Interlake Beam Capacity Chart

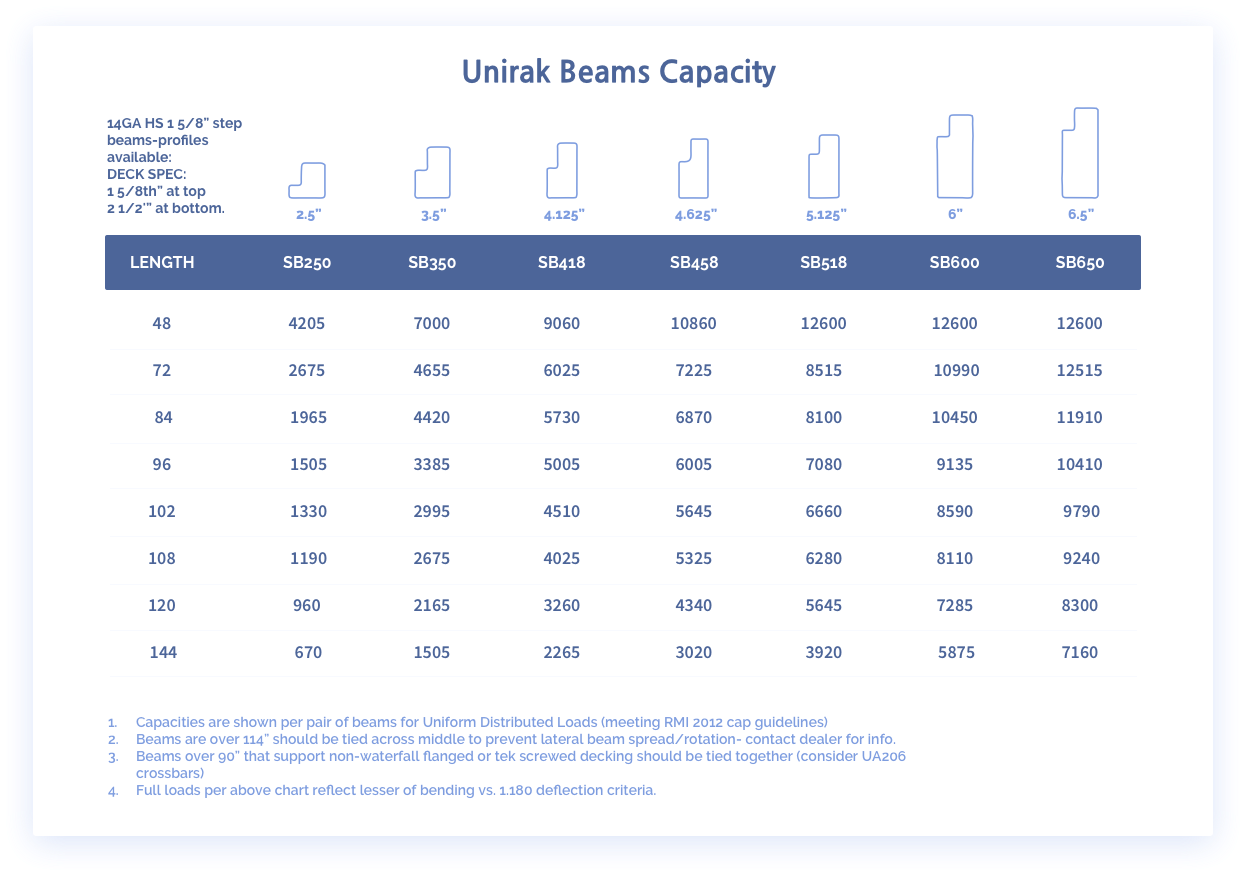

Interlake Beam Capacity Chart - • capacities are based on the 1997 rmi and the 1996 aisi specifications. The pallet rack capacity information compared in this article can be used to identify the most appropriate system to provide the best physical capacity ratio. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: Web comparing pallet rack capacity. Web values shown reflect the capacity of the beams based on the lesser of its strength in bending, or l/180 deflection criteria. • capacities are based on the 2002 rmi and the 2001 aisi specifications. Web interack 30 welded f punch frame capacity chart. Load capacities are for uniformly distributed product load plus dead load per pair of beams (dead load = weight of beams). • these capacities assume that all component parts are: Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: • these capacities assume that all component parts used are (1) manufactured by interlake, (2) in good condition, and (3) prope rly installed. (1) manufactured by interlake, (2). Web • capacities are valid when beams are connected to interlake frames. Web values shown reflect the capacity of the beams based on the lesser of its strength in bending, or l/180. Frame capacities are shown and are for product load plus dead load (dead load = 2.0% of product load). • these capacities assume that all component parts are: Load capacities are for uniformly distributed product load plus dead load per pair of beams (dead load = weight of beams). Web please view the upright frame capacity chart below to determine. • capacities are based on the 1997 rmi and the 1996 aisi specifications. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: (1) manufactured by interlake, (2). Web • capacities are valid when beams are connected to interlake frames. Web comparing pallet rack capacity. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: (1) maximum unsupported length is measured from the floor to the top of the first beam or the maximum beam spacing (whichever is greater). • these capacities assume that all component parts are: Web please view the. (1) manufactured by interlake, (2). Web comparing pallet rack capacity. Web interack 30 welded f punch frame capacity chart. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: • capacities are based on the 2002 rmi and the 2001 aisi specifications. However, physical capacity is not the only criterion to be taken into consideration. Web values shown reflect the capacity of the beams based on the lesser of its strength in bending, or l/180 deflection criteria. The pallet rack capacity information compared in this article can be used to identify the most appropriate system to provide the best physical capacity ratio.. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: Web values shown reflect the capacity of the beams based on the lesser of its strength in bending, or l/180 deflection criteria. Web interack 30 welded f punch frame capacity chart. Web • capacities are valid when. Frame capacities are shown and are for product load plus dead load (dead load = 2.0% of product load). • these capacities assume that all component parts are: However, physical capacity is not the only criterion to be taken into consideration. Web comparing pallet rack capacity. Web please view the upright frame capacity chart below to determine if your application. Web comparing pallet rack capacity. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: • capacities are based on the 2002 rmi and the 2001 aisi specifications. (1) maximum unsupported length is measured from the floor to the top of the first beam or the maximum. • capacities are based on the 1997 rmi and the 1996 aisi specifications. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: • these capacities assume that all component parts used are (1) manufactured by interlake, (2) in good condition, and (3) prope rly installed. •. Load capacities are for uniformly distributed product load plus dead load per pair of beams (dead load = weight of beams). Web • capacities are valid when beams are connected to interlake frames. Web values shown reflect the capacity of the beams based on the lesser of its strength in bending, or l/180 deflection criteria. Web • capacities are valid when beams are connected to interlake frames. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: Frame capacities are shown and are for product load plus dead load (dead load = 2.0% of product load). Web comparing pallet rack capacity. • these capacities assume that all component parts are: • capacities are based on the 2002 rmi and the 2001 aisi specifications. Web please view the upright frame capacity chart below to determine if your application preferences meet the requirements for this upright frame model: • these capacities assume that all component parts used are (1) manufactured by interlake, (2) in good condition, and (3) prope rly installed. However, physical capacity is not the only criterion to be taken into consideration. Web interack 30 welded f punch frame capacity chart.

Pallet Rack Beam Capacity Chart A Visual Reference of Charts Chart

Interlake Beam Capacity Chart

Interlake Pallet Rack Beams & Uprights Interlake Shelving

Interlake Pallet Rack Capacity Chart

Interlake Racking Capacity Chart

Interlake Mecalux Beam Capacity Chart

Interlake Beam Capacity Chart

Beam Load Capacities Chart Interlake Mecalux

Interlake Beam Capacity Chart The Best Picture Of Beam

Interlake Racking Capacity Chart

The Pallet Rack Capacity Information Compared In This Article Can Be Used To Identify The Most Appropriate System To Provide The Best Physical Capacity Ratio.

(1) Manufactured By Interlake, (2).

• Capacities Are Based On The 1997 Rmi And The 1996 Aisi Specifications.

(1) Maximum Unsupported Length Is Measured From The Floor To The Top Of The First Beam Or The Maximum Beam Spacing (Whichever Is Greater).

Related Post: