. The design of jigs and fixtures is based on several principles, including the workpiece position, clamping force, guiding elements, and repeatability. Web jigs and fixtures are critical tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes. This can reduce workplace injury. On the other hand, a fixture supports and locates a workpiece during the machining or assembly processes. Web jig and fixture design. Accurate positioning of the workpiece is crucial for precision machining. Web this video describes design of jig and fixture by taking fundamental principles of mechanical engineering, video has been illustrated with 3d animation and clear description of step by step. Web jig and fixture design manual. We integrate features to ensure a complete test solution that performs your tests the way you need it done. This can reduce workplace injury.. Web this video describes design of jig and fixture by taking fundamental principles of mechanical engineering, video has been illustrated with 3d animation and clear description of step by step. Web jigs and fixtures minimize the time spent on setup and changeovers by ensuring the correct alignment of workpieces, reducing errors and rework. Accurate positioning of the workpiece is crucial. Written for the experienced engineer as well as the student, this comprehensive reference presents the fundamental aspects of jig and fixture design. Web jigs and fixtures are critical tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes. Create a design using the fewest steps possible. Web in this article, we'll explore the importance of jigs and. Web jig and fixture design. Web locating and clamping play pivotal roles in any workholding system. All six degrees of freedom, along x, y, and z axis, both laterally and rotationally, need be constrained for a part to be fully located. This can reduce workplace injury. On the other hand, a fixture supports and locates a workpiece during the machining. On the other hand, fixtures maintain a workpiece steady in a defined position, orientation, or location rather than guiding a cutting tool. Web this video describes design of jig and fixture by taking fundamental principles of mechanical engineering, video has been illustrated with 3d animation and clear description of step by step. Web jig and fixture design manual. All six. Written for the experienced engineer as well as the student, this comprehensive reference presents the fundamental aspects of jig and fixture design. Web our expertise in tools, dies, jigs, fixtures, gages, prototypes and specialty machining ranges from intricate parts and fixturing for the medical field to large support tooling and ground handling equipment for the aerospace industry. Locating the work. Web what are jigs and fixtures? Web jig and fixture design. We integrate features to ensure a complete test solution that performs your tests the way you need it done. Web our expertise in tools, dies, jigs, fixtures, gages, prototypes and specialty machining ranges from intricate parts and fixturing for the medical field to large support tooling and ground handling. Web this section links to several of our most valuable engineering resources, including information on the principles of locating and clamping and clamping force calculations. On the other hand, a fixture supports and locates a workpiece during the machining or assembly processes. This section provides a comprehensive guide to understanding the design of jigs and fixtures and how each of. Web jigs and fixtures are critical tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes. All six degrees of freedom, along x, y, and z axis, both laterally and rotationally, need be constrained for a part to be fully located. Web jig and fixture design manual. Web what are jigs and fixtures? Web a jig controls. Web jig and fixture design. Locating the work is a prime necessity and requires suitable facilities. On the other hand, fixtures maintain a workpiece steady in a defined position, orientation, or location rather than guiding a cutting tool. We integrate features to ensure a complete test solution that performs your tests the way you need it done. On the other. Beginning with basic design fundamentals, the book. Web what are jigs and fixtures? Delves into the essential principles of locating and clamping, offering valuable insights into achieving precise and consistent results. Web design pcb test fixtures to your needs. Web basic principles of jigs and fixtures design. Web this section links to several of our most valuable engineering resources, including information on the principles of locating and clamping and clamping force calculations. Web this article will describe the difference between jigs and fixture assembly aids as well as how jigs and fixtures work, where they are used, specific design considerations, and their various advantages. On the other hand, a fixture supports and locates a workpiece during the machining or assembly processes. Locating the work is a prime necessity and requires suitable facilities. The correct setup ensures smooth insertion of a workpiece in the proper position and removing a workpiece from a jig without operational hassles or time consumption. Web jig and fixture design manual. Web jig and fixture design. Web in this article, we'll explore the importance of jigs and fixtures, their types, applications, design principles and much more. We integrate features to ensure a complete test solution that performs your tests the way you need it done. This section provides a comprehensive guide to understanding the design of jigs and fixtures and how each of these critical workholding devices operates in practice. Web jigs and fixtures are critical tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes.

Jig & Fixture design Industry Learning

Weld Jig & Fixture Design Donner IndustrialDonner Industrial

Design Principles of Jigs and Fixtures for Improved Manufacturing

Jigs and Fixtures MechanicsTips

CNC Training & Consultancy » Jig & Fixture Design

Jig and Fixture Basic Interview Question and Answers

Precision Jig & Fixture Design ACCUTECH

Jigs and Fixtures All You Need To Know Industrial News

to Jig/Fixture Design YouTube

Designing jigs and fixtures Design guide Vention

Web The Following Guide Covers The Basic Design Principles That Vention Uses For Jigs And Fixtures.

Web Our Expertise In Tools, Dies, Jigs, Fixtures, Gages, Prototypes And Specialty Machining Ranges From Intricate Parts And Fixturing For The Medical Field To Large Support Tooling And Ground Handling Equipment For The Aerospace Industry.

Web Jig And Fixture Design Is Essential For Successful Machining Operations.

Opt For Geometries That Make Misalignment Errors Obvious.

Related Post: