Injection Molding Mold Design

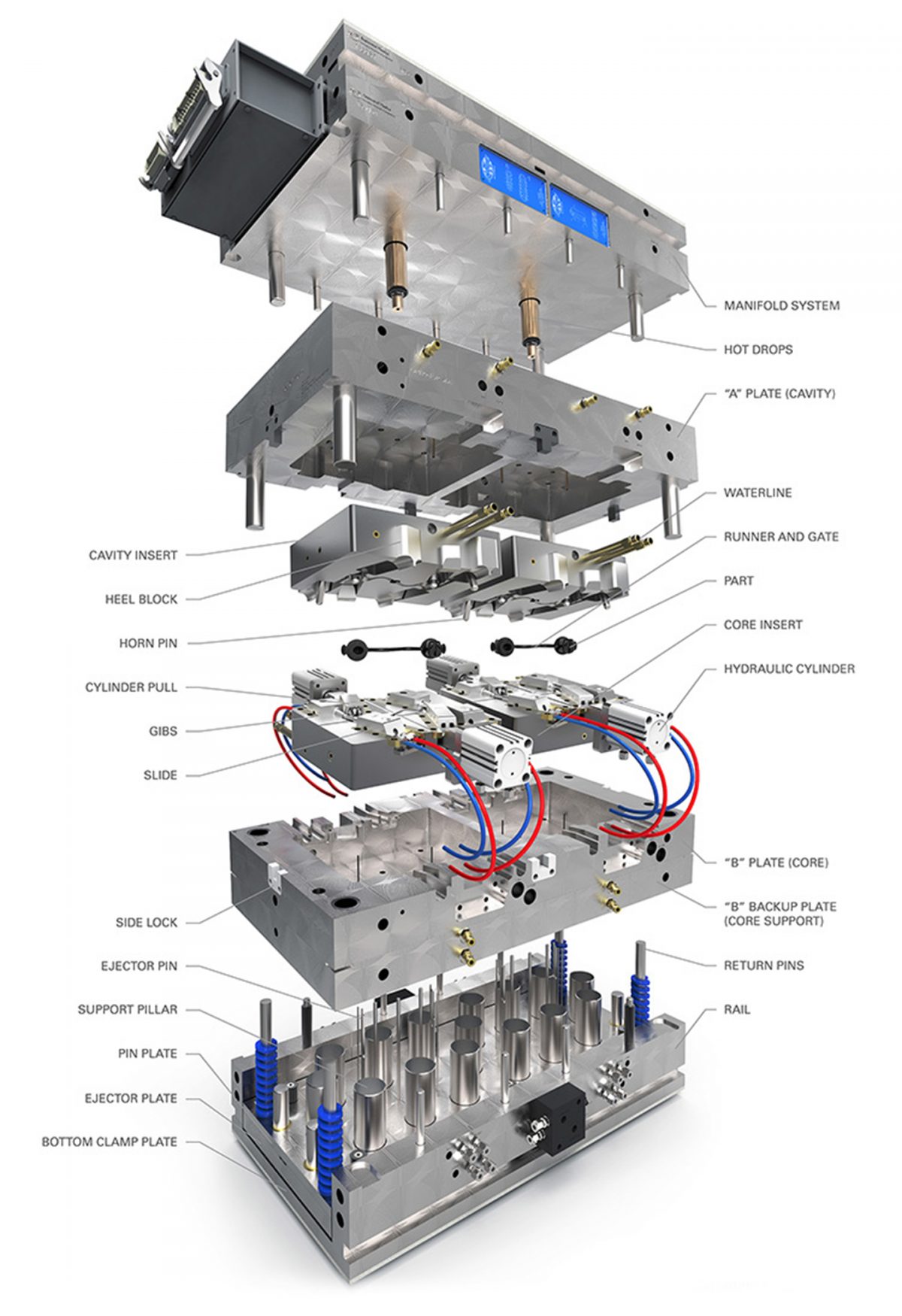

Injection Molding Mold Design - Competencies · article library · sustainability · locations · news+ Web learn how to select the right material for your injection molding design with this technical overview of thermoplastic resins. Web what is injection molding? Web injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a specific shape or design. Common industrial applications of injection molding. Web learning correct mold design for the plastic injection molding process is critical to project success. Injection molding produces plastic parts through a straightforward approach. Web before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Web injection molding design: This guide covers everything you need. Web rjg’s part & mold design for injection molding course provides molders, tool makers, quality team members and design engineers with a common language and the. However, once finished, the molds can be reused over and over. Web mold design is fundamental to the success of the molded product and the molding operation. Web injection molding is a manufacturing process. Web our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall. Web injection molding design guide. In this video, you’ll learn the fund. An extruder is used to mix additives with a polymer base, to bestow the polymer with the required characteristics. The course begins by identifying the. Web injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a specific shape or design. However, once finished, the molds can be reused over and over. An extruder is used to mix additives with a polymer base, to bestow the polymer with the required characteristics. Common terms used to describe the tool. Plastic pellets feed into a heated barrel to melt. Common industrial applications of injection molding. Web rjg’s part & mold design for injection molding course provides molders, tool makers, quality team members and design engineers with a common language and the. Web our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic. Web injection molding design: Web learning correct mold design for the plastic injection molding process is critical to project success. Web injection molding operations require an initial investment in the design and construction of injection molds. Competencies · article library · sustainability · locations · news+ Web our basic guidelines for plastic injection molding include important design considerations to help. Common industrial applications of injection molding. Injection molding produces plastic parts through a straightforward approach. Common terms used to describe the tool used to produce injection molded parts. Starting your part design comes with ten major considerations. Web the design of the main components of an injection mold will be discussed and good design practices, rules of thumb, and key. Web the most fundamental knowledge needed for any designer faced with designing an injection molded part is understanding the basics of mold (also referred to. Similar to an injection molding. Plastic pellets feed into a heated barrel to melt. The design of the mold, as. Web the design of the main components of an injection mold will be discussed and. Web injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a specific shape or design. Major factors affecting the cost of injection molding. Web injection molding design guide. This guide covers everything you need. Web our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance. The course begins by identifying the five key systems of a mold: Starting your part design comes with ten major considerations. Common industrial applications of injection molding. Major factors affecting the cost of injection molding. This guide covers everything you need. Web learning correct mold design for the plastic injection molding process is critical to project success. Web injection molding design: Web rjg’s part & mold design for injection molding course provides molders, tool makers, quality team members and design engineers with a common language and the. Web mold design is fundamental to the success of the molded product and the. Web injection molding design: Web the design of the main components of an injection mold will be discussed and good design practices, rules of thumb, and key calculations will be shared. Web the basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin. Web before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Web the most fundamental knowledge needed for any designer faced with designing an injection molded part is understanding the basics of mold (also referred to. Common terms used to describe the tool used to produce injection molded parts. In this video, you’ll learn the fund. Web a beginner's guide to injection molding. Web what is injection molding? The course begins by identifying the five key systems of a mold: Starting your part design comes with ten major considerations. Similar to an injection molding. Common industrial applications of injection molding. Web our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall. Plastic pellets feed into a heated barrel to melt. Major factors affecting the cost of injection molding.

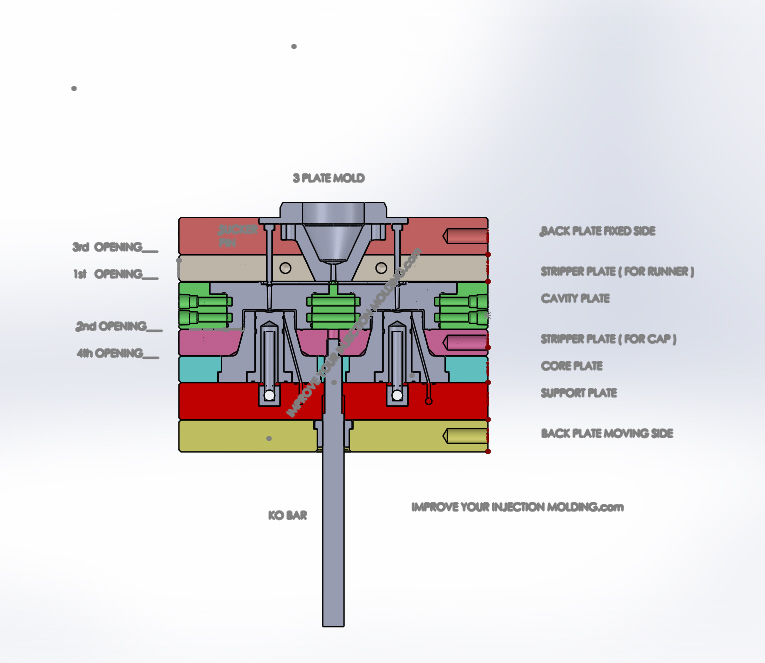

3 Plate Mold Design For Injection Molding

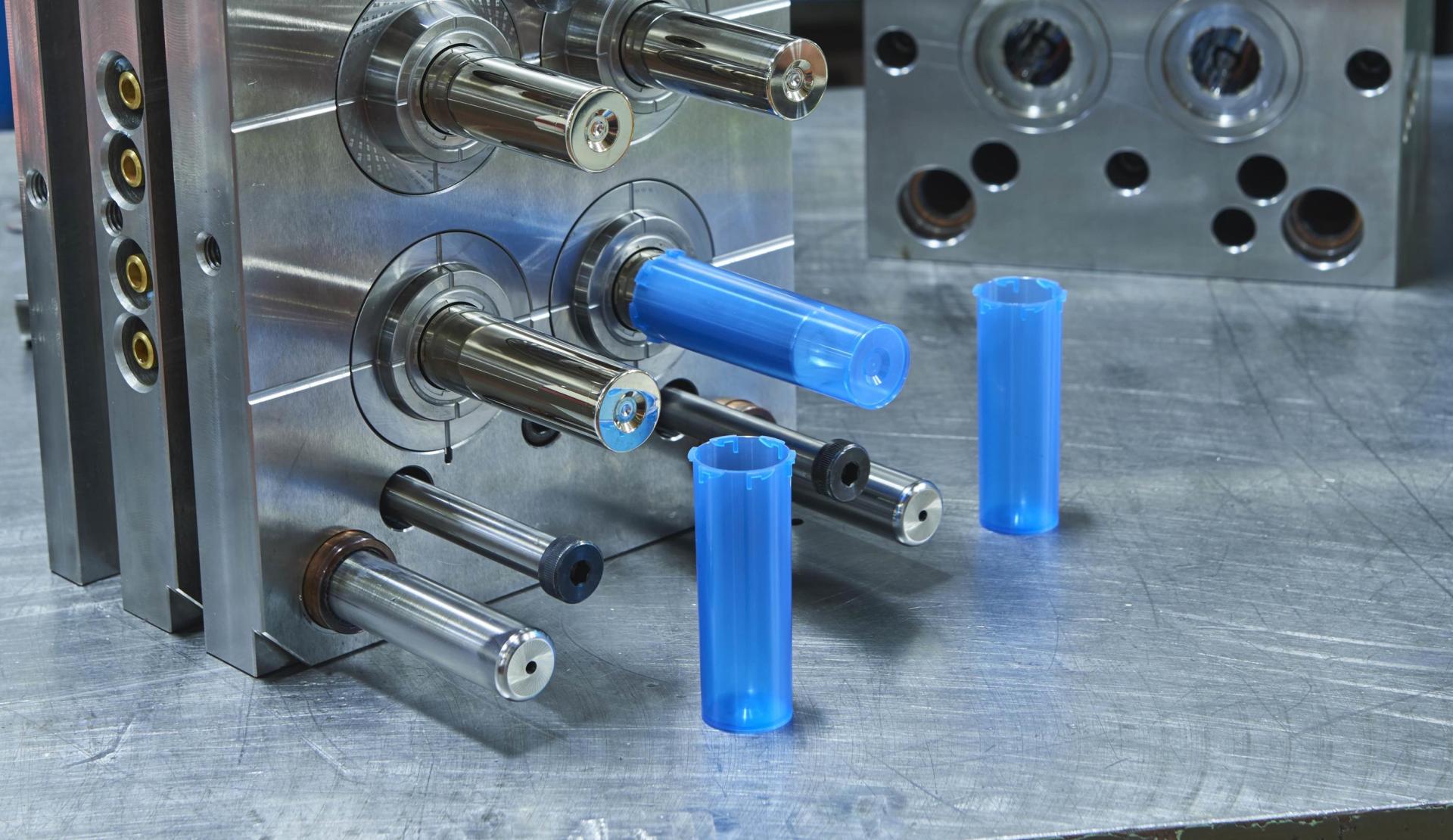

Basics of Injection Molding Design 3D Systems

How to Design for Injection Moulding MADE Products

The Basic Process Of Injection Molding Mold Design

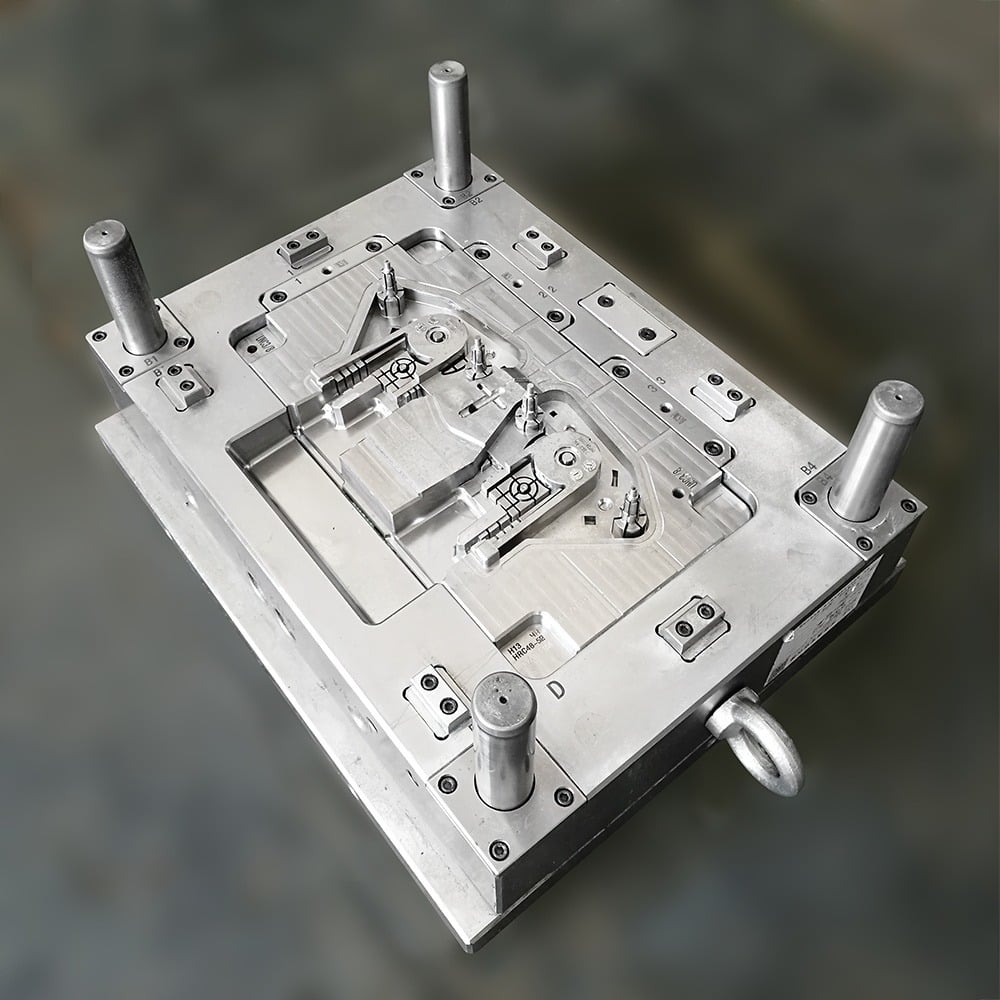

Anatomy of a Mold PTI Plastic Injection Molding

![]()

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

Injection Molding Mold Design For Elbow Plastic Parts UPMOLD

Injection Molding Mold Design Tutorial Mold design Guidance Upmold

Injection Molding Design Validation Medical Device Biopolymers

One Picture to Understand the Structure of an Injection Mold

Web Injection Molding Design Guide.

An Extruder Is Used To Mix Additives With A Polymer Base, To Bestow The Polymer With The Required Characteristics.

Web Learning Correct Mold Design For The Plastic Injection Molding Process Is Critical To Project Success.

Injection Molding Produces Plastic Parts Through A Straightforward Approach.

Related Post: